Solid SmartScan50 Installation and operating instructions

________________________________________1 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

Application Note

SmartScan50

Volume and Custom Flume

Configuration

Version 1.1

June 2011

This document contains proprietar information that is the sole propert of

Solid

Applied

Technologies td. The document is submitted to the recipient for his use onl . B receiving

this document; the recipient undertakes not to duplicate or to disclose, in part or the

whole, an of the information contained herein; to an third part ; without a-prior

written permission from Solid Applied Technologies td.

________________________________________2 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

Table of Contents

1. SCOPE .................................................................................................................................................. 3

2. OBJECTIVES ......................................................................................................................................... 3

3. METHOD FOR MEASURING VOLUME ................................................................................................... 3

4. MANUAL INSERTION OF STRAPPING TABLE .......................................................................................... 5

5. SEMI-AUTOMATIC INSERTION OF THE STRAPPING TABLE .................................................................... 6

6. LOOP-CURRENT CONFIGURATION FOR VOLUME .................................................................................. 8

7. CONFIGURING SPECIAL VESSEL SHAPES ............................................................................................... 9

8. WEIGHT CALCULATIONS ...................................................................................................................... 9

9. FLOW MEASUREMENT OF CUSTOM FLUME ....................................................................................... 10

10. LOOP-CURRENT CONFIGURATION FOR CUSTOM FLUMES ................................................................ 12

APPENDIX A: VOLUME CALCULATIONS .................................................................................................. 13

________________________________________3 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

1. SCOPE

This document describes the configuration procedure of SmartScan50 unit for volume measurement

and for flow measurement in custom flumes. The document should be read jointl with the user manual

of SmartScan s stems.

2. OBJECTIVES

Familiarize the user of SmartScan50 with:

•Configuration methods for making volume and flow measurements.

•Configuring volume measurements using manual insertion of strapping tables.

•Configuring volume measurements using semi-automatic insertion of strapping tables.

•Setting 4-20mA configurations for volume and for custom flow measurements.

•Weight calculations using the “K factor”.

3. METHOD FOR MEASURING VO UME

Ultrasonic level sensors measure DISTANCE between the sensor and surface of the target. If distance

between sensor and bottom of tank is known (TOTAL HEIGHT), SmartScan50 can also calculate LEVEL.

For VOLUME, the user should configure SmartScan50 to map between LEVEL and VOLUME.

SmartScan50 provides for a mapping table (also known as strapping table) of up to 24 points. The user

enters a minimum of 8 points and for each point the user defines LEVEL and corresponding VOLUME.

