Solimar Air Knocker Series User manual

KNR-30-DI / KNR-40-DI KNR-60-DI / KNR-80-DI KNR-100-DI

KNR-20

KNR-20-SS

KNR-30 / KNR-40

KNR-30-SS / KNR-40-SS

KNR-60 / KNR-80

KNR-60-SS

KNR-100

Since 1985

Instruction Manual

AIR KNOCKER SERIES

KNR-15-SS

32

• The Air Knocker is designed to prevent materials from adhering to or blocking flow in process

equipment by using forced air. Do not use the Air Knocker for any other purpose.

• Care has been taken to ensure the safety of the Knocker. Be sure to read this instruction

manual and note the warning and caution messages before using the Knocker.

• The following symbols represent warning and caution messages to be observed when using

the Knocker to prevent injury or damages to users or other persons.

Refers to a hazard that may cause death or serious injury.

Refers to a hazard that may cause slight or medium injury.

WARNING

TO PREVENT DEATH:

• After installing the Knocker, make sure to attach the fall prevention wire to it to

prevent it from falling due to percussion during operation.

• In the event that the Knocker falls, be sure to replace the fall prevention wire even if

it appears to be undamaged.

• Do not connect the electric control devices (Knocker control board or three-way

solenoid valve) for the Knocker to a power source which is not equipped with a

breaker for preventing electric shock.

CAUTION

TO PREVENT INJURY OR DAMAGES:

• When removing the piping tube, please be sure to close the air supply from the

control equipment and to release the air pressure which remains in the Knocker. If

the tube is removed while air pressure still remains, the Knocker will operate, and

there is a possibility of an unexpected injury.

• Securely weld Knocker base to the vessel so that the Knocker does not fall due to

percussion during operation.

• If the vessel metal thickness is too thin, weld a reinforcing plate onto it to prevent

the mount plate from being damaged as a result of impact during operations.

WARNING

CAUTION

Safety Precautions

• Be sure to read this instruction manual carefully before using the Knocker.

• Handle the Knocker appropriately and inspect it to maintain its performance.

• Keep this manual for future reference.

Safety Precautions 2

Warning 2

Caution 2

Introduction 3

Safety 4

Caution (For personal protection during operation) 4

Caution (For longer service life) 5

Names of Parts 6

Installation 8

Piping 11

Test Operation and Settings Before Use 15

Inspection 15

Replacement Period for Consumables 16

Troubleshooting 16

Specifications 17

Dimensions 18

Introduction

Contents

54

Safety

CAUTION

FOR PERSONAL PROTECTION DURING OPERATION:

• Put on a safety helmet, safety boots, safety gloves and a safety belt, before any

installation work is started.

• Conduct all required lock-out, tag-out or similar required procedures prior to inspection

or repair.

• When using the fall prevention wire to prevent Knocker from falling, be sure to secure

shackle with appropriate tie to prevent shackle screw from loosening from percussion

during operation.

CAUTION

FOR LONGER SERVICE LIFE:

• When installing the air line, include a filter or filter/regulator prior to the Solenoid

valve to minimize dust getting into the Solenoid valve, which may inhibit the Knocker

from operating properly.

• Make sure the force of impact does not exceed the maximum level, as excessive

impact may damage the vessel it is mounted on.

• When applying continuous impact at short cycles, allow an interval of at least one

second. An interval of less than one second may lead to damage or operation

problems.

• Only start air lines after checking that there is no foreign substance, chips, or slag

on the piping materials.

• Flush with the air pressure of 44 psi or more, to clean any debris or contamination

in the piping.

• Use air that passed through an air filter 5 micrometers or less. Moisture or dust in

line will potentially cause poor operation and air leakage.

• The line should connect to the IN side in the direction of the flow and to the IN port

displayed on the product.

• Do not use in an area with corrosive explosive gas.

• When using a sealant, be careful to keep from inside the line, and seal to prevent

external leaks. When wrapping sealing tape around the screw part, wrap the tip of

the screws leaving 2 to 3 threads. Also, when using a liquid sealant, coat leaving 2

to 3 threads. Do not coat the female screws of the equipment. Tighten and check

for air leaks.

• In cold areas, please protect against freezing. (Air should not freeze)

• Avoid placing a heavy load on the lines.

• Operation air should contain some moisture or light oil. Operating using dry air may

shorten the product’s life cycle.

