solidat MicroScan User manual

MicroScan

User Manual

MicroScan User’s Manual

ii

Important Notice

This manual is delivered subject to the following conditions

and restrictions:

)This manual contains proprietary information belonging

to Solid Applied Technologies Ltd. Such information is

supplied solely for the purpose of assisting explicitly and

properly authorized users of MicroScan.

)No part of its contents may be used for any other

purpose, disclosed to any person or firm or reproduced

by any means, electronic or mechanical, without the

express prior written permission of Solid Technologies

Ltd.

)The text and graphics are for the purpose of illustration

and reference only. The specifications on which they

are based are subject to change without notice.

)Information in this document is subject to change

without notice. Corporate and individual names and

data used in examples herein are fictitious unless

otherwise noted.

Copyright 2004. All rights reserved.

MicroScan is a trademark of Solid Applied Technologies Ltd.

Other company and brand products and service names are

trademarks or registered trademarks of their respective

holders.

Date Revision Software Version Catalog Number

Feb.2004 1.5 4.09 English 6800200

Safety Guidelines

iii

Safety Guidelines

)MicroScan must be installed, connected and

operated according to the instructions in this

Manual.

)If installed incorrectly or used for applications for

which it is not intended, application-related dangers

may arise.

)Only qualified personnel are authorized to install

and operate MicroScan.

)Do not open the MicroScan unit. If the unit is opened,

the warranty is null and void.

)Modifications and repairs to MicroScan are

permissible only when the manufacturer expressly

approves them.

MicroScan User’s Manual

iv

Table of Contents

Chapter 1: Introducing MicroScan............................................... 1

MicroScan Specifications .............................................................................. 3

Measuring Ranges................................................................................. 3

Mechanical Specifications .................................................................... 4

Electrical Specifications ........................................................................ 4

MSU (MicroScan Setup Unit) Specifications ................................................. 4

Sensor Recommendations..................................................................... 5

Chapter 2: Installing MicroScan................................................... 6

Precautions ................................................................................................... 6

Installing MicroScan...................................................................................... 7

Installing MicroScan on Threaded Flange/Thread-Free Flange .............. 8

Installing MicroScan via Extension Pipes .............................................. 9

Connecting the MicroScan to a Power Cable ..................................... 11

Connecting the MicroScan to the MSU .............................................. 12

Non-Intrinsically Safe Connections ..................................................... 13

Chapter 3: Setting Up and Calibrating MicroScan ..................... 15

Using MicroScan Functions......................................................................... 18

Resetting MicroScan.................................................................................... 21

Entering the Tank Height Value .................................................................. 22

Defining Interfering Signals......................................................................... 24

Configuring 4 mA Current Output .............................................................. 27

Configuring 20 mA Current Output ............................................................ 30

Selecting Low/High Dynamic Speed (Open Channels and Liquid Only)..... 32

Table of Contents

v

Defining Working Area ............................................................................... 33

Selecting Distance or Level Display ............................................................ 35

Restoring the Default Settings ..................................................................... 37

Shifting the Blocking Distance..................................................................... 38

Verifying the Version Number..................................................................... 39

Defining 22mA Signal Error Messages ........................................................ 39

Chapter 4: Troubleshooting MicroScan ......................................41

22mA Signal Error Messages ............................................................... 42

Index..........................................................................................44

MonoScan User’s Manual

vi

Table of Figures

Figure 1: Front View of MicroScan..................................................................... 2

Figure 2: Side View of MicroScan ...................................................................... 2

Figure 3: Threaded Flange/Thread-Free Flange Mounting .................................. 8

Figure 4: MicroScan Power Connections ......................................................... 11

Figure 4.1: MSU Communication Connector ................................................... 12

Figure 5: Non-Intrinsically Safe Positive Ground Connection........................... 13

Figure 6: Non-Intrinsically Safe Negative Ground Connection......................... 13

Figure 7: MSU Mounted on the MicroScan Unit .............................................. 16

Figure 8: MicroScan Functions Menus ............................................................. 17

Figure 9: MSU Display and Function Buttons .................................................. 18

Figure 10: Scan Distance Process..................................................................... 24

Figure 11: Working Area.................................................................................. 33

Introducing MicroScan

CHAPTER 1

1

Chapter 1

Introducing MicroScan

MicroScan is an ultrasonic, non-contact level measurement

device of mono-block construction (combing the sensor and

electronic components in a single unit). MicroScan provides

reliable and precise level measurement results of both liquids

and solids.

