SOLIDDRIVE SD1-XFMR-Ti Operating manual

SolidDrive

INSTALLATION & USE GUIDE

for SolidDrive SD1-XFMR-Ti

into walls and ceilings

INSTALLATION OF SOLIDDRIVE SD1 INTO WALLS

AND CEILINGS

GETTING STARTED WITH SOLIDDRIVE

WARRANTY

WARNING

SolidDrive SD1-XFMR-Ti Specications

Type

Construction

Dimensions

Weight

SolidDrive SD1 In-Wall and

In-Ceiling Mounting Bracket Specications

NOTE: When installed in Canada, this product must be installed in accordance

with the Canadian Electrical Code, C22.1, Part1.

Type

Frequency Response(Hz)

Recommended Amplier Power

Dimensions

Weight

UL Listing

Full Range Transducer

70 Hz to 15 kHz

10 Watts

2.28'' Diameter x 4.8'' Height

Mounting Plate 3.5'' Diameter

1.5 lb / .68 kg

1480 & 2043 Pending

Patented balanced cantilever spring bracket

Heavy duty, galvanized steel

12OC – 2.0'' H x 17.5'' W x 5.0'' D

16OC – 2.0'' H x 25.5'' W x 5.0'' D

24OC – 2.0'' H x 13.5'' W x 5.0'' D

1.0 lb / .45 kg

Experience Audio Perfection

REV-09-10-19

Induction Dynamics extensive line of audio

products makes it easy to create the ultimate

audio system, regardless of installation require-

ments. Induction Dynamics builds these products

with only the most select components and materi-

als; and utilizes numerous unique and proven

technologies.

SolidDrives, SolidDrive subwoofers, and A4 ampliers are guaranteed for 7 years

from date of purchase. Any misuses or modications to this equipment in any way

will void the warranty.

Read instructions prior to operating. To reduce the risk of re or electric shock, do

not expose this product to rain or moisture. Unplug prior to cleaning and clean with

a damp cloth. There are no user-serviceable parts in this product, please refer all

servicing to qualied personnel.

By utilizing these basic installation steps, you can install the

SolidDrive SD1-XFMR-Ti into walls and ceilings to create sound for

boardrooms, home theater, and distributed audio.

What’s included with the SolidDrive SD1-XFMR-Ti for installation

into walls and ceilings and what is supplied by the installer —

A SolidDrive SD1-XFMR-Ti consists of: One (1) SolidDrive

SD1-XFMR-Ti unit with included 10W transformer, suppplied with 5

hard wire leads and one duplex conduit connector. *Additional

mounting materials may need to be ordered with the SolidDrive

SD1-XFMR-Ti or supplied by the installer depending on the applica-

tion.

For drywall: For in-wall and in-ceiling installation, you will have

ordered one (1) or more SolidDrive SD1-XFMR-Ti’s and one (1) or

more patented acoustic in-wall mounting brackets (one (1) bracket

per SD1-XFMR-Ti), which comes with four (4) #8-32 x 5/16''

Phillips at head machine screws for mounting the drive to the

bracket. At the time of the order, you will also have specied

mounting bracket(s) in widths of 12OC, 16OC, or 24OC (ON CENTER

of wall studs or ceiling joists) for proper width. *Installation also

requires four (4) 1 3/8'' drywall screws and one (1) container of

3M® Super 77 Spray Adhesive (supplied by the installer).

EXISTING DRYWALL INSTALLATION NOTE:

For retrotting the SolidDrive SD1-XFMR-Ti into existing drywall

installations, it will be necessary to remove a portion of the existing

drywall before installation and to replace the drywall after the

SolidDrive SD1-XFMR-Ti is installed. Please refer to the instructions

marked with EXISTING DRYWALL for the steps necessary for the

type of installation. If installing the SolidDrive SD1-XFMR-Ti in new

construction, IGNORE the EXISTING DRYWALL steps.

