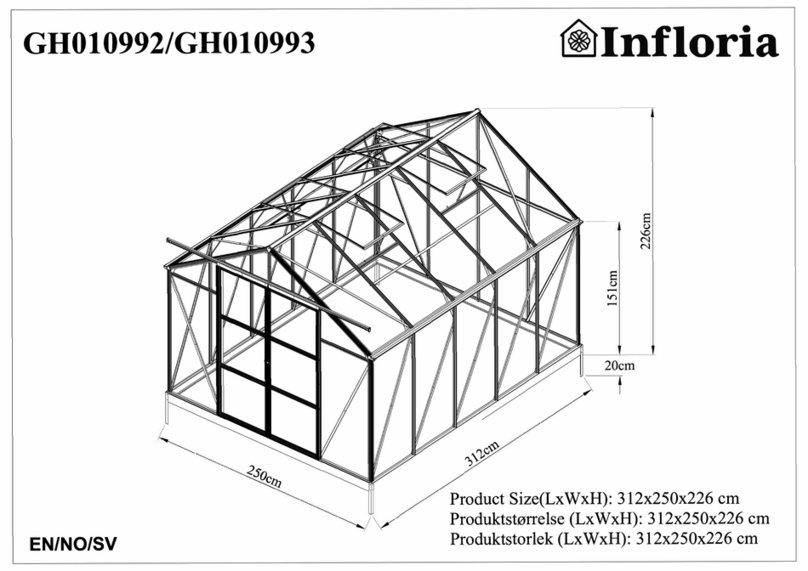

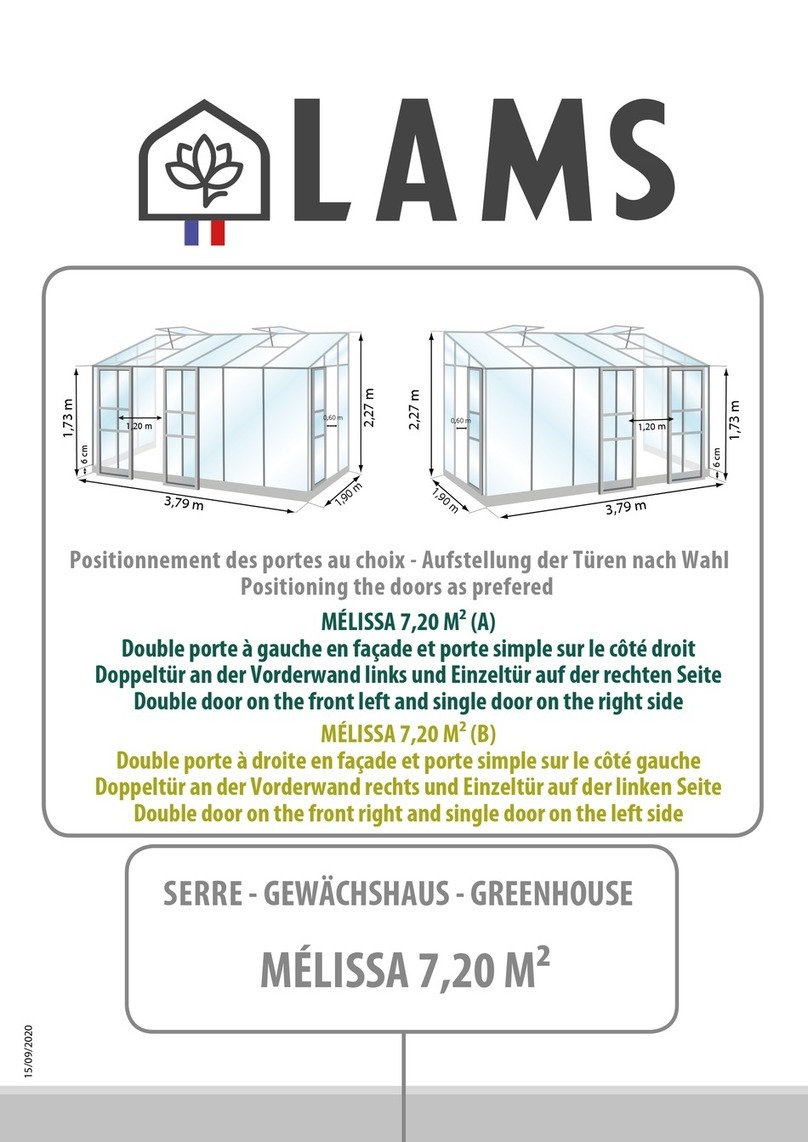

Infloria GS010997 User manual

Walk-in Greenhouse

Assembly Instructions

—— For Double Sliding Door

Article No: GS010997

2

Thank you for purchasing your new greenhouse. We recommend you familiarize yourself

with the instructions and read all safety information before you commence assembly.