Safety

Helmet

Safety

Boots

Safety

Gloves

Safety

Belt

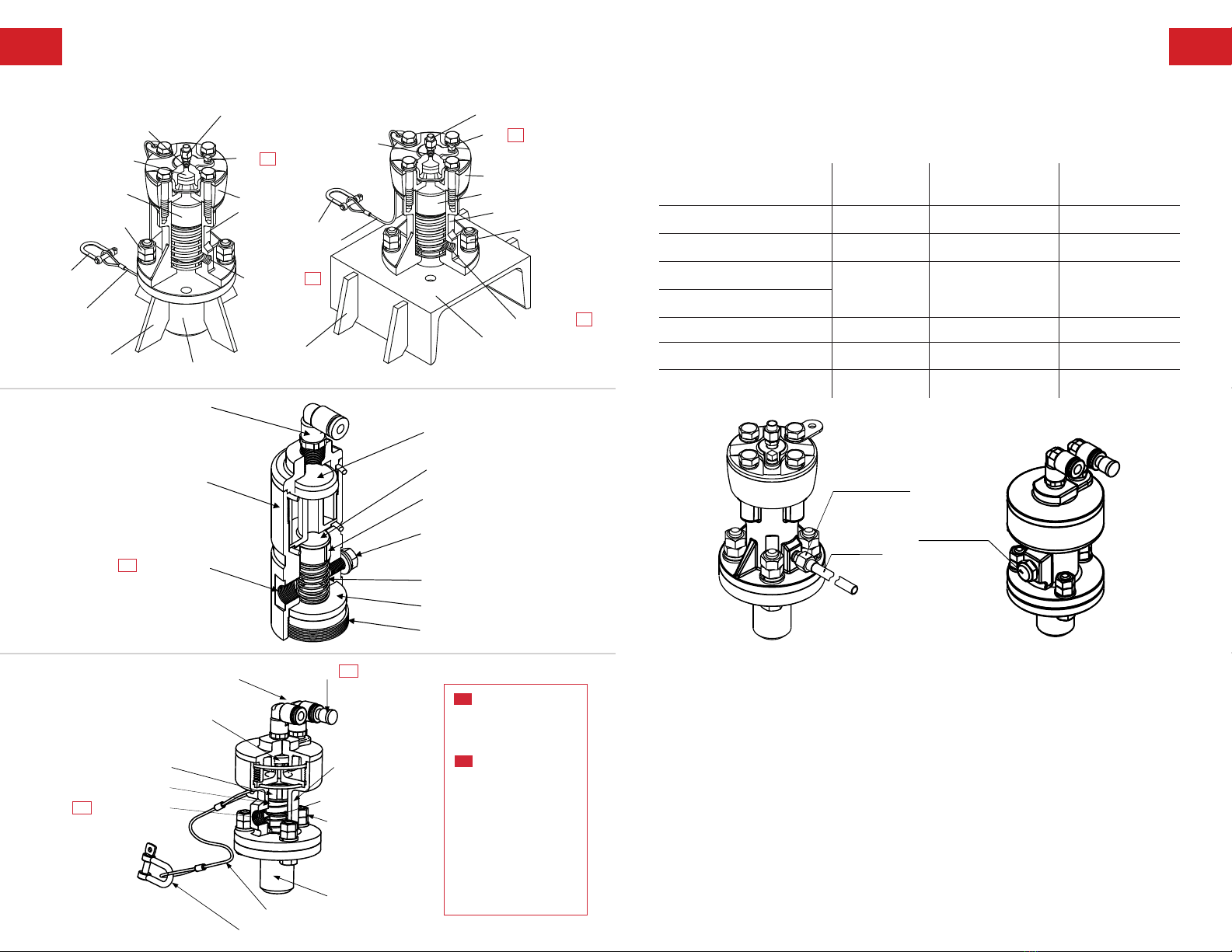

76 Names of Parts

#1 Using relay piping,

remove the blank plug

and insert a relay piping

tube in the outlet.

#2 When using a

Knocker where exhaust

air must be directed

away from installation

site, please screw a

tube connector into the

Knocker’s exhaust hole,

and make exhaust air

discharge outside with

an extension tube. A

sintered metal exhaust

filter may also be used.

KNR Models KNR-DI Models

KNR-15-SS

Extension Tube / Tube Connector Option

Model (KNR-) Dia. of Exhaust

Hole Screw

I.D. of

Recommended Tube

Max. Distance of

Extension Tube

15-SS 1/8 NPT 1/4” 130 ft.

20 / 20-SS 1/8 NPT 1/4” 130 ft.

30 / 30-DI /30-SS

1/4 NPT 5/16” 130 ft.

40 / 40-D I / 40-SS

60 / 60-DI / 60-SS 3/8 NPT 3/8” 130 ft.

80 / 80-DI 1/2 NPT 1/2” 130 ft.

100 / 100-DI 3/4 NPT 1/2” 130 ft.

When Discharge Exhaust Outside When Use Exhaust Filter

Exhaust filter

Tube connector

Extension tube

Push-one elbow

C

y

linder

Mushroom valve

Piston

Piston ring

Spring

Exhaust port

Impact plate

Inner base

Bolt M5

Mushroom valve

Wire assembly

Shackle

Push-one elbow Plug

Spring

Exhaust port

Double nut

Cylinder

Base assembly

Piston ring

Piston

#2

#1

#2

Push-one elbow

C

y

linder

Mushroom valve

Piston

Piston ring

Spring

Exhaust port

Impact plate

Inner base

Bolt M5

Mushroom valve

Wire assembly

Shackle

Push-one elbow Plug

Spring

Exhaust port

Double nut

Cylinder

Base assembly

Piston ring

Piston

#2

#1

#2

Wireassembly

Shackle

Hardlocknut

Tubeconnector

Airsupplyandexhaustopening

Plug#1

Mushroomvalve

Airtank

Cylinder

Piston

Exhausthole#2

Plug #1

Tubeconnector

Airtank

Piston

Exhausthole#2

Base

Reinforcingrib

Cylinder

Shackle

Wireassembly

Hardlocknut

Airsupplyandexhaustopening

Baseassembly

Reinforcingrib

KNR-20

KNR-20-SS

98

2. WELDING THE REINFORCING PLATE:

• If the vessel wall thickness is too thin, weld a reinforcing plate onto it. Welding procedure should use

all-around welding so that no gap arises between the vessel and the reinforcing plate. Leave one spot

unwelded for bleeding air. If no spot is left unwelded for bleeding the air, the air creates a cushion,

dampening the effect of impact.

