Solcon MPS 3000 User manual

MPS 3000

MOTOR PROTECTION SYSTEM

Version: 18.7.2006

CHANGES FROM MPC2000 TO MPS3000

Page 2 of 67

CHANGES FROM MPC2000 TO MPS3000

1. Four programmable discrete (digital) inputs to the MPS3000 (one, before – for Key only).

2. Four programmable Analog outputs

3. Four Programmable Analog Inputs with four new trips (protections)

4. Real time clock.

5. Statistical Data of last 10 trips with time & date stamp.

6. Larger Display.

7. Switch Mode power supply for AC or DC (one unit from 85V to 230V)

8. Baud Rate (MODBUS) up to 19200 bps.

9. MPS3000 includes 10 Temperature sensors. Two models: one (Standard) model with 10 RTD (as

before), second (optional) model with 6 RTD and 4 thermistors. Must be ordered from factory. Field

modifications are not possible.

10. Control function (for MPS3000-C) with MODBUS function 6 and 16. Functions 1,2,5,15 are canceled.

11. MODBUS new group of 20 user selected actual data parameters for fast scanning.

12. Unbalance calculation using Negative and Positive Sequence instead Imax and Imin.

13. UNBALANCE MIN T (unbalance minimum time = 1..30 sec.) new parameter to prevent too fast response.

14. Standard “American” Thermal Overload curves

15. RTD Bias (of thermal overload)

16. Unbalance Bias (Of Thermal Overload)

17. New program for current, voltage and temperature fault simulation. (useful for testing and for learning

the MPS3000, "on the engineer table")

18. Power measurement even if single phase voltage is connected (V1n,V2n,V3n = V12)

19. KWH (Energy) Display and KWH output (pulse relay)

20. Programmable Output Relays.

21. Too Many Starts Pre Alarm can be configured to energize output relay.

22. (I > 0) After Trip can be configured to energize output relay B (to trip upstream breaker).

23. Every fault group can be configured to energize output relays A & B (similar to MPR6).

24. NO START PROCESS new setting of STARTING METHOD, to allow switching to run, if I>= 10%.

25. Capture and display of minimum and maximum RMS average (of three phases) voltage and current.

Capture of minimum and maximum frequency.

26. G/F During Start setting, new feature to eliminate nuisance ground fault tripping when residual CT

connection (not required with Core Balance) is used.

27. New Emergency Restart function. Reset of Thermal capacity by pressing reset twice is canceled.

28. Modified Restart- after mains failure or Auxiliary Power Supply failure.

29. Separate Aux Power Supply and Control Voltage (option –S).

30. KVARH, added.

31. New setting parameter UV ACTIVE AT STOP, to enable/disable Under Voltage protection at stop.

TABLE OF CONTENTS

Page 3 of 67

TABLE OF CONTENTS

CHANGES FROM MPC2000 TO MPS3000...........................................................................................................2

TABLE OF CONTENTS..........................................................................................................................................3

INTRODUCTION ....................................................................................................................................................5

Protection Features .............................................................................................................................................5

Control Features..................................................................................................................................................6

Supervision and Communication Features .........................................................................................................6

WIRING DIAGRAM - MPS3000..............................................................................................................................7

WIRING DIAGRAM - MPS3000-C ..........................................................................................................................8

REAR PANEL - MPS3000 and MPS3000-C ..........................................................................................................9

MPS3000 TERMINALS.........................................................................................................................................10

Auxiliary Power Supply......................................................................................................................................10

Current & Voltage & Temperature (RTD, Thermistor) inputs............................................................................10

Line Voltages.....................................................................................................................................................10

Line Currents .....................................................................................................................................................10

Ground Fault Current ........................................................................................................................................10

Temperature Sensors........................................................................................................................................10

Analog Outputs..................................................................................................................................................11

Analog Inputs ....................................................................................................................................................11

MPS3000-C Discrete Inputs:.............................................................................................................................12

Output Relays....................................................................................................................................................14

Serial Link..........................................................................................................................................................15

"C/T" WIRING DIAGRAMS ...................................................................................................................................16

Three "C/T"s + Ground Fault Core Balance "C/T" ............................................................................................16

Three "C/T's" in a Residual Ground Fault Connection......................................................................................16