These instructions are divided into sections: Base, Part lists, Preparation, Side wall, Rear

wall, Front wall, Roof, Vent, Door, PVC capping bar, Polycarbonate or Glass, Down pipes,

Optional Turbine Vent, Anchoring greenhouse to slab or base etc.

Shelving and Staging inside greenhouse are optional also, not including in this instructions.

Package1(x2) mainly for side wall parts, Package 2 for front and rear gable parts and side

wall sill bottom bars parts, Package 3 for roof frames and parts, Package 4 for vent parts,

Package 5 for door parts, Package 6 for PVC bars and fixing clips parts, Package 7 for down

pipes parts, and etc.

Safety Warning

1. Aluminum profiles, polycarbonate and glass can potentially cause injury. Please ensure you wear pro-

tective goggles, gloves, headgear and suitable footwear when assembling and glazing the building.

2. Please remember that glass is fragile and should be handled with extreme care. Always clear up and

dispose of any breakages immediately.

3. Do not assemble the greenhouse in high winds.

4. For safety reasons and ease of assembly, we recommend that this greenhouse is assembled by a

minimum of two people.

5. The product you have purchased is intended only for the growing of plants and should only be used

for this purpose. When used for other purposes we will take no responsibility.

6. When using a step ladder one person should steady it at all times whilst the other works.

7. Should you encounter difficulties constructing this house, or in positioning the glass or polycarbonate

sheets, please contact your retailer–do not use force!

8. The greenhouse must always be anchored.

9. Please clear all lying snow from the greenhouse roof as it can cause the roof to buckle or collapse.

Site Preparation

1. When selecting a site for your greenhouse, Always try to select a sunny location, it is vital that you

choose as flat and level an area as possible.

2. Supplier's original chamber box section Alu. base or a concrete or slab base will provide the most

solid foundation for your greenhouse.

3. Do not fix your building down until the building is fully assembled, including glazing.

4. Avoid placing your greenhouse under trees or in other vulnerable locations.

5. To minimize the risk of wind damage, try to select as sheltered a site as possible, e.g. beside a

hedgerow or garden fence.

3

Important

Before assembling your new greenhouse, please check that all parts in the provided list are included.

Please take each bundle out of the packaging in order to identify the parts better. Most parts are num-

bered and can be identified by a stamped number or removable label. Alternatively, the components can

be identified by lengths detailed in the packing list (see diagram below). Please also note that NOT all

parts for a specific area will be packed together, i.e. door related components are packed together and

some are used in main frame construction. and some side wall bottom sill bars parts were packed in front

& rear wall parts package No.2.

It is important that the opened bundles do not get mixed with one another. If something is missing please

contact your retailer.

Additional Considerations

1. Please bear in mind that assembling your greenhouse can be time consuming. You may need to

spread the construction over two or more days. We recommend that you avoid leaving the building

partially glazed. If you ever have to leave your greenhouse half assembled and not anchored down,

weigh it down with slabs or bags of sand to stop the wind moving it.

2. You will find it helpful to prepare a large, clean and clear area in which to work in. A garage floor or

flat lawn area is ideal.

3. Anchoring down your greenhouse should be the final stage of construction just after glazing.

Necessary Tools

Screw drivers (Normal and Crosshead PH2),10 mm socket spanner or wrench, 10 mm combination span-

ner, knife, measuring stick, spirit level,Accu-drill with adjustable torque, Step ladder.

Maintenance

The greenhouse should be thoroughly washed with a gentle detergent occasionally. Please check that the

detergent used does not react aggressively with aluminium or plastic.

Ensure that the door tracks are cleaned regularly to avoid a buildup of debris , If hinged door, the hinge

should be lubricated usually.

Guarantee

Your new greenhouse is guaranteed for 10 years against faulty manufacture of the framework. This does

not include glazing, moving parts, accidental damage or wind damage etc..

4

Base-Optional

Base Anchor

legs Fixing

tabs M6x10 M6 M6x10

Crop Washer

GS010996 6x2218 612 24 36 12 12

120°

4436

2218

3842

30 1

We cannot emphasis how important it is to have a proper base for your Greenhouse to be erected upon.

It is essential that the BASE IS FLAT, LEVEL AND SUBSTANTIAL enough to take the weight of the

greenhouse including its polycarbonate panels or heavy glass.

Give yourself enough room around your base to allow for fitting the polycarbonate panel or glass and any

ongoing maintenance / cleaning. A slab base which is larger than the greenhouse is the ideal solution and

is our preferred foundation. If you use supplier's original chamber box section alu. base, also recom-

mended.

A brick perimeter base is equally suitable providing there is a concrete foundation beneath it. We suggest

using a solid brick with no frogs or holes (quality stock bricks or semi-engineering bricks).