• A large impact force is transferred to the reinforcing plate at the time of operation. In order to avoid

failure, install as instructed.

Reinforcing Plate Size (inches)

Model (KNR-) Square Type Round Type ΦAΦBC

30 / 30-SS / 30-DI □6 × t1/8 Φ6 × t1/8

5/8

3/4

2

40 / 40-SS / 40-DI □8 × t1/8 Φ8 × t1/8 3

60 / 60-SS / 60-DI □12 × t3/8 Φ12 × t3/8

2

3 1/2

80 / 80-DI □16 × t3/8 Φ16 × t3/8

1

4 3/4

100 / 100-DI □20 × t1/4 Φ20 × t1/4 3 3/8 5 1/2

Welding

Installation

Welding

3/8 inch 3/8 inch

C C

Reinforcing Plate

Air deflation

ΦB ΦB

KNR - DI

Welding

Air deflation

3/8 inch 3/8 inch

ΦA

Reinforcing Plate

ΦA

KNR

1. INSTALLING POSITION

INSTALLING POSITION

For small cone,pyramid hopper. For large cone,pyramid hopper.

In case of clinging on the surface

of wall and the inside pipe.

In case of bad fluid materials.

L

1/3L

L

1/2L

L

1/2L

L

1/2L

L

L

1/3L

1/4L

L

1/3L

L

1/3L

INSTALLING POSITION

For small cone,pyramid hopper. For large cone,pyramid hopper.

In case of clinging on the surface

of wall and the inside pipe.

In case of bad fluid materials.

L

1/3L

L

1/2L

L

1/2L

L

1/2L

L

L

1/3L

1/4L

L

1/3L

L

1/3L

1110

<Attach to flat surface><Attach to curved surface>

Long reinforcing ribs

Base assembly

Reinforcing plate

(Not required for KNR 20 / 20-SS)

Hopper

Per

p

endicular line of the ho

pp

er

Attaching surface Attaching surface

3. WELDING THE BASE ASSEMBLY AND REINFORCING RIB:

• Cut the reinforcing rib to match the configuration of the part to which it is to be mounted.

• Orient the holes in the base so that exhaust port of Knocker faces downward.

• Use all-around welding to weld the base assembly and make sure that the bolt holes on the right and

left sides are symmetrical.

KNR-DI Models KNR Models

KNR Model: Install Reinforcing Rib

Install to Plane Surface Install to Curved Surface

Reinforcing rib

Cut as adjust curved surface

Baseassembly

Reinforcingrib

Reinforcing

palate

Baseassembly

Reinforcingrib

Reinforcing

palate

Baseassembly

Reinforcingrib

Reinforcing

palate

Baseassembly

Reinforcingrib

Reinforcing

palate

ORIENTATION BASE ASSEMBLY

Please make sure that the holes in the vessel and the base are

correct so that the exhaust port of the Knocker faces downward.

KNR 20

KNR 30 /40 /60 /80

1312

4. MOUNTING THE KNOCKER:

When attaching Knocker unit and base with bolt set, pay attention to

the torque to prevent loosening by the impact of the Knocker.

Wire Assembly

Clamp Torque Nut Size

Model (KNR-) 20 30 40 60 80 100

Nut Size M6 M8 M12 M14 M16 M20

Tightening

Torque

(lbf • ft)

Lower Nut 4.0 8.0 26.0 42.0 62.0 123.0

Upper Nut 4.0 6.0 18.0 29.0 44.0 86.0

Model (KNR-) Wire Diameter Wire Length Shackle

15-SS

1/16

12

5/32

20 /20-SS 6

30 /30-DI /30-SS

3/32

7

1/4

40 /40-DI /40-SS 14

60 /60-DI /60-SS

1/8 17

80 /80-DI

100 /100-DI 3/16 20 5/16

• To prevent falling, suspend the Knocker by the wire and the shackle.

• Adjust the position of the metal fittings so that the wire assembly does not loosen.

Knocker Bolt Set

* The washer is not attached to KNR-20/KNR-20-SS.

The bolt set is unnecessary in KNR-15-SS.

* The fall prevention wire is an option. (KNR 15-SS)

Knocker

Bolt set

Upper nut

Lower nut

Spring washer

*1 Washer

Bolt

Base assembly

Knocker

Bolt set

Upper nut

Lower nut

Spring washer

*1 Washer

Bolt

Base assembly

Hanging metal fittings

Wire assembly

The wire assembly is

an option.

Shackle

Wire assembly

Exhaust port of

the knocker body

becomes downward

Wire assembly fixes with

this bolt.