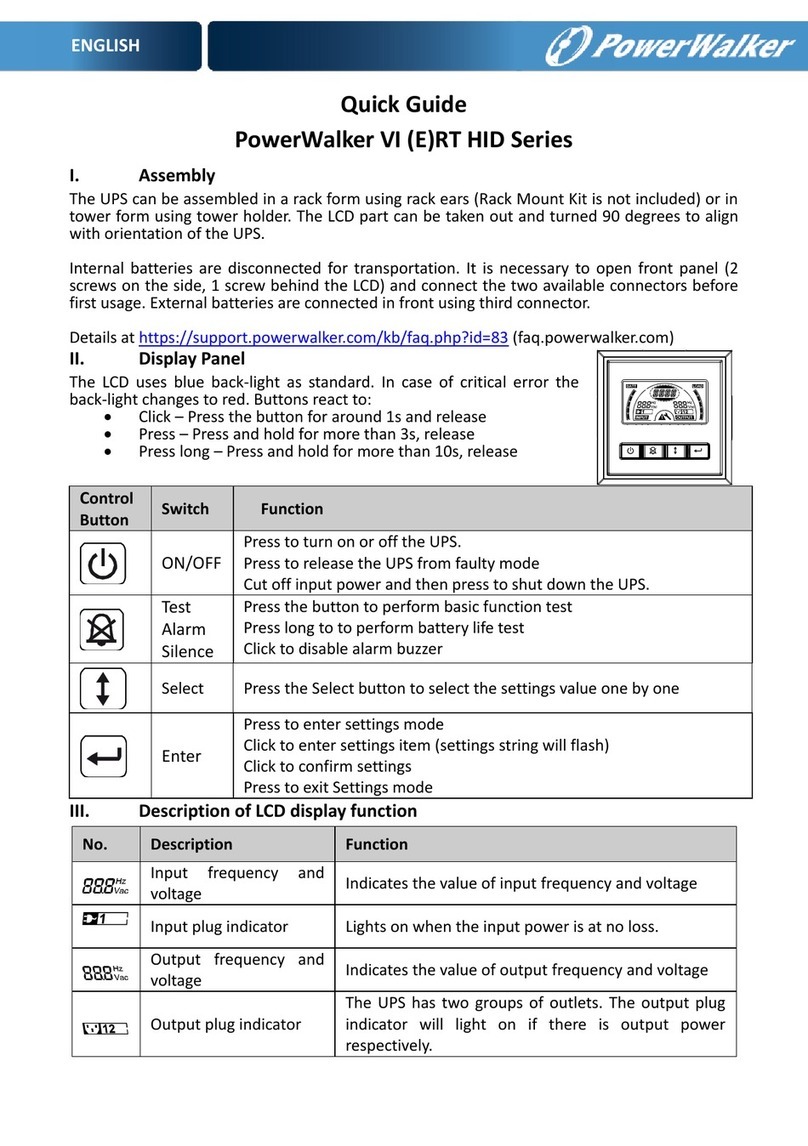

FRONT PANEL OVERVIEW ................................................................................................................................17

LEDS: ................................................................................................................................................................17

LCD Display.......................................................................................................................................................17

Keys Overview ..................................................................................................................................................18

FRONT PANEL SETTINGS..................................................................................................................................19

Startup ...............................................................................................................................................................19

Reset to Factory Default Values:.......................................................................................................................19

MESSAGES ..........................................................................................................................................................20

Blinking Messages ...........................................................................................................................................20

CONSTANT MESSAGES ................................................................................................................................21

MENU NAVIGATION TOP....................................................................................................................................22

Parameter Settings............................................................................................................................................22

Data Review ......................................................................................................................................................22

Test / Maintenance............................................................................................................................................22

MENU....................................................................................................................................................................23

Navigation..........................................................................................................................................................23

SET PAGE - MENUS............................................................................................................................................26

System Parameters...........................................................................................................................................26

Voltage Settings ................................................................................................................................................29

Current Settings ................................................................................................................................................31

Overload Settings..............................................................................................................................................33

Power Settings ..................................................................................................................................................35

Temperature Settings........................................................................................................................................36

Analog I/O Settings ...........................................................................................................................................38

Communication Settings ...................................................................................................................................40

Tripping/Alarm Options......................................................................................................................................41

Tripping Alarm Common Settings..................................................................................................................41