IMPORTANT: Do not anchor your greenhouse down until it is fully assembled including glazing unless you

are 100% sure your base is square and level. If not your polycarbonate panels or glass will not fit properly.

Article No: GS010996

5

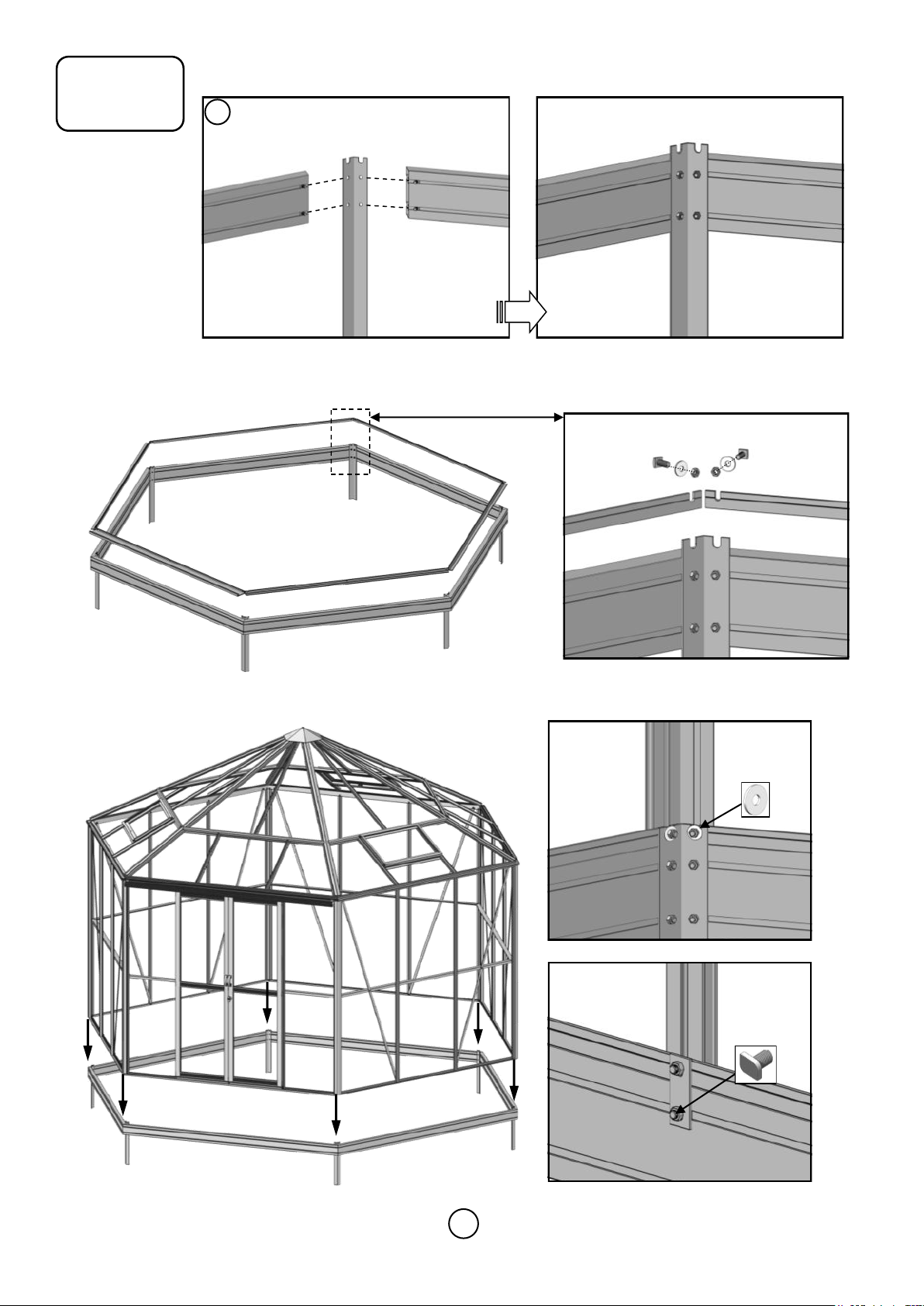

1

Base

IMPORTANT Before assembling aluminium base, the end trough centers of seven legs should match

both end trough centers of side sills and front & rear sills at the same time.

Please match six legs

troughs together at the

same time

side sills

side sills

6

1. For this final stage you will need No.10 X

2” screws, grey wall plugs, a 8mm ma-

sonry drill bit and a hammer drill.

2. Fixing the greenhouse to the ground is

very simple to do. When you built the

front, rear and side assemblies you will

have attached base brackets (m5) in spe-

cific places around the building.

3. Make sure the greenhouse structure is

square (Diagonal measurements should

be equal) and level.

4. Drill down through the holes in the base

brackets into the concrete.

