solexx Garden Master G-512 User manual

ADAPT8, INC - MAKERS OF SOLEXX™ GREENHOUSES 1-877-476-5399

ASSEMBLY INSTRUCTIONS

12’ X 8’ X 8’9” Garden Master

G-512 (3.5mm)

This kit includes (3) double-decker benches, (2) hanging rods and (1) Louver.

Assembly Required - All pipe has been precut - (No cutting is required.)

It is important to panel the greenhouse frame once it is completed and before it is rained on.

The protective coating on the fittings is to protect the fittings from rust due to moisture or

condensation. The protective coating was not designed for the volume of water produced when

the fittings are rained on for a period of time with out the paneling on the greenhouse.

TOOLS PROVIDED:

A. ¼” nut driver

TOOLS NEEDED:

A. VARIABLE SPEED DRILL

B. SCREWDRIVER

C. LONG SHARP KNIFE

D. TAPE MEASURE

E. STEP LADDER

F. PLIERS

G. 2-3 tubes “Clear” 100% silicone (We recommend IS800 Silicone Rubber Adhesive Sealant) & a

Caulking Gun

H. 8 oz. can of “Clear” PVC CEMENT (Available at a hardware store). **

I. DUCT TAPE

**Follow the instructions on the glue can. Do not apply glue if it is colder than the

instructions indicate for proper use.

uNOTE: GLUE DRIES VERY QUICKLY! Hold pipe into fitting for 30 seconds until the glue has set.

Please read instructions carefully and refer to the diagrams.

uuAttention:

There are two types of frame tubing in your kit. The Composite Tubing is a heavier thick-walled tubing

that has a gray fiber weave throughout (looks like a fiber texture) while the PVC tubing is a thin-walled

tubing. The super strong Composite Tubing will be used for the structural areas of the greenhouse frame.

The PVC is used in areas where the pipe needs to be flexible to bend or in non-structural areas.

Feb 20

12’ Garden Master (3.5mm) Page 1

PARTS LIST

12' X 8' X 8'9” Garden Master With 3.5mm Solexx™ Paneling

G-512 (3.5mm)

*Please make sure your kit includes all the following parts before you begin assembly

ROLL BOX 1 106 lbs (24” x 24” x 51”) - Box 1 & 2 = 145 / 146 lbs.

____ 2 49 ½" x 145" Panels

_____ 4 42" x 145" Panel

_____ 1 42" x 115" Panel

_____ 1 36 ½” x 80” Door Panel

_____ 4 31" x 94 ½" Panels

_____ 1 29" x 42" Panel

_____ 7 44” Composite Tubing - Red

_____ 3 35 ¾" Composite Tubing - White

_____ 1 33” Composite Tubing- Cross Bar with Snap T (for door) - Slotted

INNER BOX 2 51 lbs (10” x 10” x 50”)

Bag #1_____ 10 4-Way 120° Metal-T’s

Bag #2_____ 5 4-Way 120° Metal-T’s

Bag #3_____ 6 3-Way 120° Metal Corner Post’s

Bag #4_____ 8 Metal Corner Posts

Bag #5_____ 8 4-way Metal-T’s

Bag #6_____ 8 4-way Metal-T’s

Bag #7

_____ 4 90° Metal Elbow

_____ 8 Metal Rings

_____ 8 1 ½" x 3/16" Machine Screws

_____ 8 3/16" Wing Nuts

_____ 5 Yellow Banding

_____ 5 Metal Banding Clips

_____ 35 Small Phillips Screws

_____ 1 Door Parts Bag:

Outside Handle, Inside Handle, 3-point Cam

Hinge Bag: 1/4” x 1-3/4” Bolts (4), Lock Nuts (4), Hinge halves and pins (2), Flat Washers (2)

Door Parts Bag: 8/32 Hex Lock Nut, 3/8” Lock Nut, 32 x 1-3/4” Machine Screw, 1” Metal Screw,

4mm Allen Wrench

Door Cable Bag: Turnbuckle, 76” Wire Cable, 1/16” Wire Cable Clamps (2)

Bag #8

_____ 4 PVC Elbows

_____ 4 PVC 2" Nipples

_____ 9 Large Black Zip Ties

_____ 545 1" Screws

_____ 1 ¼" Driver

Feb 20

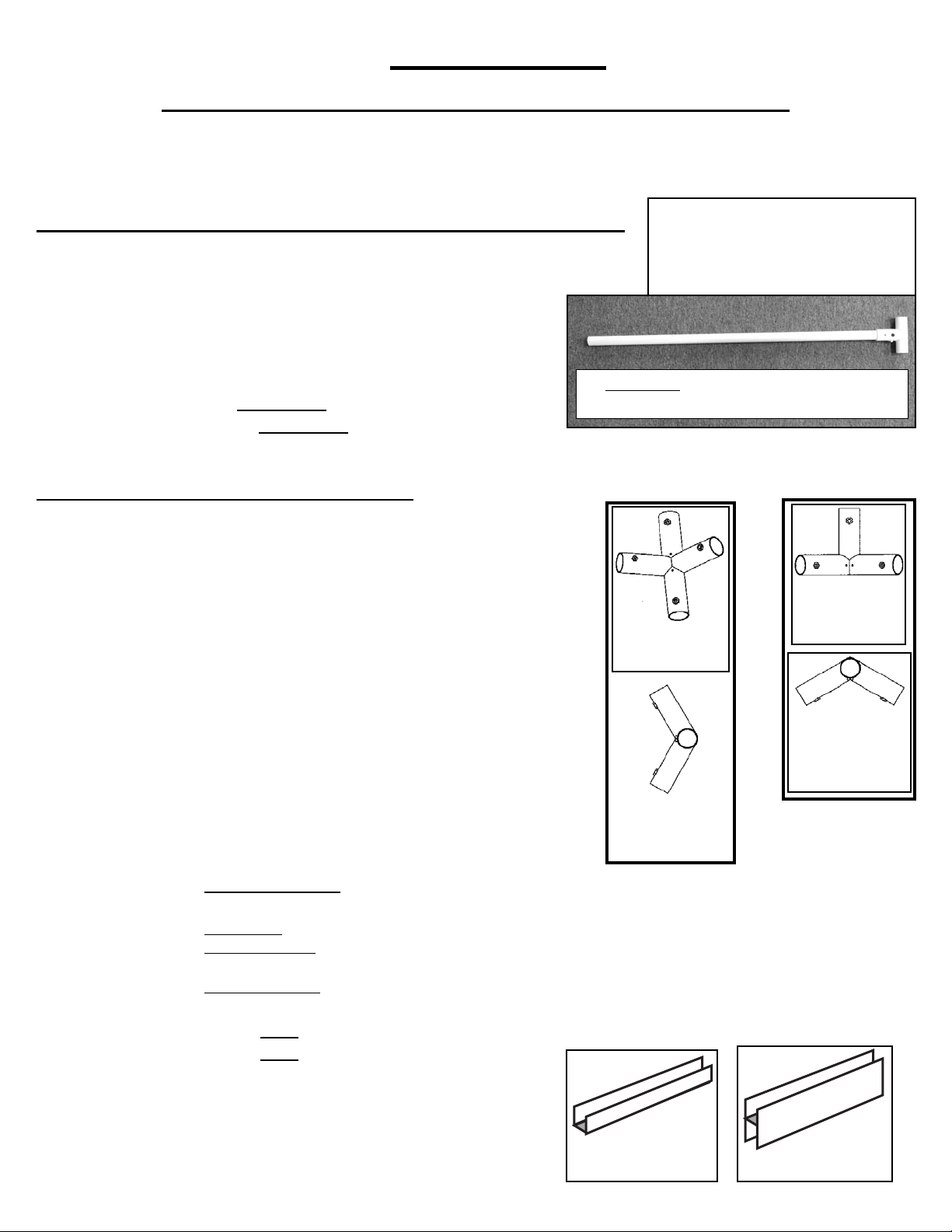

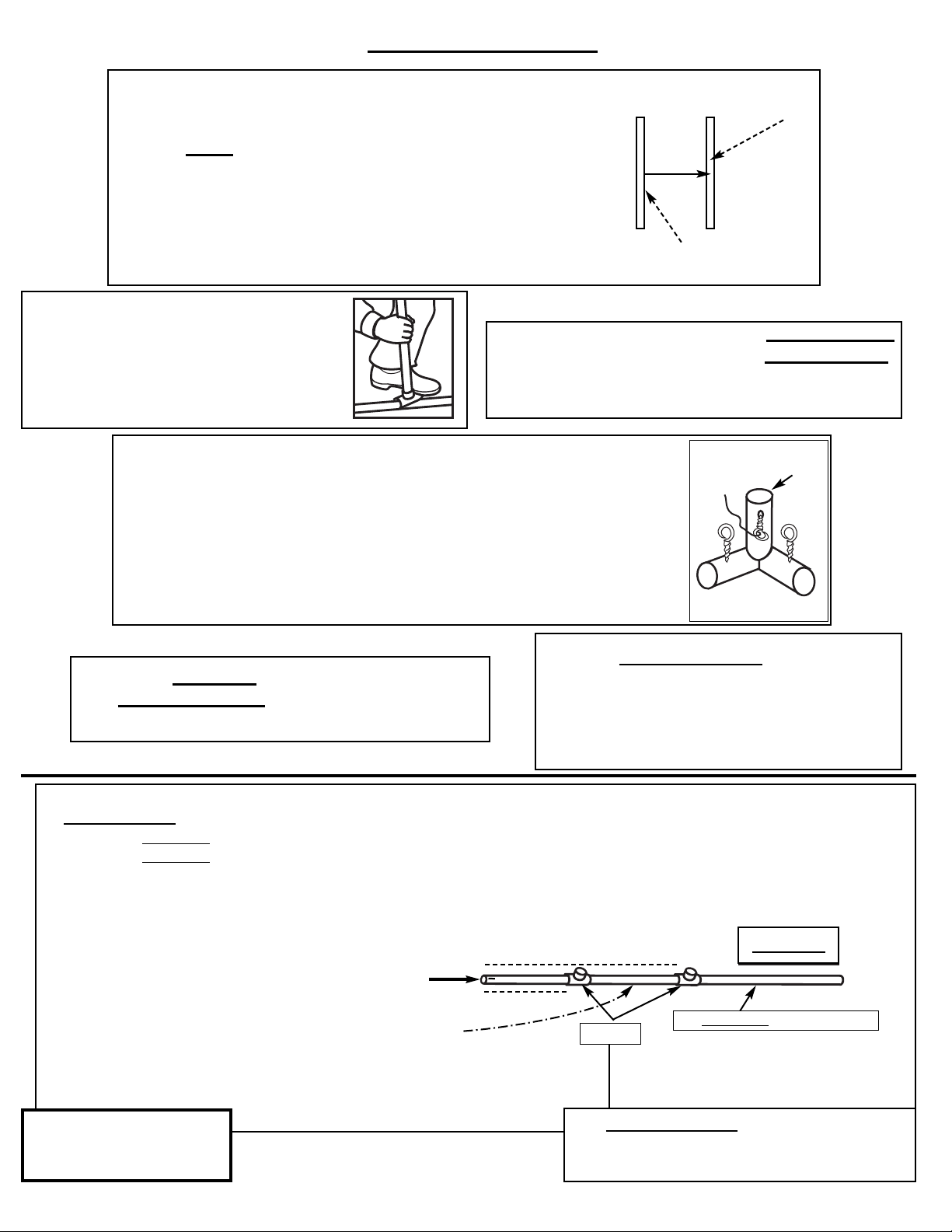

3-Way

120° Metal

Corner Post

3-Way

120° Metal

Corner Post

(Top View)

4-Way 120°

Metal-T

4-Way 120°

Metal-T

(Top View)

U Trim H-Channel

NOTE: To conserve shipping space,

U-Trim and 1/2” diameter tubibng are

sometimes inserted into 3/4” tubing.

Please check frame pieces before

assembly.