Multiple Alarm/Trip considerations ................................................................................................................43

Tripping/Alarm Individual Settings .................................................................................................................44

Tripping/Alarm Default Settings.....................................................................................................................53

DATA PAGE - MENUS .........................................................................................................................................55

Measured Data..................................................................................................................................................55

Calculated Data.................................................................................................................................................56

Logical Inputs Contact Status............................................................................................................................57

TABLE OF CONTENTS

Page 4 of 67

Statistical Data ..................................................................................................................................................59

Fault Data ..........................................................................................................................................................60

TEST / MAINTENANCE OPTIONS ......................................................................................................................61

COMMUNICATIONS – SERIAL LINK ..................................................................................................................63

TECHNICAL SPECIFICATIONS...........................................................................................................................64

Note

Installation, operation and maintenance should be in strict accordance with the instructions in this

manual, national codes and good practice. Installation or operation not performed in strict

accordance with these instructions shall void the manufacturer's warranty.

Note

Disconnect all power inputs before wiring or servicing the equipment.

Warning

Unit must be grounded to insure correct operation and safety.

INTRODUCTION

Page 5 of 67

INTRODUCTION

The MPS 3000 Motor Protection System is a new generation of micro processor based relay / controller designed to

operate with a three (3) phase induction motors.

True RMS voltages and currents are measured at a sampling rate of 0.5 ms, enables the MPS3000 to be used with

electronic motor drives like soft starters.

The MPS3000 incorporates two main features.

a. Motor protection.

b. Supervision and communication.

The MPS3000-C is identical to MPS3000, but incorporates in addition to all MPS3000 features, also:

c. Motor control.

Protection Features

AC motors are very rugged and reliable when operating within product specification limits. However, they are

usually designed to operate close to their rated limits with minimal margins for operating under abnormal conditions.

A comprehensive protection device is required to accurately create a Thermal Modeling, in order to allow motor run

safely up to its limits. The Thermal Model is based mainly on currents, but it may be biased also by RTD and by

Unbalance Currents.

This relay should protect the motor from abnormal conditions in the mains voltage, motor and cabling faults as well

as operator malfunctions.

The MPS3000 monitors three phase voltages, three phase + ground fault currents, temperature inputs from up to 10

sensors, Four analog inputs and four programmable Discrete (Optically isolated logical) inputs. The MPS3000-C

incorporates additional 16 discrete digital inputs.

The MPS3000 incorporates four programmable Analog Outputs as well as four programmable output change-over

(form C) relays. One or more relays can be configured as Trip and / or Alarm. All inputs and outputs are combined

to provide the most comprehensive protection package.

The MPS3000 can handle 52 different trips / alarms.

Voltage base protections Under-voltage, Over-voltage, Phase-loss, Phase

sequence, Maximum start time.

Current base protections Too many starts, Under current, Load increase,

Over-current level 1 (Stall/Locked protection) ,

Over-current level 2 (Short circuit) Thermal

Overload, Unbalanced current, Ground fault

current.

Voltage/Current based protections Under power, Low power factor.

Temperature based Up to 10 sensors (10 RTDs are standard or

optionally 6 RTDs + 4 thermistors).

General based protection Control circuit fault (C only), Welded contact (C

only), Three external faults, Comm. Port Failure.

Analog Inputs based protection For external devices such as Vibration sensor.

INTRODUCTION

Page 6 of 67

Two levels for most faults Usually used for Alarm and Trip.

Protection levels and time delay settings are individually configured using the key pad on the front panel or through

communication.

Unique Tripping / Alarm options make it possible to program any fault as an Alarm, Trip, both or none. This unique

facility also enables controlled fault Reset possibilities. Authorized key, extends the reset possibilities.

A unique calculated "Time to Trip" feature allows the operator or host computer to take corrective actions before

tripping.

Control Features

The MPS3000-C has the same functionality as the MPS3000 and also incorporates also control capabilities. It can

control various starting methods like Direct Online, Star Delta, Soft Starters, Reversing and Two Speeds.

Twenty optically isolated logic inputs are used to enable many types of control: Local, remote (for PLC without serial

link) or through RS485 serial link.

Two or three relays may be used to control DOL (direct online), Star/Delta, Soft-starters, Two Speed and Reversing

-starting.

Throughout the entire document MPS3000–C information is written over a gray background. Please ignore this

information for the MPS3000.

