Solcon SI-DCB User manual

lnstruction

Manual

Ver. 0822

––

2

Table of Contents

Page

Subject

3

Brake selection

4

Installation Notes

5

Mode of operation

6-8

Wiring and operation

9

Potentiometer settings and Start up procedure

10

Fuse Selection Table

11-12

Dimensions

13

Technical Specification

14

Ordering Information

* Read this manual carefully before operating the equipment and follow its instructions

* Installation, operation, and maintenance should be in strict accordance with this manual, national

codes and good practice. Installation or operation not performed in strict accordance with these

instructions will void manufacturer's warranty.

* Disconnect all power inputs before servicing the SI-DCB and/or the motor.

* After installation, check and verify that no parts (bolts, washers, etc) have fallen into the power

Section (IP00).

ATTENTION

1. This product was designed and tested for compliance with IEC947-4-2 for class A equipment.

2. The SI-DCB brakes are designed to meet UL requirements

3. Use of the product in domestic environments may cause radio interference, in which case the user

may be required to employ additional mitigation methods.

4. Utilization category is AC-53a or AC53b. Form1.

5. For further information see Technical Specification

WARNING

* Internal components and P.C.B's are at mains potential when the SI-DCB is connected

to mains.

This voltage is extremely dangerous and may cause death or severe injury if contacted.

* When the SI-DCB is connected to mains, even if operation signal is disconnected full

voltage may appear on SI-DCB output.

* Unit must be grounded to ensure correct operation, safety and to prevent damage.

* Check that Power Factor capacitors are not connected to the output side of the SI-DCB.

Brake Selection

3

General

The SI-DCB - Solid State Motor Brake provides fast,

smooth, frictionless braking of three-phase squirrel-cage

motors by injecting controlled DC current to the motor

windings, after Mains contactor opened. This induces a

stationary magnetic field, which exerts a brakingtorqueon

the rotor.

Stopping time can be similar to the time it takes to reach

full speed on a Direct-On-Line starting.

Adjustable Braking Torque and Braking Time enable

perfect matching of the brake to the driven load.

Automatic sensing System turns the brake off

automatically when the motor comes to a full stop. This

minimizes the motor heating.

Brakes ratings and Frame sizes

Max Motor

FLA (Amp)

Brake Type

FLC

Frame

Size

Case

material

10

SI-DCB 10

SB0

PC/ABS

17

SI-DCB 17

SB1

Aluminum

31

SI-DCB 31

58

SI-DCB 58

105

SI-DCB 105

SB2

Metal

210

SI-DCB 210

310

SI-DCB 310

SB3

390

SI-DCB 390

460

SI-DCB 460

Dimensions (mm)

Size

Width

Height

Depth

SB0

45

75

105

SB1

65

190

114

SB2

154

280

160

SB3

224

384

222

Select the brake according to the following criteria:

Motor Current & starting conditions

•Motor's Full Load Ampere (FLA) - as indicated

on its nameplate (even if the motor is not fully

loaded).

•The SI-DCB is designed for a duty cycle of 10%

or less; e.g. 10 sec. operation, 90 sec. rest.

Duty Cycle - the ratio between operating time

and

total cycle time (rest time + Braking time).

Braking time

Duty Cycle = ------------------------------- x 100 (%)

Rest time + Braking time

Note:

If a higher duty cycle is required select a higher SI-DCB

type to allow enough brake time current.

Mains Voltage (line to line)

Thyristor's PIV rating, internal circuitry and insulation

determines six voltage levels: Each brake is factory set

for one of the following levels according to the Ordering

Information.

Voltage

Tolerance

230 V

+10 -15 %

400 V

+10 -15 %

440 V

+10 -15 %

480 V

+10 -15 %

600 V

+10 -15 %

690 V (210A-460A)

+10 -15 %

Each brake is factory set for one of the above levels and

suitable for 50 or for 60 Hz (±5%).

Options (see Ordering Information)

For extended braking time - consult factory and provide

the following information:

•Ambient temperature.

•Actual stopping current.

•Actual stopping time.