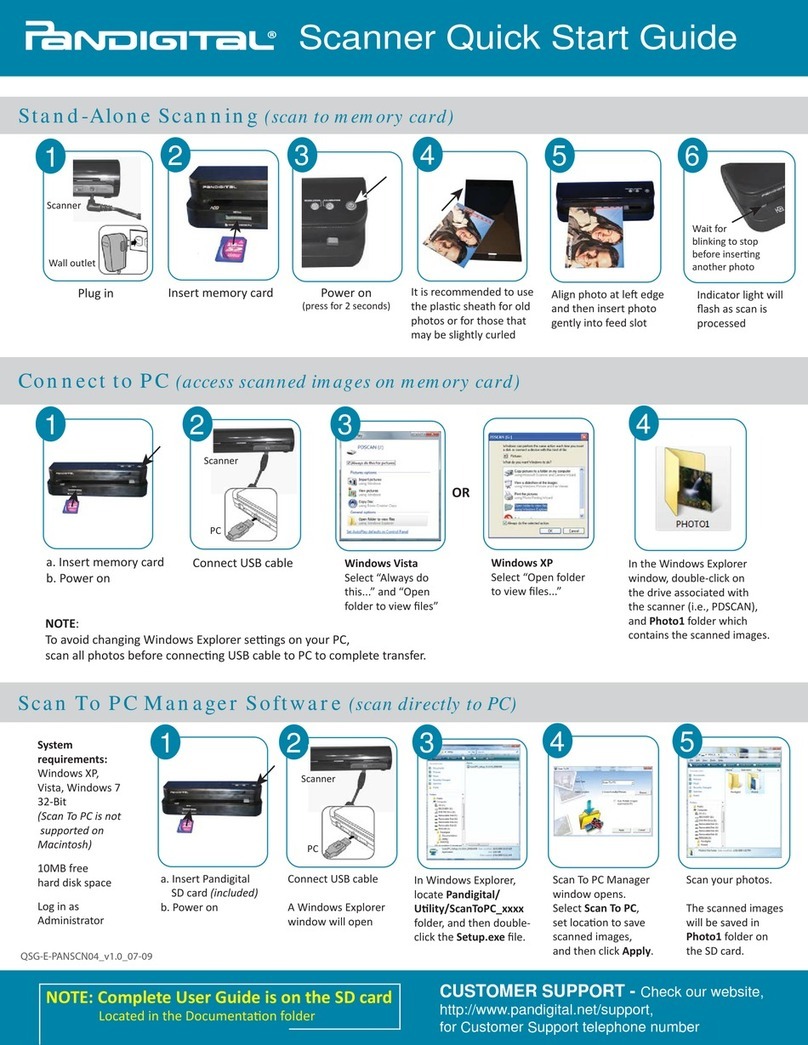

The drawing below illustrates the insertion of LEVEL points into the strapping table:

TOTAL HEIGHT

10 meter

P8 Level = 8 meter Volume = 9600 Liter

P7 Level = 7 meter Volume = 8400 Liter

P6 Level = 6 meter Volume = 7200 Liter

P5 Level = 5 meter Volume = 6000 Liter

P4 Level = 4 meter Volume = 4800 Liter

P3 Level = 3 meter Volume = 3600 Liter

P2 Level = 2 meter Volume = 2400 Liter

P1 Level = 1 meter Volume = 1200

Liter

Sensor

________________________________________4 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

The strapping table is set b entering point b point from the low level and up. Each point involves three

main steps and step 3 consists of two entries:

Step

Description

Example

Explanation

1

Point

number

4

Point number 4

2

LEVEL measured from bottom of tank

004.000

Level is 4 meters

3

VOLUME for this LEVEL

4800.5

Desired volume is 4800.5 Liters

3.1

Truncated part of the VOLUME

004800

Truncated part is 4800

3.2

Decimal part of the VOLUME

800.500

Entr includes 3 rightmost digits

from the truncated part.

Note that in step 3.2, the user re-enters the three rightmost digits which have been entered in step 3.1

and one additional digit to the right of the decimal point. The strapping table that corresponds to the

drawing is now:

Point

evel

Volume step 1

Volume step 2

1

00

1

.000

001200

200.000

2

00

2

.000

002400

400.000

3

00

3

.000

003600

600.000

4

00

4

.000

004800

800.000

5

00

5

.000

006000

000.000

6

00

6

.000

007200

200.000

7

00

7

.000

008400

400.000

8

00

8

.000

009600

600.000

Important n

ote

s

:

1. Values are entered as LEVEL not DISTANCE.

2. First point indicates bottom of the vessel with minimum volume. As ou add more points to the

strapping table, the level increases corresponding to increasing volume.

3. No need to add a point with a LEVEL zero to represent the bottom of vessel with zero volume.

4. It is forbidden enter an zero value of volume, the first volume value should be greater than zero.

5. It is forbidden to enter a level value which is greater than TOTAL HEIGHT.

6. The thickness of the “slices” does not need to be equal. On the contrar , for different vessel shapes it

is reasonable to define thinner slices where the volume does not increase linearl .

7. Minimum of 8 strapping points is required.

________________________________________5 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

Setting SmartScan50 to VOLUME measurement:

From the main configuration menu set the following parameters:

• T pe of application – Set to Level.

• Units – Set our own units (i.e. meter, inch, feet, etc.).

• Tank height – Set vessel height bottom to sensor.

Do not define the 4-20mA current values et.

From the “additional configuration” menu set the following parameters:

• Pr.0 – Set Ind1 for volume measurement.

• Pr.1 or Pr.2 – Define strapping table.

With SmartScan it is possible to define the strapping table in two methods:

•Manual insertion of strapping table: The user enters both LEVEL and VOLUME values.