Shackle

Exhaust hole of the knocker

body becomes downward

Wire assembly

Prescribed Dimensions

Prescribed Dimensions

Model (KNR-) Dim X

30-DI 2

40-DI 3

60-DI

3.5

80-DI

100-DI

Dim X

5. PRESCRIBED DIMENSIONS FOR THE KNR-DI MODEL MOUNTING:

If not using the base assembly provided, make sure that the dimensions of the part to which the

Knocker is mounted and the base mounting part meet the prescribed dimensions listed below.

Effective Length: 9.5mm

t (mm) L

Less than 4mm 1M10 × 14

From 4 to less than 6 M10 × 16

From 6 to less than 8 M10 × 18

KNR-15-SS:

• The KNR-15-SS type uses M10 bolts.

• Please strictly observe the torque specs for bolts.

• Bolt size and material: M10 SUS or M10 SS

• Clamp torque: 12.5 lb•ft•

L: length of bolt t: thickness of plate

An additional washer with thickness of at

least 2mm must be used with wall thickness

less than 2mm

Bolt M10

(inches)

(inches)

1514

Piping

• Select either standard or relay system piping per the examples below.

• When only one system is used with the control board (HKA and EKE models), place a

blind stopper in the unused system.

• In the control board (HKA and EKE models), the Knocker can be connected to line A or

line B, but note that the pressure accumulation and percussion operations are reversed

on one system.

1. EXAMPLE IN STANDARD PIPING: A/B/C

A. When using a three-way solenoid valve:

B. When using the HKA and EKE model exclusive control board:

C. When using the air operation controller KNR-CONTROL AOC model:

5/16 OD

KNR-CONTROL AOC

OFF

ON

When using the air operation controller KNR-CONTROL AOC

Air Knocker

Exhaust

Filter Regulator

Compressor

Control panel

Power Source

5/16 OD

A line

B line

Exhaust

When using the HKA, EKE exclusive control panel

Hopper

Air Knocker

Filter Regulator

Compressor

2. TUBE LENGTH IN STANDARD PIPING

• Make air lines as short as possible to maximize the impact force.

• The maximum length of a piping tube changes with model, air pressure,

and control unit, and may decrease Knocker effectiveness by 10 to 20%.

• When adding another pipe, the length of the tube from the branch point to each Knocker

should be equal.

• Avoid extreme bending and adding extra lines. It may affect operation and impact force

especially in units furthest from the air supply.

• It is recommended to set the minimum tube pressure at 44 psi to maintain stable

performance. Impact force can be maintained by increasing air pressure.

• When arranging the piping between the Knocker and the control devices, use nylon or

urethane tube which has a OD of 5/16 in.

A. When using the solenoid valve:

B. When using the HKA and EKE model

exclusive control board (per system):

C. Maximum Tube Length (ft) between KNR-CONTROL AOC and Knocker:

Model (KNR-) Tube Length (ft)

15-SS / 15 6.5

20 / 20-SS / 20 6.5

30 / 30-SS / 30-DI 6.5

40 / 40-SS / 40-DI 9.75

60 / 60-SS / 60-DI 26.25

80 / 80-DI 32.75

100 / 100-DI

80 / 80-DI

100 / 100-DI

40 / 40-SS / 40-DI

60 / 60-SS / 60-DI

30 / 30-SS / 30-DI

20 / 20-SS

15-SS

66

49

32

16

0

Pressure (PSI)

Tube length (feet)

When using solenoid valve

44 58 73 87 102

Pressure (PSI)

80 / 80-DI

100 / 100-DI

40 / 40-SS / 40-DI

60 / 60-SS / 60-DI

30 / 30-SS / 30-DI

20 / 20-SS

15-SS

262

197

131

66

044 58 73 87 102

Tube length (feet)

When using the HKA, EKE model exclusive control panel (per system)