www.soliddrive.com | 913.663.5600 | 10661 Rene St. | Lenexa, KS 66215

STEP 1

INSTALLATION INTO EXISTING DRYWALL

STEP 2

Attach the SolidDrive mounting bracket to wall studs or ceiling joists

STEP 3

Insert the SolidDrive into the bracket

STEP 4

Electrical connections

STEP 5

Apply adhesive to the drywall surface and base of the SolidDrive

STEP 6

EXISTING DRYWALL

Re-install rectangular cutout in wall

STEP 7

Install the new drywall

STEP 8

Equalize the SolidDrive sound system

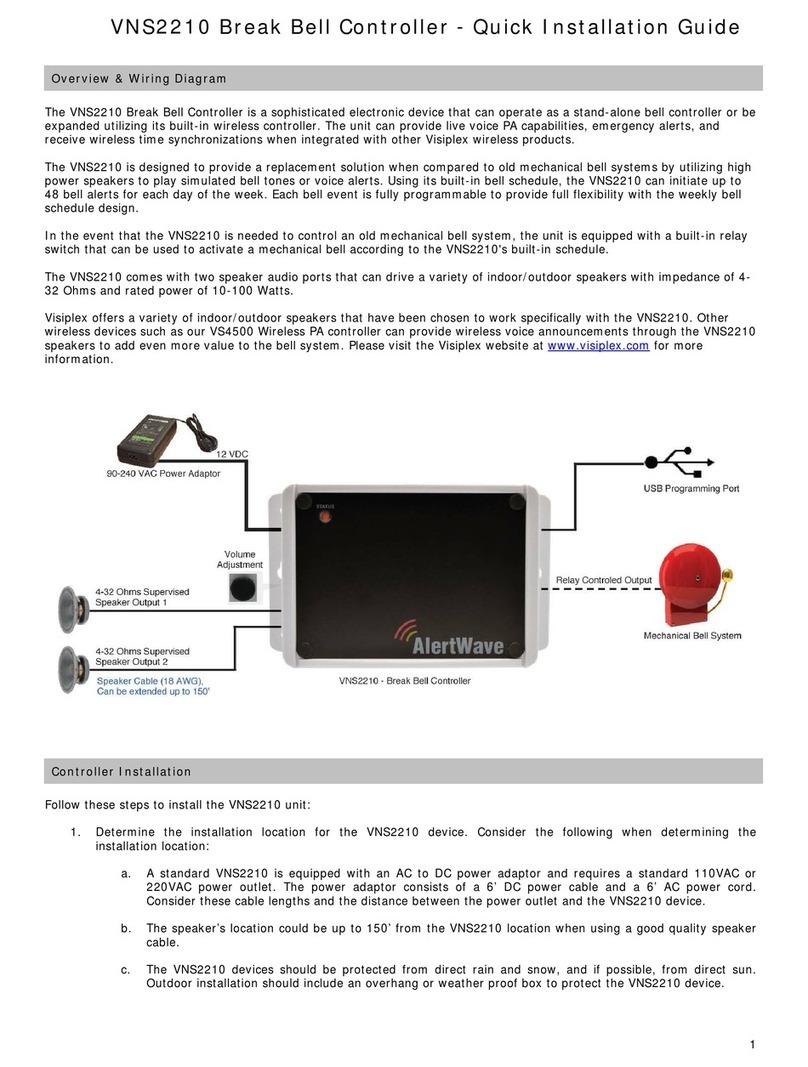

For installing the SolidDrive SD1-XFMR-Ti mounting bracket into existing

drywall, rst cut a rectangular opening in the drywall. The minimum

recommended opening size is approximately fteen inches tall and

beyond the width of the adjacent wall studs. This will help in attaching the

mounting bracket, feathering the drywall back in, and getting the drywall

to meet at the seams (Figure 1). This will allow proper distribution of sound

and the SolidDrive SD1-XFMR-Ti will function with optimum performance.