Supervision and Communication Features

A Liquid Crystal Display (LCD), together with a keypad and LEDs enables user friendly interface, accurate digital

parameters setting, actual parameters readings, and detailed trip and alarm message displays. Unauthorized setting

changes can easily be prevented by the correct use of the Authorized key input terminals.

Measured data Phase and line voltages, Phase currents, Ground fault current, Power, Reactive

Power, Power factor, RTD temperatures (thermistor resistances) and Analog Inputs.

Calculated data Motor load in % of FLC, Equivalent motor current, Unbalance current, Thermal

Capacity, Time to trip, Time to start.

Logic inputs status Individual status of all input contacts.

Statistical data Motors running hours, Total number of starts, Total number of trips, Last start time,

last start peak current, Total Energy, minimum and maximum values of voltage,

current and frequency.

Fault data Last Trip, Last Alarm, Phase currents at time of trip, Ground fault current at time of

trip, Phase voltages at time of trip, last 10 faults with time and date stamp.

Fault Simulation – Special Test / Maintenance page allows simulation (only during first 10 hours

from auxiliary supply power up) by setting voltages currents and temperature

“actual” values. The Simulation mode can be used for periodic testing of the

relay. It can be used also for getting familiar with the MPS3000 modes of

operation and features.

RS485 serial link (with MODBUS RTU communication protocol), operating at baud rate of 1200 to 38400 bps

enables monitoring of both the "set page" and actual parameters. Changes of the "set page" parameters through

the serial link make it very easy to enter user’s set points in place of the factory default parameters. The serial link

enables remote control of both the MPS3000 and the motor.

RS485 enables 32 MPS3000 units to be connected on the same link to the host computer. When a need for more

than 32 units arises, using MMI & Data highway equipment non limited number of MPS3000's can be connected to

a host computer.

WIRING DIAGRAM - MPS3000

Page 7 of 67

WIRING DIAGRAM - MPS3000

WIRING DIAGRAM - MPS3000-C

Page 8 of 67

WIRING DIAGRAM - MPS3000-C

REAR PANEL - MPS3000 and MPS3000-C

Page 9 of 67

REAR PANEL - MPS3000 and MPS3000-C

MPS3000 TERMINALS

Page 10 of 67

MPS3000 TERMINALS

Auxiliary Power Supply

85…230VDC or AC (50/60) Hz With option (-S) for separate Aux. Power Supply and Control

Phase or DC (+) ...................................... 61 Voltage:

Neutral or DC (-) .................................... 62 Phase or DC (+) ...................................... 64

Ground .................................................... 63 Neutral or DC (-) .................................... 65

Current & Voltage & Temperature (RTD, Thermistor) inputs

The MPS3000 can measure: Three voltages analog inputs, four currents analog inputs and ten temperature

sensors. True RMS measurement is used both for voltages and currents. Frequency should be in the range of

45-66 Hz. All current and voltage analog inputs incorporate internal isolating transformers.

Line Voltages

Direct connection of line to line voltages up to 690 VAC. For higher voltages, up to 25 KV, V/Ts must be used.

Voltage terminals are:

Phase L1 .................................................78

Phase L2 .................................................79

Phase L3 .................................................80

Neutral (when used)….......................... 81

Notes:

1. Line voltages must be connected for frequency sensing. If voltage analog inputs are not available,

currents measurement is accurate only if frequency is 50Hz or 60Hz, as set.

2. For low voltage mains, all three phase voltages must be connected as shown in the wiring diagram.

3. For Medium and high voltage systems, when only a single V/T is used:

•Connect "V/T" primary to mains V12 (“live” to V1 and “return” to V2).

•Connect "V/T" secondary: “live” to phase voltage inputs (78, 79, 80) and “return” to neutral input

(81).

•Decrease primary voltage setting by a 1.73 factor. In this type of connection, Line to Line voltage

is connected to Line to Neutral input.

•MPS3000 cannot detect phase sequence. A positive phase sequence is assumed.

For Medium and high voltage systems, when system voltage VTs are not available and AC power supply is used, connect

auxiliary power supply (61) to phase voltage inputs (78,79, 80) and (62) to neutral input (81).

Line Currents

Currents measured through "C/T" secondary of 5 A or 1 A.

