Solcon TPS User manual

Solcon Industries Ltd.

T

TP

PS

S

T

Th

hy

yr

ri

is

st

to

or

r

P

Po

ow

we

er

r

S

Sy

ys

st

te

em

m

8

8-

-1

15

50

00

0A

A,

,

2

23

30

0-

-1

10

00

00

0V

V

IInnssttrruuccttiioonn

MMaannuuaall

Ver. 22042019

www.solcon.com

2 • Table of content

________________________________________________________________________________________________

TPS Instruction Manual

1. TABLE OF CONTENT

1.Table of content....................................................................................................................... 2

2.Safety & Warnings................................................................................................................... 4

2.1Safety......................................................................................................................................... 4

2.2Attention..................................................................................................................................... 4

2.3Warnings.................................................................................................................................... 4

3.Technical Data ......................................................................................................................... 5

3.1Introduction ................................................................................................................................ 5

3.2Rating, Frames sizes and Weights ............................................................................................ 5

Refer to section 5 page 15 for detailed dimensional drawings ......................................................... 5

3.3TPS Selection ............................................................................................................................ 5

3.4Ordering Information .................................................................................................................. 6

3.5Mains and control description .................................................................................................... 7

3.6Input / Output indication............................................................................................................. 9

3.7Load Connections ...................................................................................................................... 9

3.8Modes of operation .................................................................................................................... 9

3.8.1Zero Crossing..................................................................................................................9

3.8.2Phase Control................................................................................................................10

3.8.3Phase control to zero crossing (Soft start) ....................................................................10

3.8.4Phase Control-Power ....................................................................................................10

3.9Synchronized mode ................................................................................................................. 11

4.Recommended Wiring Scheme............................................................................................ 12

4.1Load connection schemes ....................................................................................................... 12

4.2INSIDE DELTA Wiring ............................................................................................................. 13

4.3Typical control scheme ............................................................................................................ 13

4.4Communication and Synchronization wiring ............................................................................ 14

4.5Wiring Notes ............................................................................................................................ 14

4.5.1Short Circuit Protection .................................................................................................15

4.5.2Transient Protection ......................................................................................................15

5.Dimensions ............................................................................................................................ 15

5.1400-690VAC Models................................................................................................................ 15

5.21000VAC Models ..................................................................................................................... 19

6.Installation.............................................................................................................................. 20

6.1Prior to Installation ................................................................................................................... 20

6.2Mounting .................................................................................................................................. 20

6.3Temperature range & heat dissipation..................................................................................... 20

6.4Protection bus-bars covers for power terminals....................................................................... 20

6.5Jumpers settings for analogue input configuration .................................................................. 21

6.6Dip switches settings for analogue output optional PCB ......................................................... 21

7.Control Keypad...................................................................................................................... 23

7.1LCD Arrangement .................................................................................................................... 23

7.2Push-buttons............................................................................................................................ 23

7.3Status LEDs. ............................................................................................................................ 24

7.4Reviewing and modifying parameters...................................................................................... 24

7.5Special actions performed by the key-pad............................................................................... 24

7.5.1Run self test, Software version, default parameters and clear statistical data ..............24

7.6Mode Pages............................................................................................................................. 25

7.7Mode Pages, parameters & default values .............................................................................. 26

7.7.1Main parameters settings – page 1...............................................................................28

7.7.2I/O Parameters – page 2 ...............................................................................................30

7.7.3Protection Parameters – page 3....................................................................................32

3 • Table of content

________________________________________________________________________________________________

7.7.4Load sheding parameters settings– page 4 ..................................................................34

7.7.5Tripping/alarm prameters – page 5 ...............................................................................35

7.7.6Comm. Parameters – page 6 ........................................................................................36

7.7.7Actual data – page 7 .....................................................................................................37

7.7.8Statistical data – page 8................................................................................................38

7.7.9Fault data – page 9 ......................................................................................................38

8.TROUBLE SHOOTING........................................................................................................... 39

8.1Warranty Claim and Fault Report ............................................................................................ 41

To be completed By Solcon Service Dept. ................................................................................41

Return Material Authorization Number......................................................................................41

9.TECHNICAL SPECIFICATIONS............................................................................................. 42

4 • Safety & Warnings

________________________________________________________________________________________________

2. SAFETY & WARNINGS

2.1 Safety

1 Read this manual carefully before operating the equipment and follow its

instructions.