When using with three-way solenoid valve

Compressor

Filter Regulator

Timer1 Complex timer or Switch

Timer2

Air Knocker

Hopper

OUT IN

EXH

1716

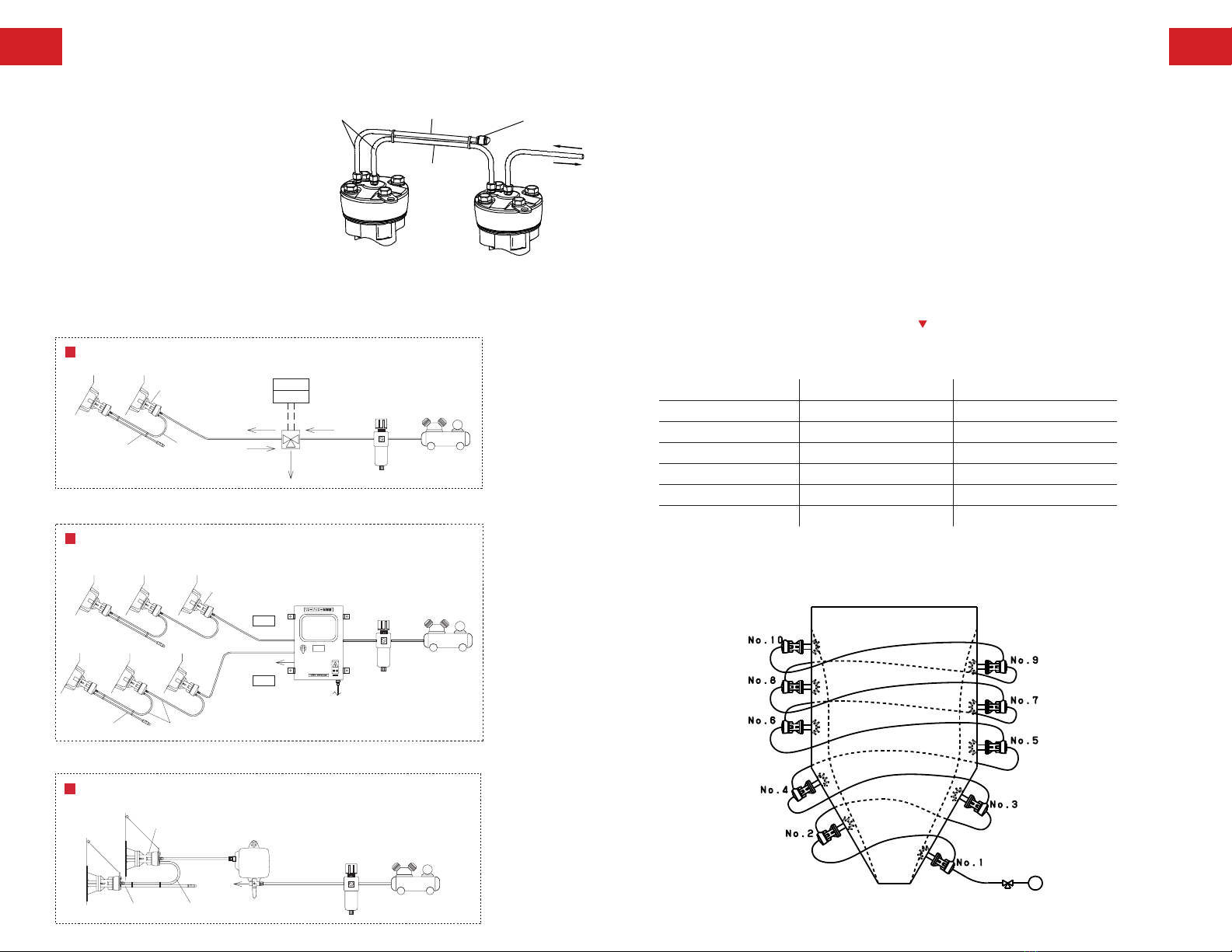

3. EXAMPLE IN RELAY SYSTEM PIPING: D/E/F

• Relay system piping method that connects two or

more Knockers in series. This method is connecting

a relay tube from air tank of the Knocker (cross

valve side) to air supply and exhaust opening of

another Knocker.

• When using relay system piping, Knocking action

starts in order from a Knocker that is located

in cross valve side to other Knockers. The

maximum number of Knocker that can be used

is regulated by the type of control.

• When arranging relay piping, please set the

actuation of the solenoid valve at 1 second or more. When the tube length of relay piping becomes

long and/or the number of relay pipes increase, please extend actuation of the solenoid valve.