Phase L1 ... 1 a, 5 a, Comm. ................. 82, 83, 84

Phase L2 ... 1 a, 5 a, Comm. ................. 85, 86, 87

Phase L3 ... 1 a, 5 a, Comm. ................. 88, 89, 90

Note :

Power and Power Factor can be calculated only if three voltage inputs and three current inputs are applied to the

MPS3000

.

Ground Fault Current

Currents measured through a differential "C/T" with a secondary of 5 A or 1A.

All phases..1 A, 5 A, COMM.................. 91, 92, 93

Note: It is recommended to use Core Balance "C/T". If a Core Balance "C/T" is not available, Ground Fault can

be measured according to "C/T" Wiring Diagrams on Page 14.

Temperature Sensors

The MPS3000 can accept inputs from Up to 10 RTDs of the following types:

•Copper 10 Ohm

•Platinum 100 Ohm

•Nickel 120 Ohm

LCD display is in °C (see temperature table on page 40).

Notes:

1. All sensors must be of same type.

2. An optional unit with 6 RTDs and 4 thermistors (No. 7...No. 10) is available.

RTDs three wire measurement system is used to compensate for cable resistance. (max. cable resistance

allowed is 25% of sensor resistance at 0°C). Only two wires are used for thermistor.

MPS3000 TERMINALS

Page 11 of 67

T1 ................................................... 66+67, 68

T2 ................................................... 69+70, 71

T3 ................................................... 72+73, 74

T4 ................................................... 75+76, 77

T5 ................................................... 100+101, 102

T6 ................................................... 103+104, 105

T7 ................................................... 106+107, 108 (Leave 106 open for thermistor, see note 2 above)

T8 ................................................... 109+110, 111 (Leave 109 open for thermistor, see note 2 above)

T9 ................................................... 112+113, 114 (Leave 112 open for thermistor, see note 2 above)

T10 .................................................. 115+116, 117 (Leave 115 open for thermistor, see note 2 above)

Note - If Temp sensors are not used, leave all relevant terminals open. Disable all the relevant Trip and Alarms.

Twisted and Shielded cables must be used for all temperature inputs. Shield should be connected to Chassis

Ground externally, near the MPS3000.

Analog Outputs

The MPS3000 incorporates four programmable analog outputs. Outputs type can be programmed to 4..20 mA

or 0..20 mA. Load resistance should be less than 400Ω. The four outputs share one common point. 0..1 mA

type is also available. Each output can be configured to represent one of twenty different parameters. Outputs

are updated every 100mS. Range of parameter for each output is fully programmable.

Analog Out 1 .................................. 121

Analog Out 2 .................................. 122

Analog Out 3 .................................. 123

Analog Out 4 .................................. 124

Analog Out Common ..............….......... 125

Note: The analog outputs electronics is isolated as one group together with the Analog inputs (and with the

Temperature input) circuits. Please note that only one common connection (Ground) have to be used for the

analog inputs and outputs. (The Temperature input wires are normally individually isolated, so they have no

common connection).

Twisted and Shielded cable must be used for all analog outputs. Shield should be connected to Chassis

Ground externally, near the MPS3000.

Analog Inputs

The MPS3000 incorporates four programmable analog Inputs. Each input can be individually programmed for

4..20 mA or 0..20 mA types. The four inputs share one common point. 0..1 model is available. A fault protection

is assigned for each analog input. Level and time delay is adjustable for each input. Scan cycle time: 100mS.

Analog In 1 ................ ..................... 126

Analog In 2 ...................................... 127

Analog In 3 ...................................... 128

Analog In 4 ...................................... 129

Analog In Common ............................... 130

Note: The analog inputs electronics is isolated as one group together with the Analog outputs (and with the

Temperature input) circuits. Please note that only one common connection (Ground) have to be used for the

analog inputs and outputs. (The Temperature input wires are normally individually isolated, so they have no

common connection).

Twisted and Shielded cable must be used for all analog inputs. Shield should be connected to Chassis Ground

externally, near the MPS3000.

MPS3000 TERMINALS

Page 12 of 67

MPS3000-C Discrete Inputs:

Local Start-A

.................................... 1&24

Close the contact to operate contactor A. Maintained or Momentary contacts can be used.

Local Start-B

.................................... 2&25

Close the contact to operate contactor B. Maintained or Momentary contacts can be used.