Figure 1

Cut an

opening large

enough to

install the

mounting

bracket to the

wall studs

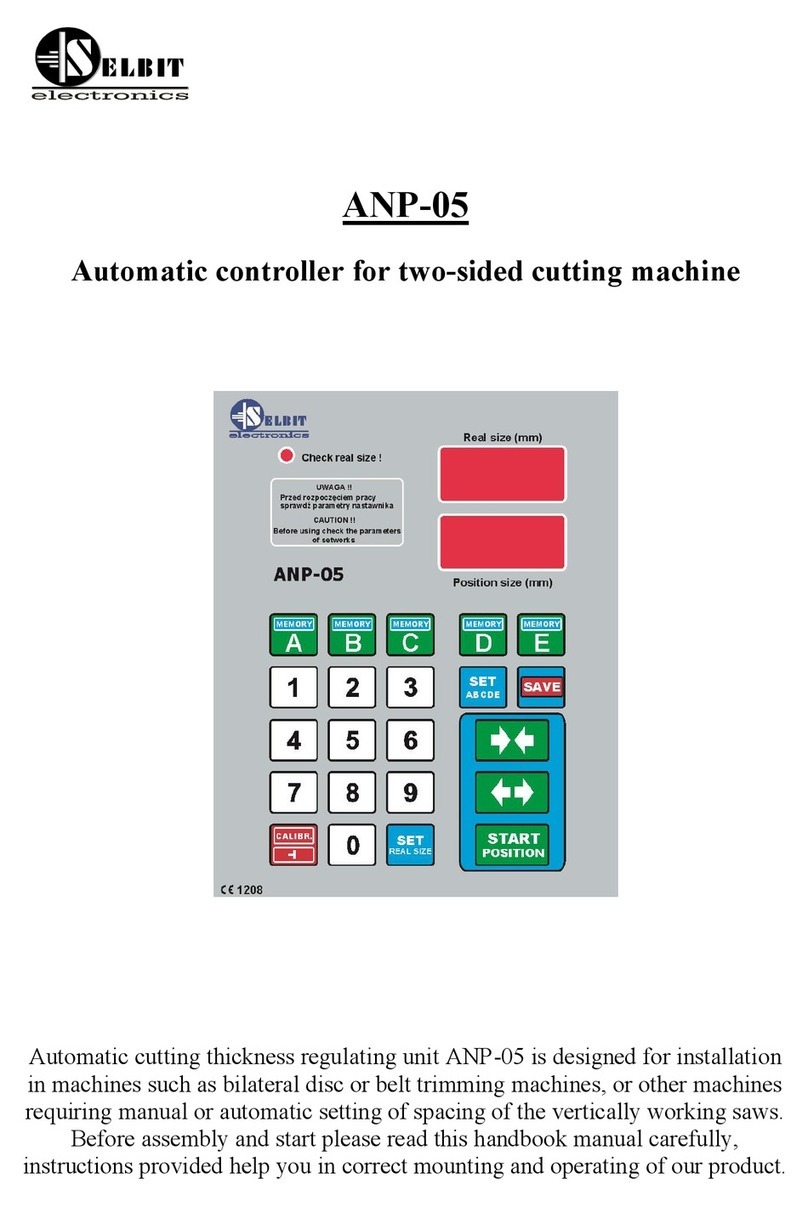

Place the mounting bracket between the wall studs or ceiling joists and

secure with four 1 3/8" drywall screws. Insert the screws through the four

pre-drilled holes in each ange and screw them into the face of each wall

stud or ceiling joist (Figure 2). The drywall screws need to be driven ush

with the surface of the ange so that the drywall sets ush on the bracket

ange.