D. When using the three-way solenoid valve model (maximum 5 units):

E. When using the HKA and EKE model exclusive control board (maximum 10 units per system):

F. When using the air operation controller KNR-CONTROL AOC model (maximum 3 units):

Dummy tube

Relay tube

Tube cap

Intake

Exhaust

Knocker

K

nocker

No.2 No.1

Make the length of the

p

i

p

in

g

tubes e

q

ual

5/16 OD

When using the HKA, EKE exclusive control panel

Hopper

Air Knocker

Relay tube

Dummy tube

Hopper

A line

B line

Exhaust

Power Source

Control panel

Compressor

Filter Regulator

Relay tube

5/16 OD OUT

Dummy tube

When using with three-way solenoid valve

Hopper Air Knocker Timer1

Timer2

Compressor

Filter Regulator

Complex timer or Switch

IN

EXH

KNR-CONTROL AOC

OFF

ON

5/16 OD

When using the air operation controller KNR-CONTROL AOC

Exhaust

Compressor

Filter Regulator

Air Knocker

Relay tube

Dummy tube

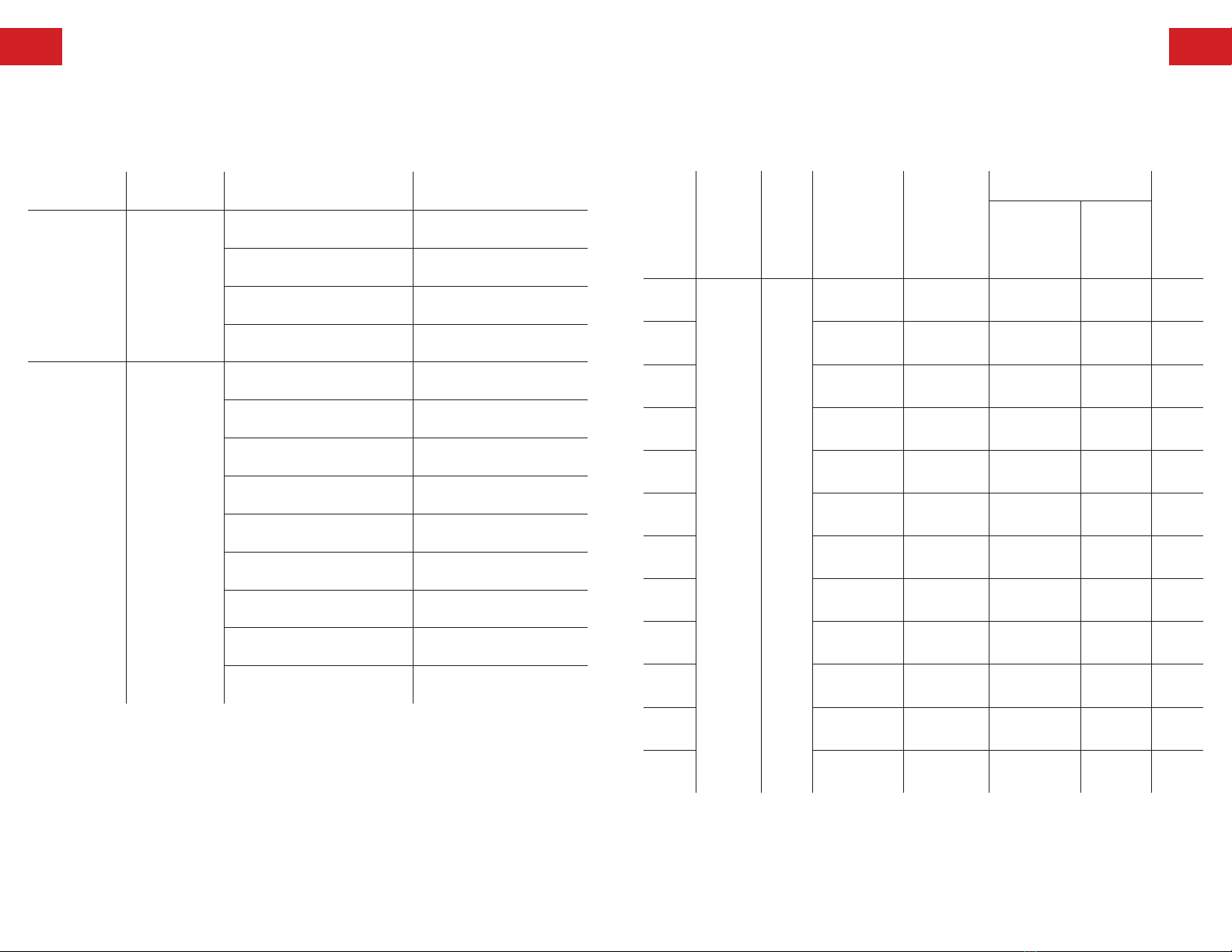

4. TUBE LENGTH OF RELAY SYSTEM PIPING AND AIR PRESSURE

• In relay system piping, compressed air in the relay tube is also used for operation air of the Knocker.

Accordingly, the air pressure is not to exceed the regulated valve. (Refer to length of relay tube in

relay system piping and air pressure)

• Use 5/16 OD nylon or urethane tube when arrange piping between Knockers and control

equipment. (Please use 1/4 OD tube for KNR-20.)

• Arrange tube length to the first Knocker as referenced in standard piping, section 2.

• It is recommended to connect a piece of dummy tube (that is same length as the relay tube) to the

terminal Knocker, so the knocking force of every Knocker is equal. (Refer to Section 3. Example of

relay system piping - pg. 13)

• In order to prevent an air leak, please equip the end of the dummy tube with a cap.

• In relay system piping, the knocking force increases when the tube length is extended but it will effect

the durability of the Knocker unit.

• Length of connecting tube (relay tube) for 2nd and other Knockers are dependent on the type of

Knocker. Length between is not to exceed the maximum length. Also, make the length as even as

possible to balance knocking force. (Refer to table)

Knocking force at value listed above is equivalent to the knocking force at maximum air

pressure (102 psi) in standard piping

Start Knocking in Order from No. 1

(From Lower to Upper)

Length of Relay Tube in Relay System Piping and Air Pressure

Model (KNR-) Relay Tube Length (ft) Working Pressure (PSI)

20 / 20-SS / 20 3.25 or less 44 or above

30 / 30-SS / 30-DI 3.25 or less 44 or above

40 / 40-SS / 40-DI 16.5 or less 58 or above

60 / 60-SS / 60-DI 16.5 or less 73 or above

80 / 80-DI 32.75 or less 73 or above

100 / 100-DI 32.75 or less 80 or above

1918

Test Operation and

Settings Before Use

After mounting and piping the Knocker, run a test operation and complete the settings in

accordance with the following procedure:

1. Set the air pressure to 44 psi. (14.5 psi at relay piping)

2. Set the most suitable air pressure in the regulated range by increasing the air pressure

of the regulator 5 psi apiece.

Note: The farther the Knocker is from the regulator, the lower the pressure at the Knocker compared to the

pressure indicated at the regulator. In such a configuration, set the pressure slightly higher.