Used for low speed of two speed motor and for reversing applications.

Leave open if not used.

Local Stop

.......................................... 3&26

Open the contact to stop the motor. Maintained or Momentary contacts can be used.

Note: Open contact override any other inputs and force stop condition

Local/Remote

................................... 4&27

Open - For Local control

Closed - For Remote control

When contact is open, Motor can be locally started by above Local Start-A or Local Start-B contacts.

For safety reasons, Local Stop is always active, even if Local/Remote contact is in Remote position.

PLC/Serial Port .

.............................. 5&28

Open - For PLC control

Closed - For Serial Port control

Operative only when Local/Remote input is in closed (Remote) position. Determines if control commands are

accepted from PLC or Serial Port inputs.

PLC Reset

.......................................... 6&29

MPS3000 fault reset through momentary N.O contact.

(See default authorization table page 31)

PLC control-A

................................... 7&30

Maintained N.O contact

Open - To stop motor.

Closed - To operate contactor A and start the motor.

PLC Control-B

.................................. 8&31

Maintained N.O contact.

Open - To stop motor.

Closed - To operate contactor B and start the motor. Used for low speed of two speed motor and for reversing

applications.

Speed Switch

..................................... 9&32

Open - indicating that motor minimum speed has been reached

Closed- indicating that motor minimum speed has not been reached.

Indicates that the motor is turning. Leave input open if speed switch is not used.

Plant Interlock

...................................10&33

Open - To prevent operation

Closed - To enable operation

Permits additional systems interlocking.

If not used, Contact MUST be closed.

Authorized Key

................................ 11&34

Open - Disabled

MPS3000 TERMINALS

Page 13 of 67

Closed - To enable the following:

Note: For MPS3000, any one of the four discrete inputs (terminals 13.. 16) can be configured as Authorized key.

* Change of parameters (through keyboard).

* Reset of any alarm/trip, regardless setting.

* Reset of the thermal capacity.

* Run self test.

* Store default settings.

* Reset and store of statistical data.

External Fault 1

................................ 12&35

Open – Run Enable

Closed - Fault

If not used, disable Alarm and Trip for External fault 1 in the MPS3000 setting, (see table page 31).

The following four logical inputs, Discrete Input A to Discrete Input D, are common to both MPS3000 and the

MPS3000-C.

Discrete Input A contact ........................ 13&36

Discrete Input B contact ........................ 14&37

Discrete Input C contact ........................ 15&38

Discrete Input D contact ....................... .16&39

Each of

the above four discrete inputs can be configured for many applications. (like Emergency Restart, Low

speed of two speed motor, Remote Reset and External Faults).

Isolator

Aux. contacts of a local Isolator switch. Prevents contactors operation when the isolator is open. Start is enabled

Only if 17-40 is open and 18-41 is closed. (e.g. Isolator is closed).

N.C. ........................................................... 17&40

N.O. ........................................................... 18&41

If not used 18-41 must be closed.

External Fault 2

................................ 19&42

Open - Run Enable

Closed - Fault

If not used, disable Alarm and Trip for External Fault 2 in the MPS3000 setting, (see table page 31)

External Fault 3

.............................. 20&43

Open - Run Enable

Closed - Fault

If not used, disable Alarm and Trip for External Fault 3 in the MPS3000 setting. (see table on page 31).

MPS3000 TERMINALS

Page 14 of 67

Output Relays

The MPS3000 incorporates four output relays. Each has a C/O contact, rated 8 A / 250 VAC resistive, 2000 VA

inductive.

The four relays can be configured for alarm, alarm fail-safe, trip, trip fail-safe, overload, earth (Ground) Fault, KWH

pulses and also for external contactors control required for the MPS3000-C.

Note: When a relay is configured as an alarm Fail-Safe or trip Fail-Safe, the relay is immediately energized when

the auxiliary power supply is connected to terminals 61 & 62. The following N.O and N.C. terminals are given for

Non-Energized relays.

Output Relay A:

N.C .......................................................... 44&45

N.O .......................................................... 44&46

Relay A can be configured as an Alarm, Alarm Fail-Safe, Tripping / Alarm (where it can be set for any group of

faults), # Of Starts Pre Alarm (can be used to prevent start which will cause Too Many Starts fault) , U/V start

prevent or KWH pulse relay. See later for additional control functions used with the MPS3000-C.