2 Installation, operation and maintenance should be in strict accordance

with this manual, national codes and good practice.

3 Installation or operation not performed in strict accordance with these

instructions will void manufacturer warranty.

4 Disconnect all power inputs before servicing the TPS and/or the load.

5 After installation, check and verify that no parts (bolts, washers, etc) have

fallen into the TPS.

2.2 Attention

1 This product was designed for compliance with IEC 947-4-3 for class A

equipment. TPS 1000V were also type tested to meet this standard.

2 Use of the product in domestic environments may cause radio

interference, in which case, the user may be required to employ

additional mitigation methods.

3 Utilization category is AC-51: 1,4 x Ie – 1 s, uninterrupted duty. For

further information, see Technical Specification

2.3 Warnings

1 Internal components and PCBs are at mains potential when the TPS is

connected to mains. This voltage is extremely dangerous and will cause

death or severe injury if contacted.

2 When TPS is connected to mains, even if control voltage is disconnected,

full voltage may appear on its output.

3 The TPS must be grounded to ensure correct operation, safety and to

prevent damage.

4 Check that Power Factor capacitors are not connected to the output side

of the soft TPS.

5 Do not interchange line and load connections

6 Phase Control Firing, may cause Radio interferences, in which case the

user may be required to employ additional mitigation methods.

The company reserves the right to make any improvements or modifications to its products without

prior notice.

5 • Technical Data

________________________________________________________________________________________________

3. TECHNICAL DATA

3.1 Introduction

Solcons’ Thyristor based Power System (TPS) is a heavy duty fully digital, Zero-crossing, Phase Control or

Phase Control-Power, three phase control power unit for all types of Resistive/Inductive loads (temperature

control of heaters, etc.).

Providing a wide range 8-1500A, 230-1000V, 50/60Hz, it can be installed in a variety of heating systems.

Control of output voltage can be done by input signal of 0-10VDC, 4-20mA, 0-20mA, by a potentiometer

(Optional) or via communication (Optional) for precision temperature control.

A special optional digital synchronization system enables load sharing and prevents excessive loading in multi

controller applications.

Fully programmable with 9 protection functions, including “Load Unbalance” alarm to detect a faulty element,

even in parallel connected element system and “Under power level” alarm to detect faulty element in case the

system is designed to work unbalanced.

Two line, 16 character LCD display is used for the TPS programming, actual values, statistical & maintenance

data.

Options:

- Potentiometer input for control. (Without the need for external power supply)

- Multi TPS synchronization system for load shedding

- RS-485 communication for TPS programming, remote data readings and controlling.

- Analogue output PCB (4-20mA, 0-20mA or 0-10V).

3.2 Rating, Frames sizes and Weights

Please note that the company reserves the right to

make any improvements or modifications to its

products without prior notice!

Refer to section 5 page 15 for detailed

dimensional drawings

3.3 TPS Selection

Select the TPS according to LOAD RATED CURRENT(FLA) - as indicated on its nameplate.

Note:

TPS withdrawn current by the load must not exceed TPS RATED CURRENT in each and every phase of the

TPS!

TPS

type

up to

690VAC

Rated

Current

[A]

Dimensions

WxHxD

[mm]

Weight

[Kg]

TPS 8 8 172x291x185 6.3

TPS 17 17 172x291x185 6.3

TPS 31 31 172x291x185 6.4

TPS 44 44 172x291x185 6.5

TPS 58 58 172x291x185 6.5

TPS 72 72 172x291x185 6.5

TPS 85 85 172x390x195 8.5

TPS 105 105 172x390x195 8.5

TPS 145 145 274x385x238 14.5

TPS 170 170 274x385x238 14.5

TPS 210 210 274x385x238 14.5

TPS 310 310 380x455x292 31

TPS 390 390 380x455x292 31

TPS 460 460 380x555x292 51

TPS 580 580 470x640x302 53

TPS 820 820 470x640x302 53

TPS 950 950 Consult factory

TPS 1100 1100 Consult factory

TPS 1500 1500 Consult factory

TPS

Model

1000VAC

Rated

Current

[A]

Dimensions

WxHxD

[mm]