5. Insert a wall plug into each hole.

6. Finally drive a screw into each hole.

7. You can now check the greenhouse and

look for any gaps where water might

come in, fill these using the silicone sup-

plied.

8. Your greenhouse is now complete.

Anchoring building to slab / concrete base

8mm

7

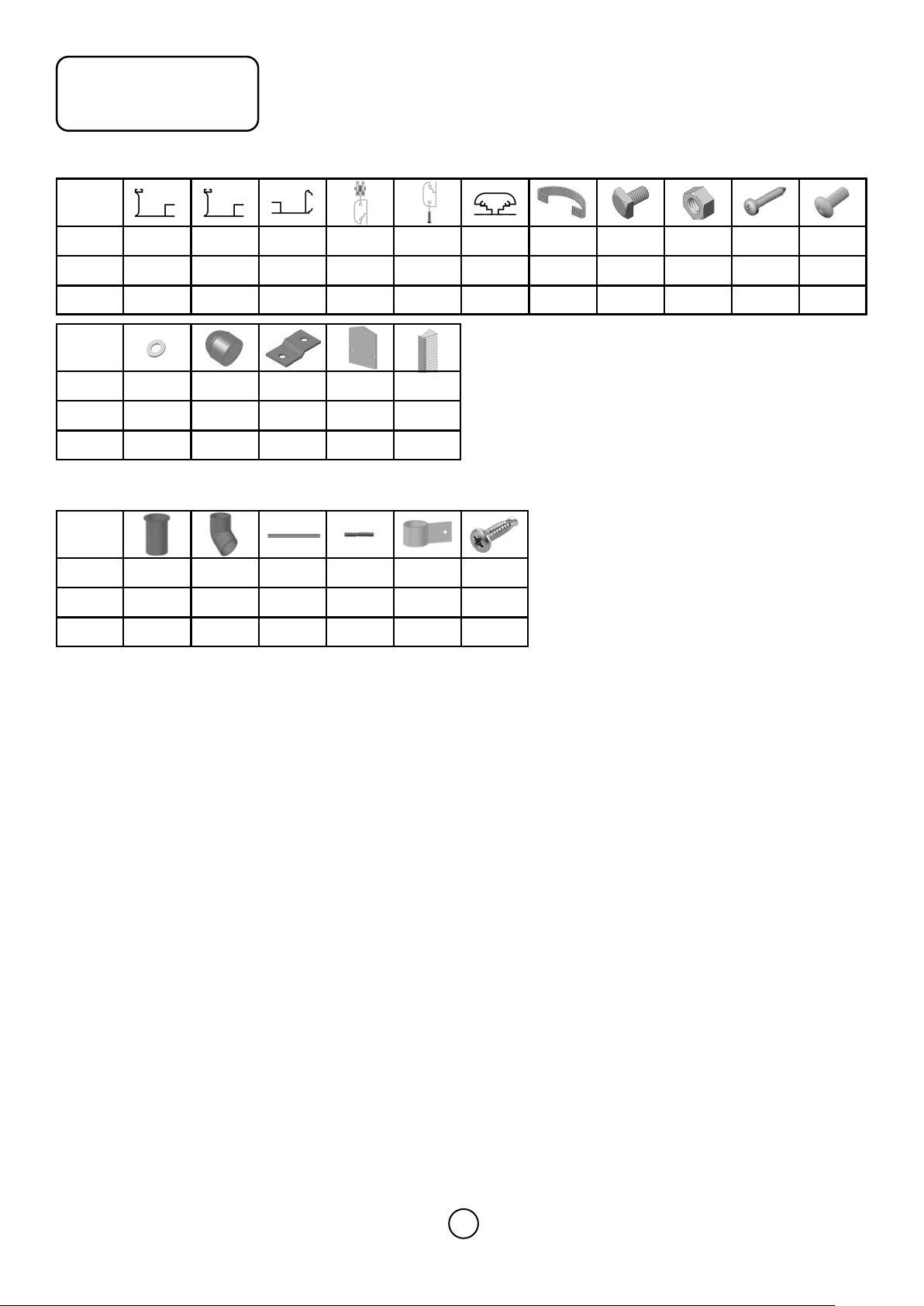

Parts List

# 7901 7607 7908 7909 7910 7912 a1 a2 a3 a20

Size 1922 1922 2237 2237 2033 2167 M6x10 M6 M6x15 -

QTY 34114224 32 832

Package 1

# 7023 7931 7907 7909 7607 7910 7912 7945 7936 7937 a1 a2

Size 2179 2179 2237 2237 1922 2033 2167 554 2139 1097 M6x10 M6

QTY 511142121124 32

Package 2

# a3 a20

Size M6x15 -

QTY 832

# 7915 7919 7920 7922 7991 7992 7993 7994 m3 p10 a1 a2

Size 2335 1348 686 1472 81 -----M6x10 M6

QTY 6612 6111118 690 90

Package 3

# a24 a25 a20

Size M6x110 M6-L -

QTY 1190

# 7053 7923 7055 7924 7057 a1 a2 a4 a7 a10 p3 a20 p11

Size 739 718 701 400 300 M6x10 M6

Φ3.9x8

M4x8 M4 ---

QTY 1112166222264

Package 4

8

Parts List

Package 5

# P11 P12 P13 P14 P15 a18

Size 1400 200 Φ3.5x13

QTY 222222

Package 7

# 7938 7939 7940 7941 7942 7943 7065 a1 a2 a5 a15

Size 1838 1838 1838 535 535 535 -M6x10 M6

Φ3.5x19

M6x12

QTY 21122228928 1

# a16 a20 m13 G-p5 FLUFF

Size Φ6---1838

QTY 19222

9

BASE

Base dimensions and recommendations. Ensure that your base is level as this will make assembly of

the building, especially the glazing of the roof much more straight forward.

PARTS LIST Most components should have a code punched into their metal surface. Identify and

separate all like for like components prior to assembly. The parts lists also separates parts into the various

sections Package1 - Package 7 shown above. Parts can also be identified by their profile pictures and

stated lengths etc..

PREPARATION The frame is assembled by feeding square headed bolts, either 10mm or 15mm in

length into the slots on glazing bars and then locating those bolts through holes in purlings and cills, etc…

Twist in (rectangular) crop headed bolts are also used towards the end of construction to attach compo-

nents to the frame when the glazing bar slots are no longer exposed at the ends.

