2

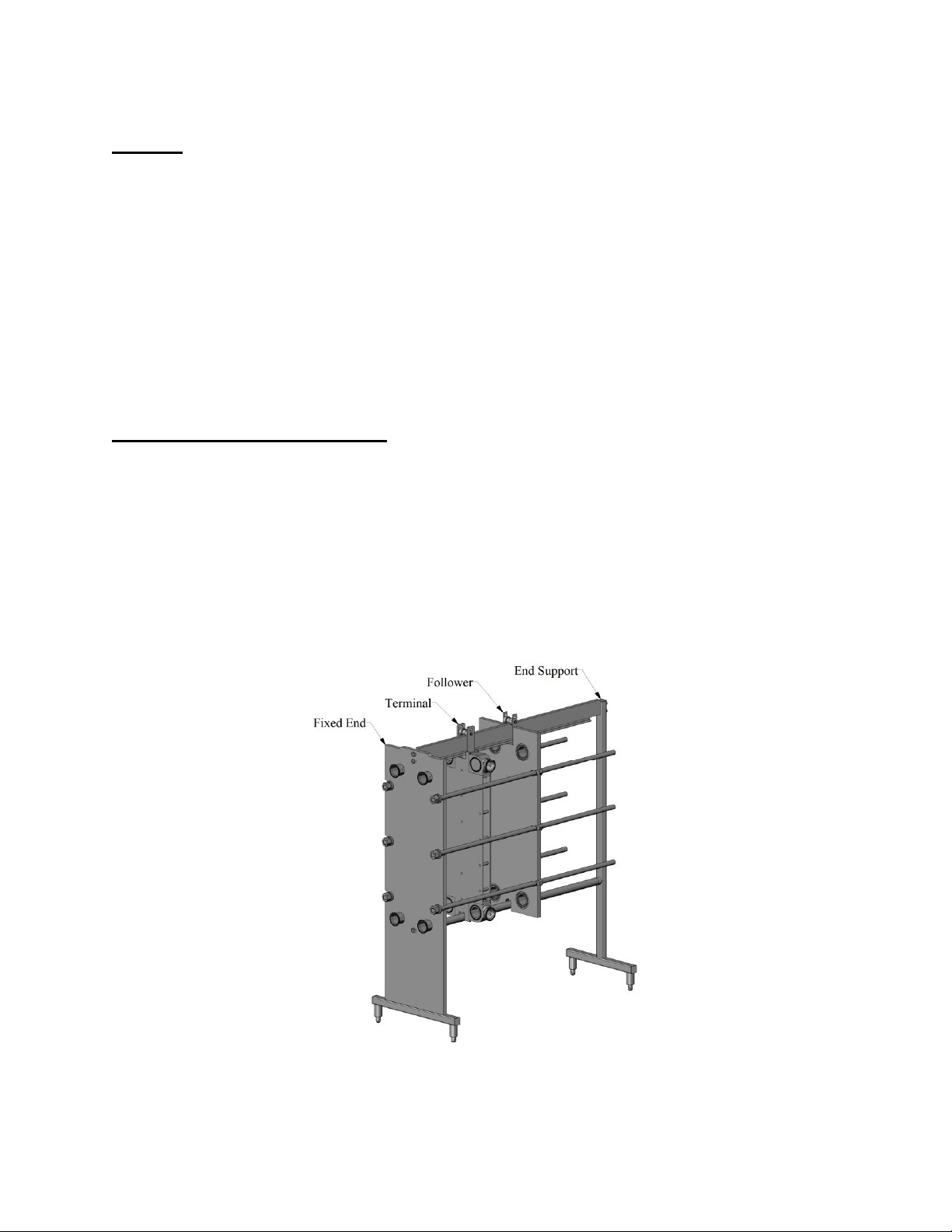

Normally, Pro3-XP frames are shipped with the plates installed. As a result the press and plates

can weigh several thousand pounds. We recommend only qualified forklift operators should lift and

position the unit. It should be noted that the high leg frame, also known as the Pro3-XPH, can be top heavy

and could tip if they are not moved properly.