Weight

[Kg]

TPS 55 55 280x550x346 33.5

TPS 105 105 280x550x346 33.5

TPS 160 160 280x550x346 33.5

TPS 200 200 280x550x346 33.5

6 • Technical Data

________________________________________________________________________________________________

3.4 Ordering Information

TPS 31- 400- 230- 230- 0- S

Full load

Current Mains

Voltage Control

Voltage Control

inputs

Voltage

Options Front Panel

Full load Current

Specify Description

TPS - Rated Current [A]

Models 400-690VAC

8, 17, 31, 44, 58, 72, 85, 105, 145, 170, 210, 310, 390, 460, 580, 820, 950, 1100,

1500

TPS - Rated Current [A]

Models 1000VAC

55, 105, 160, 200

Mains Voltage

Specify Description

400 230 – 400 VAC, +10% -15%, 50/60Hz

480 480 VAC, +10% -15%, 50/60Hz

600 600 VAC, +10% -15%, 50/60Hz

690 690 VAC, +10% -15%, 50/60Hz

1000 1000 VAC, +10% -15%, 50/60Hz

Control Voltage

Specify Description

115 115 VAC, 50/60Hz, +10% -15%

230 230 VAC, 50/60Hz, +10% -15%

110 VDC 110 VDC

(1)

, +10% -15%

24VDC 24 VDC

(1)

Notes:

(1) For DC control voltage or control inputs voltage - consult factory.

Options

Specify Description

0 No options

3M Communication RS-485 (MODBUS)

(1)

5 Analogue card

(1)

8 Harsh environment treatment

(1)

D Remote panel mounting replacing the original panel. (Supplied with 1.5 m cable).

(1)

,

(2)

Sync. Synchronization between up to 10 TPS units.

(1)

P Potentiometer control. (No need for external power source)

(1)

RU Russian display

Notes: For more than one option indicate, for example: 8+5 (Harsh environment and analogue

card)

(1) Must be ordered in factory – cannot be installed on site.

(2) D option is available for TPS 145A and up.

Front Panel

Specify Description

S Standard

Example:

TPS rated 820A, mains voltage - 230V, control voltage- 230VAC, control inputs- 48VDC Modbus

communication card, Harsh environment treatment, Synchronized TPS and standard front panel: TPS 820 -

230 – 230 - 48 - 3M+8+SYNC – S

Control inputs voltage

Specify Description

115 or 230 90 – 230 VAC, 50/60Hz or 90 – 230 VDC

24 24VAC, 50/60Hz or 24VDC

(1)

48 48VAC, 50/60Hz or 48VDC

(1)

Notes:

(1) For DC control voltage or control inputs voltage - consult factory.

7 • Technical Data

________________________________________________________________________________________________

3.5 Mains and control description

Indication Description Remarks

L1, L2, L3 Connection to mains voltage up to 690V.

Three Main Voltage levels are available:

400V (230-400V), 480V, 600V,690V and

1000V.

Note:

400V applies for 230 to 400V.

U, V, W Connection to resistive/inductive load. Load connection must be programmed to

TPS. Refer to section 3.7 page 9.

G Connection to Ground.

Terminal 1 Control phase (Positive – for DC control)

Three control voltages are available:

115VAC (50/60Hz), 230VAC (50/60Hz),

110VDC.

Terminal 3 Control Neutral (Return)

Terminal 4 Input – RUN command.

Terminal 5 Input - Auxiliary programmable input. Auxiliary Input can be programmed as one

of the options:

SYNC.

AUTHORIZED KEY

REMOTE RESET

N.C. EXT. FAULT

N.O. EXT. FAULT

N.C. INTERLOCK

N.O. INTERLOCK

Refer to section 7.7.2 page 30.

Terminal 6 Common. This terminal is a reference to terminals 4

& 5.

Terminal 7 Programmable output relay A –

Common.

Any of the output relays A, B or C can be

programmed to one of the following

functions:

Run, Alarm, Alarm fail safe, Trip, Trip fail

safe, Tripping/Alarm (Any fault

programmed in the tripping and alarm

options will energize the relay.)

Refer to section 7.7.2 page 30 for

programming output relays.

Terminal 8 Programmable output relay A –

Normally open (NO).

Terminal 9 Programmable output relay A –

Normally closed (NC).