•Time interval between starts

•Load characteristics

Centrifuge

RPM

Stopping Time

t

Solbrake

Wood Saw

Installation Notes

4

Prior to Installation

Check that Motor's Full Load Ampere (FLA) is lower than

or equal to SI-DCB Full Load Current (FLC) and verify

that Mains voltage and frequency are as indicated on the

SI-DCB label.

Mounting

* The SI-DCB must be mounted vertically, allow

space above and below the unit for sufficient airflow.

* It is recommended to mount the SI-DCB directly on the

rear metal plate for better heat dissipation.

* Do not mount the SI-DCB near heat sources.

* Protect the SI-DCB from dust and corrosive

atmosphere.

Temp. Range and Heat Dissipation

The SI-DCB is rated to operate over a temperaturerange of

-10C (14F) to +50C (122F).

Relative non-condensed humidity inside the enclosure

should not exceed 93%.

The average heat dissipation of the SI-DCBdependsonthe

Braking Torque setting and on the duty cycle.

Heating inside the enclosure can be reduced through the

use of additional ventilation.

Note: The heat generated in the motor during braking is

similar to the heat generated during starting. Therefore,

high setting of the Braking Torque and/ora highdutycycle

may require an external cooling fan for the motor. It is

recommended to use temperature sensor in the motor

which will allow restarting only after the motor

temperature has reduced to an allowed level.

Short Circuit Protection

The SI-DCB must be protected against short circuit by

fast-acting fuses. Recommended I2 t values in page 9.

Transient Protection

Line transient voltages can cause malfunctioning of the

brake and damage to the SCRs.

When high transients are expected, an external protection

should be used, (consult factory).

Wiring

Connections to L1, L2, U, V should be done with full size

power cables. Connections to terminals 1-6 and W are

control wires size.

Do not connect two SI-DCB brakes in parallel as they are

not synchronized and will be damaged.

Mechanical and electrical interlock between Mains

contactor C1and braking contactor Cbr must be installed to

prevent both contactors from being closed simultaneously.

SI-DCB Wiring

The SI-DCB (10-17) is meant for installation on a Din-

Rail. See options list for other Din-Rail ratings.

U

V

W

L

1

L

2

1

2

3

4

5

6

Power Factor Capacitors

Power factor correction capacitors must not be installedon

the load side of the SI-DCB. When required, capacitors

should be installed on the SI-DCB line side.

Notes:

1. The SI-DCB uses Mains power to produce the

braking torque. Therefore, a power failure or

disconnection will disable the DC braking and the

motor will coast to a stop without braking.

2. When required to stop a motor during a power

outage, an electro-mechanical brake must be used.

3. The SI-DCB cannot be used for continuous holding

of loads, after motor had stopped. An electro-

mechanical brake should be used for holding atstop

position.

Warning

Wrong connections of SI-DCB line and load sides

will cause damage to the brake and motor.

Mode of Operation

5

Stop signal opens motor contactor

C1that in turn initiates the closing of

brake contacts Cbr.

The Thyristor is switched on and

fire (to inject DC current to the

motor) after time delay, to induce

the braking current.

The torque, which is a function of

the DC current, can be controlled

by the firing angle of the Thyristor.

Note: there is a time delay between

opening of one contactor and

closing the other one to reduce the

EMF. The time delay correlate to

the size of the motor.

Braking Time

Braking time depends on the inertia, friction of the load,

speed, and braking current. The required braking time is

best established by practical experience.

The SI-DCB offers two operating modes, Automatic and

Manual. Selection between the modes is done by an

internal dip switch.

Dip sw. Operation Mode

On Manual

Off Automatic

It is recommended to use the Automatic mode (factory

default setting) to reduce the braking time and minimize

motor heating.

Automatic operation

DC injection duration is

automatically controlled

by the SI-DCB.

Injection ceases when

Motor has come to a

complete stop.

Manual operation

DC injection duration is

according to the Braking

Time setting on the front

panel.

Notes:

1. Motor heating during braking is similar to heating

during Direct Online starting. Therefore, always adjust

for the shortest DC injection time duration.