Output Relay B:

N.C .......................................................... 47&48

N.O .......................................................... 47&49

Relay B can be configured as Trip, Trip Fail-Safe, Tripping / Alarm (where it can be set for any group of faults) or #

Of Starts Pre Alarm, u/v Start Prevent or (I > 0) After Trip relay. See later for additional control functions used with

the MPS3000-C. When configured as (I > 0) After Trip, it can be used to trip upstream breaker if current still flows

After the MPS3000 has issued a Trip signal.

Output Relay C:

N.C .......................................................... 50&51

N.O ...........................................................50&52

Relay C can be configured as Alarm Fail-Safe, Alarm, Contactor A/B status, Start/Run and Running indication.

See later for additional control functions used with the MPS3000-C.

Output Relay D:

N.C .......................................................... 53&54

N.O ...........................................................53&55

Relay D can be configured as a Trip, Trip Fail Safe or Ready relay.

The relays can be configured to receive two isolated alarm signals and two isolated trip signals.

Note: When a relay is configured for Fail Safe operation, relay is energized when MPS3000 is powered and de-

energized upon fault. Relay C is designed mainly to be used as an alarm fail-safe, to alarm constantly when the unit

is not powered.

MPS3000 TERMINALS

Page 15 of 67

MPS3000-C special use:

The relays can be configured with contactors control functions which may be required, according to the control

application.

Output A Relay:

Can be configured as one of:

* DOL starting

* Star period of Star-Delta starting

* Forward of a forward-reverse motor

* High speed of two-speed motor

Output B Relay:

Can be configured (by parameter setting) as one of the following functions:

* Delta period of Star/Delta starting

* Reverse of a forward-reverse motor

* Low speed of two-speed motor

Output C Relay:

Can be configured (by parameter setting) as one of the following functions:

* Contactor A status.

* Contactor B status.

* Start/Run - controls line contactor in Star-Delta starters.

Serial Link

Standard RS485 Half Duplex, with MODBUS protocol.

Twisted shielded pair should be used for wiring. Shield should be connected to Chassis Ground externally,

near the MPS3000.

Acceptable baud rates: 1200, 2400, 4800, 9600 and 19200 BPS.

Serial Port (+) .........................................23

Serial Port (-) ......................................... 22

Serial Port (shield) ................................. 63

Notes:

1. Auxiliary Power Supply must power-cycled after changing communication's settings (e.g. baud-

rate).

2. Connect 120 Ohm resistors between (+) and (-) at the end and at the beginning of the line.

"C/T" WIRING DIAGRAMS

Page 16 of 67

"C/T" WIRING DIAGRAMS

Three "C/T"s + Ground Fault Core Balance "C/T"

It is the preferred connection. It drawback is that a relatively large Core Balance transformer is required.

In the following drawings, the 5A inputs are used and the 1A are left open.

In this diagram terminal 92 which is the Ground Fault input current gets the sum of the three phase currents. If there

is no ground fault leakage current in the motor or cables, this current equals 0.

Three "C/T's" in a Residual Ground Fault Connection

When Core Balance "C/T" is not used and ground fault protection is required, use the residual Ground Fault

Connection.

In this diagram terminal 92 which is the Ground Fault input current, receives the sum of the "C/T" outputs of the

phase currents.

Ideally, if there is no ground fault leakage current, this current equals 0. Since "C/T"s may saturate slightly during

starting, their sum may not be 0 even when there is no leakage current to ground in the motor (or cables).

Note: In System Parameter page, the G/F DURING START setting parameter, is designed to significantly increase

the G/F level, during starting (same level for alarm and for trip) to prevent nuisance alarming and / or tripping.

For Residual Connection, It is recommended to leave the value in its default value which is 100% of FLC.

FRONT PANEL OVERVIEW

Page 17 of 67

FRONT PANEL OVERVIEW

LCD Display

Two lines of 16

characters each

Used for display of all data and system messages.

LEDS:

ON ON when auxiliary power supply voltage is connected.

Stopped ON in stop condition.

Starting ON as a response to start command. Indicates that command is still "ON" and motor's

average current is above 115% of rated current.

Running ON after completion of starting process. Indicates that motor's average current decreased

below 115% of rated current.

Output A ON when Output A relay is energized.