Terminal 10 Programmable output relay B –

Common.

Terminal 11 Programmable output relay B –

Normally open (NO).

Terminal 12 Programmable output relay B –

Normally closed (NC).

Terminal 13 Programmable output relay C –

Common.

Terminal 14 Programmable output relay C –

Normally open (NO).

Terminal 15 Programmable output relay C –

Normally closed (NC).

8 • Technical Data

________________________________________________________________________________________________

Indication Description Remarks

Terminal 16 Analogue input signal (+) Terminals 16 & 17 are used for both, 0-

10V and 4-20mA, 0-20mA analogue

signals.

Terminals 16, 17 are used also when

potentiometer option is installed.

Refer to section 7.7.2 page 30 for

analogue input programming.

Notes:

Set internal jumper on the main control

board for the selected analogue input

signal. Refer to section 6.4 page 20.

When the TPS is programmed to get its

analog input via communication, these

inputs are not operative. Refer to section

7.7.6 page 36.

Caution

Damage may occur if jumpers are not

properly set (see instructions for JP1, JP2,

JP3 & JP4).

Jumpers are factory set for 4-20mA input.

Terminal 17 Analogue input signal (-)

Terminal 18 Synchronization signal (+) (Optional) Sync. signal use Shielded twisted pair, for

daisy chaining.

Up to 10 TPS units can be connected for

master slave configuration. Master Slave

configuration is designed for units located

in the vicinity of 20 meter maximum. Refer

to section 3.9 page 11.

Terminal 19 Synchronization signal (-) (Optional)

Terminal 20 POT. CW - Output voltage for potentiometer

connection (Only when option “P” is

present.) (Optional).

When option “P” is present connect

potentiometer CW to terminal 20,

potentiometer slide to terminal 16 and

potentiometer CCW to terminal 17.

For potentiometer input control refer to

section 6.4 page 20 for jumper settings

and program TPS input to “Voltage input

– Refer to section 7.7.2 page 30 for

analogue input programming.

Notes:

A potentiometer of 10kOhm must be used!

Use a high precision potentiometer for

better resolution.

When the TPS is programmed to get its

analog input via communication, these

inputs are not operative. Refer to section

7.7.6 page 36.

Terminal 21 Not connected

Terminal 22 Comm. Ground (Optional) Communication use Shielded twisted pair,

for daisy chaining.

Up 32 units can be connected for Modbus

RS485 communication.

For reliable communication, units should

be installed in the vicinity of 200m

maximum, from the first to the last unit.

Terminal 23 RS-485 Communication (-) (Optional)

Terminal 24 RS-485 Communication (+) (Optional)

(+) OUT Analogue output (+)(Optional) This output is used when analogue output

option is installed. Analogue output can be

9 • Technical Data

________________________________________________________________________________________________

Indication Description Remarks

(-) OUT Analogue output (-)(Optional) configured as 4-20mA, 0-20mA or 0-10V.

Refer to section 6.6 page 21 for hardware

settings. .

Analogue output can be programmed as a

signal proportional to output power or

average of 3 phase currents or I1 or I2 or

I3 or as a reflection of the analogue input

to the TPS.

Refer to section 7.7.2 page 30 for

programming analogue output.

3.6 Input / Output indication

3.7 Load Connections

The TPS can be connect the load as shown in section 4.1 on page 12. The available configurations are:

Wye with Neutral Connected, Wye with Neutral not Connected, Delta or inside Delta.

Load connection type must be programmed to TPS. Refer to section 7.7.1 page 28.

Note:

Any number of parallel branches may be connected in the shown connection types provided that the total

connected load will not exceed the current rating of the TPS unit.

3.8 Modes of operation

3.8.1 Zero Crossing

In this mode of operation thyristor’s firing is performed so that current starts at its zero crossing point .

Main advantages of this mode are:

Minimizing RFI noise.

Minimizing current THD.Main disadvantages are:

No “Soft start”.

High inrush current in case of load with temperature dependant characteristic (lower resistance when

cold)

Current may vary in time.

In this mode of operation the TPS is programmed to operate in a cycle. (Tct)

When, during this cycle, analogue input is set to maximum – The TPS will conduct continuously.

When analogue input is lower, a proportional number of waves will be delivered to the load during Tct.

