SOLATHERM PV360 User manual

Power Control Equipment

PV DC Electric Hot Water

Owner Manual

1/52 Barnett Ave, Glynde, SA 5070

Phone 08 8337 8881

www.solatherm.com.au

Model:

PV360Heating Only

Power Control Equipment (PCE)

1 | P a g e

ATTENTION

The Solatherm controller and water heater vessel must be installed by an

authorised person and the installation must comply with all the relevant Australian

Standards, local and industry regulations.

ATTENTION

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

WARNING

Once installed the hot water tank is powered by TWO SOURCES of Power Supply,

both sources must be isolated before working on the appliance.

Before commencement of any service work on the hot water circuit,

including work that partially or completely drains the storage vessel,

ensure all electrical supplies, the Photovoltaic array and AC connection

have been disconnected as per the System Shutdown procedure in this

manual.

PV ARRAY WARNING

When the photovoltaic array is exposed to light, it supplies a d.c. voltage to the PCE.

WARNING

The controller is only to be connected to a hot water cylinder specifically designed

and configured for use with the Solatherm DC controller (P.C.E.). It is not for retrofit.

WARNING

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

CONNECTION WARNING

Solatherm Photo Voltaic Over Temperature Cut Out (PVOTC) must be installed in

the power supply feed to the DC heating element.

WARNING

DANGER the operation of the PV (DC) thermal cut out indicates a possibly

dangerous situation. The water heater must be inspected by a qualified person and

the PV-OTC (PV thermal cut out) replaced.

2 | P a g e

WARNING

DANGER the operation of the 240V AC thermal cut out indicates a possibly

dangerous situation. Do not reset the 240V AC thermal cut out until the water

heater has been serviced by a qualified person.

PV ARRAY WARNING

Maximum array power of 3.84kW must not be exceeded. Current must not exceed

22 Amps, array design must not exceed 2 strings. Voltage must not exceed 270V,

String length must not exceed 6 panels.

Max power must not be exceeded.

3.84kW can be either 270V @14.2A or 174V @ 22.0A or in between.

P=IR (Volts x Current), 3840W must not be exceeded.

WARNING

The controller has no user serviceable parts. Opening the cover will void all

warranty and may expose dangerous voltages.

Removal of the covers on the storage water vessel will expose live electrical wiring.

Covers must only be removed by an authorised service person and only once dual

supply power has been isolated.

ATTENTION

Ensure all glands from the control box are firmly tightened to ensure ingress

protection.

ELECTRICAL WARNING

All electrical work and permanent wiring must be carried out by a qualified person

and in accordance with all current relevant Australian installation standards and

local authority requirements.

Means for disconnection must be incorporated in the fixed wiring in accordance

with the wiring rules.

All electrical connections must be terminated before switching any component on.

The power to the Solatherm solar control unit and water heater must NOT be

switched on until the water heater is completely filled with water and all air bled

from the system.

3 | P a g e

WATER CONNECTIONS FOR STORAGE VESSEL

Please ensure all plumbing installation work is carried out in accordance with

AS3500 and that a non-return valve is installed in the incoming water line.

Maximum inlet pressure 700kPa, minimum inlet pressure 350 kPa.

A pressure relief valve must be fitted in accordance with AS 3500, rating 850kPa

10kW. A discharge pipe must be connected to the device and be installed in a

continuously downward direction and in a frost-free environment and the end must

be left open to atmosphere.

DANGER

Failure to operate the relief valve easing gear at least once every six months may

result in the water heater exploding. Water may drip from the discharge pipe but

continuous leakage from the valve may indicate a problem with the water heater,

please have your water heater serviced by a qualified person.

If the water supply pressure exceeds the rated pressure, a pressure reducing valve is

to be fitted in the installation.

The water may drip from the discharge pipe of the pressure-relief device and that

this pipe must be left open to the atmosphere;

The pressure-relief device is to be operated regularly to remove lime deposits and

to verify that it is not blocked;

The water heater can be drained by disconnecting the water inlet.

Symbol Glossary

Symbols Used

Refer to the operating

instructions

Caution, risk of danger

Protective conductor

terminal

Caution, risk of electric

shock

Positive conductor

Negative conductor

4 | P a g e

Contents

Symbol Glossary ..............................................................................................................................................3

Contents ..........................................................................................................................................................4

About ...............................................................................................................................................................5

Display .............................................................................................................................................................6

Basic System Configuration .............................................................................................................................7

Start-up Procedure.................................................................................................................................8

System Shutdown...................................................................................................................................8

Frequently Asked Questions............................................................................................................................9

Troubleshooting ............................................................................................................................................10

Installation Instructions.................................................................................................................................11

Wiring Diagram - Controller......................................................................................................................11

On the Ground ..........................................................................................................................................12

Wall mounting PCE controller..............................................................................................................12

Mounting Clearances and Mount Point Locations ..............................................................................13

Connection - Controller to Storage Water Vessel - DC........................................................................14

Wiring Diagram - PVOTC - Element......................................................................................................15

Connection - Main Array Input ............................................................................................................16

Connection - Boost Element - AC.........................................................................................................17

ON THE ROOF............................................................................................................................................18

Panel Configuration..............................................................................................................................18