2. In general, for improved braking process to be in effect,

it is recommended to apply some minimal inertia on

the motor shaft.

The SI-DCB incorporates the following built-in time

delays:

t

1

DC Injection

Brake Contactor

Motor Contactor

1 - 2 Open

t

2

t

3

t

4

t

5

1 - 2 Closed

Power ON

Motor

Running

Braking

Process

Start

Stop

Where:

t1- Time delay between opening of motor's contactor C1

and closing of brake contactor Cbr, allowing motor's

back EMF to diminish (see table below).

t2- Time delay of 0.05 sec between closing of brake

contactor Cbr and initiation of DC current, to ensure

that brake contactor does not switch DC current,

enabling the use of regular AC contactor.

t3- In Auto Mode –Enabling of DC current injection.

In Manual Mode - time of DC current injection.

Range: 1-10 sec.

t4- Time delay between end of DC current injection and

opening of brake contactor Cbr to ensure that the

contactor does not switch DC current, enabling the

use of regular AC contactor (see table below).

t5- Time delay of 0.2 sec. between opening of brake

contactor Cbr and enabling motor’s restart.

Approximate Time Delays (sec).

SI-DCB

10

17

58

105

210

390

t1

0.2

0.3

0.6

1.1

1.7

2.5

t4

0.2

0.2

0.3

0.8

1.2

1.9

Torque at standstill

When required to maintain theDCbraking currentafterthe

motor has come to a complete stop, set Auto/Man Dip

Switch to On (Manual operation). Set Braking Time to a

longer time than it takes the motor to come to a complete

stop.

Note - DC Injection after motor has come to a complete

stop may cause excessive heating of boththemotorandthe

brake.

Sec.

10

1

DC Injection

Motor Stopped

Braking contactor Closed

Restart Enable

Sec.

10

1

DC Injection

Motor Stopped

Braking contactor

Closed

Restart Enable

M

Wiring & Operation

6

SI-DCB with Direct on Line Starter

Motor contactor C1(with one N.O + two N.C contacts).

* Contact C1 - Holding N.O contact of contactor C1

* Contact C1 - auxiliary N.C contact of contactor C1,

initiates the braking process.

* Contact C1 - auxiliary N.C contact of motor contactor

acts as an interlock preventing operation of brake

contactor as long as motor contactor is closed.

Brake contactor Cbr(with one N.C contacts).

* Contact Cbr - auxiliary N.C contact of contactor Cbr,

acts as an interlock preventing operation of motor

contactor as long as brake contactor is closed.

Note:

It is recommended to electro mechanically interlock

contactors C1and Cbr.

SI-DCB contacts

* Ca contact (SI-DCB terminals 3-4), contact closeswhen

Mains voltage is connected to SI-DCB terminals and

terminal 1-2 are open.

* Cb contact (SI-DCB terminals 5-6), closes upon stop

signal and contact terminals 1-2 closes after time delay

t1.

Notes

* Motor contactor C1cannot be operated when Mains

voltage is not connected to terminals L1and L2 (internal

contact Ca in SI-DCB, controlling motor contactor,

closes after Mains voltage is connected and terminal 1-2

are open.

* When operating in Manual mode, DC injection will stop

after time delay t3as set on the Braking Time

potentiometer.

Operation

Upon start signal, as Ca is closed, motor contactor C1

closes, motor will operate and contact C1-1 opens.

Upon stop signal, motor contactor C1opens, contact C1-1

closes and initiates the braking process.

Contact Ca opens, preventing motor contactor operation,

and after time delay t1 contact Cbcloses, closing the brake

contactor Cbr.

The yellow LED on SI-DCB front panel will light up

indicating that brake contactor is closed.

After time delay of approx. 0.05 sec. DC current will be

injected to motors' winding.

The yellow LED on SI-DCB front panel will light up

indicating that braking current is now injected to the

motor.

The DC injection will automatically cease when motor

comes to a complete stop (when Automatic mode is

selected) and the yellow LED turns off.

Contact Ca closes after time delay t5, permitting motor

restarting.