Inspection

Inspect the following items at least once every three months to minimize trouble during operation:

1. Are any nuts or bolts loose?

2. Are any welded parts cracked?

3. Have any contaminants gotten into the Knocker?

4. Is there any abnormal wear on the cylinders or pistons?

5. Is there any spring damage?

6. Is there any damage to safety wire assembly?

Replacement Period

For Consumables

Replace consumables as set out in the following table:

Note: Contact the branch, sales office or designated service center closest to you for repair or overhauling of the Knocker

Part How to determine the replacement period

from visual and audible signs

Replacement

Period

(Average)

Mushroom

Valve

Determine according to the amount of wear,

scratches and cracks (visual)

1,000,000

Strokes

Piston Determine according to the amount of wear (visual) 1,000,000

Strokes

Spring Determine according to the amount of wear

and operation conditions (Visual and audible)

1,000,000

Strokes

Spring Determine according to the amount of wear

and operation conditions (Visual and audible)

1,000,000

Strokes

Impact plate

(KNR-15-SS) Judge in the wear condition of the tip part (visual) 500,000

strokes

2120

Troubleshooting

Simple diagnosis by checking audible and visual signs and signs detectable by touch.

Phenomenon Sign Cause Action

Chatter Low Impulsive

Force

The air pressure is low Increase the air pressure

The three-way valve is defective Repair or replace the valve

The spring is damaged Replace the spring

Foreign matter has

got into the cylinder Clean the cylinder

No Percussion No Percussion

The air pressure is low Increase the air pressure

The three-way valve is defective Repair or replace the valve

The spring is damaged Replace the spring

Foreign matter has got

into the cylinder Clean the cylinder

The tube is bent Improve the piping

The tube is too long Improve the piping

The cylinder is worn Replace the cylinder

The piston is worn Replace the piston

The mushroom valve is worn or

damaged

Replace the

mushroom valve

Specifications

List of Models:

Model

(KNR-)

Working

Pressure

(PSI)

Stroke

Cycle

(cycle/

min)

Air

Consumption

(cf/cycle)

Stroke

Energy

(lbf • ft)

Impulsive Force

Weight

(lb)*

ft • lbf/s

Converts

into

Hammer

pound

(lb)

15-SS

44 - 102 1 - 60

0.001 - 0.002 2.0 - 4.6 2.2 -3.6 Below 0.4 0.95

20 /

20-SS 0.001 - 0.004 3.2 - 6.1 4.3 - 5.8 Below 0.6 1.8

30 /

30-SS 0.002 - 0.005 4.1 - 9.7 8.7 - 13.0 Below 1.0 3.1

40 /

40-SS 0.005 - 0.013 6.8 - 16.4 18.8 - 28.9 1.0 - 1.5 7.7

60 /

60-SS 0.012 - 0.027 15.2 - 36.1 49.9 - 76.7 1.5 - 3.0 20.5

80 0.021 - 0.049 33.3 - 80.4 109.9 - 171.4 3.0 - 8.0 32.0

100 0.034 - 0.080 60.8 - 148.3 217.0 - 339.2 6.0 - 15.0 75.1

30-DI 0.002 - 0.005 4.1 - 9.7 8.7 - 13.0 Below 1.0 4.6

40-DI 0.005 - 0.013 6.8 - 16.4 18.8 - 28.9 1.0 - 1.5 12.3

60-DI 0.012 - 0.027 15.2 - 36.1 49.9 - 76.7 1.5 - 3.0 28.9

80-DI 0.021 - 0.049 33.3 - 80.4 109.9 - 171.4 3.0 - 8.0 40.6

100-DI 0.034 - 0.080 60.8 - 148.3 217.0 - 339.2 6.0 - 15.0 78.3

*Weight includes base.