33” Composite Cross Bar with Snap T (for

door) - slotted

12’ Garden Master (3.5mm) Page 3

G-512 (3.5mm)

BOX 3 56 lbs (99” x 7 ¼” x 5”)

_____ 3 94 ½" Composite Tubing - Green

_____ 3 94 ½” Composite Tubing - Green (Double-

Slotted)

_____ 13 92" Composite Tubing - Red

_____ 4 90" Composite Tubing- Yellow

_____ 4 56" U-Trim

_____ 4 78" U-Trim

_____ 1 36” U-Trim

BOX 4 41/42 lbs (99” x 7 ¼” x 5”)

_____ 2 90” Composite Tubing - Yellow (Single-Slotted)

_____ 14 54 ¼” PVC pipes - Yellow

_____ 3 35 ¾" PVC pipes - White

_____ 2 33" Composite Tubing - Black

_____ 3 24" Composite Tubing - Orange (Double-Slotted)

_____ 4 12 ½" PVC pipes - White

_____ 6 H-Channel Clips

____ 20 28” Composite Tubing- Green (Double-Slotted)

_____ 2 28” PVC pipes - Green

_____ 6 22” Composite Tubing - White (Double-Slotted)

_____ 6 18” PVC pipe - ½” diameter

_____ 1 76” Side Door Casing

_____ 1 76” Side Door Casing (with hinge halves attached)

_____ 1 38” Top Door Casing

BOX 5 38/39 lbs. (77” X 7 ¼” X 5”)

_____ 12 6’ H-Channel

_____ 2 74” Composite Tubing Black (1 with holes for hinges)

_____ 6 75” Composite Tubing- Orange

_____ 8 75” Composite Tubing- Orange (Single-Slotted)

_____ 1 3’ H-Channel

_____ 6 22" Composite Tubing - White (Double-Slotted)

Box 6 7 / 8 lbs (13” x 13” x 6”)

Bags

1, 2 ,3 & 4 _____ 100 Snap-T’s (25 per bag)

BOX 7 6 lbs (30” x 16” x 3”)

_____ 1 Louver

_____ 1 Bag (Chain, Lever, 2 Screws)

(Note: Deluxe Greenhouse kits do not have this

bag for manual louver only)

Packed

by:__________________________

Date: ________________________

Feb 20

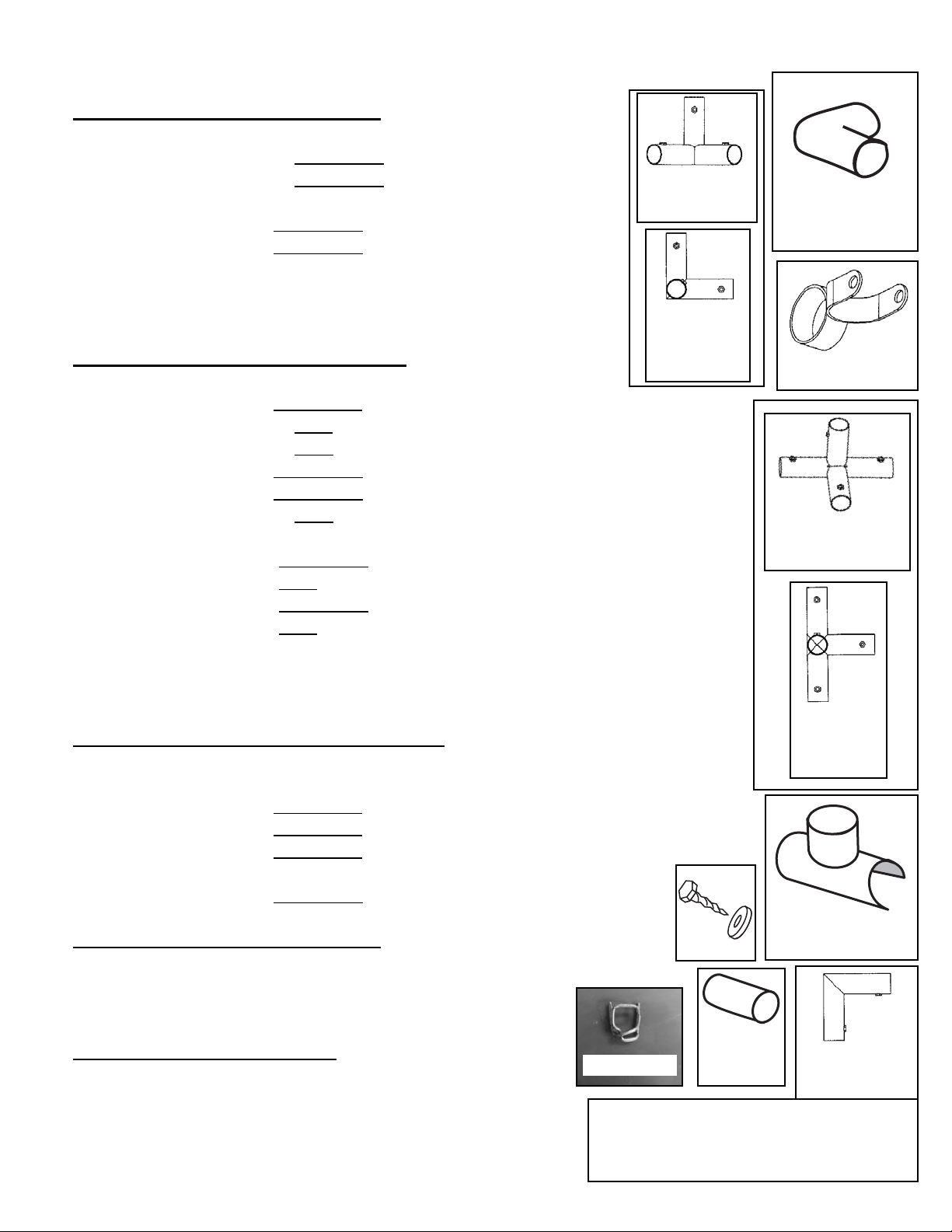

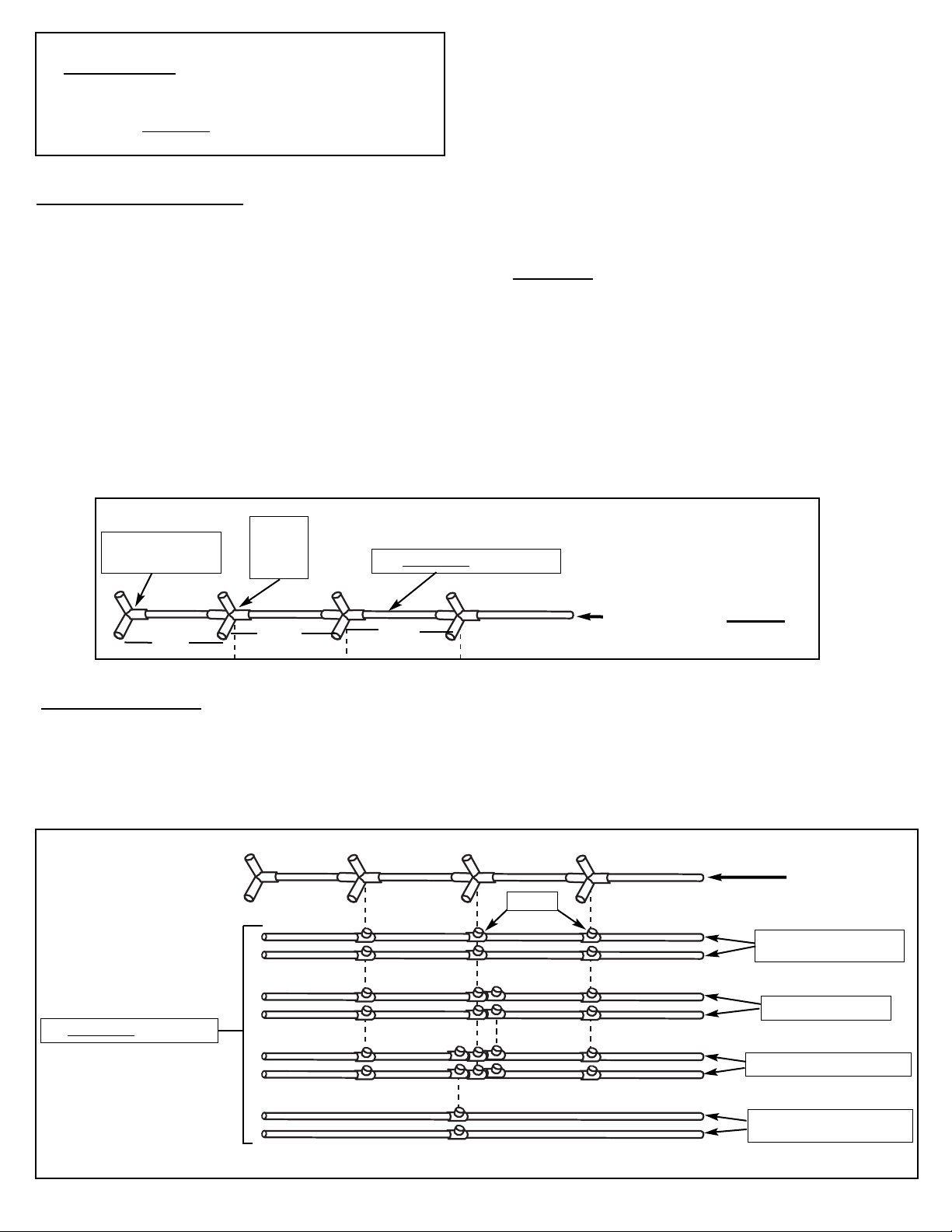

4-way

Metal-T

(Top View)

4-way

Metal-T

90°

Metal Elbow

Metal Ring

Metal

Corner Post

Metal

Corner Post

(Top View)

Banding Clip

1” Screws

PVC Snap-T

PVC Elbow

2” PVC

Nipple

Page 4 12’ Garden Master (3.5mm)

uuVery Important!! NEVER glue

the underside of the Snap-T. You

need to be able to slide the Snap-T

along the pipe. You only glue tubes

into the enclosed arm

F.

uuNOTE: Attaching Snap-T’s

this way prevents pinched

fingers! Use a small pipe and

step on the Snap-T.

B.

uuNote: The 3-Way Metal Corner posts have a red mark

on the “dead end” arm. In order for all measurements to

be correct, the 3-Way Metal Corner Posts must be oriented

correctly on the Base Frame and on the End Wall Frames.

Follow lthe directions carefully about where the red arm is

pointing. Please look at these fittings and check out the

arm with the red marking.

D.

uuNote: Tubes that are double-slotted

have slots on each end. Single-slotted

tubes only have slots on 1 end.

All Slotted ends attach to Snap-T’s.

C.

uuPVC Pipe is White and flexable.

Composite Pipe is white with small gray

fibers throughout and will not bend.

E.

3-Way Corner Post

Post With

Red Marking

Center

of tube

“In” side of tube

uuNote: All measurements are taken from the “in”

side of one tube to the center of the other tube

so one person can easily take the measurement by

her/himself.

A.

1. SIDE WALLS

Pieces Required:

6 75” Composite Tubing - ORANGE

8 75” Composite Tubing - ORANGE (Single-Slotted)

30 Snap-T’s

1. Attach 1 Snap-T about 23” from the end of the 75” tube

and a second Snap-T about 48 ¼” from the end of the

tube. (Do this to all 14 tubes -

Both slotted and non slotted tubes)

2. On two of the non-slotted side wall tubes add a snap-T

between the two snap-T’s. You can adjust the snap-T’s in a later step.

Side Walls are used in step 7.

75” Composite Tubing - Orange

Make 14

22 ¾”

48 ¼”

Snap-T

Very Important!! NEVER glue the

underside of the Snap-T. You need to be

able to slide the Snap-T along the tube.

Slotted End

Step #2 is no longer

needed so it has been

deleted

Hints for Preassembly

12’ Garden Master (3.5mm) Page 5

Making the 8’ Ridge Frames

Complete as shown on a level surface so the 8” Ridge Frames will be flat and not twisted. Ridge Frames are used in Step 7,

Side Walls and in Step 9, Top Ridge Assembly.

1. Insert 3-way 120° Metal Corner Post snugly on one end of a 92” Composite Tube - (Red) and twist

eyebolt until tight. (Insert a screwdriver or long bolt through the eyebolts and twist the eyebolt clockwise.)