•Semi-automatic insertion of strapping table: SmartScan measures LEVEL and the user onl

enters the corresponding VOLUME value.

Loop current values 4-20mA are set after strapping table is configured. SmartScan50 is read for volume

measurement after exiting the configuration menu.

4. MANUA INSERTION OF STRAPPING TAB E

Use “manual insertion of strapping table” when:

•There is a fixed known ratio between LEVEL and VOLUME for our vessel.

•The vessel is of standard shape such as c linder or cone or and it is eas to map LEVEL to VOLUME.

Refer to appendix A for some examples.

•It is not possible to use the semi-automatic mode.

Manual insertion of strapping table is performed with the additional menu configuration - Pr.1.

Important n

ote

s

:

It

is recommended to map vessel interferences using Scan

Distance option

. R

efer

to the User Manual of SmartScan for details.

________________________________________6 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

When entering Pr.1, SmartScan50 will prompt with the first point, P1. For each point the user should

define the required LEVEL and corresponding VOLUME.

For example, for the vessel discussed above:

P1 <Ent>

evel:

Volume, first screen:

Volume, second screen:

001.000 <Ent>

001200 <Ent>

200.000 <Ent>

P2 <Ent>

evel:

Volume, first screen:

Volume, second screen:

002.000 <Ent>

002400 <Ent>

400.000 <Ent>

P3 <Ent>

evel:

Volume, first screen:

Volume, second screen:

003.000 <Ent>

003600 <Ent>

600.000 <Ent>

…

P8 <Ent>

evel:

Volume, first screen:

Volume, second screen:

008.000 <Ent>

009600 <Ent>

600.000 <Esc>

Pressing <Esc> after the eighth point, indicates that this point is the last of the table.

5. SEMI-AUTOMATIC INSERTION OF THE STRAPPING TAB E

Use “semi-automatic insertion of strapping table” when:

•The ratio between LEVEL and VOLUME for our vessel is not known.

•The vessel is of unique shape and it is complicated or impossible to map between LEVEL and

VOLUME.

________________________________________7 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

Semi-automatic insertion of strapping table involves a calibration phase using a controlled filling process

and should be performed after interferences were identified and mapped using the “Scan Distance”

technique.

The procedure for semi-automatic insertion of mapping table is as follows:

1. Start with an almost empt vessel or at the first point where the contained volume is known.

2. In semi-automatic mode, the level is measured and calculated automaticall b SmartScan50. Accept

the displa level b pressing <Ent>.

The level measurement ma be incorrect. If so, press <Next> to search for a next level target.

3. Enter the volume value for this level.

4. Fill the tank with known volume value. As a result the level of the material within the vessel will be

increased.

5. For a new point, the unit will calculate the new level.

6. For the new point enter the new volume value.

7. Repeat steps 4 through 6 until the last point is entered.

This method provides more accurate volume calculations when compared with the manual method, but

entails slower calibration due to the need for filling the vessel with known quantit per each point.

This method is activated from Pr.2 of the “Additional menu”.

For example, for the same vessel discussed above, the process is as following:

Important n

ote

:

It is recommended that strapping table points will

not overlap scan distance points

.

Keep a gap of at least 40 cm between the nearest strapping table point and interference. For

example: if there is an interfering echo at 2meter level, use “semi-automatic” level points at 1.6

meter and/or 2.4 meter.

________________________________________8 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

P1 <Ent>

evel:

Volume, first screen:

Volume, second screen:

Searching

001.000 <Ent>

001200 <Ent>

200.000 <Ent>

P2 <Ent>

evel:

Volume, first screen:

Volume, second screen:

Searching

002.000 <Ent>

002400 <Ent>

400.000 <Ent>

P3 <Ent>

evel:

Volume, first screen:

Volume, second screen:

Searching

003.000 <Ent>

003600 <Ent>

600.000 <Ent>

…

P8 <Ent>

evel:

Volume, first screen:

Volume, second screen:

Searching

008.000 <Ent>

009600 <Ent>

600.000 <Esc>

Pressing <Esc> after the eighth point indicates that point eight is the last point in the strapping table.