Output B ON when Output B relay is energized.

Alarm ON indicates Alarm condition. Remains ON even if the alarm condition disappears, turns

off only after resetting.

Trip ON indicates Trip condition. Stays ON even if the trip condition disappears, turns off only

after resetting.

Internal Fault ON indicates internal fault detection. Stays lit even if internal fault disappears turns off after

resetting.

FRONT PANEL OVERVIEW

Page 18 of 67

Keys Overview

Set Page Press to change set parameter pages in positive cyclical order.

Data Page Press to change the data page in positive cyclic order.

Select FWD Press to forward parameters listed in this page. If key is pressed for more than 0.5

sec, parameters will be displayed at a fast rate.

Select REV Press to reverse parameters listed in this page. If key is pressed for more than 0.5

sec, previous parameters will be displayed at a fast rate.

▲Press once to increase parameter value. Press and hold to increase parameter

value at a fast rate.

▼Press once to decrease parameter value. Press and hold to decrease parameter

value at a fast rate.

Reset Press to Reset displayed Alarm or Trip

Store Press to store displayed parameter value in the non-volatile memory.

Note: If “Authorized Key” is locked out (open), only parameters viewing is possible.

When the Key is closed, it is possible to view, change and store any set parameter.

FRONT PANEL OVERVIEW

Page 19 of 67

FRONT PANEL SETTINGS

Startup

On startup the following occurs: ON and Stopped LED's are turned on

The LCD will display:

System Parameter

*** Settings ***

In order to review above page settings, press Select FWD. key.

Messages are displayed on the LCD in two lines.

* Upper line describes the parameter's name.

* Lower line shows its value.

When Authorized key terminals are open, it is possible to view parameters but not to change or store them.

An attempt to change a value by

▲

,

▼

or to store will result in "Unauthorized Access" message.

To change settings, when Authorized key is closed, press

▲

or

▼

keys and save the new value by pressing

Store key. Once data was properly stored in the non-volatile memory the LCD displays the 2 Sec. flash

message:

Data Saved OK

Notes:

1. A new parameter setting becomes effective only after storing it in the non-volatile memory.

Setting a parameter, without storing, and moving to another parameter, will return the

parameter to its previously stored value.

2. Any "set page" parameters can be viewed, altered and stored at any time. However, it is not

recommended to change and store important parameters while the motor is starting or running.

3. Any stored parameter is kept indefinitely in the non-volatile memory.

Reset to Factory Default Values:

Press Set Page key and ▲key simultaneously, the LCD will display:

Test/Maintenance

*** Options ***

Press Select FWD. key three times, the LCD will display:

Store Now ?

Default Settings

Press Store and Set Page keys simultaneously, the LCD will display:

Data Saved OK

Note: Storing Default parameters erases all previously updated parameters

MESSAGES

Page 20 of 67

MESSAGES

Blinking Messages

Blinking messages are displayed as a response to an event. For example:

The message is displayed for a short while (2 seconds) only. Display then returns to the previous message.

Blinking messages are usually displayed as a response to an operator action.

It is used either to confirm activation of the requested operation, or to indicate reason for not doing so.

The blinking messages are:

Display

Description

Data Saved OK

Displayed after pressing Store key. If an error is

found during store process, then next message is

shown.

Storage Error

Displayed when an error is found in the store

process.

Wrong Parameters

Displayed after power-up, if the non-volatile

parameter check sum is found to be wrong.

Unauthorized Access

When Authorized Key is open (locked), and a

parameter change is attempted. Also displayed

after Unauthorized Store and Reset action.

Unable to Start

Local / Remote

•Displayed if local Start is pressed

but starting was not initiated

because Local / Remote input is

on Remote position.

•Similar "Unable to Start" with

another second line massage

may appear specifying the real

cause of the "Unable to Start".

•Possible reasons:

•Local/Remote input =

"Remote".

•Local stop input is open (= stop).

•"U/V Start Prevent", prevents

starting due to low voltage.

•A trip is active.

•External interlock = open (locked

out)

•Isolator status is "Isolate".

•Protection only is set to "Yes".

•Other reasons will cause "Check

systems" massage to appear in

the second line.

Self Test Passed

Displayed as a response to running the built in

test procedure, provided that all tests were

Data Saved OK

Table of contents

Other Solcon Power Supply manuals