2. Slide a 4-way 120° Metal-T over the 92” tube so that the distance from the “in” side of the 3-way 120° Metal Corner Post to

the center of the 4-way 120° Metal-T is 22 ¾”. Twist the eyebolts tight.

3. Slide over the 2nd 4-way 120° Metal-T so the distance from the inside of the 1st 4-way 120° Metal-T to the center of the

2nd 4-way 120° Metal-T is 22 ¾” - tighten. Slide over the 3rd 4-way 120° Metal-T so the distance from the inside of the

2nd 4-way 120° Metal-T to the center of the 3rd 4-way 120° Metal-T is 22 ¾” - tighten eyebolts

4. Repeat steps 1-3 twice for a total of three 8’ Ridge Frames.

Aligning the Snap-T’s

5. Use a Ridge Frame to line up the Snap-T’s on the remaining 92” tubes. Follow the pattern below. Label the

tubes (BF, base frame; TB, top bench; BB, bottom bench; BS, Base Support) with a permanent marker to lessen

confusion about the tubes in later steps.

92” Composite Tubing - Red

4-way

120°

Metal-T

3-way 120° Metal

Corner Post

22 3/4” 22 3/4”

22 3/4”

8’ Ridge Frame (MAKE 3)

BF- Base Frame

TB- Top Bench

BS - Base Support

BB- Bottom Bench

92” Composite Tubes - Red

8’ Ridge Frame

BF

BF

TB

TB

BB

BB

BS

BS

Snap-T

3A. 8’ RIDGE FRAMES, BENCH & BASE RODS

Pieces Required:

9 4-way 120° Metal-T’s

3 3-way 120° Metal Corner Posts

11 92” Composite Tubing - RED

26 Snap-T’s

Page 6 12’ Garden Master (3.5mm)

1. Slide two 4-way Metal-T’s onto a 94 ½” Composite Tube - Green.

Attach a Metal Corner Post (arm with the Red Mark is vertical)

to one end of the 94 ½” Composite Tube - GREEN and tighten the

eyebolt. Attach a 2nd Metal Corner Post to the opposite end and

adjust the Metal Corner Post so that the measurement from the “in”

side of one Corner Post to the center of the opposite Corner Post is

95 ¼”. Secure each 4-way Metal-T at 28 ¾” (“in” side to center) from

each Metal corner Post with eyebolts on the outside arms and 1”

Screws on the inside arms (see diagram 1 to the right). This is the

Front Base Frame Assembly.

2. Use the Front Base Frame assembly as a measuring device to line

up the fittings on the Middle and Back Base Frame Assemblies. On

the Middle Base Frame, attach four 4-way Metal-T’s onto the 2nd

94 ½” Composite Tube - Green. For the Back Base Frame, attach

two Metal Corner Posts and two Snap-T’s to the 3rd 94 ½”

Composite Tube - Green (see diagram 2 to the right).

3. Attach both BF- 92” Composite Tubes - Red to the Metal Corner

Posts of the Front Base Frame assembly. Attach both BS - 92”

Composite Tubes to the 4-way Metal-T’s of the Front Base Frame

assembly. (See diagram 3 to the right)

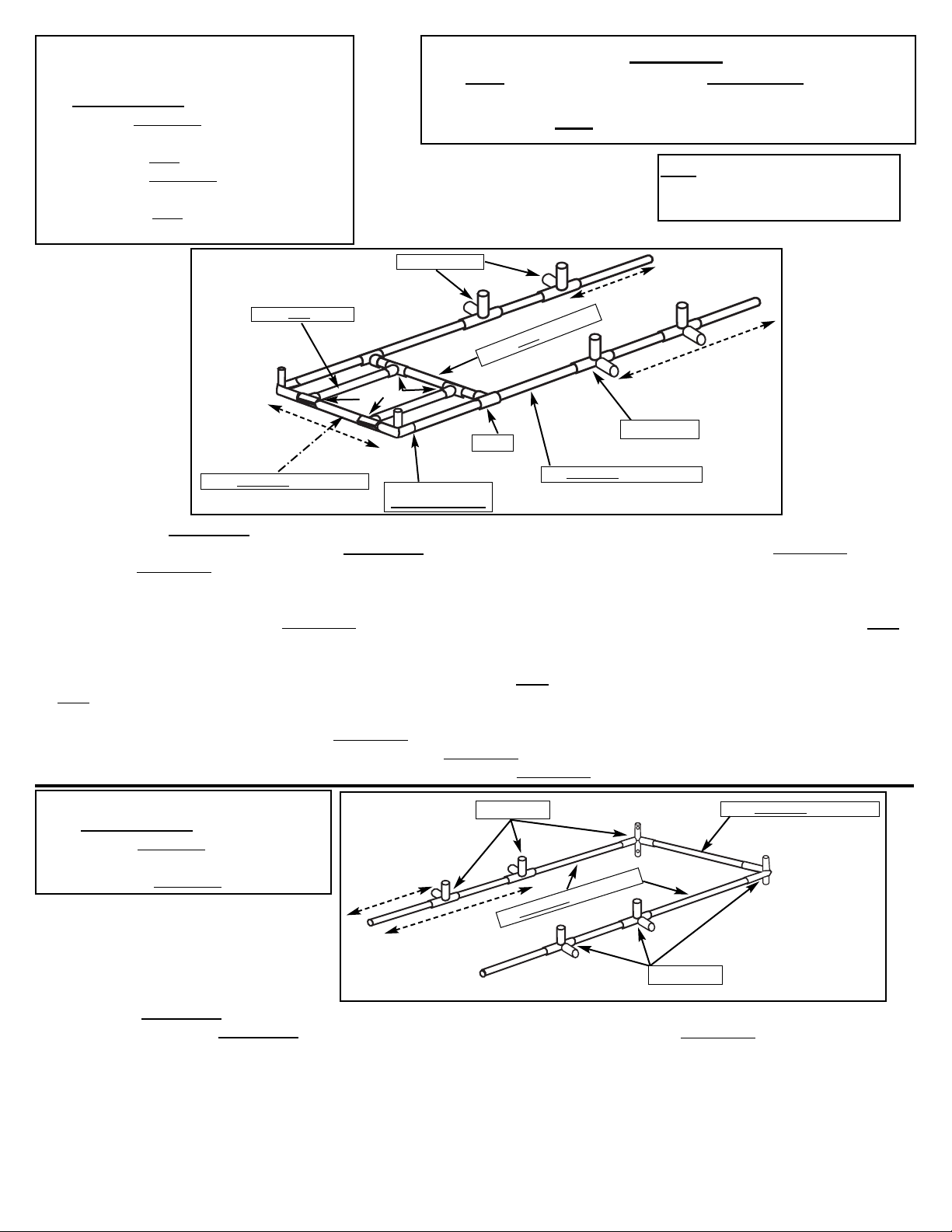

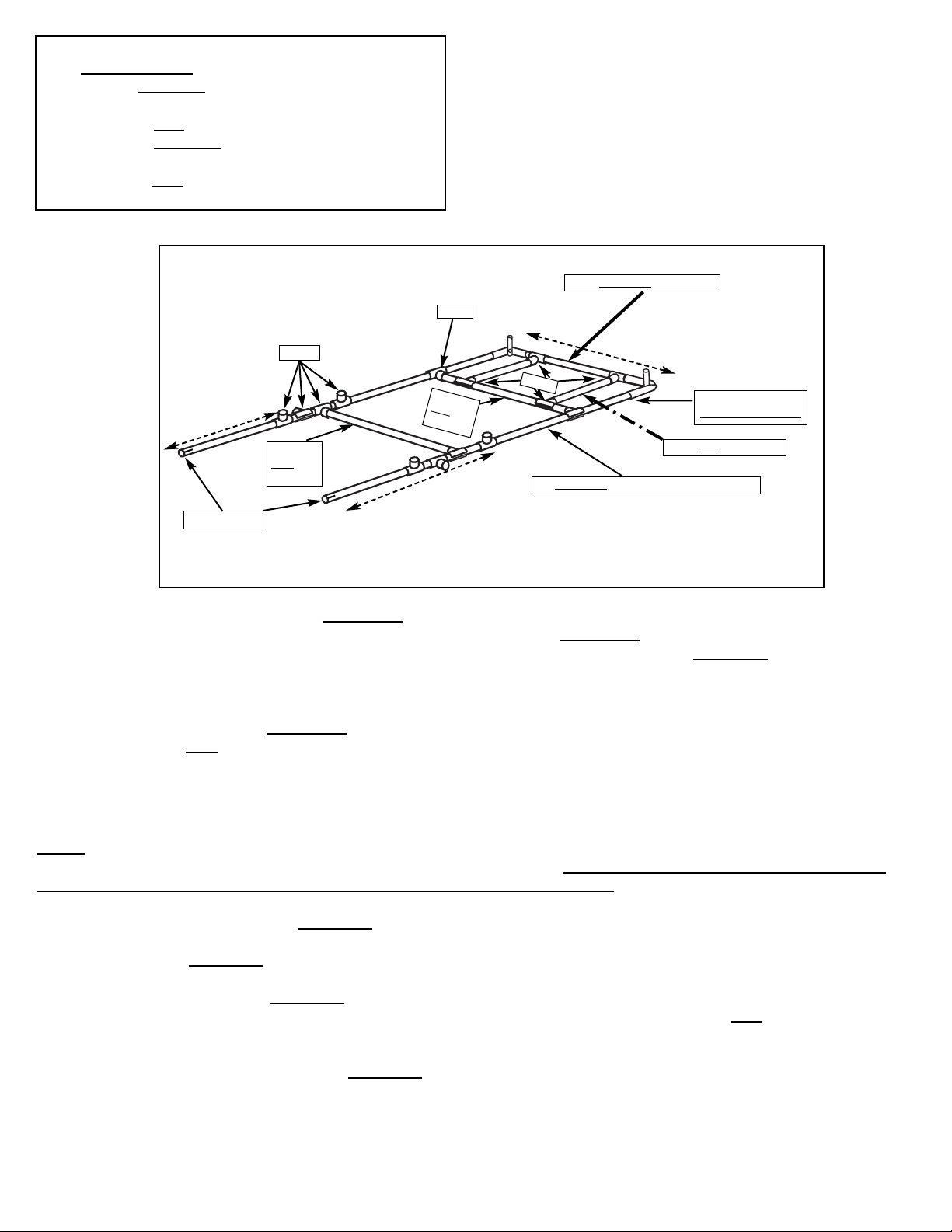

4. BASE FRAME

Make sure working surface is clean and level!

Pieces required:

4 Metal Corner Posts

6 4-way Metal-T’s

3 94 ½ ” Composite Tubing - GREEN

1 94 ½ ” Composite Tubing - GREEN (Double-Slotted)

2BF- 92” Composite Tubing - RED (from Step 3A)

2BS

- 92” Composite Tubing - RED (from Step 3A)

4 Snap-T’s

2 44” Composite Tubing - RED (from Step 3B)

2 1” Screws

Middle Base Frame

4-way Metal-T

4-way Metal-T

Metal Corner Post - Arm with red mark is facing up

Snap-T

Back Base Frame

3B. 4’ RIDGE FRAMES & BASE RODS

Pieces Required:

3 4-Way 120° Metal-T’s

3 3-Way 120° Metal Corner Posts

4 Snap-T’s

5 44” Composite Tubing - RED

1. Insert a 3-Way 120° Metal Corner Post snugly on one end of a 44” Composite Tube - Red and twist eyebolt until tight.

Insert a screwdriver or long bolt through the eyebolt and twist the eyebolt clockwise another ½ to full turn.

2. Slide a 4-Way 120° Metal-T over the 44” composite tube - Red so that the distance from the “in” side of the 3-Way 120°

Metal Corner Post to the center of the 4-Way 120° Metal-T is 22 5/8”. Twist the eyebolt tight. Repeat for a total of three

4’ Ridge Frames.