Commissioning Start Up ...........................................................................................................................19

Shut down Procedure ...............................................................................................................................19

Warranty........................................................................................................................................................20

Warranty Definitions ................................................................................................................................20

Warranty Conditions.................................................................................................................................20

Warranty Exclusions .................................................................................................................................21

Commissioning ..............................................................................................................................................22

System Information - Form A....................................................................................................................22

System Diagram ........................................................................................................................................24

Technical Data ...............................................................................................................................................25

5 | P a g e

About

The Solatherm control unit regulates DC electricity generated by a photovoltaic

array and applies it to a resistive heating element, located in a storage hot

water vessel, to generate hot water. The microprocessor constantly monitors

the water temperature in the storage vessel and energizes the heating element

when sufficient power is available from the array and the water stored in the

vessel is below the set temperature. (Factory set temperature 600or 700Celsius)

When the temperature is reached the unit will turn the element off until the

water temperature falls.

Once the water is up to temperature the controller monitors the temperature of

the stored water to ensure maximum hot water is maintained.

Solatherm Control Units are independent from the grid and require no mains

power connection to operate, hence, the unit will only operate and display user

information when there is sufficient energy from the sun. It is normal for the

LCD display and lights to flicker or not fully display in low light conditions.

During periods of low solar input where there is insufficient power available to

heat the stored water to 600C the independent 240V AC boost element will top

up the temperature of the water in the storage vessel.

NB: Generally the independent AC boost element is connected to an off peak

(controlled load) power supply. If only peak is available it is recommended to install a

din rail timer and set a heating period during the early evening and/or early morning

depending on the household demand. If the water in the storage vessel is higher than

the 600C thermostat setting the unit will not draw any power as there is no need. If the

water is below 600C during the set periods the boost element will top up the

temperature to ensure hot water is available. The boost element heats approximately

125L of water. Connection via a timer will maximise solar gain during the day, minimise

energy consumption and allow for ease of use. High usage households may require

extended boost periods or continuous mains connection to meet high demand.