It can be used for the following measurement tasks:

)Liquid tanks with calm surfaces

)Solids tanks that are dust-free

MicroScan has a range of up to 5 m (16.5 ft) with an

accuracy of approx. 0.25% within that range.

MicroScan is available in two configurations:

)MicroScan with no display and no keyboard ("Blind" unit)

)MicroScan with optional display but without keyboard

The following models are available for each configuration:

)MicroScan L for liquids

)MicroScan S for solids

MicroScan User’s Manual

2

The following diagrams show the front and side views of

MicroScan, and its dimensions:

Figure 1: Front View of MicroScan Figure 2: Side View of MicroScan

Introducing MicroScan

CHAPTER 1

3

MicroScan Specifications

Accuracy 0.25%* of measuring range

Resolution 1 mm (0.04")

Beam angle 5°@ 3db point

Ambient temp’

compensation

Automatic

* 0.25% or 1.25cm whichever is greater.

Measuring Ranges

MicroScan L for liquids 0.25 m — 5 m

0.8 ft — 16.4 ft

MicroScan S for solids 0.25 m — 3.5 m

0.8 ft — 11.5 ft

Mechanical Specifications

Enclosure IP 65, mono-block construction.

Plastic enclosure: ABS+UV

Wetted parts Sensor body: PolyProp. PVDF, optional.

Stainless Steel for Liquid model; Coated

Aluminum for Solid/Liquid model.

Operating

temperature

-40°C to + 70°C

(-40°F to +158°F)

Mounting 2" BSP or 2" NPT

MicroScan User’s Manual

4

Mechanical fitting Conduit connection M20x2.5 or

1/2" NPT

Operating pressure Atmospheric

Dimensions 22.3 x 11 x 4.5cm (8.7 x 4.3x 1.7in)

Weight Approx. 0.75Kg (1.65lb)

Electrical Specifications

Optional Display LCD, four digits, seven segments

Operation Four push buttons

Loop current 4 — 20 mA, 750 Ω@ 28 VDC

Supply 12 — 28 VDC (CE certified)

Certificates CE — EMC

MSU Specifications

Display LCD (4 digits — 7 segments)

Keyboard 4 buttons

Cable 0.60m (23.6in)

Housing material ABS + UV

Dimensions 9.5X11X2.5cm (3.7X4.3X0.98 in)

Weight 0.25 Kg (0.55 lb)

Certifications CE

Introducing MicroScan

CHAPTER 1

5

Sensor Recommendations

Material Description

Stainless Steel For liquid applications.

High resistance in highly

acidic and alcoholic

environments.

Less sensitive to echoes (in

Solid applications).

Coated Aluminum Designed for complex

environments with

problematic echoes, such as

non-conductive vapors, solids

or liquids.

Good performance in

problematic applications.

High sensitivity to echoes.

MicroScan User’s Manual

6

Chapter 2

Installing MicroScan

Precautions

)Ensure that MicroScan is mounted in an area that meets the

stated temperature, pressure and technical specifications.

)Ensure that high-voltage sources or cables are at least 1 m away

from the sensor and its cable.

)Use a conduit connector that is either 1/2" NPT or M20x2.5

compatible (depending on the MicroScan model you have), to

ensure the unit remains sealed.

)Use 26-16 AWG round wires for the MicroScan’s electrical

connections.

)Ensure that cables are routed correctly and tightened along walls

or pipes.

)Installation and operation of this product should be performed,

according to the Product User Manual and Product Certification,

otherwise the use of this product is prohibited.

Installing MicroScan

CHAPTER 2

7

Installing MicroScan

When installing MicroScan, ensure that it is:

)Mounted above the dead-zone area.

NOTE:

If the device enters the blocking distance (dead

zone), it will not measure correctly.

)Positioned at least 0.5 m (1.64 ft) away

from the tank walls.

)Perpendicular to the surface of the

target.

NOTE:

Even the slightest difference in angle may affect

echo quality.

MicroScan User’s Manual

8

)Placed as far as possible from noisy

areas, such as a filling inlet.

Installing MicroScan on Threaded

Flange/Thread-Free Flange

MicroScan is available in two thread types, 2" BSP or 2" NPT.

MicroScan can be installed with threaded-flange mounting or

with thread-free flange mounting, as shown below:

Figure 3: Threaded Flange/Thread-Free Flange Mounting

Installing MicroScan

CHAPTER 2

9

NOTES:

When installing a thread-free flange mounted unit, you will need a 2"

locking nut to secure the unit inside the tank.

When installing a threaded flange, ensure that it matches the MicroScan

threads.