3. Use a 4’ Ridge Frame to line up the Snap-T’s on the remaining 44” Composite Tubes - Red. Follow the pattern above.

3-Way 120°

Metal Corner

Post 4-Way 120° Metal-T

Snap-T

(Make 3)

4’ Ridge Frames

44” Composite Tubing - Red

22 5/8”

NOTE: It is important that the

corner post is put on the right way.

(Red Mark is on the vertical arm)

28 ¾” 36 ½”

28 ¾”

95 ¼”

Metal Corner Post

(red mark on the

vertical arm) 4-way Metal-T

Remove eyebolt

Install 1” Screw

Front Base Assembly

94 ½” Composite Tubing - Green

94 ½” Composite Tubing - Green

Front Base Frame

Front Base Assembly

BS - 92” Composite Tubing - Red

BF - 92” Composite Tubing - Red

1.

2.

3.

12’ Garden Master (3.5mm) Page 7

4. Attach the fittings of the Middle Base Frame assembly (made in step 3B-2) to the open ends of both BF - 92” Composite

Tubes - RED and both BS - 92” Composite Tubes - RED.Push both BS - 92” Composite Tubes - RED all the way into the

4-way Metal-T’s. Adjust the middle base frame assembly so that the measurements from the “in” side edge of the Front

Base Assembly to the center of the Back Base Assembly is 92 ¾”.

5. Attach both 44” Composite Tubes - Red (with Snap-T’s from Step 3B-3) to the 4-way metal-T’s on the ends of the

Middle Base Frame.

6. Attach the Metal Corner Posts of the Back Base Frame assembly to the opposite ends of the 44” Composite Tubes - Red

that you just added in the step above (Step 4-5). Making sure the arm with the red mark is facing up on the metal corner

posts. Adjust the Back Base Frame Assembly so that the measurement from the 94 ½” Composite Tube of the Middle Base

Frame Assembly to the 94 ½” Composite Tube of the Back Base Frame Assembly is 44 ¼” from “in” side to center. Tighten

the eyebolts.

7. Attach a 94 ½” Composite Tube - Green (Double-Slotted) into the Snap-T’s on the 44” Composite Tubes (added in Step

4-5) that are closest to the Back Base Frame Assembly. Use glue to help lubricate the tube to make it easier to slide

into the Snap-T’s. The glue does not adhere to the CompositeTubing, so you will have to secure the tubing by

drilling a screw through the top of the Snap-T and into the 94 ½” Composite Tube. Attach two Snap-T’s on to the

94 ½” Composite Tube - Green. Line up the Snap-T’s with the Snap-T’s that are on the Back Base Frame assembly.

CONT..... BASE FRAME

44” Composite Tubing - Red

Snap-T

Snap-T

Back Base Frame

Middle Base Frame

44 1/4”

(“In” side to center)

Corner Post with red

mark pointing up

BF- 92” Composite Tubing - Red

Middle Base Assembly

FRONT

SIDE

SIDE

BF- 92” Composite Tubing - Red

95 ¼” (“In” side to center)

BS - 92” Composite Tubing - Red

92 ¾” (“In” side to center)

4-Way Metal-T

BS - 92” Composite Tubing - Red

4-Way Metal-T

94 ½” Composite Tube

Green (Double-Slotted)

Snap-T

Page 8 12’ Garden Master (3.5mm)

5. END WALL FRAMES

5A. Front End wall Frame

Pieces Required:

2 90” Composite Tubing - YELLOW

2 Metal Corner Posts

1 35 ¾” PVC Pipes. - WHITE

1 35 ¾” Composite Tubing - WHITE

6 Snap-T’s

2 12 ½ ” PVC pipes -WHITE

4 4-Way Metal-T’s

5B. Middle End wall Frame

Pieces Required:

2 90” Composite Tubes - YELLOW

6 4-Way Metal-T’s

1 35 ¾” Composite Tube - WHITE

1. Slide a 90” Composite Tube - yellow snugly into a 4-way Metal-T (As pictured above) and tighten the eyebolt. Do this

twice. Attach a 35 ¾” Composite Tube - White between the 4-way Metal-T’s on the 90” Composite Tubes - yellow.

Measure the distance between the two 4-way Metal-T’s and adjust them so they are 36 1/2” from “in” side to center.

Tighten the eyebolts.

2. Slide two 4-way Metal-T’s on to each 90” Composite Tube - yellow (Note the direction of the posts pictured above).

Tighten the eyebolts of the the top 4-way metal-T so the distance from the center of the middle arm to the bottom of the

90” composite tube - yellow is 48 ¼” and the distance from the center of the middle arm of the bottom 4-way metal-T to the

bottom of the 90” composite tube - yellow is 22 ¾”.

35 ¾” Composite Tubing -White

4-way Metal-T

uuBe sure to get the composite tubing and the

PVC pipe in the right spot. Composite tubing

has a gray fiber throughout and does not flex.

While the PVC is white and flexable

Note: On Metal Corner Posts, the

Arm with red mark attaches

to 90” Composite Tube.

35 3/4” PVC pipe - White

90” Composite Tubing - Yellow

35 ¾” Composite Tubing - White

Snap-T

4-way Metal-T

Metal Corner Post

(arm with red mark)

12 ½” PVC - White

22 ¾”

48 ¼”

36 1/2”

Snap-T

4-way Metal-T

1. Slide each 90” Composite Tube - Yellow snugly into a Metal Corner Post (insert tube into the arm with the red mark)

and tighten the eyebolt. Attach a 35 ¾” Composite Tube between the Metal Corner Posts on the 90” Composite Tubes.

Adjust 90” Composite Tubes (With metal coner posts on them) so the distance between the Metal Corner Posts is 36 ½”

from “in” side to center - tighten the eyebolts.

2. Attach a Snap-T on to both 90” Composite Tubes about 13” below the Metal Corner Posts. Insert and glue a 35 ¾” PVC

pipe between these Snap-T’s.

3. Attach two Snap-T’s to both 35 ¾” pipes. Attach and glue 12 ½” PVC pipes between the Snap-T’s. Slide over each 12½”

PVC pipe - white (With snap-Ts attached) to the edge of the Metal Corner Posts.

4. Slide two 4-way metal-T’s on both 90” Composite Tubes - yellow (Note direction of the posts). Tighten both bottom 4-way

metal-T’s so they are 22 ¾” from the bottom of the 90” Composite Tube - yellow to the center of the fitting. Tighten both

top 4-way metal-T’s so they are 48 ¼” from the bottom of the 90” Composite Tube - yellow to the center of the fitting.

90” Composite Tubing -Yellow

4-way Metal-T

22 ¾”

48 ¼”

12’ Garden Master (3.5mm) Page 9

1. Slide the non-slotted end of each 90” Composite Tube - Yellow (Single-Slotted) into a Metal Corner Post (Insert tube

into the arm with the red mark) and tighten the eyebolt. Attach a 35 ¾” Composite Tube - White between the Metal

Corner Posts attached to the 90” Composite Tubes - Yellow (Single-Slotted). Adjust the 90” Composite Tubes with the

metal corner posts attached so the distance between the Metal Corner Posts is 36 ½” from “in” side to center. Tighten

the eyebolts.

2. Attach a Snap-T to each 90” Composite Tube - Yellow (Single-Slotted) , about 13” below the Metal Corner Post. Insert

and glue a 35 ¾” PVC pipe - White between these Snap-T’s.

3. Attach two Snap-T’s on to both 35 ¾” pipes. Attach and glue a 12 ½” PVC pipe - White between these Snap-T’s. Slide

each 12 ½” pipe (With snap-t’s attached) over so it is 10 ½” from the “in” side of the 90” tube to the center of the 12 ½” pipe

(leaving about 13 ½” between the 12 ½” pipes).

NOTE: This spacing applies when installing a 12” Exhaust Fan. If installing a 16” fan or larger, replace the 12 ½” pipes with

the larger pipes included with the fan (refer to Fan installation instructions). If a Fan was not purchased, slide over both

12 1/2” pipes (with snap-T’s attached) to the edge of the Metal Corner Posts.

4. Attach two Snap-T’s on each 90” Composite Tube - Yellow (Single-Slotted). The center of the top Snap-T is at 48 ¼” from

the bottom of the 90” composite tube - Yellow (Single-Slotted) and the center of the 2nd Snap-T is at 22 ¾” from the

bottom of the 90” Composite Tube - Yellow (Single-Slotted).

5. Attach a Snap-T on each 90” Composite Tube - Yellow (Single-Slotted) between (Approximately - it can be adjusted later)

the top and bottom Snap-T’s attached in the previous step (Step 5C-4). Insert and glue a 35 ¾” PVC pipe - White into

these Snap-T’s.

6. Attach an additional Snap-T on each 90” Composite Tube - Yellow (Single-Slotted) below the Snap-T you just put on in

step 5C-5.

5C. Back End wall Frame

Pieces Required:

2 90” Composite Tubes - YELLOW (Single-Slotted)

2 Metal Corner Posts

2 35 ¾” PVC Pipes. - WHITE

1 35 ¾” Composite Tubing - WHITE

14 Snap-T’s

2 12 ½” PVC pipes - WHITE

35 ¾” Composite Tube - White

90” Composite Tube -Yellow (Single-Slotted)

12 ½” PVC pipe - White

Snap-T

Metal Corner Post

(Arm marked with red)

22 ¾”

48 ¼”

35 ¾”

PVC pipe

White

35 ¾”

PVC pipe

White

Slotted end

Snap-T

Snap-T

36 ½”

Page 10 12’ Garden Master (3.5mm)

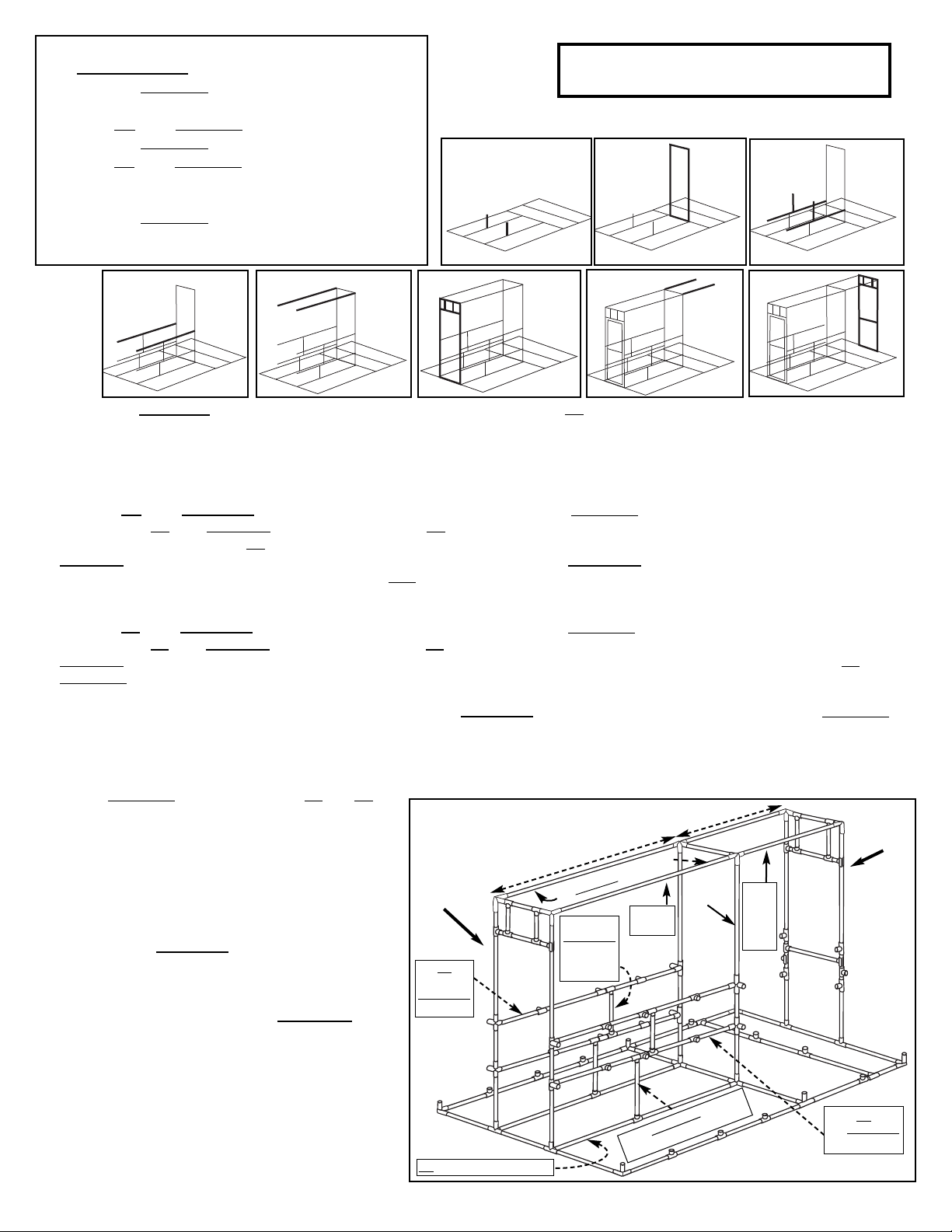

1. Attach a 22” Composite Tube - White (Double-Slotted) into the Snap-T’s on Both BS - 92” Base Frame tubes. Secure tubing into the

Snap-T’s with a 1” Screw. See diagram 1 above.