Wiring & Operation

7

Emergency Brake

A dedicated Emergency Stop button, with

two contacts initiates braking.

When Stop contact is opened, contactor C1opens,

the SI-DCB is not initiated.

When Emergency Button is pressed, the Emergency

Stop closes and initiates the braking process.

When Emergency Stop contact is opened, C1

contactor opens and the SI-DCB is operated,

initiating the braking process.

Forward/Reverse

Cbr - SI-DCB Contactor.

Cf - Forward Contactor

Cr - Reversing Contactor

Mechanically Interlocked Contactors.

Braking process is initiated

when Contactors Cf or Cr open.

Star-Delta

Cbr - SI-DCB Contactor.

Cs - Star Contactor

Cd - Delta Contactor

T1, T2 - Timer Relays

Braking process is initiated

when Contactors Cd,Cs & Cl will

open. Hence, a mechanical

interlock between Cbr and Cl

is recommended.

Wiring & Operation

8

Star-Delta Forward / Reverse

Cf - Forward Contactor

Cr - Reversing Contactor

Cs - Star Contactor

Cd - Delta Contactor

Cl - Line Contactor

T1, T2 - Timer Relays

Braking process is initiated

when Contactors Cd, Cs, Cf & Cr will be

open. Hence, an electrical interlock

between Cbr and Cf & Cr

is recommended.

Potentiometer Setting Start-Up Procedure

9

Braking torque

Determines the value of DC current the SI-DCB injects to

the motor. The SI-DCB can produce a braking current of

up to four times motor's nominal current.

A too high setting may cause a fast stop and high

mechanical shock. A too low setting may result in

prolonged time until motor stops.

Braking Time

* For Automatic Time-out - The setting on the front

panel determines the period of time during which the

braking contactor is closed. DC current ceases

automatically when the motor stops (Factory

default internal Dip Switch setting).

* For Manual Time-out - The setting on the front panel

determines the period of time during which

DC current is injected to motor windings, regardless of

when the motor stops (can be modified with the

internal

Dip Switch).

LED Display

The Green LED indicates that power supply is connected

to the SI-DCB (L1, L2).

The Yellow LED indicates that contactor Cbr is closed.

Motor restart is disabled when this LED is lit.

The yellow LED indicates that DCcurrentisbeinginjected

in the motor windings.

During start-up the dip switch should be in the Offposition

for Automatic Time-Out.

1. Set Braking Torque to 5

2. Set Braking Time to 10

3. Start motor and wait until it reaches full speed.

4. Stop motor and check the braking procedure.

a If braking has ceased and motor is still turning,

increase braking Torque setting and try again.

b If motor has stopped and the Yellow LED remains

on, decrease Braking Time setting until the Yellow

LED turns off shortly after the yellow LED has

turned off.

Note: Set Braking Time potentiometer t3to a slightly

longer time than the time required for motor to come to a

complete stop, even if the brake operates in an Automatic

mode. This is required for two reasons:

1. Ensuring that even if the automatic time-out

circuit did not sense that motor had stopped,

the DC injection will cease shortly after motor

stopped preventing excessive heating.

2. During time delay t3, braking contactor

remains closed even if the Automatic Time-

Out circuit has stopped the DC current.

Measuring the Braking Current

Approximate measurement of the braking current can be

made with a true RMS ammeter.

Trouble Shooting

1. Disconnect Mains voltage and check that contacts 3-4

and 5-6 are open.

2. Connect power to L1and L2. The green LED (On)

should light up.

3. Check that contact between terminals 3-4 is closed.

4. Check that contact between terminals 5-6 is open.

5. Start the motor. Motor contactor should close. If it

doesn't, check connection to contactor.

6. Press Stop button; motor contactor should open and

brake contactor should close after a short time delay.

Simultaneously the Braking Time and DC injection

LEDs should be lit. If LEDs do not light up, check that

auxiliary contact of Mains contactor connectedbetween

control terminals 1-2 is closed.

BrakingTorque

2 10Sec.

110

BrakingTime(Sec.)