¾To install MicroScan:

1Insert the threaded end of MicroScan into the aperture at

the top of the tank or pipe.

2Bolt MicroScan into place in one of the following ways:

)Threaded-flange mounting: Screw the unit into a

flange with a threaded 2" hole.

)Thread-free mounting: Place MicroScan in the flange,

and bolt it from within the tank with a 2" locking nut.

NOTES:

Tighten the nut by hand only. When tightening the nut, hold the

sensor housing (refrain from holding the MicroScan unit when

tightening the nut).Make sure that the seal is leak proof.

MicroScan User’s Manual

10

Installing MicroScan via Extension

Pipes

If the level of the measured surface falls within the dead-zone

area, you should use an extension pipe to mount MicroScan.

When using an extension pipe, ensure that:

)The sensor is positioned in the center of

the pipe.

)The pipe extension is parallel to the

side/tank walls.

)The internal pipe diameter is at least 3"

wide.

When installing the MicroScan with extension pipes, follow

these specifications:

Pipe Length Internal Pipe Diameter

0.50 m (1.64 ft) 3"

1 m (3.28 ft) 3"

NOTE:

It is always recommended to use interference signal feature (Pr.03)

to locate interfering signals when using an extension pipe.

It is highly recommended that the extension pipes material would

be PVC or Plastic and not Stainless Steel.

Installing MicroScan

CHAPTER 2

11

Connecting the MicroScan to a Power Cable

1Unscrew the four Allen screws from the MicroScan front door.

2Detach the front door from the MicroScan unit.

3Remove the rubber sealing from the conduit entry.

4Thread the power cable through the conduit entry.

5Remove the plastic shell from the power cable.

6Connect the +24VDC wire to Terminal 1, connect the

0VDC (GND) wire to Terminal 2 on the wiring block.

7Make sure that the terminals’ screws are properly fastened.

8Attach the front door to the MicroScan unit.

9Screw the four Allen screws to the plastic door.

Figure 4: MicroScan Power Connections

NOTE:

Make sure that the O-Ring of the MicroScan's front door is properly

positioned to maintain the unit sealed.

MicroScan User’s Manual

12

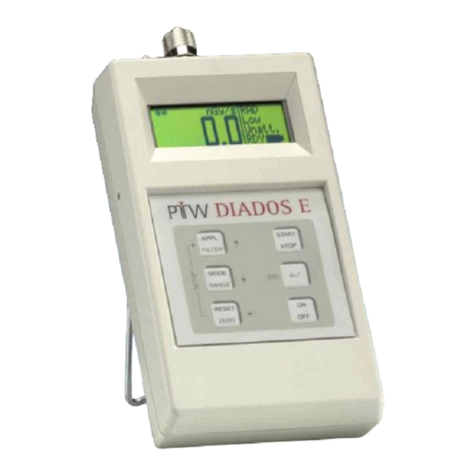

Connecting the MicroScan to the MSU

(MicroScan Setup Unit)

The MSU is an hand held device which enables you to

configure the MicroScan unit according to your application

requirements, quickly and simply. Once the MicroScan unit

configuration is completed, the MSU can be utilized to

configure other MicroScan units.

The MSU should be connected to the MicroScan unit after

connecting the unit to a power supply.

1Remove the plastic cap from the MSU connector located

on the MicroScan unit (the cap is chained to the

MicroScan unit).

2Remove the plastic cover from the MSU multi-pin

connector.

3Attach the MSU male connector to the female connector

on the MicroScan unit, located on its left side panel.

4Make sure that the connectors are in the right position

and properly attached.

5Rotate the plastic clasp on the MSU connector, half way

to the right, to ensure the connectors are firmly closed.

Figure 4.1: MSU Communication Connector

Installing MicroScan

CHAPTER 2

13

Non-Intrinsically Safe Connections

Figure 5: Non-Intrinsically Safe Positive Ground Connection

Figure 6: Non-Intrinsically Safe Negative Ground Connection

MicroScan User’s Manual

14

Power Supply and Load Resistance Recommendations

The following table specifies the recommended resistance

range for each power supply voltage (Non-Intrinsically Safe).

Power Supply

Voltage

Minimum Current

on Resistor

Maximum Current

on Resistor

12 V 0 Ω50 Ω

15 V 0 Ω220 Ω

24 V 41 Ω610 Ω

28 V 68 Ω820 Ω

Ripple/Noise Parameters Recommended for

the Power Supply

The following ripple/noise parameters are recommended for

the power supply:

)For less than 15 V: 75 mV p-p max

)For more than 15 V: 100 mV p-p max

Table of contents