2. Attach Middle End wall to the 4-way Metal-T’s on the Middle Base Frame and tighten the eyebolts. (The Lower and middle 4-way

metal-T’s face towards the front base assembly. See diagram 2 above and diagram below.)

3. Insert the BB - 92” Composite Tubes into the bottom 4-way Metal-T’s on the 90” Composite Tubes - Yellow (Middle End wall). Attach

the end of the BB - 92” composite tubes that were marked BB from step 3A-5, into the post and tighten the eyebolts. There are 3

snap-T’s on the middle of the BB tubes, of these three snap-T’s, join the snap-T that is farthest from the Middle end wall onto the 22”

composite tube - white (Double-Slotted), from Step 6-1 above. Next, attach a 24” Composite Tube - Orange (Double-Slotted) into

the Snap-T that is closest to the Middle end wall (on both BB - 92” Composite tubes). Secure all Snap-T’s to the tubes with 1” Screws.

See diagram 3 above and diagram below.

4. Insert the TB - 92” Composite Tubes into the Middle 4-way Metal-T’s on the 90” Composite Tubes - Yellow (Middle End wall). Attach

the end of the TB - 92” composite tubes that were marked TB from step 3A-5, into the post and tighten the eyebolts. Attach the 24”

composite Tubes - orange (Double-Slotted) to the Snap-T’s (That are right of center - Closest to the middle end wall) on both TB - 92”

Composite Tubes. Secure them with1” Screws. See diagram 4 above and diagram below.

5. Use a marker and draw a line 2 ¾” in from both ends of the 92” Composite Tubes - Red (Do this on both tubes). Put 92” Composite

Tubes - red into the top 4-way metal-T’s on the Middle End Wall. Slide tubes into the posts until the line you just marked on them is even

with the post and tighten the eyebolts. See diagram 5 above and diagram below.

6. Lift and attach the Front End wall to the 4-way Metal-T’s on the Front Base Frame and tighten the eyebolts. Insert the opposite sides of

the 92” Composite Tubes (Including all TB and BB

assemblies) into the corresponding Metal Fittings and

tighten the eyebolts.

Check the measurements of the Hanging Rods.

They should be 92 ¾” from the “in” side of one 35 ¾”

Middle End Wall tube to the center of the 35 ¾” Front

End wall tube. See diagram 6 and diagram to the right.

7. Insert both 44” Composite Tubes - Red into the 4-way

Metal-T’s at the top of the Middle End Wall. See

diagram 7 and diagram to the right.

8. Attach the Back End Wall (Insert slotted end

completely into the Snap-T’s on the Back base frame.

Use glue to help lubricate the tube to make it easier to

slide into the Snap-T’s. The glue does not adhere to

the Composite Tubing, so you will have to secure the

tubing by drilling a screw through the top of the

snap-T and into the 90” Composite Tubes.

Insert the opposite ends of the 44” Composite Tubes into

the Metal Corner Posts at the top of the Back End Wall.

The measurement from the “in” side of the 35 ¾” Middle

End wall tube to the center of the opposite 35 ¾” Back

End Wall tube should be 44 ¼”

6.

6. HANGING RODS & BENCH RODS

Pieces Required:

2 22” Composite Tube - White (Double-Slotted)

1 Middle End wall (from Step 5B)

2 BB - 92” Composite Tube - RED (from step 3)

2 24” Composite Tube - Orange (Double-Slotted)

2 TB - 92” Composite Tube - RED (from step 3)

2 92” Composite Tube - RED

1 Front End wall (from Step 5A)

2 44” Composite Tube - Red

1 Back End wall (from Step 5C)

8 1” Screws

1. 2. 3.

4. 5. 7. 8.

Two people & ladder recommended!

Hanging

Rod

Front

End Wall

44 ¼”

Middle

End wall

92” Composite Tubing - Red

92 ¾”

Back

End wall

24”

Composite

Tubing

(Double

Slotted)

TB

92”

Composite

Tubing

22” Composite Tubing

white (Double-slotted)

BB

92” Composite

Tubing

BS - 92” Base Frame Tube

44”

Com-

posite

tube

Red

12’ Garden Master (3.5mm) Page 11

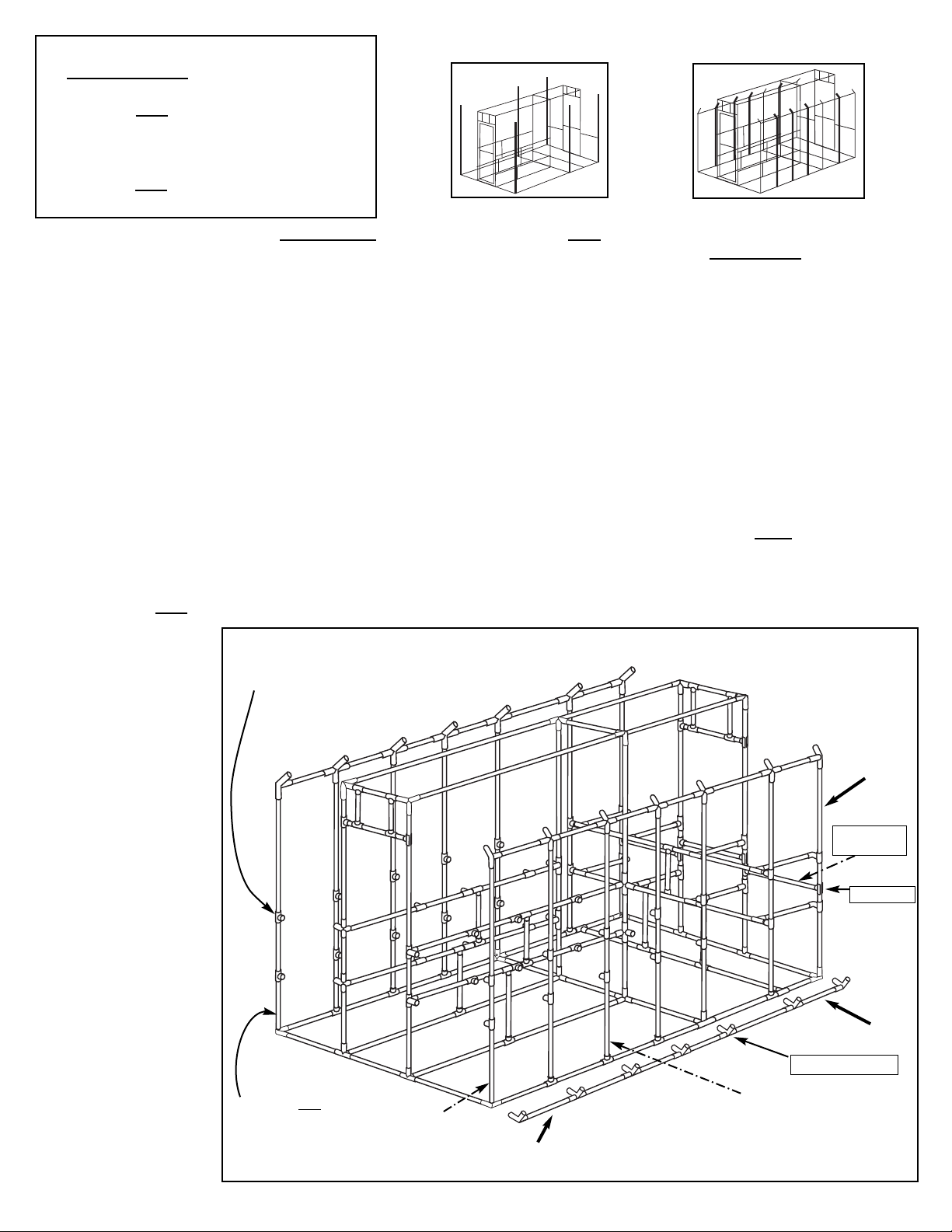

1. Locate the 6 Side Wall tubes (without slots - From step 1). Slip an 18” PVC pipe -½” diameter into the center (bottom) of

the Side Wall Tube (It sits loose inside of the tube) and then insert the side wall tube into the Metal Fitting on the base

frame (Do this for all six side wall tubes - with out slots. Insert the two Side Wall tubes with the extra Snap-T on it, into the

Corner Posts on the Back Base Frame. Tighten the eyebolts. Draw a line 2 ¾” down from the top of the corner side wall

tubes. Do this on all four corner side wall tubes.

2. Use a 1” Screw to attach the 8 remaining Side Wall tubes (Single-Slotted) into the Snap-T’s on the BASE FRAME. Make

sure the Side Wall tubes are seated all the way into the Snap-T’s. Adjust the Snap-T’s on the side wall tubes so they

face towards the inside of the greenhouse.

3. Line up an 8’ Ridge Frame with the 8’ base frame of the greenhouse. Make sure the Snap-T’s and Metal fittings on the

base frame are lined up with the Metal Fittings of the 8’ Ridge Frame. Add a 4-way 120° metal-T to the end of the 8’

Ridge Frame and tighten the eyebolt. Insert the 4’ Ridge Frame into the opposite end of the 4-way 120° metal-T making

sure that the metal fittings on the 4’ ridge frame line up with fittings on the base frame that the side wall tubes go into.

tighten the eyebolts. Repeat this step to make two 12’ Side Ridge Frames.

4. Place the Metal fittings of a Ridge Frame onto the top of the Side Wall tubes. Tighten the eyebolts. Note: On the corner

Side Wall tubes, move the ridge frame up or down so the arm of the 3-way 120° Metal Corner Post lines up with the line

drawn on the Side Wall tubes in step 7-1 above. Repeat this step for the other side wall.

5. Attach a 28” PVC pipe - Green between the Snap-T’s (B) on the Back End wall and Back Side Wall tubes. See diagram

below.

Adjust all the Snap-T’s on the side

wall tubes to face towards the

inside of the greenhouse.

Snap-T (B)

7. SIDE WALL ASSEMBLY

Pieces required:

14 Side Walls (Made in step 1)

2 28” PVC pipes - Green

2 8’ Side Ridge Frames (from Step 3A)

2 4’ Side Ridge Frames (from Step 3B)

2 4-Way 120° Metal-T

6 18” PVC pipe - ½” diameter

8 1” Screws

28” PVC pipe

Green

Side Wall

tube with

extra Snap-T

8’ Side Ridge Frame

4-Way 120° Metal-T

4’ Side Ridge Frame

Composite drawing for Steps 7 & 8A

Slotted end goes into the Snap-T.

Secure 74” tube with 1” Screw

Insert an 18” PVC pipe - 1/2” diameter into the

Side Wall Tubes that go into metal fittings.

This pipe provides support when

attaching the anchor kit (If purchased) to the

greenhouse.

1. 2.