On

Braking

DCInjectionOn

Dip Sw. S1.2 = Not in use

Off = Automatic

1 2

On = Manual

Dip Sw. S1.1=Auto/Man.

Solbrake, Main PCB

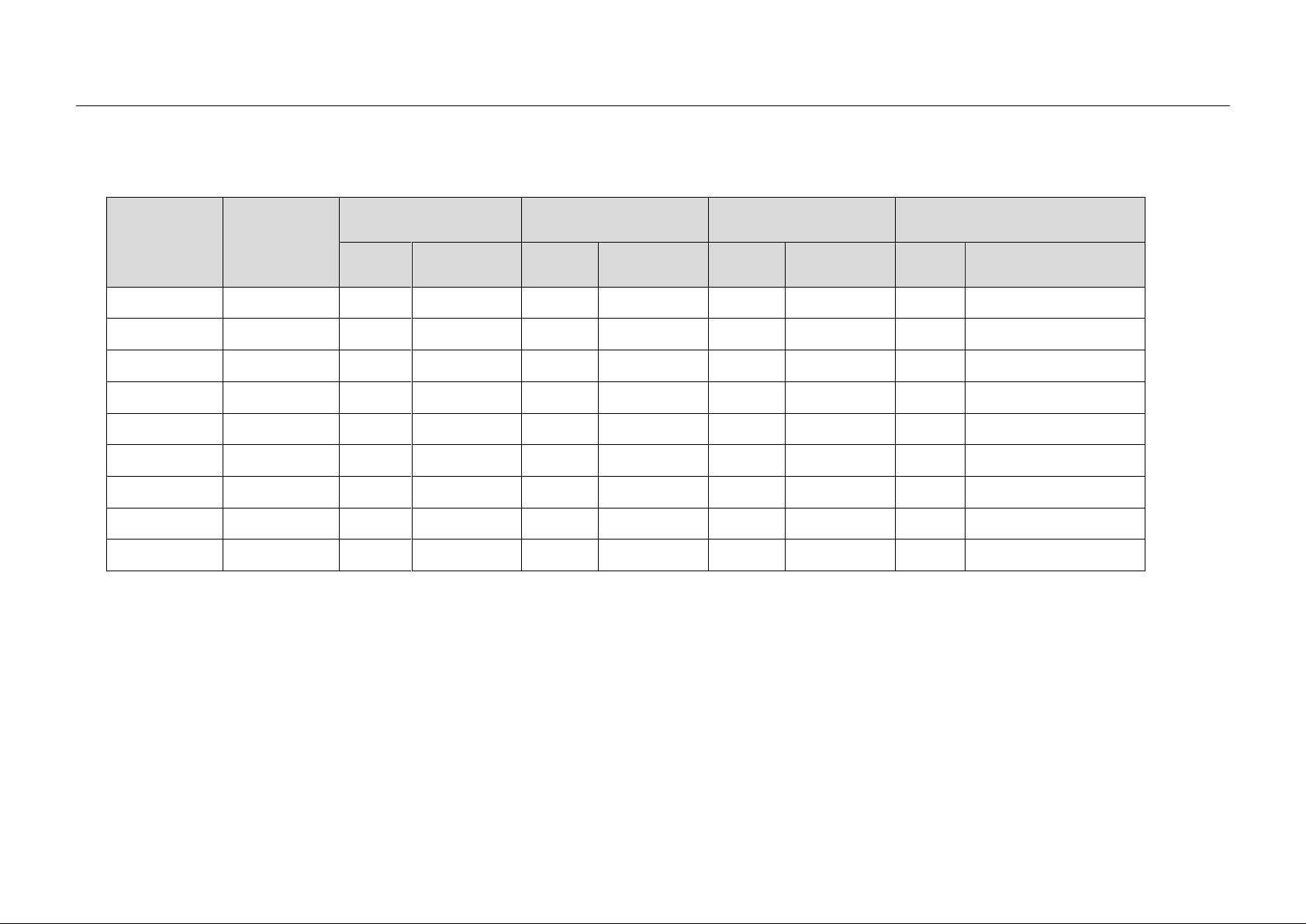

Fuse Selection Table(400V)

10

FUSE SELECTION (recommended values for mains supply of 400V)

RVS-DX

Max.