6 | P a g e

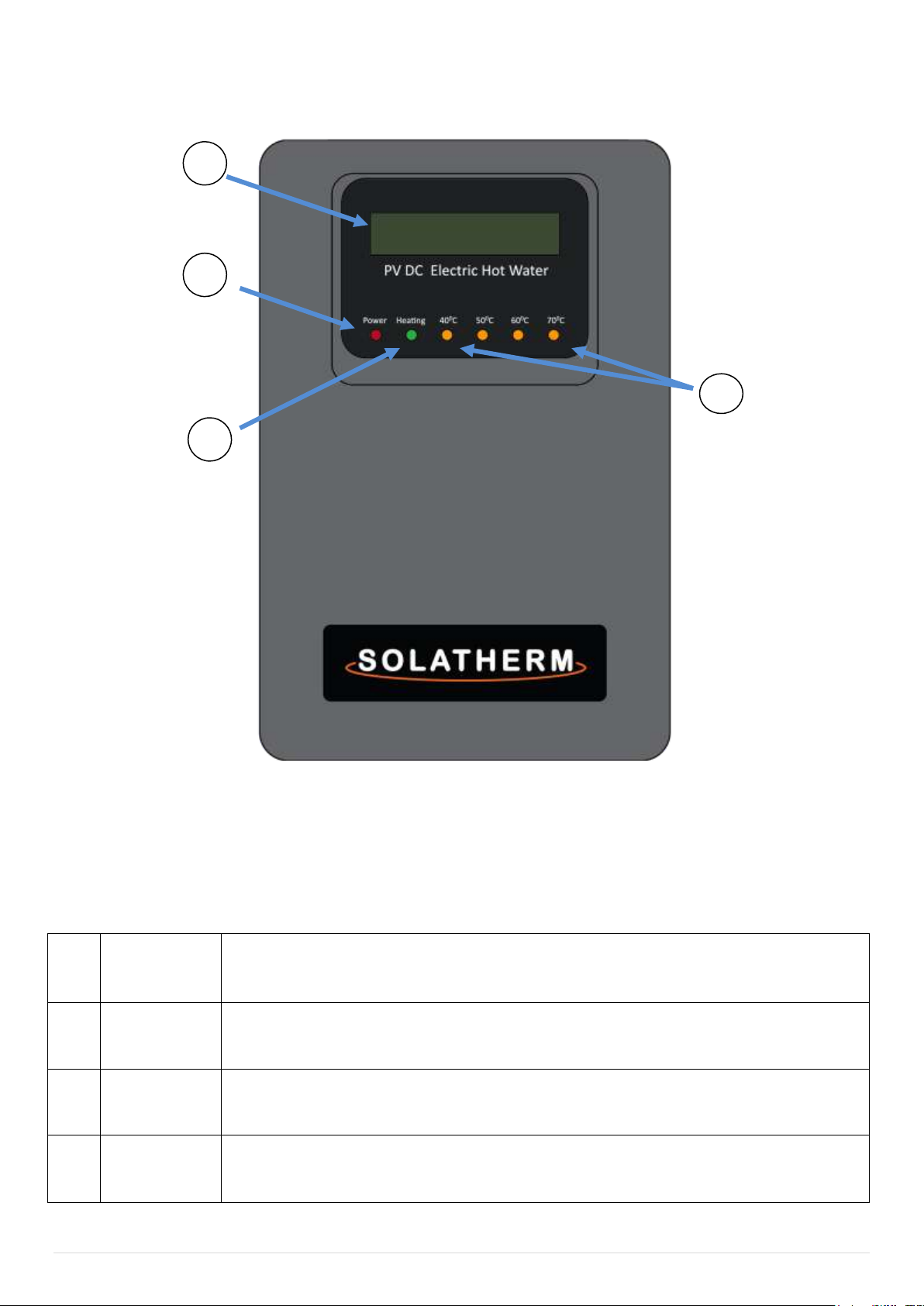

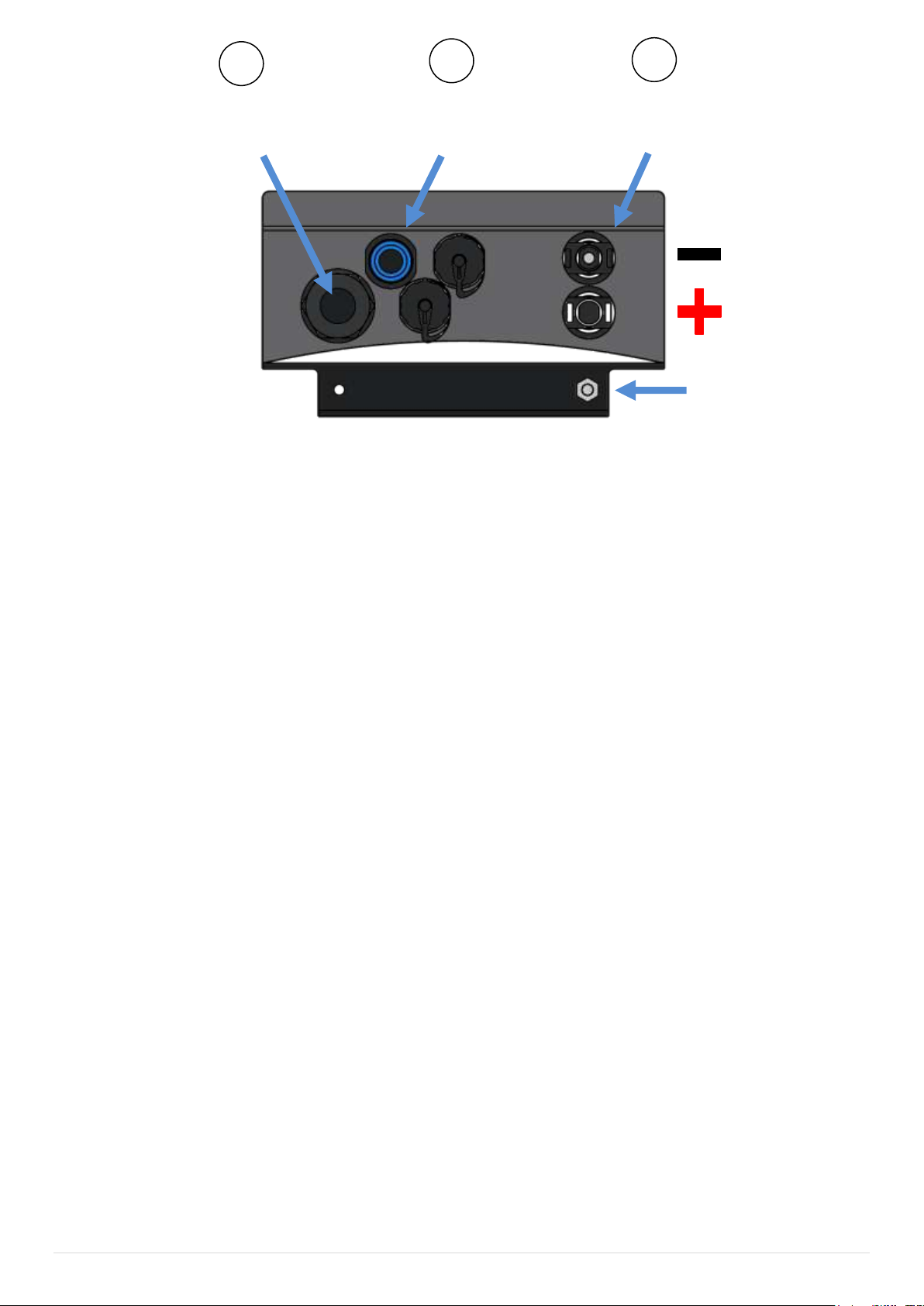

Display

Solatherm Control Units are independent from the grid and require no mains

power connection to operate, hence, the unit will only operate and display

user information when there is sufficient energy from the sun. It is normal for

the LCD display and lights to flicker or not fully display in low light conditions.

1

LCD Display

Scrolling display showing the array voltage and when the heating element is

activated, the current and power. The second line shows the kW/h consumed for

the day and the total kW/h consumption.

2

Power

LED illuminated red when the main array is connected and supplying power to the

unit. In low light conditions this light may be the only LED lit or flashing.

3

Heating

LED illuminated green when the controller has energized the heating element.

4

400-700C

LED's illuminated orange - an approximate indication of the average temperature

of the water stored in the storage vessel.