Page 12 12’ Garden Master (3.5mm)

8A. BACK BENCH ASSEMBLY

Pieces Required:

2 94 ½” Composite Tubing - Green (Double-Slotted)

10 22” Composite Tubing - White (Double-Slotted)

1 24” Composite Tubing - Orange (Double-Slotted)

12 Snap-T’s

4 PVC Elbows

4 PVC Nipples

38 1” Screws

MAKE 4

22” Composite Tubing - White (Double-Slotted)

PVC Elbow PVC Nipple

Bench Assembly with Elbow:

1. Insert a PVC Elbow onto a 22” Composite Tube - White (Double-Slotted). Secure with a 1” Screw.

2. Insert and glue a PVC Nipple into the PVC Elbow. Repeat these two steps to make a total of 4 bench assemblies (with

elbow). See diagram to the upper right.

3. Attach two 22” Composite Tubes - white (Double-Slotted) into the Snap-T’s on the 94 ½” Composite Tube - green

(Double-Slotted). The base frame tube added in step 4 - 7. Attach a Snap-T to the top of the 22” Composite Tubes - White.

(Double-Slotted). Secure with 1” Screws. These tubes will support the bench pipes.

4. Attach five Snap-T’s to a 94 ½” Composite Tube - Green (Double-Slotted). See diagram A below and space the snap-Ts

approximately as shown. They can be adjusted as you assemble. Insert this tube into the bottom Snap-T’s on both Ribs #6

Secure with 1” screws.

4a. Glue the 2” Nipple of a Bench Assembly With Elbow into the bottom Snap-T on Rib 7. Attach the other end of the Bench

Assembly to a Snap-T on the 94 ½” Composite Tube - green (Double-Slotted) bottom bench rod as shown in diagram A.

Repeat for the opposite side. Attach a 22” Composite Tube - White (Double-Slotted) between the bottom Snap-T’s on

the Back End Wall and the Snap-T’s on the 94 ½” bottom bench rod. Snap these 22” tubes into the Snap-T’s on the vertical

22” Composite Tubes you installed in step 8A-3 above.

5. Attach a 24” Composite Tube - Orange (Double-Slotted) to the remaining center Snap-T on the 94 ½” bottom bench rod

installed in step 8A-4 above. Attach five Snap-T’s to the remaining 94 ½” Composite Tube - Green (Double Slotted)and

insert the tube into the top Snap-T’s on both Ribs #6. Secure with 1” Screws. Attach the 24” Composite Tube to the center

Snap-T on the top 94 ½” Composite Tube - Green (Double-slotted) - Upper bench rod.

6. Repeat Step 8a-4a (above) for the top bench, except you will use the upper snap-T’s on ribs 6 & 7. Secure all Snap-T’s to

the tubing with 1” Screws.

7. Adjust Bench Frame pipes by sliding the Snap-T’s on the Ribs up or down, so that the Snap-T’s of each bench frame are at

an equal height. HINT: Use a rubber mallet to tap the

pipe up or down. After everything is level, attach a 1”

screw through the “snap” portion of the Snap-T’s on the

side walls and end walls to prevent the shelf tubes from

sliding down.

3.

5.

4.

6.

Bench

Assembly

with Elbow

Side Wall (Rib) 6

Side Wall (Rib) 7

Side Wall

(Rib) 6

Side Wall (Rib) 7 Back End Wall

22” Composite Tubing

White (Double-Slotted)

24” Composite Tubing

Orange (Double-Slotted)

94 ½” Composite Tubing

(Double-slotted) Bench Rods

Bench Assembly with Elbow

22”

Composite

Tubing

(White)

Double-

Slotted

A.

12’ Garden Master (3.5mm) Page 13

Attach

1” Screws

8B. BENCH ASSEMBLY

Pieces Required:

20 28” Composite Tubing - GREEN (Double-Slotted)

42 1” Screws

92” Composite Tubing - Red

(Bench Rod)

28” Composite Tubing -Green

(Double-Slotted)

BB - 92” Composite Tubing - Red

(Bench Rod)

Attach screw here

(See picture below)

4-way Metal-T

22 ¾”

48 ¼”

28” Composite Tubing -Green (Double-Slotted)

Snap-T

1” screw

Top of Snap-T

Composite Tube

1. Insert eight 28” Composite Tubes - Green (Double-Slotted) into the 4-way Metal-T’s that are on the end walls. Attach

the opposite ends of the 28” Composite Tubes - Green (Double-Slotted) into the snap-T’s on the corner side wall tubes.

(NOTE: The glue does not adhere to the Composite Tubing. Apply glue around the outer end of the pipe and inside

the top of the Snap-T fitting for lubrication. The tubing will be easier to slide into the Snap-T’s.) You will need to

secure the tubing by putting a 1” Screw through the top of the Snap-T and into the 28” Composite Tubes - Green

(Double-Slotted) - See picture below. Attach the remaining 28” Green Composite Tubes between the Snap-T’s on the rib

pipes and the Snap-T’s on the 92” Bench Rods using glue to lubricate and 1” Screws to secure.

2. Double check measurements and make sure that the 4 -way Metal-T’s on the End walls are at 22 ¾” and 48 ¼” from the

top of the BS - 92” Base Frame Tube to the center of the fitting. (See diagram above)

3. Adjust Bench Frame tubes (by moving Snap-T’s on the Ribs up or down) so Snap-T’s of each bottom bench frame

are at an equal height and level with each other. HINT: Use a rubber mallet to tap the snap-T up or down.

4. After everything is level on the bench frames, attach a 1” Screw through the top of the vertical Snap-T’s on the Side Wall

Tubes to prevent shelf brackets from sliding down (See picture below).

Page 14 12’ Garden Master (3.5mm)

A. B.

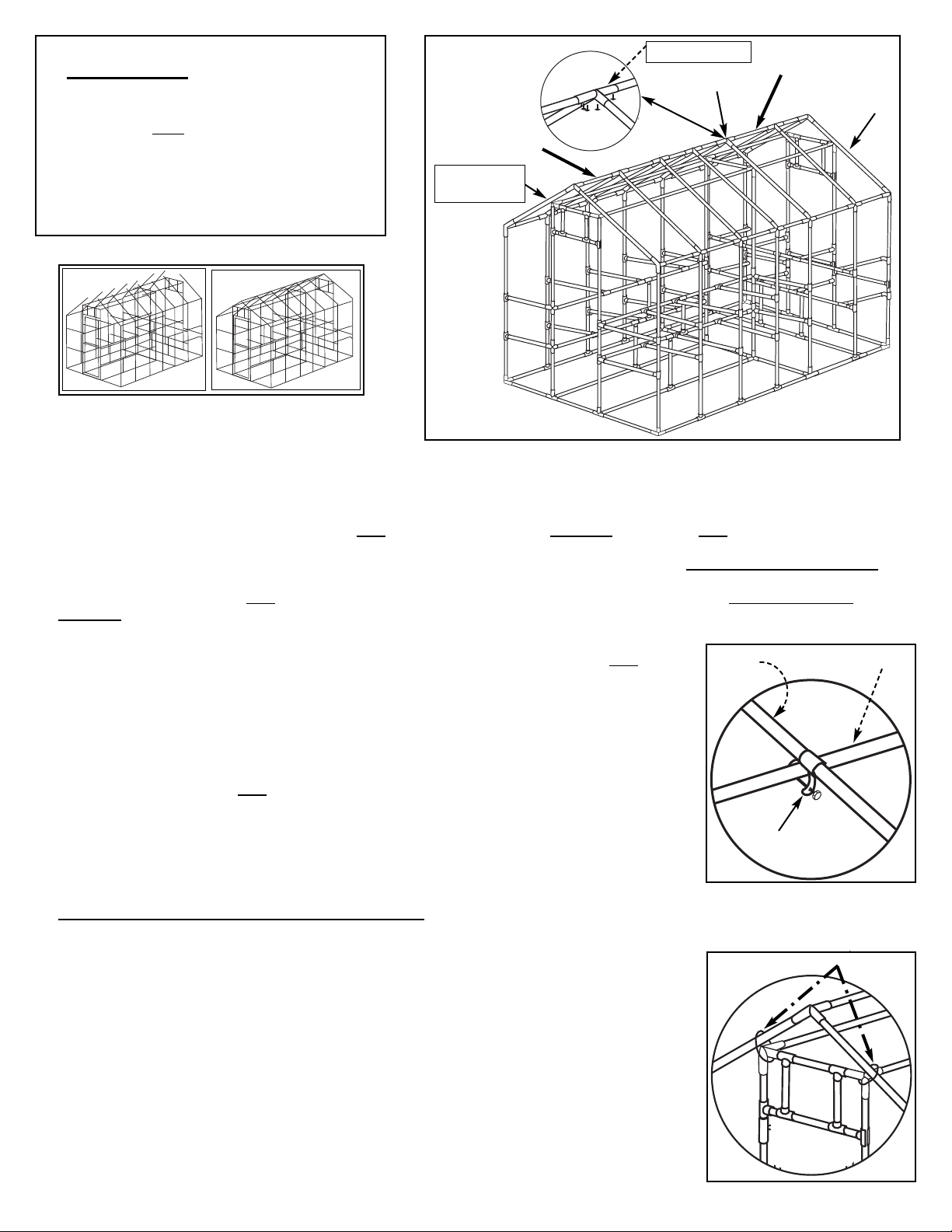

1. Line up the 8’ Top Ridge Frame with the 8’ base frame of the greenhouse (see picture Step 7). Make sure the Snap-T’s and the metal

fittings on the base frame are lined up with the metal fittings of the 8’ Top Ridge Frame. Add a 4-way 120° Metal-T to the end of the 8’

Ridge Frame and tighten the eyebolt. Insert the 4’ Top Ridge Frame into the opposite end of the 4-way 120° Metal-T. Line up the metal

fittings of the 4’ Top Ridge Frame with the Side Wall tubes and tighten the eyebolt of the 4-way 120° Metal-T.

2. Draw a line 2 ¾” down from the end of a 54 ¼” PVC pipe - Yellow. Do this on both ends of six 54 ¼” PVC pipes - yellow. Set four 54 ¼”

pipes into the 3-way 120° Metal Corner Posts of the Side Ridge Frame (Rafters #1 & 7 - See diagram above) at the front and back of the

greenhouse and two 54 ¼” pipes into the 4-way 120° metal-T above the middle end wall (rafter #5). DO NOT tighten the eyebolts!!!

3. Set the remaining eight 54 ¼” PVC pipes - yellow into the 4-way 120° Metal-T’s of the Side Ridge Frames. DO NOT tighten the

eyebolts!!! - In the next step you will be pulling these tubes out of the side wall fittings and inserting them into the 12’ top ridge frame

fittings. Then you will attach the top ridge frame with the 54 ¼” tubes attached back into the side ridge frames to form the roof framing.

4. Balance the 12’ Top Ridge Frame on the hanging rods. Starting at rafter #1, pull a 54 ¼” PVC pipe -

yellow from the Side Ridge Frame and insert it into the arm of the 3-way 120° Metal Corner Post on the

12’ TOP RIDGE FRAME (54 ¼” pipe will pop out of the Metal Fitting on the side Ridge frame - this is

OK). Push the 54 ¼” pipe into the 3-way 120° Metal Corner Post (On the top ridge frame) until the line

you drew on it in step 9 - 2 is even with the arm of the 3-way 120° Metal Corner Post. Tighten the

eyebolt. Repeat on the opposite side and opposite end of the greenhosue, pulling the four corner 54 ¼”

pipes - yellow and inserting them into the 12’ Top Ridge Frame.

5. Pull out the remaining 54 ¼” PVC pipes - yellow and insert them into the remaining metal fittings on the

12’ Top Ridge Frame. Insert the 54 ¼” pipes - yellow all the way into the 4-way 120° Metal-T’s until

they stop. On rafter #5 & #7 push the 54 ¼” pipes in so the line you drew on it is even with the arm on

the post. Tighten the eyebolts.

6. Rest the top Ridge Frame and Rafter (54 ¼” pipe) assembly over the center of the Hanging Rods.

7. Insert the Rafters into the Metal Fittings of the side Ridge Frame one at a time. Slide a Metal Ring on Rafters #2, 3, 4 & 6.

Do not tighten the eyebolts until all the Rafters are in place. Once all Rafters are inserted into the metal fittings of the side Ridge

frames, tighten the eyebolts. Adjust Rafters on the front, middle and back end walls so the line drawn is even with the post of the fitting.