Figure 2

SolidDrive

SD1-XFMR

mounting

bracket

attached to

the wall studs

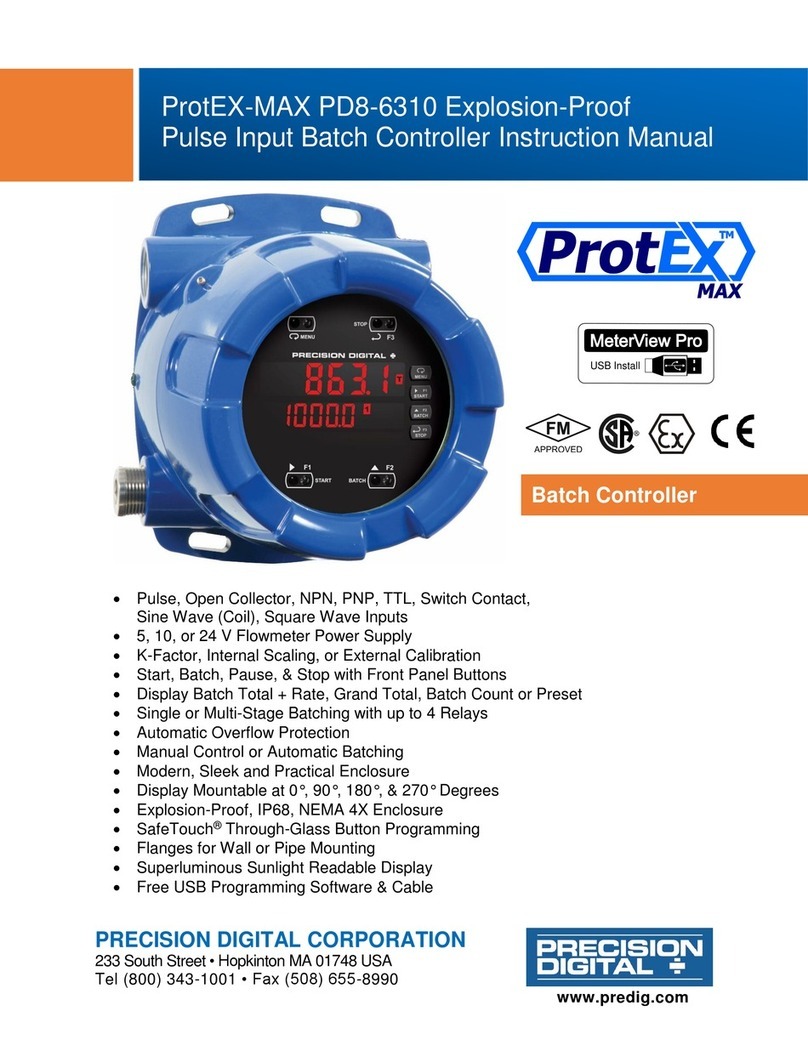

Feed the SolidDrive SD1-XFMR-Ti cable through the round opening in the

face of the mounting bracket. Insert the SolidDrive SD1-XFMR-Ti through

the same opening with the oversized mounting base facing outward toward

the side that the drywall will be installed and ush against the bracket face.

Align the pre-drilled holes in the mounting base to the threaded holes in the

bracket face (Figure 3). Attach the SolidDrive SD1-XFMR-Ti securely to the

mounting bracket using the 4 Phillips at head machine screws.

Figure 3

SolidDrive

SD1-XFMR

being installed

into the

mounting

bracket

If possible, position the drywall panel so that the SolidDrive SD1-XFMR-Ti

is at the center of the panel or as far from the edge of the panel as possi-

ble. This will allow proper distribution of sound and the SolidDrive

SD1-XFMR-Ti will function with optimum performance. Prior to mounting,

take measurements of the new drywall panel to determine the exact area

that will come in contact with the base of the SolidDrive SD1-XFMR-Ti and

spray that area liberally with the 3M® Super 77 contact spray adhesive.

Also, liberally spray the surface of the oversized mounting base of the

SolidDrive SD1-XFMR-Ti (masking around the base is highly recommend-

ed to prevent overspray). NOTE: Failure to apply the adhesive to both

the drywall surface and oversized mounting base will prevent the

system from functioning properly.

Make the electrical connection between the

SolidDrive SD1-XFMR-Ti and the speaker

cable using the desired transformer setting.

NOTE:When installed in Canada, this prod-

uct must be installed in accordance with

the Canadian Electrical Code, C22.1,

Part1.

Black-

Red-

Blue-

Yellow-

10W: 5 wire input

10 W

GND

2.5 W

5 W

10 W

For re-installing the rectangle drywall panel that was cut out to install the

SolidDrive SD1-XFMR-Ti, it is important to create a uniform seal between

the cut drywall and the existing drywall. This will allow proper distribution

of sound and the SolidDrive SD1-XFMR-Ti will function with optimum

performance. Apply fast setting joint compound, not vinyl based, in the

space between the cutout section and the existing drywall panel. Make

sure to ll the space completely with drywall compound then proceed with

the normal taping, sanding and nishing routine.

Immediately install the new drywall before the spray adhesive sets up

(approximately 10 minutes). This allows adjustment of the panel before

the nal location is determined. The drywall panel is to be tted to the wall

studs or ceiling joists and screwed into position. Apply joint compound in

the space between the drywall panels and proceed with the normal

taping, sanding and nishing routine. The joint compound lled between

the panels will improve the distribution of sound as well as overall sound

quality.

The surface material plays a key role in the system’s sound performance.

To ensure an optimal listening experience the installer MUST equalize the

SolidDrive SD1-XFMR-Ti system. Equalization is accomplished by using the

optional SolidDrive Drywall Passive Equalization Module (not UL approved)

or using the auto equalization feature available on some receivers.

Installation is now complete, you can enjoy the audio perfection of

the Induction Dynamics SolidDrive SD1-XFMR-Ti sound system.

Figure 4 Transformer connections

AMP SolidDrive SolidDrive SolidDrive

Daisy chaining multiple SolidDrives

Run the positive wire from the amplier to the selected colored tap wire of

the SD1-XFMR-Ti. Place another positive wire (headed to the subsequent

SD1-XFMR-Ti), the signal wire from the amplier, and the colored tap

setting wire into a wire nut and secure. Each wire nut should have a

positive in, a positive out, and the colored tap setting wire. Repeat this

same procedure for the negative side.

Popular Controllers manuals by other brands

OPW

OPW M00-051.00 FSC3000 Command-line configuration guide

Kübler

Kübler CODIX 564 manual

AAON

AAON V12100 MHGRV-X Field Technical Guide

Carrier

Carrier OPN-OPT-OL Installation and startup guide

AUGIER Energy

AUGIER Energy OCEM DIAM3200 Series Installation & maintenance

Atmel

Atmel ARM Thumb AT91 Application note