1

2

3

4

Figure 1.

7 | P a g e

Basic System Configuration

Figure 2.

8 | P a g e

Start-up Procedure

NOTE: ENSURE HOT WATER VESSEL IS COMPLETELY FILLED WITH WATER

BEFORE COMENCING START UP PROCEDURE.

1. Turn on Isolator. RED LED POWER LIGHT SHOULD BE ON. The LCD will

illuminate and start to indicate incoming power (providing supply

voltage is over 40 Volts). The controller should show start up

information as it runs though a power up test sequence. When test is

complete LCD will display system voltage etc.

2. After the start up sequence is complete the green heating LED will light

up if sufficient power is available to commence heating. Note: The

controller has several built in time delays of up to 1.5 minutes, to allow

for power stabilisation.

3. Turn on 240V AC Booster breaker switch in household fuse box.

System Shutdown

1. Turn off main array isolator (lock switch if required)

2. Controller should now be off, red light and LCD display should be off.

3. Turn off 240V AC Booster isolator and breaker switch in household fuse

box.

4. System should now be electrically isolated.

9 | P a g e

Frequently Asked Questions

Q: My LCD show 0 Watts but the sun is out?

A:

1. The water in the storage tank is up to temperature.

Dependant on the factory set temperature 600C or 700C.

2. During periods of low light intensity such as, early morning, late evening or

in dark cloud the main array may not be able to produce the minimum

amount of power needed. The controller requires a stable 250 Watts to be

available when the element is energized to commence heating. The green

heating light will flick approximately every 25 seconds as the controller is

testing the amount of power available from the array.

Q: The heating light has been on all day but there is no hot water at the end

of the day?

A:

1. The hot water produced has been consumed during the day.

2. If the display is showing 0 Watts with the heating light on there may be a

fault with the element or the over temperature cut out. Please contact your

installer.

Q: Run out of hot water or warm water only.

A:

1. The hot water produced has been consumed during the day.

2. Not enough solar input during the day. Ensure booster is connected and

the AC boost timer settings are correct for the household demand or

season.

10 | P a g e

Troubleshooting

All observations for potential faults need to be conducted in clear daylight conditions.

Observation

Fault

Dim/flickering LCD display

& lights

Should this occur in bright sunshine please

contact your installer. No Fault if seen in low

light conditions. Re-check in brighter

conditions.

Please see note in Frequently Asked Questions

Flashing temperature

lights (Orange LEDs)

Fault with storage water temperature sensor or

internal temperature of the enclosure is too

high e.g. Controller mounted in full direct

sunshine.

No heating light

(Green LED)

Element not powered. The controller will only

energise the element when there is enough

solar energy available and the storage water

temperature is below the set point. If clear

conditions, the water is cold and no green light

appears, contact your installer. Also see FAQ.

Heating light on but no hot

water. (Green LED)

Not enough heating time has passed. Allow

more time for heating. If light is on but LCD

display shows no Power (Watt) figure contact

your installer. Possible Element Fault.

Flick of green light

(Green LED)

Approximately every 20 seconds. This is the

unit testing the power available. A high voltage

may display but no current may be available.

Not enough sunlight to engage element.

No power light.

(Red LED)

Not enough power being produced by the main

arrray. If in clear conditions contact your

installer.

No temperature lights

(Orange LEDs)