8. Slide the Metal Rings up to the Hanging Rods. Adjust the “U” bracket so it straddles the hanging rod.

Slide a 1 ½” x 3/16” machine screw through the bolt hole of the Metal Rings and attach a 3/16” wing

nut.

9. Attach a Zip Tie around the Rafter and Metal Corner Post at each end wall. Do this on Rafters #1, 5 &

7 - Front, middle and back end wall. See diagram to the right.

9. TOP RIDGE ASSEMBLY

Pieces required:

1 8’ Top Ridge Frame, made in step 3A

1 4’ Top Ridge Frame, made in step 3B

14 54 ¼” PVC pipes - Yellow

1 4-Way 120° Metal-T

8 Metal Rings

8 1 ½” x 3/16” Machine Screws

8 3/16” wing nuts

6 Large Black Zip Ties

Metal Ring

Rafter Hanging Rod

4-Way 120° Metal-T

8’ Top Ridge Frame

4’ Top Ridge Frame

54 ½” PVC pipe

(Rafter #1)

Zip Tie

Rafter #7

Rafter #5

12’ Garden Master (3.5mm) Page 15

Banding 1

Banding 2

Banding 3

FIG 10A

1. On the front end wall, loop Banding 1 through an

eyebolt on the Metal Corner Post on the base frame.

Loop the other end of the banding through an eyebolt

on the opposite 3-Way 120° Metal Corner Post on the

Side Ridge Frame.

2. Thread banding through the metal buckle as

shown/explained in Fig 10B.

3. Thread Banding 2 to the opposite diagonals.

4. Tighten Banding 1 & 2 so the diagonals are equal in

length. If they are not equal in length. Lossen the

shorter one and then tighten the longer band until the

two diagonal measurements are the same.

5. Loop Banding 3 through an eyebolt of the 3-way

120° Metal Corner Post of one Side Ridge Frame to

the eyebolt of the 3-way 120° Metal Corner Post on

the opposite Side Ridge Frame. Tighten the banding

so the measurement from the “in” side of one 3-way

120° Metal Corner Post to the center of the opposite

3-way 120° Metal Corner Post is equal to 95 ½”.

Keep banding in place until Front End wall paneling has

been applied.

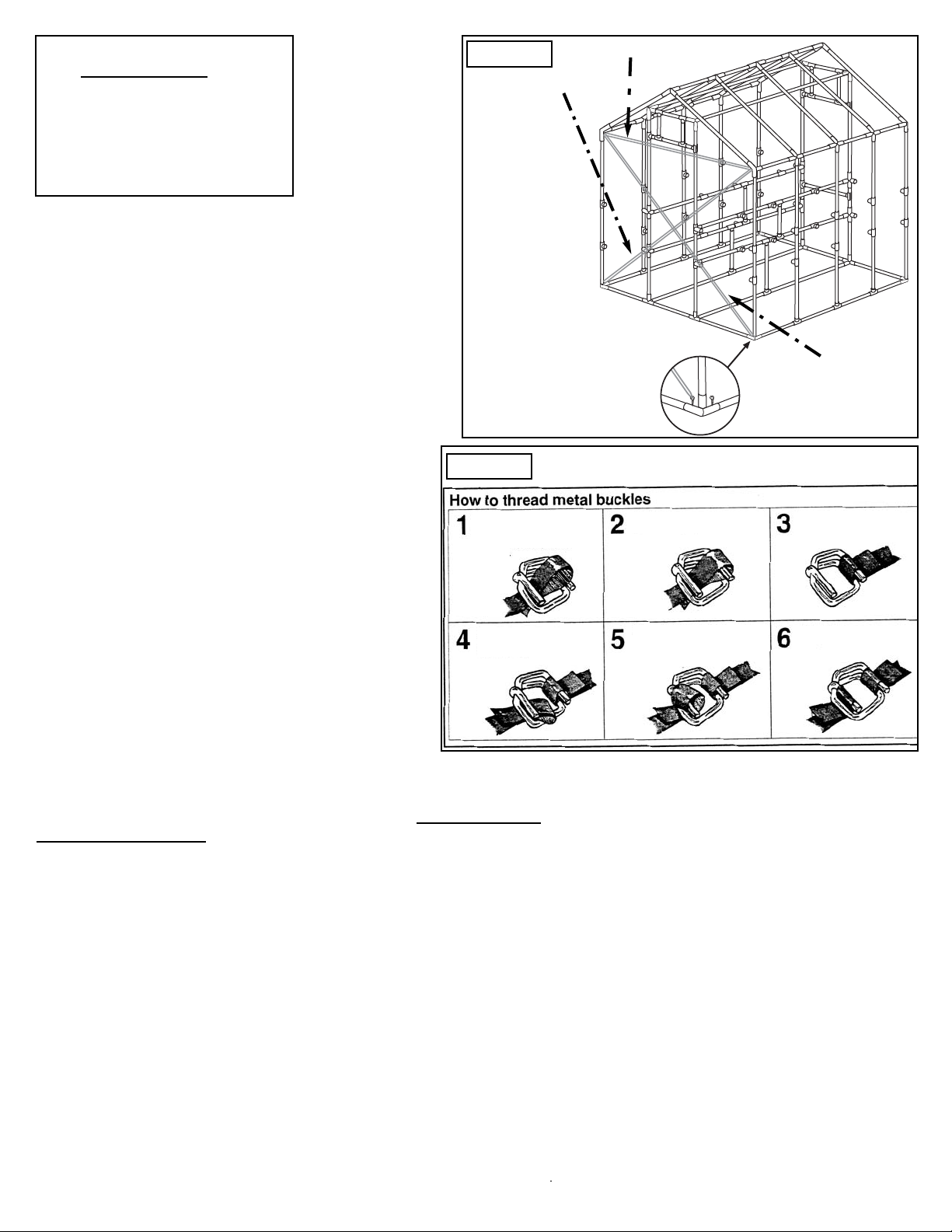

10 A. SQUARING FRAME

Pieces Required:

3 Yellow Banding

3 Metal Banding Clips

2 76” Side Door Casing

(1 with hinges)

1 38” Top Door Casing

1 1” Screw

How to thread Metal Buckles

1. Form a 3” loop by folding banding away from you,

(short end of banding needs to be on top). With

buckle tines facing upright, pass loop up through

center of buckle.

2. Slip the loop over the tine (farthest from you).

3. Pull banding down and away.

4. Place banding around specified frame area. Fold a

new loop by folding banding toward you.

5. Slip new loop over other tine.

6. Tension by pulling banding coming from coil.

7. To loosen banding, grasp coil with pliers and twist

your wrist so banding slides loose from tine.

NOTE: Measure

the diagonals with

a tape measure

first. If diagonals

are equal, skip

step 10A.

10 B. Sizing Door Frame for Door Casing

1. Using the Top Door Casing as a measuring device, check to make sure

the door opening is 36 7/8” at both the top and bottom from “in” side to

center of the 90” tubes.(The Top Door Casing fits between the snap-T’s

on the top of the 90” tubes.)

2. Make sure the door opening is square by measuring diagonally from

corner to corner and making sure the measurements are the same. Also

check that the 90” tubes are plum (Straight up and down) and the top door

frame tube is level.

3. Again place the Top Door Casing over the 35 3/4” tube. Hold in place

temporarily with one screw inserted from the front and into the tube.

4. Temporarily place the side Door Casing with the Hinge attached on

whichever side you want your door to hinge from.

5. Place the other Side Door Casing on the opposite side of the door

opening. All 3 Door Casing pieces should fit snugly.

6. Remove the Door Casing Pieces. They will be used in the Door

Assembly Step #14. Proceed with paneling.

FIG 10B

Page 16 12’ Garden Master (3.5mm)

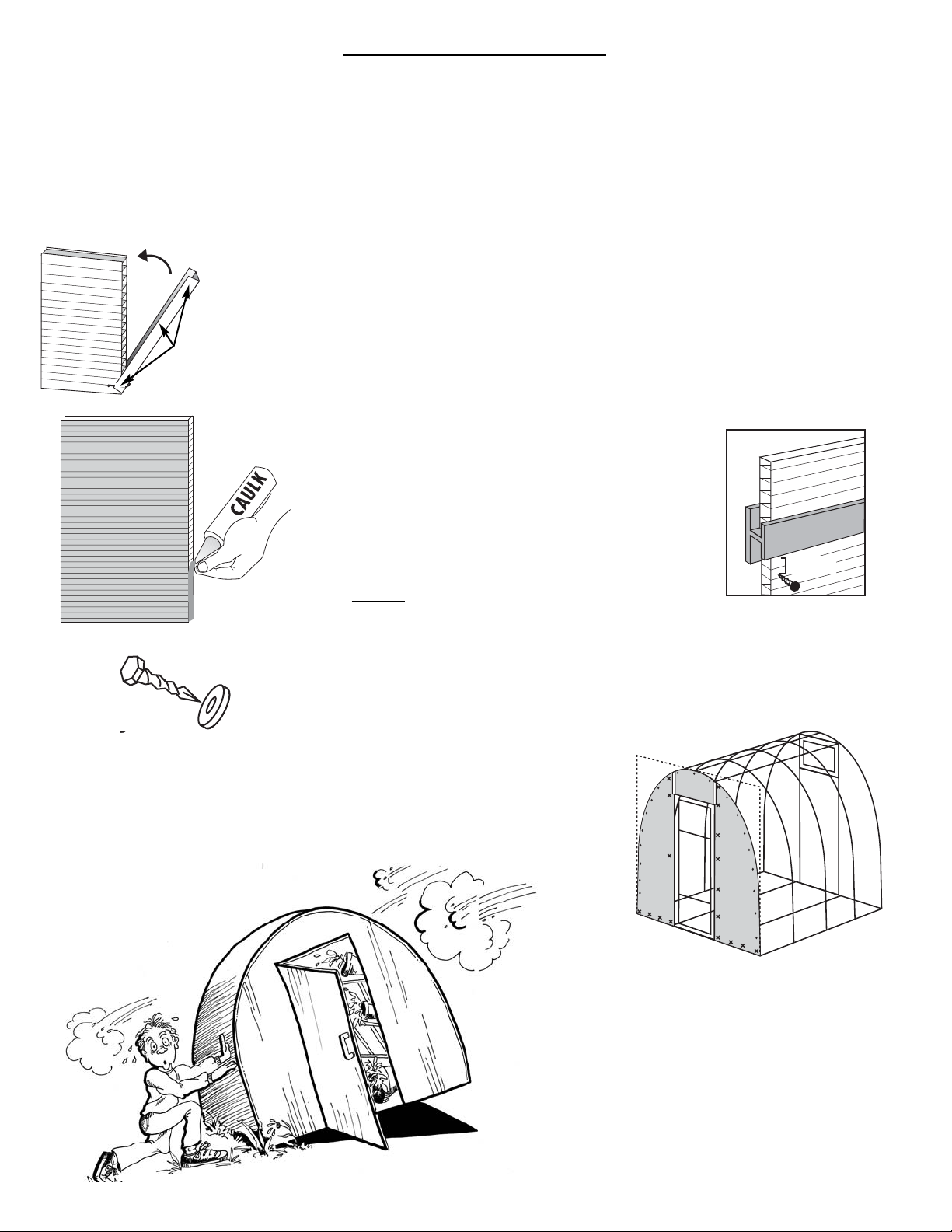

Hints for Panel Assembly

Congratulations, your frame is now finished! All that’s left is the paneling application. Listed are

several hints that will make paneling your greenhouse much easier. If you have suggestions that

would be helpful for future customers we would be happy to hear from you.

1. PANELS: Apply paneling when temperature is moderate for your area (not during a cold or hot spell). When attaching

panels to the PVC tubing, be careful not to over-torque the screws. The washers should just make a dimple in the panel.

The screws should be placed about 12” - 15” apart on the panels and about 6” apart around the perimeter of the walls, roof

and any overlapped joint.