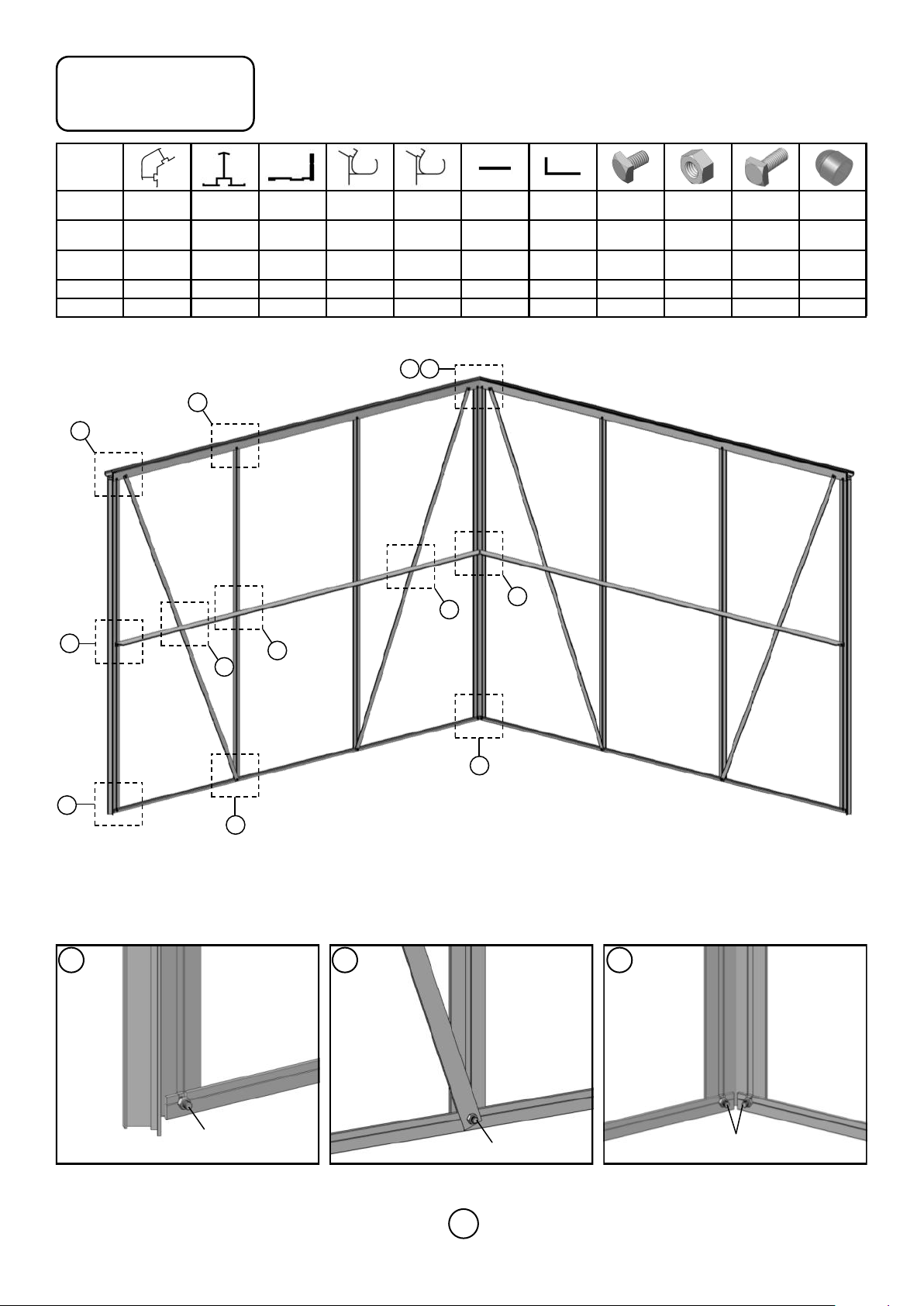

SIDE WALL

Use 10mm and 15mm bolts to join the components (note how the head of the bolt slides into each glazing

bar during construction). The correct choice of bolt is highlighted with a number #a1/#a3 in each of the dia-

grams.

Do the same for Rear wall & Front wall later.