Average water storage temperature is below 32

degrees Celsius

11 | P a g e

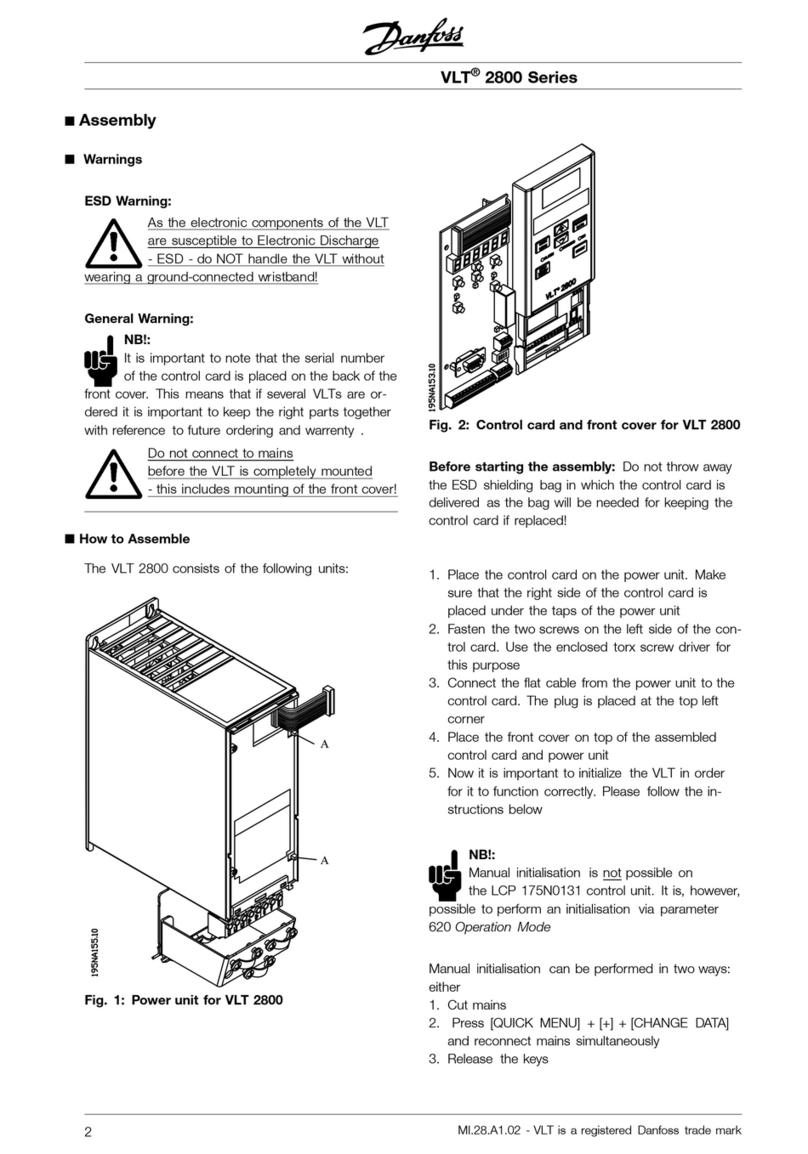

Installation Instructions

Wiring Diagram - Controller

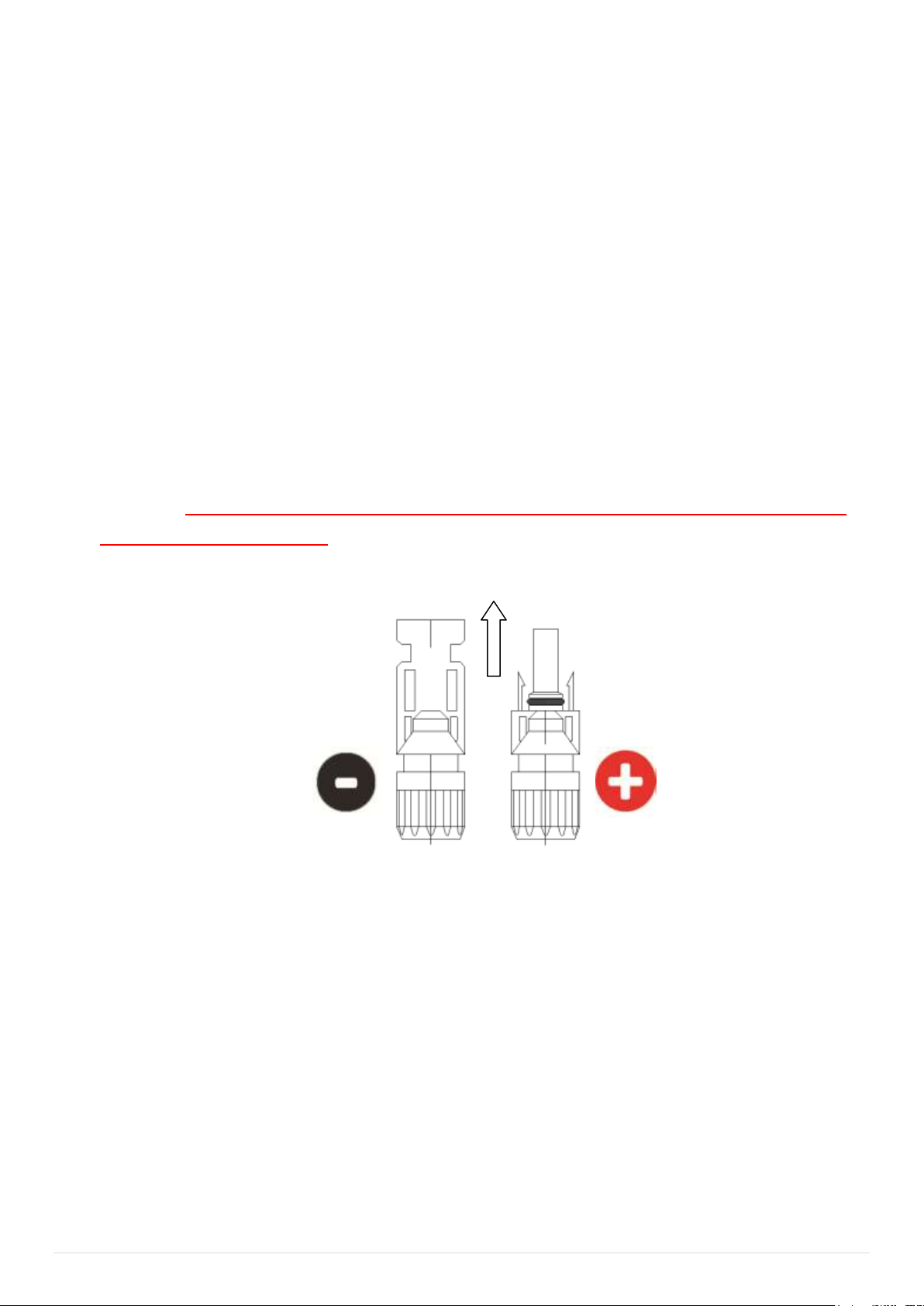

WARNING INCORRECT POLARITY WILL DAMAGE THE CONTROLLER

NO WARRANTY FOR POLARITY DAMAGE

Figure 3.