2. U-TRIM: Insert ¼” - ½” of 100% silicone caulking into open flutes to prevent water intrusion.

Place U-Trim over the 4’ ends of panels where specified in the instructions. Secure the U-Trim

with small Phillips Screws by poking a small pilot hole in the U-trim and screwing through

the U-Trim and into the panel. Use about 3 or 4 Screws per U-Trim

uNote: When using caulking, cut tip of tube at an angle. Be careful not to get caulking

on nice clothing or jewelry.

3. H-CHANNEL: If H-Channel is difficult to slide on,

spray panel edges with Pam (Vegetable oil). Also

tapping on ends of H-Channel with a rubber mallet

helps H-Channel slide on easily. Secure panels by

placing screws into pipes 2 ½” from each side of the

H-Channel. You can cut H-Channel by scoring on both

sides with a knife and then bending at the score or use

tin-snips.

NEVER attach screws into the H-Channel!

4. SCREWS: Use the pictures as a guide for placement of screws. Use your

discretion on your own greenhouse. The number of screws required for each

step in paneling may not exactly coincide with the picture.

5. CUTTING PANELS: Panels cut very easily with a long, thin sharp

knife or utility knife. Use the Frame or a straight edge for a guide when

trimming panels.

6. TIE DOWN: Please remember to tie down

your greenhouse once you begin paneling.

The greenhouse is light enough that on a

windy day it could blow over.

2 1/2"

Small

Phillips

Screw

1. Caulk the open flutes on one end of all three of the panels.

2. Screw the two 31” x 94 ½” Panels into place (caulked end

on ground) making sure they cover the door end wall tubes.

Attach to End wall tubes with 1 or 2 Screws. These screws

will be removed later when you assemble the door.

3. Cut panels carefully along the Rafters and Side Walls

using a sharp thin knife (use the tubes as a guide).

4. Attach the 29” x 42” panel above the door. Leaving a ¼”

gap between this panel and the 31” x 94 ½” Panels, so there

is room to slide the H-Channel between the panels. Cut the

3’ H-Channel in half and trim to fit.

12’ Garden Master (3.5mm) Page 17

Trim Panels

along the Rafter

31” x 94 ½” Panel

31” x 94 ½” Panel

1” Screws

11. FRONT ENDWALL PANEL

Parts Required:

2 31” x 94 ½” Panels

1 29” x 42” Panels

70 1” Screws

1 3’ H-Channel

Don’t forget to secure your greenhouse.

The panels create wind resistance.

Set Caulked end on the ground

H-Channel 29” x 42” Panel

12. BACK END WALL PANEL

Pieces Required:

3 Yellow Banding (from Step 10)

3 Metal Clips (from Step 10)

2 31” x 94 ½” Panels

1 42” x 115” Panel

87 1” Screws

1. Caulk the open flutes on one end of all three panels.

2. Remove the Banding from the Front end walls, do not cut

the banding. Use the banding to square the back end

wall. (see step 10, Squaring the frame)

3. Attach panel #1 and panel #2 (31” x 94 ½” panels)

vertically (Caulked ends on the ground). Line one side of

the panels up with the side wall tubes so they also cover

the end wall tubes. This way you should not have to trim

the panels at the side wall tubes. Do not attach screws on

the end wall tubes yet. Panel 3 will over lap panel 1 & 2.

Carefully trim panels along the rafters and side walls (If

needed).

4. Attach panel #3 (42” x 115” panel) so it overlaps panels #1 and #2 on the end wall tubes. Attach screws through both layers

of paneling and into the end wall tubes. Trim panel along the rafters.

*NOTE: If installing a fan, do not cut any holes before reading the fan installation instructions.

5. Adjust the 12 ½” pipes so there is 24 ½” between them.* Carefully hold louver up in the opening and trace the outline of

the louver on the panel. Slowly cut out the louver opening so the panel covers both 12 ½” pipes and the 35 ¾” pipes on

the back End wall. ****** Use the Louver as a stencil to trace the outline of the louver before cutting the opening.

5. Caulk all exposed flutes that are still open on the top of both end walls and in the louver opening.

Trim panels.

Use the frame

as a guide.

Carefully cut out Louver opening.

(please read Note above)

31” x 94 ½” Panel

(Panel #1)

42” x 115” Panel

(Panel #3)

IMPORTANT: If installing an exhaust fan, the fan will go

in the back of the greenhouse in place of the Louver

and the Louver will be installed above the door. Do not

cut a hole for the Louver if you have purchased or are

considering purchasing a 16” or larger fan.

31” x 94 ½”

Panel

(Panel #2)

Page 18 12’ Garden Master (3.5mm)

1. Remove Yellow Banding from the Back End wall (Do not cut).

2. On the side wall tubes, loop the banding through an eyebolt on the corner post of the base frame and run the banding

diagonally across to the 3-way 120° Metal Corner Post of the Side Ridge Frame. Repeat for the opposite diagonal. Attach

banding on both sides of the greenhouse. See step 10, Fig. 10B

3. Tighten the banding so the diagonals are equal in length. If one band is longer then the other, lossen the shorter band and

tighten the longer band until both diagonals are of equal length.

4. At the middle end wall, measure the distance from the “in” side of one Side Ridge frame to the center of the other Side

Ridge frame. If the measurement is greater than 95 ½” , attach a Yellow Band and pull the frame in until the measurement

is 95 ½”.

Yellow Banding

Metal Corner Post

Base Frame

Side Ridge

Frame

3-way 120°

Metal Corner Post

13A. SQUARING SIDE WALLS

Pieces Required:

5 Yellow Banding (3 from Back End wall, Step 12)

5 Metal Banding Clips (3 from Back End wall, Step 12)

12’ Garden Master (3.5mm) Page 19

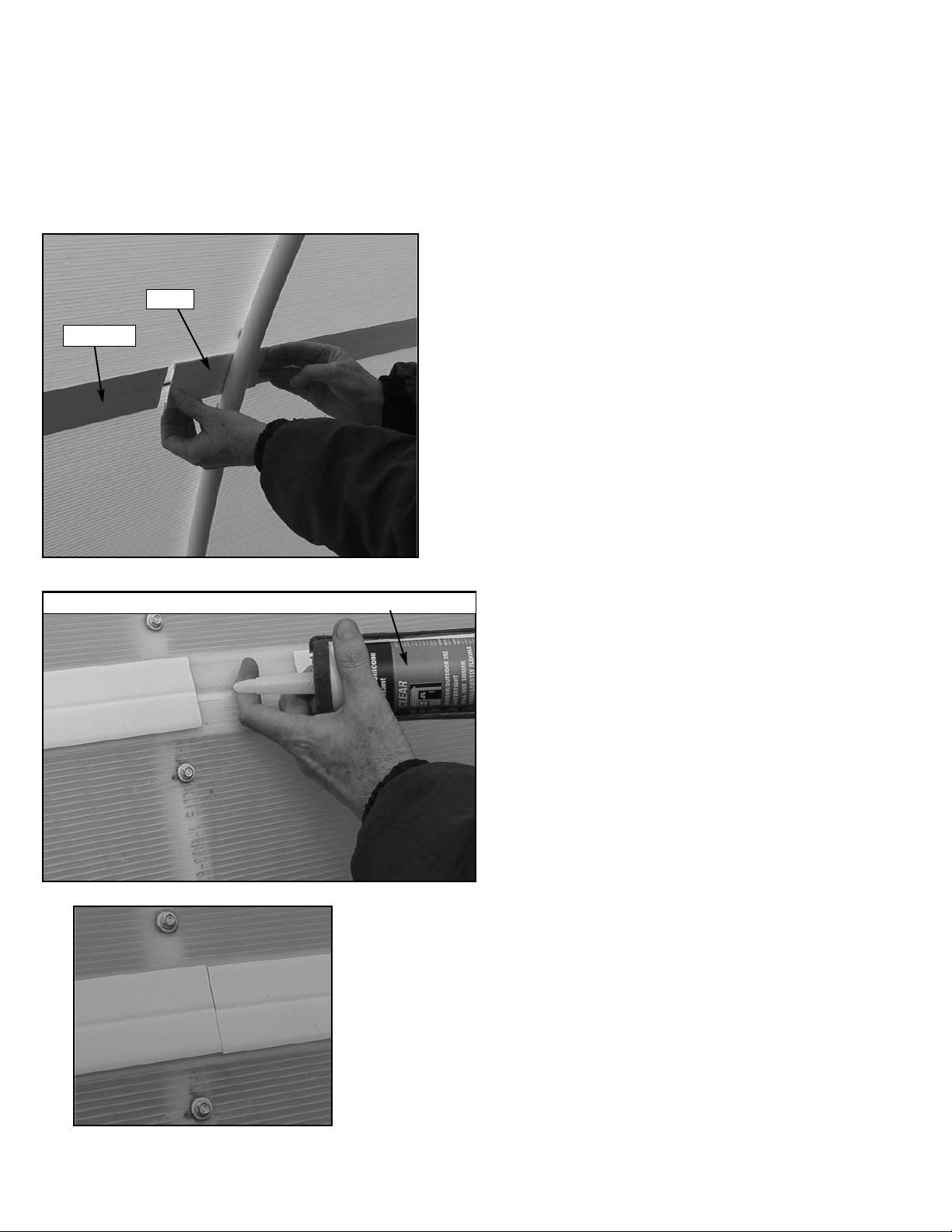

Installation instructions for

H-Channel Clips

1. Slide the H-Channel between the panels leaving a

couple inches between each piece of H-Channel.

From the inside of the greenhouse, slide the

H-Clip onto each end of the H-Channel pieces.

2. From the outside of the greenhouse,

insert about a nickel-size gob of 100%

silicone caulking into the area between

the H-Channel pieces.

3. Slide the H-Channel pieces in so they butt together.

IS 800 silicone rubber adhesive sealant or 100% silicone caulking

H-Clip

H-Channel

Page 20 12’ Garden Master (3.5mm)

uNOTE: Center the panels so the overhang is

equal over the front & back end

walls. Do not cut off the overhang.

It will help keep water out of the

end wall panels.

13B. TOP and SIDE GLAZING

Pieces Required:

2 49 ½” x 145” Panels

4 42” x 145” Panel

12 6’ H-Channel

6 H-Channel Clips

225 1” Screws

4 78” U-Trim

4 56” U-Trim

35 Small Phillips Screws

1. Caulk both ends of all six panels.

2. Lay a 49 ½” x 145” Panel on the ground and score (using a blunt object such as the back side of a butter knife) down the

center of the panel following a flute (Do not cut into the panel. You are only making a slight indenture in the panel, so when

you fold the panel, it follows this line.) Center the panel on the peak of the greenhouse, making sure there is equal

overhang over each end wall of the greenhouse. Attach with screws.

3. Attach a 42” x 145” panel ¼” below the top panel (the ¼” provides room for the H-Channel to be slide in). Score and fold

the panel down over the side ridge frame and down the side wall. - (Where the side of the greenhouse meets the roof.)

Repeat with a 42” x 145” Panel on the opposite side of the greenhouse.

4. Attach a 42” x 145” panel ¼” below the panel from step 3. Repeat with a 42” x 145” panel on the opposite side of the

greenhouse.

5. Cut a 49 ½” x 145” panel in half (to make two 24 ¾” x 145” panels) to fill in the the remaining spaces on each side of

the greenhouse. Remember to allow for ¼” between each of the panels for H-Channel.

6. Slide two 6’ H-Channels between each of the panels and join with H-Channel Clips (see instructions previous page).

7. Attach U-Trim to the panels (refer to hints on page 16). Cut U-Trim to fit when needed. Use two 56” and two 78” pieces on

each end of the greenhouse.

If you have purchased a tie down kit. Install it now!

If not, you will need to secure the greenhouse to the ground.

24 ¾” x 145” Panel

Score & fold 49 ½” x 145”

Panel at peak of greenhouse.

42” x 145” Panels

12’ H-Channel

Table of contents

Popular Greenhouse Kit manuals by other brands

Zip Tie Domes

Zip Tie Domes 2V Assembly manual

Vitavia

Vitavia Hera 4500 Assembly instructions

Robinsons

Robinsons Radley Series Assembly instructions

ModuLaro

ModuLaro GH192002 Assembly, installation and maintenance manual

juwel

juwel 20150 Mounting instructions

Vitavia

Vitavia Calypso 3000 Assembly instructions