Page | 2

Warning

Do not proceed with the installation until you have read and understood the entire installation guidelines, including the points below.

If you have any questions or require clarification of any installation procedures, please contact your Solatube supplier.

Solatube (or seller) assumes no responsibility or obligation whatsoever for the failure of an architect, contractor, installer or building

owner to comply with all applicable laws, ordinances, building codes, energy codes, fire and safety codes and requirements, and

adequate safety precautions. Installation of this product should be attempted only by individuals skilled in the use of the tools and

equipment necessary for installation. The supplier accepts no responsibility for incorrectly installed or non-appropriate applications.

Protect yourself and all persons and property during installation. If you have any doubt concerning your competence or expertise,

consult a qualified expert before proceeding. In addition, please check the Health & Safety Executive website for advice on safe working

at height http://www.hse.gov.uk. Installation is at your own risk.

Solatube product installations may be dangerous owing to the locations of the work to be undertaken. The hazardous conditions include,

but are not limited to, the following:

•During installation, the Solatube reflective tubes may focus sunlight potentially causing concentrated light

and heat. Keep the protective film on the reflective tubing prior to installation and the tubing away from

potentially flammable material.

•Sheet metal edges may be sharp. Use protective gloves to avoid lacerations.

•Installation may require climbing and working at dangerous heights, including on ladders, scaffolding, roofs

and in attic spaces. Use extreme caution to minimize risk of accidental injury and property damage

including, but not limited to, the points below:

oDo not work alone –we recommend a team of at least two people

oClear the area below your workspace of all people, animals and other items.

oAvoid working on surfaces that are slippery or wet and use footwear with excellent traction.

oUse only strong, well-supported and appropriate ladders.

oWork only in calm, dry weather.

oWhen in the attic, ensure that your weight is supported at all times with structurally sound framing;

dry wall material is not designed to carry a person’s weight.

oReduce the risk of fire, electric shock, and personal injury by following basic safety precautions

when using electric tools; always wear safety goggles or other suitable eye protection and ensure

work area is clear of all electrical wires, gas pipes, water pipes and other obstacles.

oWhen working in the attic or other dusty areas, use of a mask or respirator is recommended to

avoid lung irritation. Attic spaces may be dark, confined, and subject to extreme temperatures.

Beware of sharp protruding objects. Do not attempt installation without having someone within

range of your voice or close enough to come to your aid if necessary.

oOnly suitably qualified persons should undertake any electrical wiring.

Installation tips & safety advice

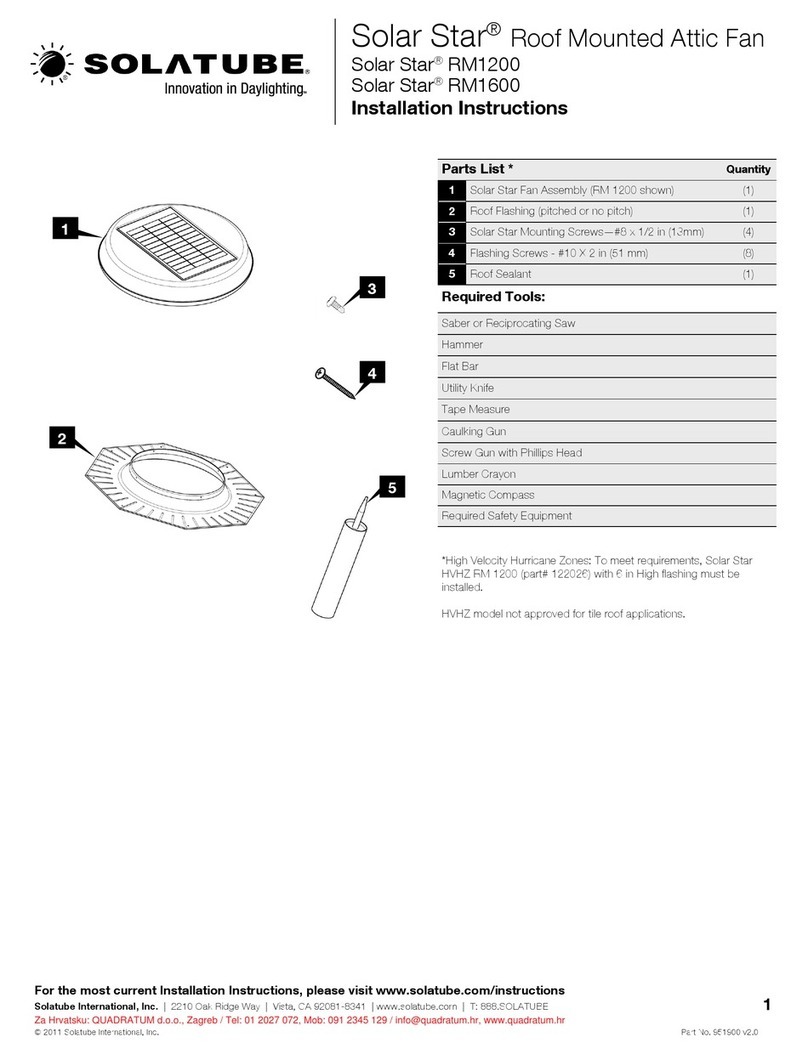

This guide offers a step-by-step guide for the installation of a Solatube 160DS and 290DS.

In general, a Solatube 160DS can provide enough daylight to illuminate a dark area of up to 10 sqm. A Solatube 290DS can provide

enough daylight to illuminate a dark area of up to 18 sq m. Both examples are based on a 2.44 m ceiling height with a 1.83 m tube

length. For larger areas, you may need to install more than one Solatube. This information is for guidance purposes only.

Allow at least 4 hours for the installation, particularly if this is your first installation.

During the day, turn off all the lights in the room to see how much natural light comes in through the windows (if any). You should then

be able to determine the best position for the Solatube diffuser.

Avoid roof dome locations shaded by trees, ridges and chimneys, or near water channels or valleys.

Avoid attic areas with obstructions such as gas, water or drain pipes, air ducts, flues or furnaces, fixed storage tanks.

Measure the distance between the roof and the ceiling to ensure you have ordered sufficient reflective tubing to cover the distance.

All reflective extension tube joints should overlap a minimum of 50mm and be fixed together using the aluminium tape (and self-tapping

screws if required).

All adhesives, seals and tapes should be applied to a dry and dust-free surface. The ideal working temperature is approximately 22°C.

Ensure all joints (including seams) are taped sufficiently and all edges well rubbed in (tip: use the tape backing paper) to

prevent the adhesive drying out.

Ensure your roof is in an appropriate condition to support the work necessary for a Solatube installation without damaging its

waterproofing properties.

Solatube will generally perform best if the roof dome is located on the south, east or west elevation. If the roof dome is to be positioned

on a north facing elevation, positioning the roof dome as high as possible on the roof will enhance performance.

You may choose to support any extension tubes with a wire or similar retainer fixed to the rafters if the extension tubes are at a

significant angle away from the vertical.

When the Solatube is initially installed, it is not uncommon for it to condensate lightly on the inside of the dome for the first few weeks

until humid air inside the tube dissipates; the dome is designed to collect any internal condensation and direct it to the outside of the

flashing. The flashing insulator provided is essential to reduce the possibility of condensation, but in particularly cold climates, it is also

advisable to tape a jacket of insulating material (optional extra) around the outside of the extension tubes and up into the void between

the top tube assembly and roof flashing; this is to prevent the possibility of condensation build-up on the exterior of the components

within the roof void.