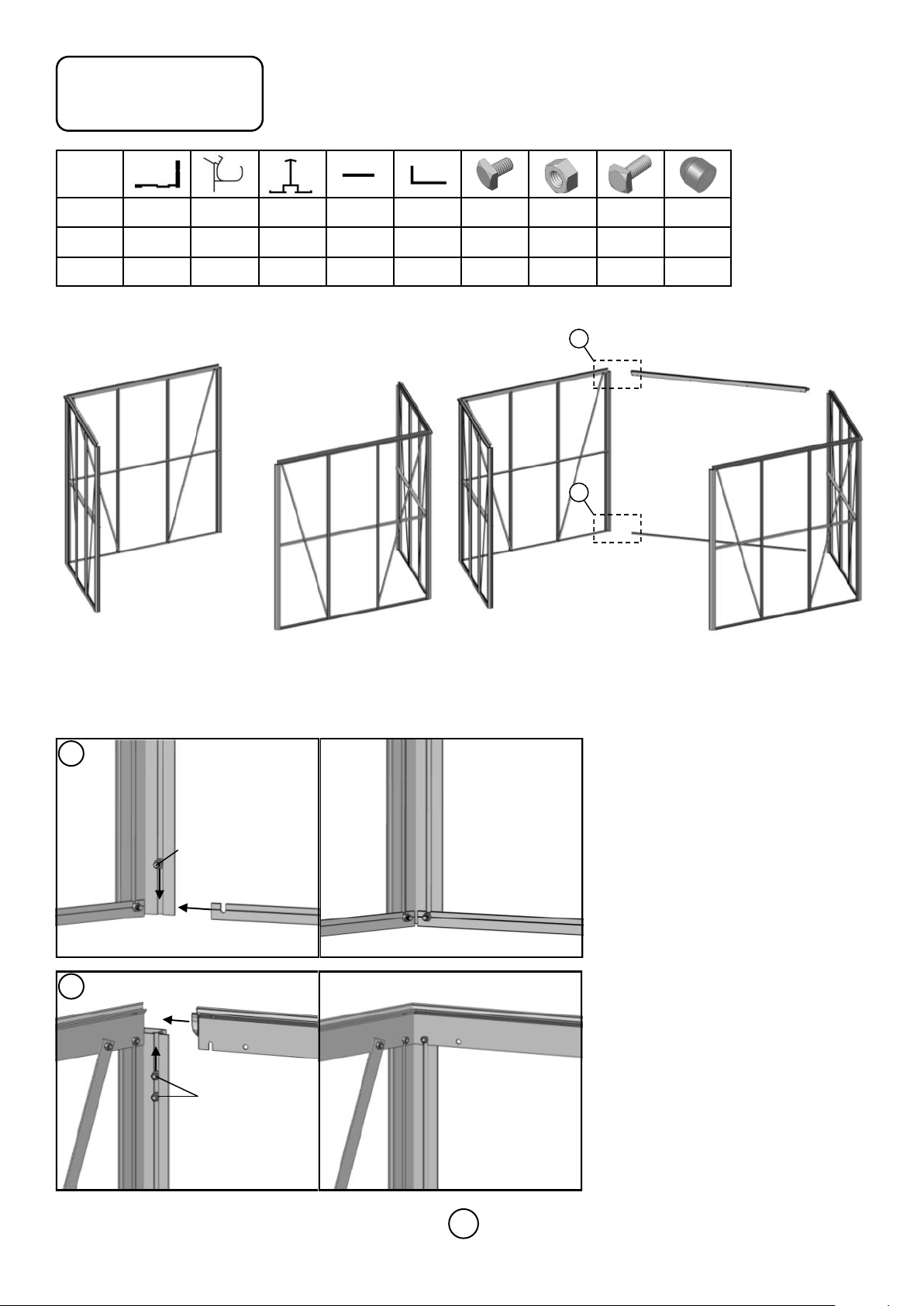

JOINING TWO SIDE WALL SECTIONS TOGETHER 1

------REAR WALL

Use the gutter #7909 and sill #7023 and side horizontal bracing bar # 7912 to join two side wall together

on rear wall, It is a good idea to tie some step ladders to the sides to support them if you do not have

anyone to hold them for you.