12 | P a g e

On the Ground

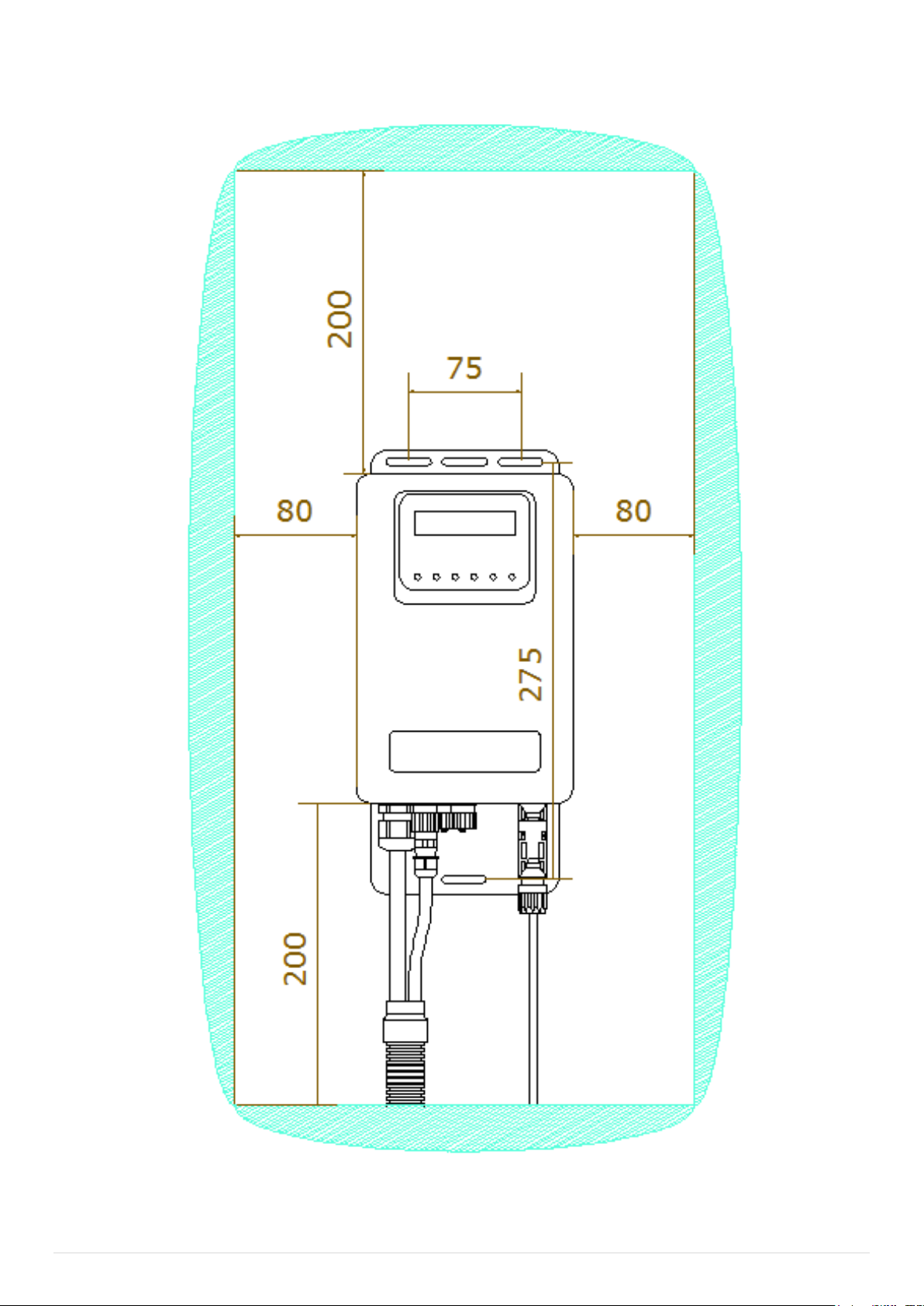

Wall mounting PCE controller

Choose a suitable location, giving consideration to the following:

1. Vertical wall mount at a height of between 1.5m to 2m above ground level

giving consideration to cable length and path to the Hot water vessel and

PV main array isolator location.

2. It is important to mount the controller out of the direct sunlight as it will

make visual reading of the LCD display difficult.

3. The control box shall be 3 x point screw mounted, via the attached slotted

metal brackets at the top and bottom of the controller e.g.: 2 x screws at

the top 1 x screw at the bottom. Determine preferred affixing mounting

screw method to suit wall substrate. The 2 x top screw holes shall be

80mm apart and the 1 x bottom screw hole shall be 275mm down central

to the top 2 x holes and control box. EG: (Like the capital letter T 80mm

across top & 275mm down).

Continued..

Figure 4.

13 | P a g e

Mounting Clearances and Mount Point Locations

* Mounting Point

Dimension

*

*

Figure 5.