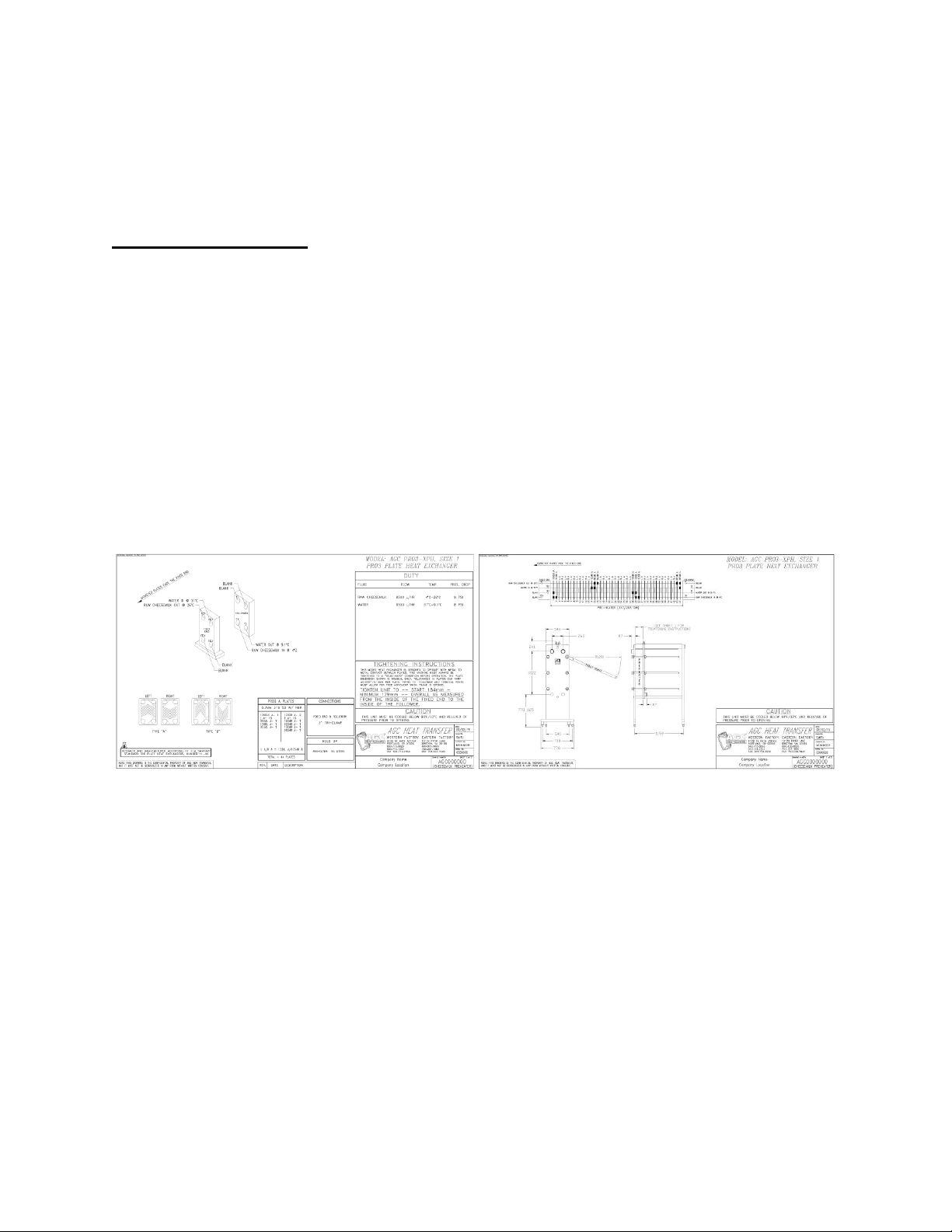

Drawing Package:

Every frame is shipped with a drawing package. This drawing package contains important

information that is specific to your heat exchanger. If you cannot find the drawing package, contact AGC

Heat Transfer or your local AGC distributor to obtain a replacement prior to installing the heat exchanger.

The drawing package is a collection of several important documents related explicitly to your heat

exchanger. The first of these is the streaming diagram. Two copies of the streaming diagram are included.