JOINING TWO SIDE WALL SECTIONS TOGETHER 2

------ FRONT WALL

Use the gutter #7907 and sill #7931 to joining two side wall together on front wall.

IMPORTANT: Door post #7607 should connect gutter #7907 and sill #7931 in central hole, the other two

holes beside of #7607 were used for hinged door only, this is sliding door greenhouse, so use central

holes of gutter #7907 only.

The door track support #7937 height will be exactly below the gutter #7907.

ROOF

Assemble 6 roof corner bars #7915 on hexagonal roof bracket #7992 . Please note #7915 overlap bracket

by distance of 42 mm. tighten all bolts.

Then lift the assembly onto the roof, Herein you should use step ladders. Loosely Connect the roof corner

bars to the eaves at all 6 corners.

Please note: You need to insert an extra bolt into each roof corner bar either side of vent hinge beam

#7922.

Connect 3 roof vent hinge beam #7922 to roof corner bar with joining plate #m3.

Join 6 roof glazing bars #7919 between the hexagonal roof bracket #7992 and the center of vent hinge

beam #7922. Please note: #7919 overlap bracket by distance of 24 mm at the one end, and connected

vent hinge beam by joining plate #m3 at the another end.

10

Join 12 short roof glazing bar #7920 between vent hinge beam #7922 and eave. At this stage you need to

decide where your roof vent are positioned so that you could insert an extra bolt into #7920 glazing bar

either side of a vent opening.

Assemble the outer hexagonal ridge cone #7994 over the assembled profiles on hexagonal bracket, using

long bolt #a24, spacer #7991, open-close disc #7993 and locknut #a25.

DOOR ATTACHMENT

The door track support #7937 height will be exactly below the gutter #7907, it could be adjusted also.

Bracket #m13 was used to support door track #7936 on both ends. It’s used to connect door track #7936

and gutter #7907, you should drill a hole on gutter #7907 by using a drill of diameter of 7mm.

GLAZING

For roof glazing, when glazing panels under hexagonal ridge cone (assembled already), PVC capping

could be started to push in from middle upper area, then slid to the top area of panels.

Also for #XE & #XF roof panels, We should push pre-cut 712mm length PVC capping bars in place

firstly, the PVC tilted & trimmed end touch the edge of roof corner bar. let them no gap to avoid wa-

ter leaking. and then push another two 1348mm and 1508mm length PVC capping bars on both sides,

slid from middle upper area to top area also.

For glass glazing, on the side walls, the single sided adhesive foam goes longitudinally over the green-

house frame, the glass just sits directly onto the aluminium cills. Two glass fixing clip holding the glass on

top in order not to let glass fall down. Remove the white paper on the foam before it gets wet as it is diffi-

cult to remove, i.e. it comes off in small pieces.

Layout the bar capping around the building like a sundial checking that all is present and correct. You

can also place the roof capping in the gutters so they are closer to hand. It is a good idea to glaze two

roof sections first to ensure the building is square followed by two side sections to ensure the building

isn't leaning. Make sure the building is square and level before you undertake the glazing and make sure

that you do not leave the building part glazed to prevent wind damage.

FINISHING TOUCHES

Now that the main body of the structure is complete you can add: downpipe fittings and roof corner bar

end cover #p10. Use the silicone to seal between the gutter sections. The downpipe bracket #p15 are at-

tached by carefully using #a18 self-drilling tapping screws which will bore into aluminium or plastic. The

water outlet jointer #p11 edge should be trimmed firstly to match the gutter hole better.

ANCHORING DOWN

Now that the greenhouse is finished and the door is operating without interference you need to anchor

the building down using 2” rawl plugs and screws. Use a 8mm masonry bit in a hammer drill to create

the holes through the M5 base brackets.