14 | P a g e

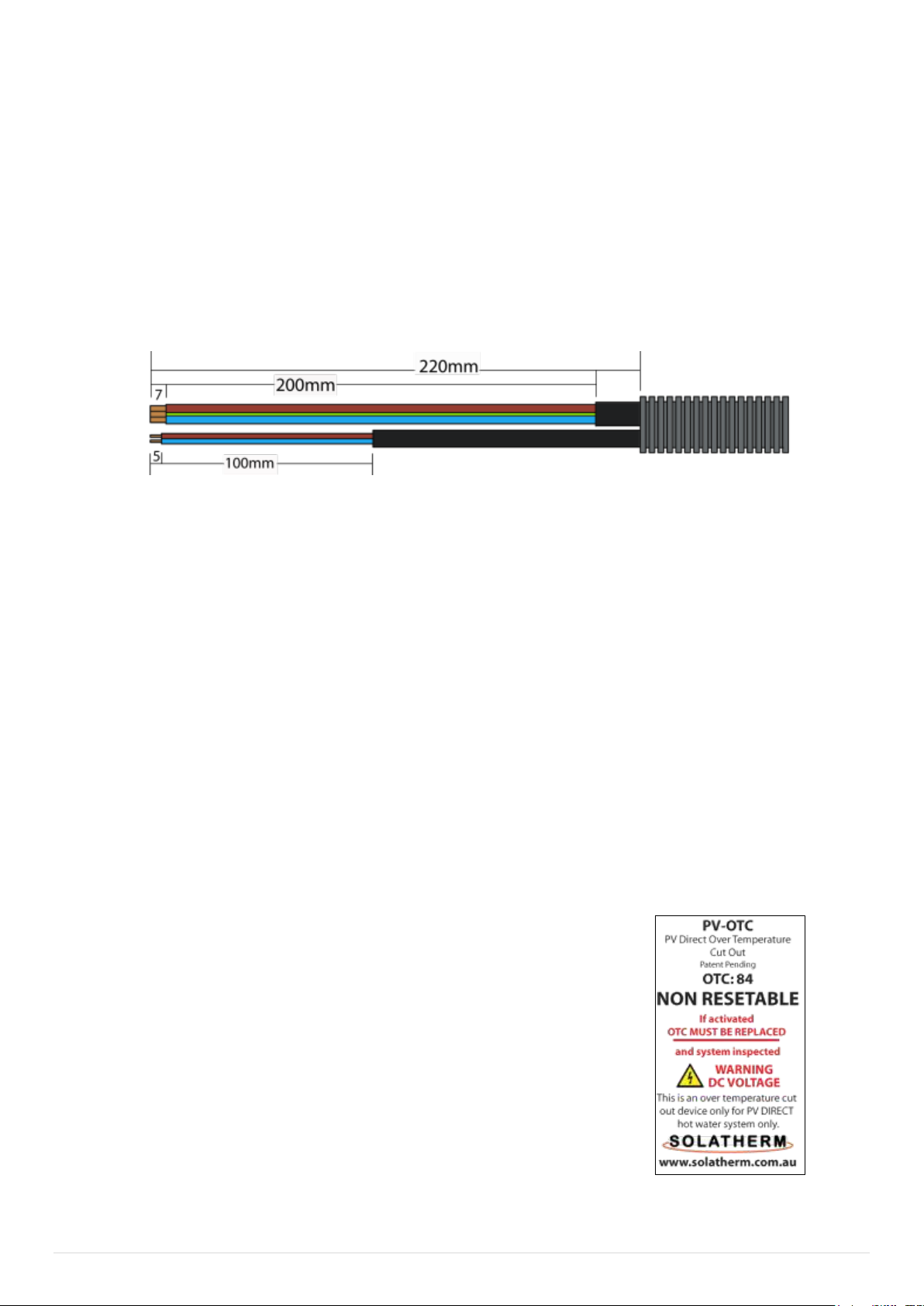

Connection - Controller to Storage Water Vessel - DC

1. Remove lower DC element cover.

2. Route the 2.5m long flexible element output cable to the bottom element

inlet conduit elbow and thread both cables though up into element

cavity. It may be necessary to use a wire hook to help thread/ pass the 2 x

cables through the elbow. (It is important to have the first outer

insulation cover removed 200mm back exposing the 3 x insulated wires,

as passing the complete cable through the elbow is very tight).

3. Terminate the element positive, negative & earth as per the instruction

label that is affixed to the inside of the element enclosure cover and per

the labelled colour coded connection points within.

4. Connect the 2 x colour coded NTC sensor wires into colour coded

mounting block.

See Figure: Wiring Diagram - PV OTC - Element

5. Ensure PVOTC which is spring located onto vessel surface has not been

disturbed during installation and is sitting in place and secure.

6. Using the supplied cable saddles and removing and replacing base lid

screws to fit saddles, secure supply cable securely to the base of the hot

water tank.

7. Refit lower DC element cover.

PVOTC is only activated by overheating of the storage

vessel which indicates a potential system fault. The

PVOTC is a onetime operation and is NON RESETABLE.

Sacrificial fuses must not be replaced at any stage, if

activated the PVOTC will need to be replaced.

Figure 6.

15 | P a g e

Wiring Diagram - PVOTC - Element

PVOTC is only activated by overheating of the storage vessel which indicates a potential

system fault. The PVOTC is a onetime operation and is NON RESETABLE. Sacrificial fuses

must not be replaced at any stage, if activated the PVOTC will need to be replaced.