Firing method must be programmed to TPS. Refer to section 7.7.1 page 28.

10 • Technical Data

________________________________________________________________________________________________

Note:

Tct = 1-10Sec.

(Adjustable in 0.1 sec

steps)

Ton=2 cycles – Tct

Seconds (Minimum

conducting time is 2

cycles)

3.8.2 Phase Control

In this mode of operation thyristor’s firing is performed in every half cycle proportional to the analogue input.

Maximum analogue input will cause a full wave to load. When analogue input is lower, a proportional part of

the sine wave will be delivered to the load.

Main advantages of this mode are:

Enables “Soft start”

Current variations are limited.

Main disadvantages are:

Relatively high RFI noise.

Relatively high current THD.

Note:

When load is connected in WYE NEUTRAL NOT CONNECTED or in LINE DELTA (both connections are

without a neutral point) AND TPS is in PHASE CONTROL it is impossible to go to zero output.

Minimum possible firing for such case gives 10-20% of output voltage. This is since in this case the firing of

each phase depends on the three phases mains and we cannot control each phase voltage down to zero.

In this case, zero input in analogue input causes the minimum possible voltage to appear in the output. Then,

upon increasing the analogue input voltage, output voltage/current is monotonically increased.

Firing method must be programmed to TPS. Refer to section 7.7.1 page 28.

3.8.3 Phase control to zero crossing (Soft start)

The user can program a time of which the TPS will function in PHASE CONTROL and then change to ZERO

CROSSING mode.

This mode of operation allows soft starting of the load. This mode is recommended when load resistance has

a temperature dependant characteristic (lower resistance when cold).

Program PHASE CONTROL TO ZERO CROSSING time to a value from 1-3600 seconds.

During starting the TPS for the first 1-3600 seconds , TPS will operate in PHASE CONTROL mode of

operation thyristor’s firing is performed in every half cycle proportional to the analogue input.

The outcome of this process will be a small current withdraw from the supply and slow heating of the heat

element thus increasing its resistance and lowering the current.

Firing method must be programmed to TPS. Refer to section 7.7.1 page 28.

3.8.4 Phase Control-Power

In this mode of operation TPS function in PHASE CONTROL (See explanations above).

In PHASE CONTROL-POWER the output power of the TPS will be kept linear to the analogue input of the

TPS.

Firing method must be programmed to TPS. Refer to section 7.7.1 page 28.

11 • Technical Data

________________________________________________________________________________________________

3.9 Synchronized mode

This mode of operation is applicable only if mode of operation is set to ZERO CROSSING.

In this mode of operation the TPS Sync. Terminals should be wired in “daisy chain” as shown in section 4.4 on

page14. This mode is used to time share the ON time (Ton) period between the units.

In this mode, the beginning of the ON cycles of the connected TPSs is equally shifted.

For example:

No. of TPS units – 3

Cycle time when TPS is in ZERO CROSSING (Tct – see section 3.8.1 page 9) – 3 seconds.

In this example TPS#1 will be set to master and TPS#2, TPS#3 will be set to slave.

When system is stated, TPS#1 will go to ON first, TPS#2 will go to ON after 1 second (3 seconds/3), TPS#3

will go to ON after 2 seconds.

So, if the required duty cycle (Ton/Tct) is less than 1/3, one TPS only can be in ON state.

The Master is transmitting a “Sync” signal, received by all connected TPSs (Sync group members).

Only one unit of the group should be set as Master. All others should be set as slaves.

Refer to section 7.7.4 page 34 for programming.

Notes:

1. Sync. LED will lit once function is enabled.

2. In order to have a full number of ON cycles it is recommended to program the ON-OFF CYCLE

time In such manner that the number of cycles (50 or 60 Hz) divided by the number of connected TPS

units will be an integer . i.e. if 3 TPS units are connected with 50Hz mains, the ON-OFF time can be,

for example, 0.9Sec (45 cycles), 1,2 Sec (60 cycles), 3Sec (150 cycles).

3. Synchronized mode cannot be implemented if one current analog input is connected to several TPS

units in series.