6. OOP-CURRENT CONFIGURATION FOR VO UME

Once the user configures SmartScan50 to volume and sets the strapping table points, it is possible to

configure 4mA and 20mA parameters to represent volume values.

The default value of volume is set automaticall based on the strapping table. The 4mA indication will be

set to the first point (minimum value) and the 20mA indication will be set to the last point (maximum

value).

________________________________________9 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

For example, based on the strapping table of the previous examples, 4mA and 20mA will automaticall

be configured as follows:

• 4mA – 001200

• 20mA – 009600

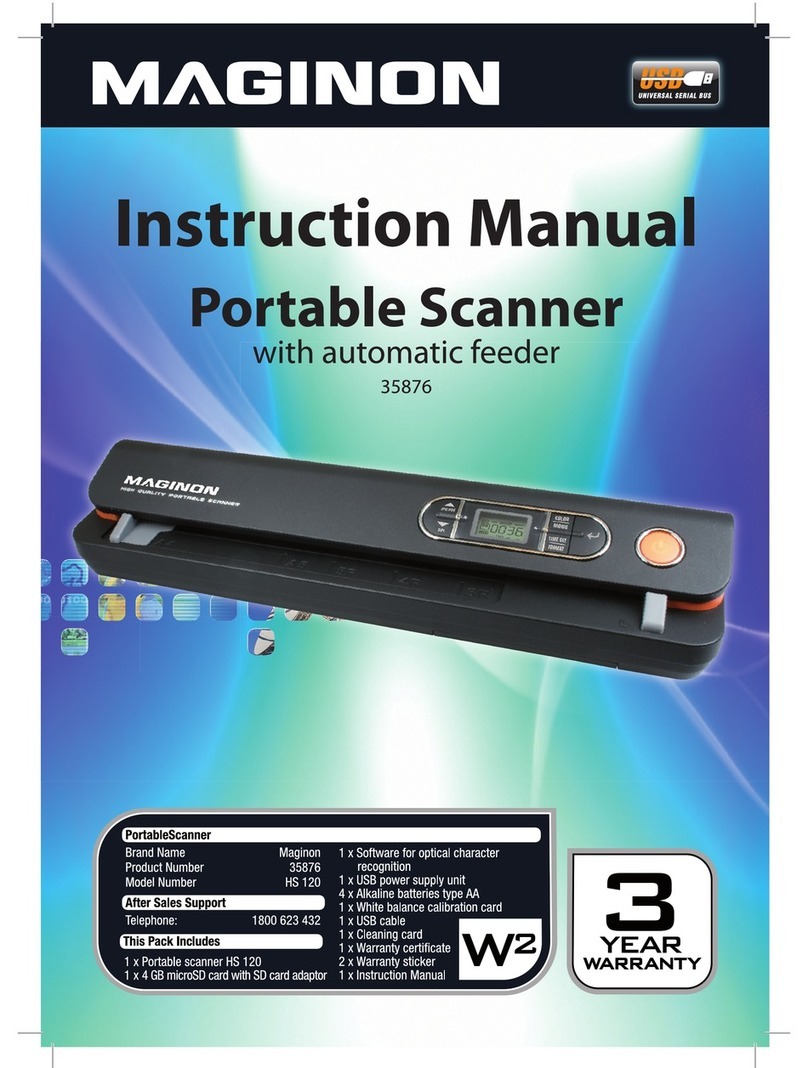

7. CONFIGURING SPECIA VESSE SHAPES

For vessels which are of odd shapes, VOLUME is not alwa s linear related with LEVEL. The user should

define the “slices” of the strapping tables unevenl and include at least one point for each irregular

mapping.

An example of such “slicing” is illustrated in the next figure.

In this drawing, one can see that a fixed deviation in LEVEL at the vessel bottom, will map to unequal

VOLUME deviations. At higher levels of the vessel the ratio between level and volume is fixed.

In this case, it is better to define more “slices” at the bottom of the vessel. The same guidelines as

defined in previous sections appl to this case as well.

8. WEIGHT CA CU ATIONS

Important n

ote

:

It is recommended to use all 24 strapping t

able points for better accurac .

________________________________________10 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

In some applications the user would like to have the WEIGHT value of the vessel content instead of

VOLUME. Weight can be calculated if both VOLUME and specific gravit densit of the material are

known.