Figure 7.

16 | P a g e

Connection - Main Array Input

1. Terminate cables with MC4 Connectors. Connect the cable to the Isolator.

Ensure Polarity on the MC4 connections is correct. TEST the polarity at the

MC4 connectors BEFORE CONNECTION TO THE CONTROLLER. Ensure to

connect the earth from the controller to the earth point from the main

array frame within the Isolator. Earth from controller and Array must be

connected to house ground point.

See Wiring Diagram - Controller - Figure 3

2. Test voltage from array. Confirm correct for controller model and cylinder

element.

3. Connect MC4 Connectors to controller input only when ready to

commission - See Commissioning Start up pg 19.

Ensure polarity at the MC4 connectors is correct before proceeding

further. TURN ISOLATOR ON AND TEST CORRECT POLARITY TO CONFIRM

BEFORE PROCEEDING.

IT IS IMPORTANT TO ENSURE THAT THE SUPPLY FROM THE MAIN ARRAY IS

TERMINATED POLLARITY CORRECT AND MUST BE CHECKED BEFORE

CONNECTION!!

THE CONTROLLER WILL BE DESTROYED IF REVERSE POLARITY CONNECTED!!

Incorrect polarity will void the warranty.

Positive on loom

from the Isolator

Negative on the loom from

the isolator

To Controller

From Array

Figure 8

17 | P a g e

Connection - Boost Element - AC

The 240V A/C Booster supply cable must be installed in accordance to

Australian Standard AS3000 and by a qualified person.

Note: Never energise the element until the water vessel is filled and

bled!

1. Remove top booster 240V A/C element cover.

2. Connect into the 25mm female elbow using 25mm flex conduit and

approved twin and earth cable suitable for the booster element fitted.

3. Following the wiring instructions affixed inside the cover, (The standard

booster element is 2.4Kw 10Amp but this may vary depending on

application ensure to identify and wire to suit load).

The hot water vessel must be connected to Earth.

**Note**

Consideration must be given to the local power supply offerings to

maximise operation of the PV solar contribution. E.g.: In locations

where a controlled load (off peak) is available the booster supply

ideally should be connected to this tariff. In locations where only peak

supply power is available, it is recommended to fit an A/C supply timer

which can be set to the individual requirements of the end user.

Element

storage vessel

E

Main Array

via Isolator

A

NTC

Temperature

T

EARTH

Figure 9.

18 | P a g e

ON THE ROOF

The main array must be installed to Australian standards and all relevant local

authority requirements by a authorised installer. Consideration must given to

the position of the isolator in relation to the final controller position. The main

array must be earthed with the earth cable into the isolator.

Panel Configuration

The PV controller is designed to operate with a matched number of PV panels

and strung as 2 x strings of 3, 4, 5 or 6 panels per string depending on the

model and DC element. The supply from the main array must be tested and

identified to be strung correctly with the correct number of panels to suit the

matched controller and element. See table 1 below and controller data spec

sheet to identify model fitted. Terminate main array into isolator testing and

ensuring TERMINATED POLLARITY IS CORRECT. The controller will show fault

and not engage where 270 Volts is exceeded.

CROSSED CONNECTION WILL RESULT IN FAILURE OF THE CONTROLLER!

Damage to reversed polarity connection will not be covered by warranty

Figure 10.

19 | P a g e

Commissioning Start Up

1. Ensure polarity at the MC4 connectors is correct before proceeding

further.

TEST CONNECTORS BEFORE CONNECTION INTO THE CONTROLLER (PCE)

2. TURN ISOLATOR ON AND TEST CORRECT POLARITY TO CONFIRM BEFORE

PROCEEDING. Figure 11.

3. Test voltage from array. Confirm correct for controller model.

4. Connect MC4 connectors to control unit.

5. Ensure all cables are terminated as per installation instructions.

6. Turn on isolator.

7. RED LED POWER LIGHT SHOULD BE ON. The controller should show start up

information as it runs though a power up test sequence. When test is

complete LCD will display system voltage etc. (providing array voltage is

over 40 Volts)

8. After the start up sequence is complete the green heating LED will light up if

sufficient power is available to commence heating. Note: The controller has

several built in time delays of up to 1.5 minutes, to allow for power

stabilisation. Some models will start on divert for 30min prior to heating.

See supplement.

9. Turn on 240V AC booster isolator and breaker switch in household fuse box.

10. Test and record data on the Commissioning sheet in this booklet and make

a copy for submission to Solatherm. Form A

Shut down Procedure

1. Turn off main array Isolator (lock switch if required)

2. Controller should now have no information displayed and is OFF.

3. Turn off 240V AC Booster Isolator and breaker switch in household fuse

box.

Positive on loom

from the Isolator

Negative on the loom from

the isolator

To Controller

From Array

Figure 11

Table of contents

Popular Inverter manuals by other brands

Toshiba

Toshiba PWU003Z instruction manual

ABB

ABB PVS800-57B Maintenance manual

Tronic

Tronic TSW 300 A1 operating instructions

True blue power

True blue power TI1200 Installation manual and operating instructions

Lenze

Lenze i700 Series Reference manual

bluetron

bluetron HSI Series Installation and operating instructions