12 • Recommended Wiring Scheme

________________________________________________________________________________________________

4. RECOMMENDED WIRING SCHEME

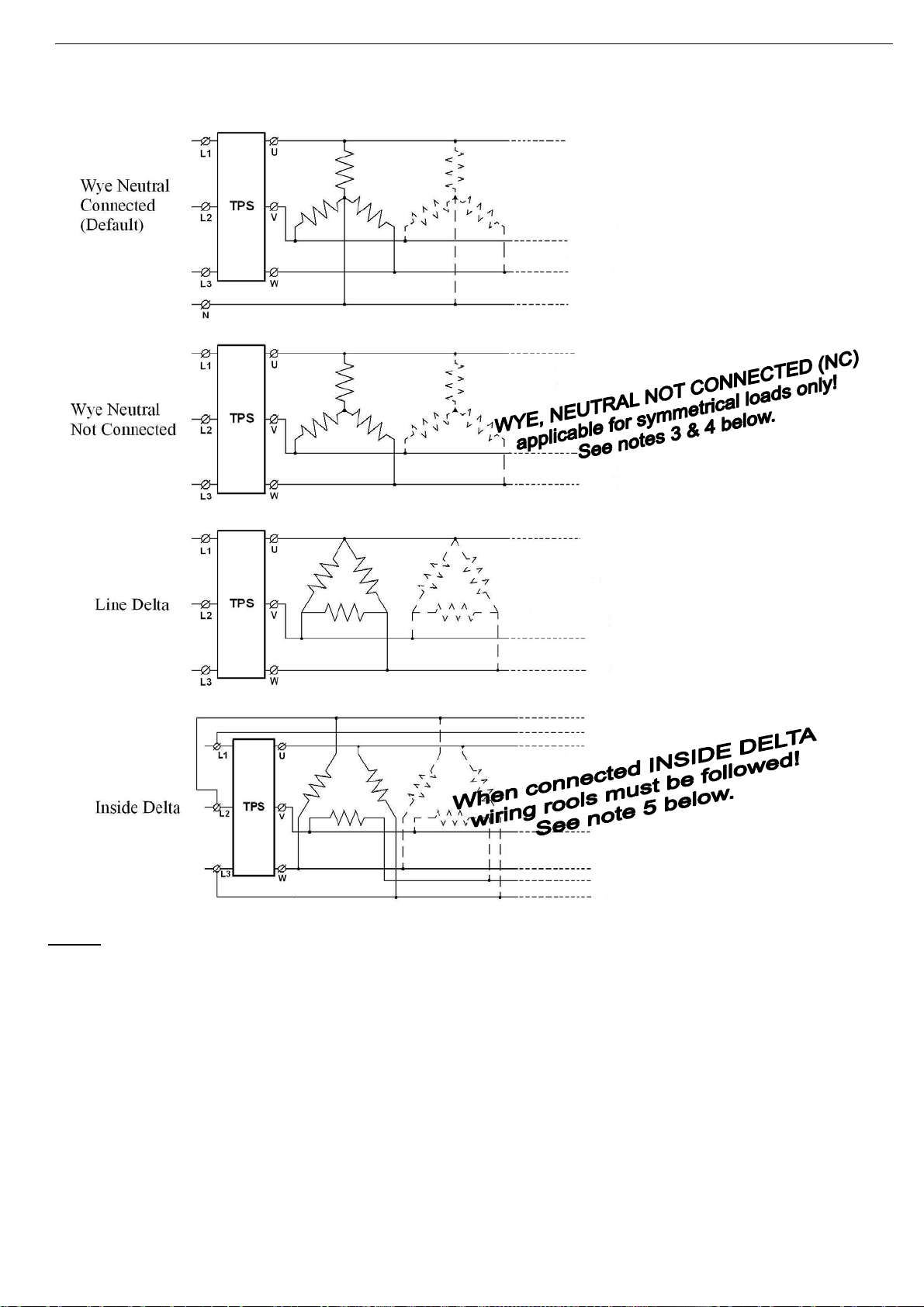

4.1 Load connection schemes

Notes: (1) – Set connection type to TPS. Refer to section 7.7.1 on page 28

(2) When load is connected in WYE NEUTRAL NOT CONNECTED or in LINE DELTA (both

connections are without a neutral point) AND TPS is in PHASE CONTROL it is impossible

to go to zero output.

Minimum possible firing for such case gives 10-20% of output voltage. This is since in this

case the firing of each phase depends on the three phases mains and we cannot control

each phase voltage down to zero.