11

# 7901 7607 7023 7908 7909 7910 7912 a1 a2 a3 a20

Size 1922 1922 2179 2237 2237 2033 2167 M6x10 M6 M6x15 -

QTY 342114224 32 832

Package 1

Package 2

Side wall

1

7901

7909

7607

7023

7910

7910

7912

2

3

4

56

78

9

10

12

11

In Package 1 & Package 2

7023

7901

7901

7910

7910

7607 7607

7607

7912

7908

123

7901

7023

a3/a2 a3/a2 a3/a2

7023

7910

7607 7901

7023 7023

12

Side wall

456

78

9

10

11

12

7901

7912

7912

7910

7912

7607

7912

7910

7912 7912

7901

7901 7910

7909 7909

7607

7909 7908

7901

7910 7910

7909 7908

13

Rear wall

# 7023 7909 7607 7910 7912 a1 a2 a3 a20

Size 2179 2237 1922 2033 2167 M6x10 M6 M6x15 -

QTY 1122112 16 416

2

7909

7023

2

1

7909

a1/a2

In Package 2

—— Join Side wall together

1

a3/a2

7023

14

345

678

34

567

8

7023

7909

7607

7910 7910

7912

7909

7910

7901

7909

7607

7901

7912 7912

7912

7910

7912

7607

7023

7910

7607

a3/a2

Rear wall

7607

15

Front wall

# 7907 7931 7607 7945 7936 7937 a1 a2 a3 a20

Size 2237 2179 1922 554 2139 1097 M6x10 M6 M6x15 -

QTY 11221112 16 416

7907

7931

1

1

2

7907

a1/a2

In Package 2

—— Join Side wall together

2

7931

a3/a2

4

7

8

7607

7931

7607

6

5

7945 7945

7937

7936

16

Front wall

Section View

7937

7936

a1/a2

3

7936 7937

7945

7901

456

78

7937

7907

7607

7937

7907

7607

7607

7945

7607

7931

a3/a2

17

Roof

# 7915 7919 7920 7922 7991 7992 7993 7994 m3 p10 a1

Size 2335 1348 686 1472 81 -----M6x10

QTY 6612 6111118 690

# a2 a24 a25 a20

Size M6 M6x110 M6-L -

QTY 90 1190

7915

7915

7915

7992

12

7915

7992

42mm

7915

1

2

7992

7915

In Package 3

7915

7915 7915

18

Roof

34

8

5

7915 7915

7915

7920

7915

7920

7919 7919

7919

7919

7919

7919

7920

7920

7920

7920

7920 7920

7922

7922 7922

34

5

6

8

7992

7919

7992

7919

24mm

7920

7919

7922

m3 7922

7915

m3

7920

7922

7915

7920

7922

7915

7920

7920

7922

7

6

7922

7920

7

19

99

a24

a25

7991

7992

7993

7994

Roof

10

10

p10

7915

open close

20

Vent

# 7053 7923 7055 7924 7057 7067 a1 a2 a4 a7 a10 p3 a20 p11

Size 739 718 701 400 300 -M6x10 M6

Φ3.9x8

M4x8 M4 ---

QTY 11121266222264

1

23

7053

7918 7918

23

7918

7053

7053

7067

a7

a10

1

7923

7924

7924

4

4

7923 7924

In Package 4

This manual suits for next models

1

Table of contents

Other Infloria Greenhouse Kit manuals

Popular Greenhouse Kit manuals by other brands

Systems Trading Corporation

Systems Trading Corporation Clear View Assembly instructions

Norfolk Greenhouses

Norfolk Greenhouses BCPOSW1915+G Assembly instructions

Robinsons

Robinsons Victorian Ratcliffe 8 Assembly instructions

Vitavia

Vitavia FLORA 2500 Assembly instructions

Deuba

Deuba 4250525324136 instructions

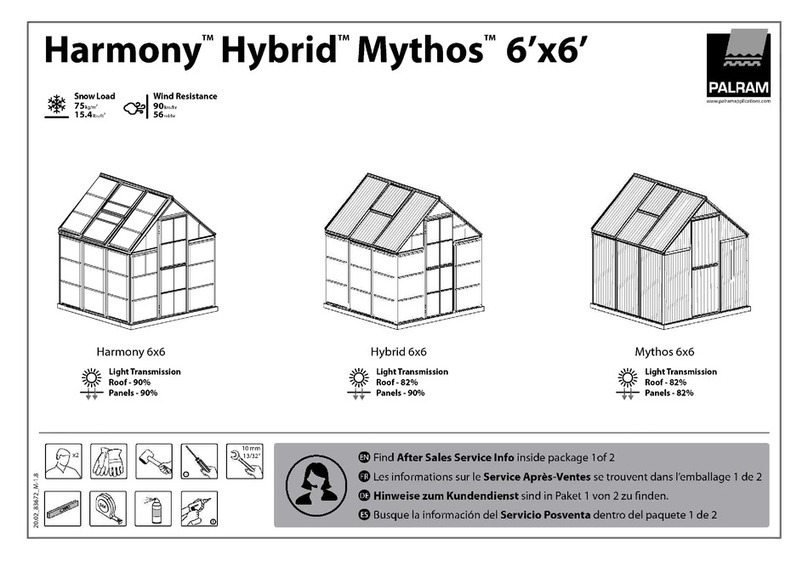

Palram

Palram CANOPIA HARMONY 6x6 manual