Let the measured volume be “Y” and the material gravit densit be ‘K’, then the weight “X” can be

calculated as follows:

Weight = Specific Gravit Densit * Volume

X = K * Y

The “K Factor” is defined Pr.3 of the “additional menu”. The default value of “K Factor” is 001.000.

9. F OW MEASUREMENT OF CUSTOM F UME

When custom flume measurements are required, the user should configure SmartScan50 to map

between FLOW and corresponding LEVEL.

SmartScan50 provides for a 24 point mapping table (also known as strapping table). For each point the

user should define the level and the corresponding flow for this level. The drawing below illustrates the

LEVEL to FLOW mapping.

TOTAL HEIGHT

________________________________________11 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

The strapping table is set as follows:

Step

Description

Example

Explanation

1

Point number

4

Point number 4

2

LEVEL measured from bottom of flume

000.400

Level is 0.4 meters

3

FLOW for this LEVEL

4800.5

Desired volume is 4800.5 Liters

3.1

Truncated part of FLOW

000480

Truncated part is 480

3.2

Decimal part of FLOW

480.000

Entr includes 3 rightmost digits

from the truncated part.

Note that the last three digits entered in the previous step, are displa ed before the decimal point and

that the user can enter one digit after the decimal point. The strapping table that corresponds to the

above drawing is as follow:

Point

evel

Flow first step

Flow second step

1

0.1 meter

000120

1

20.000

2

0.2 meter

000240

240.000

3

0.3

meter

000360

360.000

4

0.4 meter

000480

480.000

5

0.5 meter

000600

600.000

6

0.

6

meter

000

72

0

720

.000

7

0.

7

meter

000

840

840

.000

8

0.

8

meter

000

960

960

.000

Important n

ote

s

:

1. Values entered are in LEVEL for, not DISTANCE.

2. First point indicates bottom of the flume and minimum flow (it should be the first point value and

not zero level which indicates empt flume). As ou add more points to the strapping table, the level

increases and so is the flow.

3. The first point can be an value greater than zero.

4. Thickness of strapping table “slices” does not need to be even. For var ing flume shapes it is

reasonable to define thinner slices where the flow does not increase linearl .

5. A minimum of 8 strapping points is required.

6. No LEVEL value should be greater than TOTAL HEIGHT.

________________________________________12 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

Setting SmartScan50 for custom flume measurements:

From the main configuration menu set the following parameters:

• T pe of application – set to Flow.

• Units – choose our own units (i.e. M3/h, GPM).

• Tank height – set to distance from sensor face to bottom of flume

Do not define 4-20mA current values et.

From the “Main menu” set the following parameters:

• PARSH.FLUM

• For custom flume use 0.E01 (for additional information please check SmartScan User Manual)

After defining a strapping table in one of the methods mentioned above, set 4mA and 20mA values as

described in the user manual.

The device is read for custom flume measurement after exit from the configuration menu.

10. OOP-CURRENT CONFIGURATION FOR CUSTOM F UMES

Once the user configures the SmartScan50 to custom flume and sets the strapping table points, it is

possible to configure 4mA and 20mA parameters for FLOW values.

The value of FLOW should be entered manuall according to the strapping table. The 4mA indication

should be configured at the first point (minimum value) and the 20mA indication should be configured

at the last point (maximum value).

For example base on the strapping table in the table above, 4mA and 20mA should be configured as

following:

• 4mA – 000120

• 20mA – 000960

Important n

ote

s

:

20mA default value is 55490

.

________________________________________13 of 13 _____________________________________

Solid Applied Technologies Ltd. www.solidAT.com

Ashkelon 78170, Israel Tel: +972 (8) 674 4051

APPENDIX A: VO UME CA CU ATIONS

When the vessel has a c lindrical or conical standard shape, it is eas to calculate the volume of the

vessel with mathematical volume equations. The following figure illustrates c lindrical and conical vessel

volume calculations.

Using the equations, it is eas to calculate the height-to-volume mapping. For example, assume a

c linder shaped vessel with 2-meter radius and 8 meter height. The following table defines the height-

to-volume mapping:

Table of contents