In this case, zero input in analogue input causes the minimum possible voltage to appear

in the output. Then, upon increasing the analogue input voltage, output voltage/current is

monotonically increased.

(3) WYE, NEUTRAL NOT CONNECTED (NC) applicable for symmetrical loads only.

Connecting to non symmetrical loads might damage the load!

(4) When WYE, NEUTRAL NOT CONNECTED (NC) applies set the UNBALANCE protection

to the lowest practical value and trip the TPS upon UNBALANCE or else load will damage.

Refer to section 7.7.3 on page 32.

(5) Refer to section 4.2 next page for INSIDE DELTA wiring instructions.

13 • Recommended Wiring Scheme

________________________________________________________________________________________________

4.2 INSIDE DELTA Wiring

When the TPS is connected INSIDE DELTA wiring must be exactly as in the following diagram:

L1-U, L2-V, L3-W represent the three controlled TPS

phases.

R1, R2 R3 represent the load.

L1, L2, L3 are mains voltage.

Verify the following:

Phase sequence as below:

Phase L1-U of the TPS is connected between L1

and L3 of the mains.

Phase L2-V of the TPS is connected between L1

and L2 of the mains.

Phase L3-W of the TPS is connected between L2

and L3 of the mains.

4.3 Typical control scheme

Notes:

(1) - Use fuses for thyristors short circuit protection. Refer to section 4.5.1 on page 15

Note: In 1000V models semiconductor protection fuses for “type 2 coordination" are built –in.

(2) - For Aux. input programming refer to section 7.7.2 on page 30.

(3) - For programmable output relays A, B &C refer to section 7.7.2 on page 30.

(4) - When emergency Stop switch is required it is recommended to trip a series contactor or the

feeding circuit breaker. (Not shown)

(5) – Potentiometer control is only possible if option P (Potentiometer control) is ordered.

(6) – Only short current protection is mandatory in models other than 1000V. The TPS has a

built-in over current protection.

L2

L3

L1

14 • Recommended Wiring Scheme

________________________________________________________________________________________________

4.4 Communication and Synchronization wiring

Notes:

(1) – Use shielded twisted pair for Synchronization loop and for RS485 communication.

(2) – For communication cabling length of cables should not exceed 200m.

(3) - For Synchronization cabling length of cables should not exceed 20m.

(4) - Synchronized mode cannot be implemented if one current analogue input is connected

to several TPS units in series.

4.5 Wiring Notes

WARNINGS! When mains voltage is connected to the TPS, even if control voltage is

disconnected, full voltage may appear on the TPS load terminals.

Therefore, for isolation purposes, it is necessary to connect an isolating device

before the TPS.

Power factor correction capacitors must not be installed on TPS load side.

When required, install capacitors on TPS line side.

Laptop computer

RS-232

Thyristor Power System TPS Thyristor Power System TPS Thyristor Power System TPS

TPS 1 TPS 2 TPS 10

RS-485

TPS 1 TPS 2 TPS 32

Communication Loop

(up to 32 units)

Synchronization Loop

(up to 10 units)

23(-) 24(+) 23(-) 24(+) 23(-) 24(+)

18(+) 19(-) 18(+) 19(-) 18(+) 19(-)

15 • Dimensions

________________________________________________________________________________________________

4.5.1 Short Circuit Protection

For “type 2 coordination”, use fuses for semiconductor protection to protect the TPS from a short circuit.

Fuses for semiconductor protection give excellent results because they have low I²t values and high

interruption ratings.

Recommended fuse selection procedure:

(1) Fuse rated voltage: Choose minimum fuse rated voltage which is above the rated voltage of the

mains.

(2) Fuse rated current: Select a fuse which is 1.6 times the rated TPS current

(3) Fuse I²t: Verify that the I²t value of the fuse is less than or equal to the I²t value of the thyristor in the

TPS as shown in the table below.