Thyristor I2t

(A2Sec)

BUSSMAN

GEC ALSTOM

SIBA

FERRAZ –SHAWMUT

(IEC Style 690/700V)

Rated

(A)

P/N

Rated

(A)

P/N

Rated

(A)

P/N

Rated

(A)

P/N

SI-DCB 10

400

30

FWP 30B

32

B210612

32

URD 000-32

SI-DCB 17

5,000

50

FWP 50B

63

B210615

63

6.6URD30D11A0063

SI-DCB 31

12,000

125

FWP 125A

100

X320063

100

6.6URD30D11A0100

SI-DCB 58

15,000

150

FWP 150A

125

X320065

125

6.6URD30D11A0125

SI-DCB 105

60,000

250

FWP 250A

200

D320071

250

SQB1-250

250

6.6URD30D11A0250

SI-DCB 210

200,000

500

FWP 500A

450

D320485

450

SQB1-450

450

6.6URD30D11A0450

SI-DCB 310

600,000

700

FWP 700A

630

H320489

630

SQB1-630

630

6.6URD31D11A0630

SI-DCB 390

700,000

700

FWP 700A

800

T320591

800

SQB1-800

800

6.6URD31D11A0800

SI-DCB 460

1,200,000

1000

FWP 1000A

1000

W320593

900

SQB2-900

1000

6.6URD32D11A1000

Notes: 1. The above table is for maximum stop current of 400 % of FLC, maximum time of 30 sec and rated voltage of 400 V (see note 3 for exception).

2. Rating may change with different external conditions such as ambient temperature, forced cooling etc. Refer to fuse manufacturer catalogs to confirm correct values.

3. Ferraz ratings are simulated for 4xIn, 4 times per hour with a 10 sec. stop time for each stop.

Dimensions

11

SI-DCB 10A

SI-DCB 17-58A

U

V

W

L

1

L

2

1

2

3

4

5

6

75

105

90

105

Dimensions

12

SI-DCB 105-210A

SI-DCB 310-460A

160

280

263

L1

L2

U

V

W

M6

12

17

12

20

12

77

U

L

1

U

L

1

18

18

384

W

L

2

224

222

W

V

L

2

63.4

V

Technical Specification

13

Environment

Supply voltage

Two phase, line to line. 220-600VAC

(690VAC for 210A –460A)

+10% -15%

Frequency

50 / 60 Hz

Load

Three-Phase, Three-Wire, Squirrel

Cage Induction Motor

Duty cycle

10% max.

10 sec. operation, 90 sec. rest

Degree of protection

IP 20 up to 58A (IP00 up to 460A)

Altitude

1000 m above sea level

Adjustments

Braking current

1-10 for 0 - 4 times FLC

Braking time

2-10 sec.

Optionally 1-30 sec.

Protection

Automatic stopped motor sensor

Switches off the DC injection automatically when motor has come to a

complete stop.

Indications

Indication lights (LEDs)

ON - Green

Illuminates when power is connected

to SI-DCB on L1 and L2.

Cbr closed –Yellow

Illuminates when contactor Cbr is

closed.

DC Injection ON - Yellow

Illuminates when DC current is being

injected to the motor windings.

Temperatures

Operating

-10° to 50°C

Storage

-20° to 70°C

Relative humidity

93 % - non condensed

Ordering Information

14

SI-DCB 31 –400 –0 –S

Brake FLC

Mains voltage

Options

Front panel

(1) SI-DCB FLC: 10, 17, 31, 58, 105, 210, 310, 390 Amp

(2) Mains voltage Specify For

50/60Hz 230 230 Vac

+10% -15% 400 400 Vac

440 440 Vac

480 480 Vac

600 600 Vac

(3) Required options Specify For

0 No options.

E Consult Factory

8 Harsh environment treatment (factory supplied)

(4) Front panel Specify For

S Standard

(1)

(2)

(3)

(4)

This manual suits for next models

9

Table of contents

Other Solcon Power Supply manuals