One copy has been laminated to protect it. This copy is intended to be used by production and maintenance

personnel when installing and/or servicing the heat exchanger. The remaining copy should be kept on file

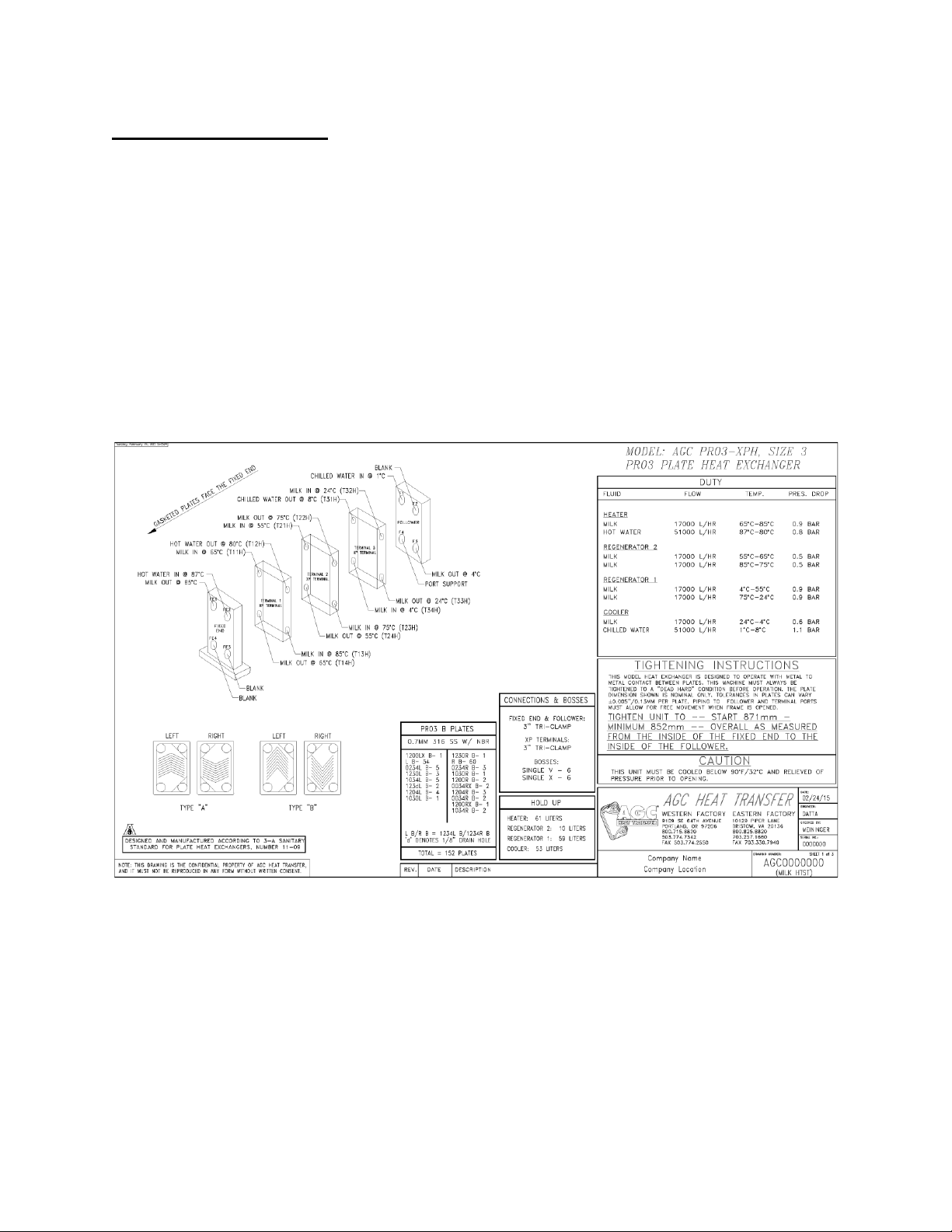

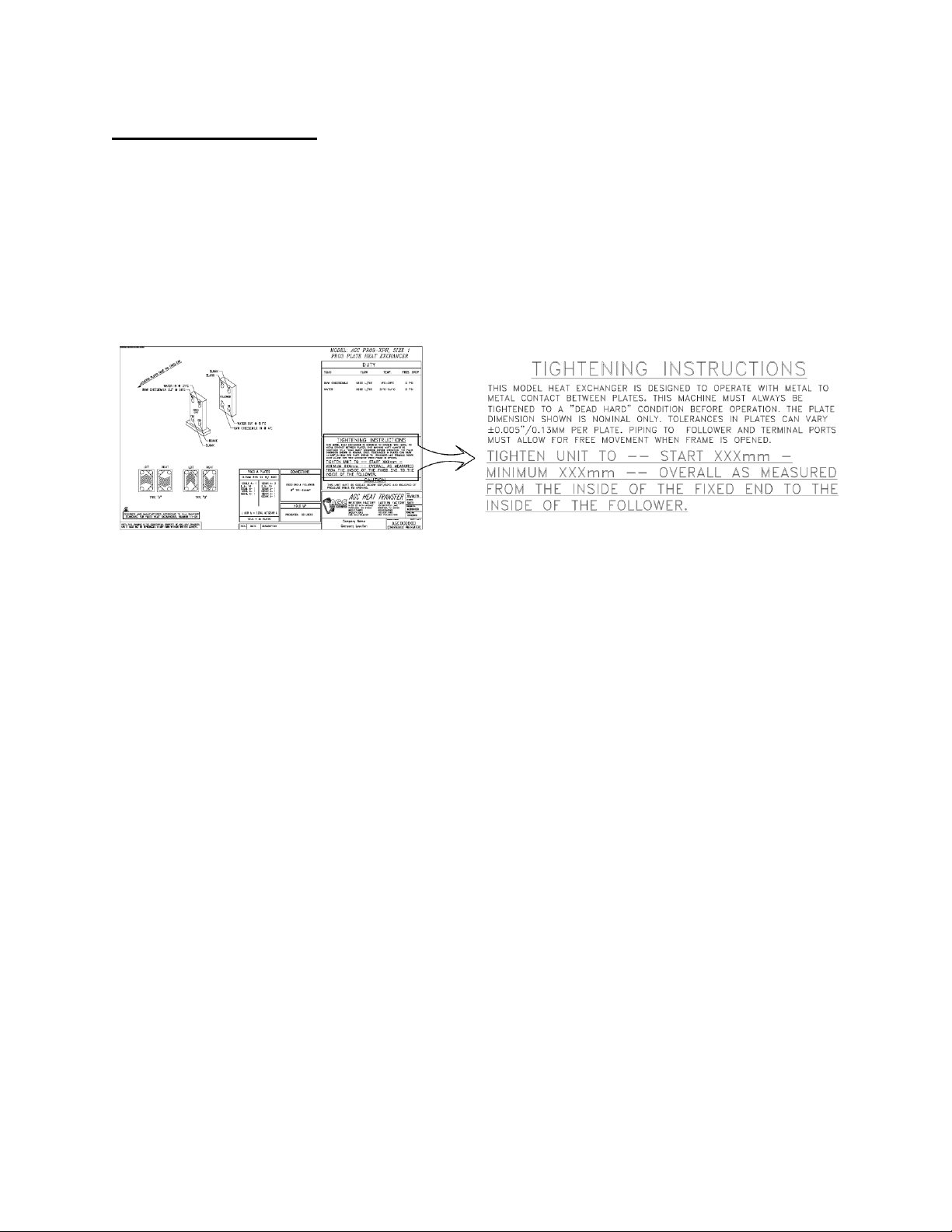

in a safe place in the event the production copy is lost or damaged. The streaming diagram (also referred

to as the drawing) describes all the characteristics of the heat exchanger. Figure 2 shows a typical two page

streaming diagram.

Figure 2

Typical Streaming Diagram

Page one shows the unit serial number, the duty, plate type, plate count, gasket type, connection

type, connection size, and the tightening dimension. Revisions are also listed on page one. Page two of

the drawing shows how the fluids pass through the heat exchanger. (The ProFlow manual describes how

to read this flow diagram). If the unit is small, such as the unit in figure two, a front and side view of the

heat exchanger will be shown as well. For larger units the front and side views are shown on page three or

page four.

The second document in the drawing package is a plate punching diagram. This diagram will show

you how to identify each Pro3 plate either by its configuration number (stamped at the top of each plate) or

by looking at the plate noting which ports have been opened. Since the Pro3 plate is a vertical flow plate,

each plate can be used for either a right or left hand plate. The ProFlow manual explains how these plates

are used in greater detail.