(4) TPS Model Max. Thyristor I2t

[A2Sec] TPS Model Max. Thyristor

I2t [A2Sec]

TPS-8 5,000 TPS-390 200,000

TPS-17 5,000 TPS-460 700,000

TPS-31 5,000 TPS-580 700,000

TPS-44 5,000 TPS-820 700,000

TPS-58 12,000 TPS-950 Consult Factory

TPS-72 12,000 TPS-1100 Consult Factory

TPS-85 12,000 TPS-1500 Consult Factory

TPS-105 15,000 1000V Models Installed fuses (A2Sec)

TPS-145 60,000 TPS-55 1000V Bussmann 170M3243 (16000)

TPS-170 60,000 TPS-105 1000V Bussmann 170M3243 (16000)

TPS-210 140,000 TPS-160 1000V Bussmann 170M3245 (54500)

TPS-310 200,000 TPS-200 1000V Bussmann 170M3246 (115000)

Note: In 1000V models semiconductor protection fuses for “type 2 coordination" are built –in.

The fuses listed under “installed fuses” in the table above are recommended, however equivalent fuses from

other manufacturers can be used as well as long as their I2t values are equal or lower to the values mentioned

in parentheses.

4.5.2 Transient Protection

Line transient voltages can cause a malfunction of the TPS and damage to the thyristors. All TPS units

incorporate Metal Oxide Varistors (MOV) to protect from normal line voltage spikes.

When higher transients are expected, additional external protection should be used (consult factory).

5. DIMENSIONS

5.1 400-690VAC Models

16 • Dimensions

________________________________________________________________________________________________

17 • Dimensions

________________________________________________________________________________________________

18 • Dimensions

________________________________________________________________________________________________

For other models dimensions – consult factory.

19 • Dimensions

________________________________________________________________________________________________

5.2 1000VAC Models

Note: In 1000V models semiconductor protection fuses for “type 2 coordination" are built –in.

20 • Installation

________________________________________________________________________________________________

For other models dimensions – consult factory.

6. INSTALLATION

WARNING! Do not interchange line and load connections

6.1 Prior to Installation

Check that LOAD RATED CURRENT (FLA) is lower than, or equal, to the TPS RATED CURRENT.

Note:

TPS RATED CURRENT (FLC)≥LOAD RATED CURRENT In all 3 phases!!

Check that Mains and Control voltages are as indicated on the TPS side label.

Make sure TPS RATED CURRENT(FLC)≥LOAD

RATED CURRENT! (In all 3 phases)

Make sure Mains voltage is right!

Make sure Control voltage is right!

TPS label - example

6.2 Mounting

The TPS must be mounted vertically. Allow sufficient space (at least 100mm) above and below the TPS for

suitable airflow.

It is recommended to mount the TPS directly on the rear metal plate for better heat dissipation.

Note:

Do not mount the TPS directly on the rear metal plate in case a ventilation fan or ventilation opening is on the

back side of the TPS.

Do not mount the TPS near heat sources.

Surrounding air temperature in the cabinet should not exceed 50ºC

Protect the TPS from dust and corrosive atmospheres.

Note: For harsh environments, it is recommended to order the TPS with printed circuit board coating. Refer to

section Error! Reference source not found. on page Error! Bookmark not defined. for ordering

information.

6.3 Temperature range & heat dissipation

The TPS is rated to operate over a temperature range of -10ºC (14ºF) to + 50ºC (122ºF).

Relative non-condensed humidity inside the enclosure should not exceed 95%.

ATTENTION! Operating at surrounding air temp. (Inside the cabinet) higher than 50ºC may

cause damage to the TPS.

Heat Dissipation is:

1.3x3xI+FAN and TPS consumption rating

Where:

Iis the RMS current of the TPS.

FAN and TPS consumption rating - is shown on the technical specifications page 42.

So, for example, the maximum heat dissipation for a 210A TPS is: 1.3x3x210+64=883Watt.

6.4 Protection bus-bars covers for power terminals.

Protection bus-bars covers can be fitted with power terminals.

Consult factory for this option.

This manual suits for next models

22

Table of contents

Other Solcon Power Supply manuals

Popular Power Supply manuals by other brands

Edge-Core

Edge-Core RPS900W installation guide

TDK-Lambda

TDK-Lambda ELC12 Series instruction manual

Capetti Elettronica

Capetti Elettronica Winecap BOX-PPS user manual

moon

moon Evolution 820S owner's manual

Federal Signal Corporation

Federal Signal Corporation SelecTone PS250 Installation and maintenance instructions

American DJ

American DJ MidiPak User instructions