2322

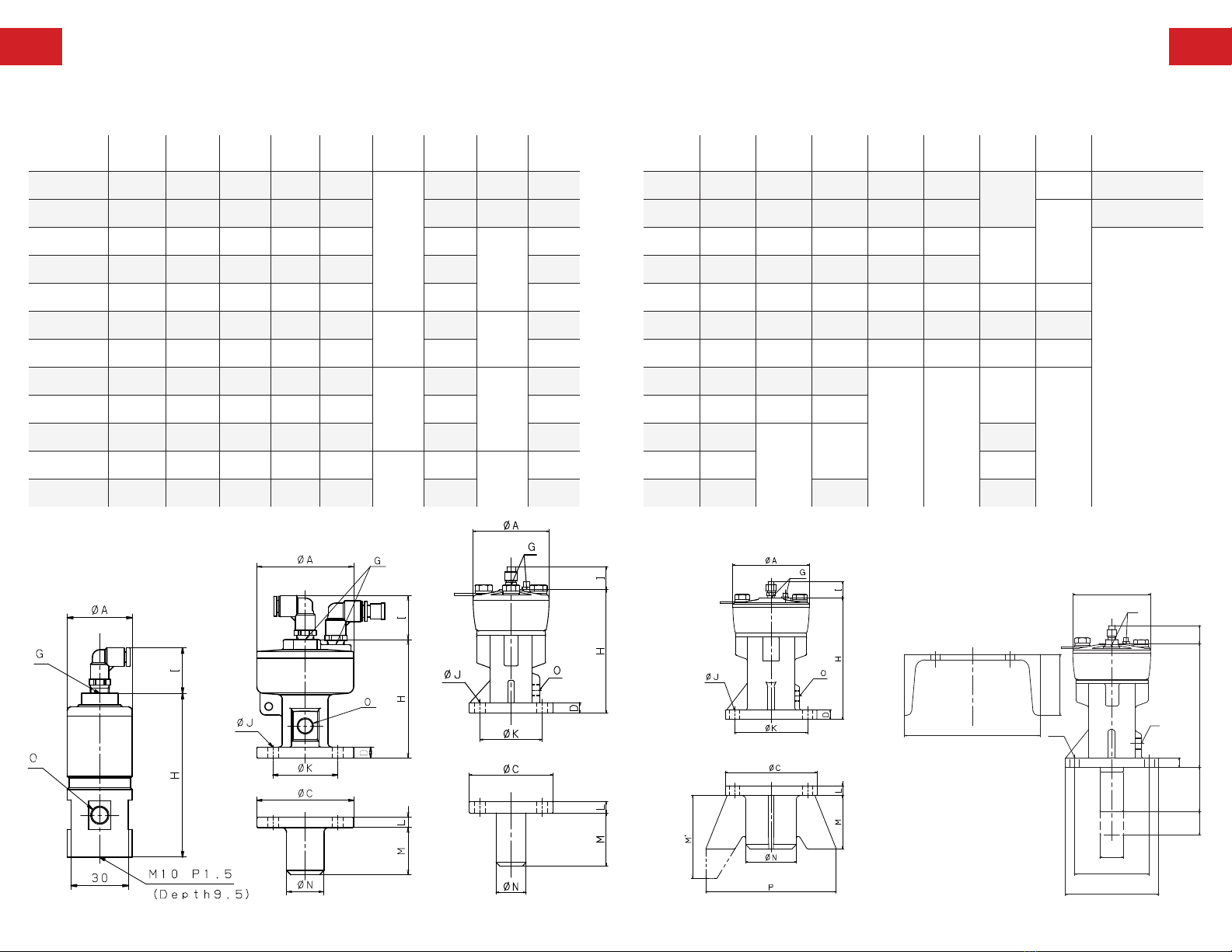

Dimensions

Model

(KNR-) ΦAΦCDΦEF G H I ΦJ

15-SS 1.34 –– –– –– ––

1/8”

NPT

3.39 (.94) ––

20 / 20-SS 2.25 2.25 0.25 - - 2.75 (1.02) 0.25

30 / 30-SS 2.59 2.75 0.31 - - 3.73

(0.98)

0.33

40 / 40-SS 3.39 3.73 0.47 - - 5.52 0.48

60 / 60-SS 4.53 5.44 0.55 - - 7.2 0.58

80 / 80-SS 5.75 5.83 0.63 - - 1/4”

NPT

8.73

(1.11)

0.67

100 6.89 8.19 0.78 - - 10.63 0.83

30-DI 2.59 2.75 0.31 0.59 1.5

1/8”

NPT

3.73

(0.98)

0.33

40-DI 3.39 3.73 0.47 0.92 2.17 5.52 0.48

60-DI 4.53 5.44 0.55 1.38 2.56 7.2 0.58

80-DI 5.75 5.83 0.63 1.88 2.36 1/4”

NPT

8.73

(1.11)

0.67

100-DI 6.89 8.19 0.78 2.14 1.97 10.63 0.83

F

L

ΦE

ΦC

M

ST

D

H I

G

ΦA

O

ΦJ

ΦK

F

L

ΦE

ΦC

M

ST

D

H I

G

ΦA

O

ΦJ

ΦK

ΦKST L M M" ΦNO W Tube Size

–– –– –– –– –– ––

1/8” NPT

–– Φ1/4 × Φ1/8

1.73 -0.23 1.11 -0.86

-

Φ1/4 × Φ1/8

2.17 -0.31 1.38 -1.09

1/4” NPT

Φ5/16 × Φ1/4

2.75 -0.52 2.36 -1.34

4.33 -0.59 3.16 4.72 33/8” NPT 7.72

4.72 -0.7 3.55 4.53 31/2” NPT 8.5

6.69 -0.91 4.53 5.31 4.5 3/4” NPT 12.13

2.17 0.67 1.97 3.94

- -

1/4” NPT

-

2.75 0.98 2.95 5 .91

4.33 1.38

3.55

7.88

3/8” NPT

4.72 1.58 1/2” NPT

6.69 1.97 9.84 3/4” NPT

M"

means curve

surface

dimension

KNR-15 Models KNR-20 Models

RKVS15

RKVS20

RKVS15

RKVS20

KNR-60/80/100 Models KNR- DI ModelsKNR-30 / KNR-40 Models

RKVS30・40

RKVS60

RKVS30・40

RKVS60

(inches)

Solimar Pneumatics | Minneapolis, MN 55432 USA | 1.800.233.7109 | P: 763.574.1820

Solimar, Solimar-USA and the Radial Ridge Design are trademarks of Solimar Pneumatics

Since 1985

This manual suits for next models

16

Table of contents

Popular Industrial Equipment manuals by other brands

Loepfe

Loepfe YarnMaster Zenit instruction manual

AVK

AVK 870 Series Installation, operation and maintenance manual

Seifert

Seifert 851200034-BZBG user manual

ABB

ABB HT574957 original operation manual

AGC

AGC ProFlow Pro3-XP Operation and maintenance manual

PCB Piezotronics

PCB Piezotronics J353B32 Installation and operating manual