SDI-12 User Guide for AquaVent

Page 7

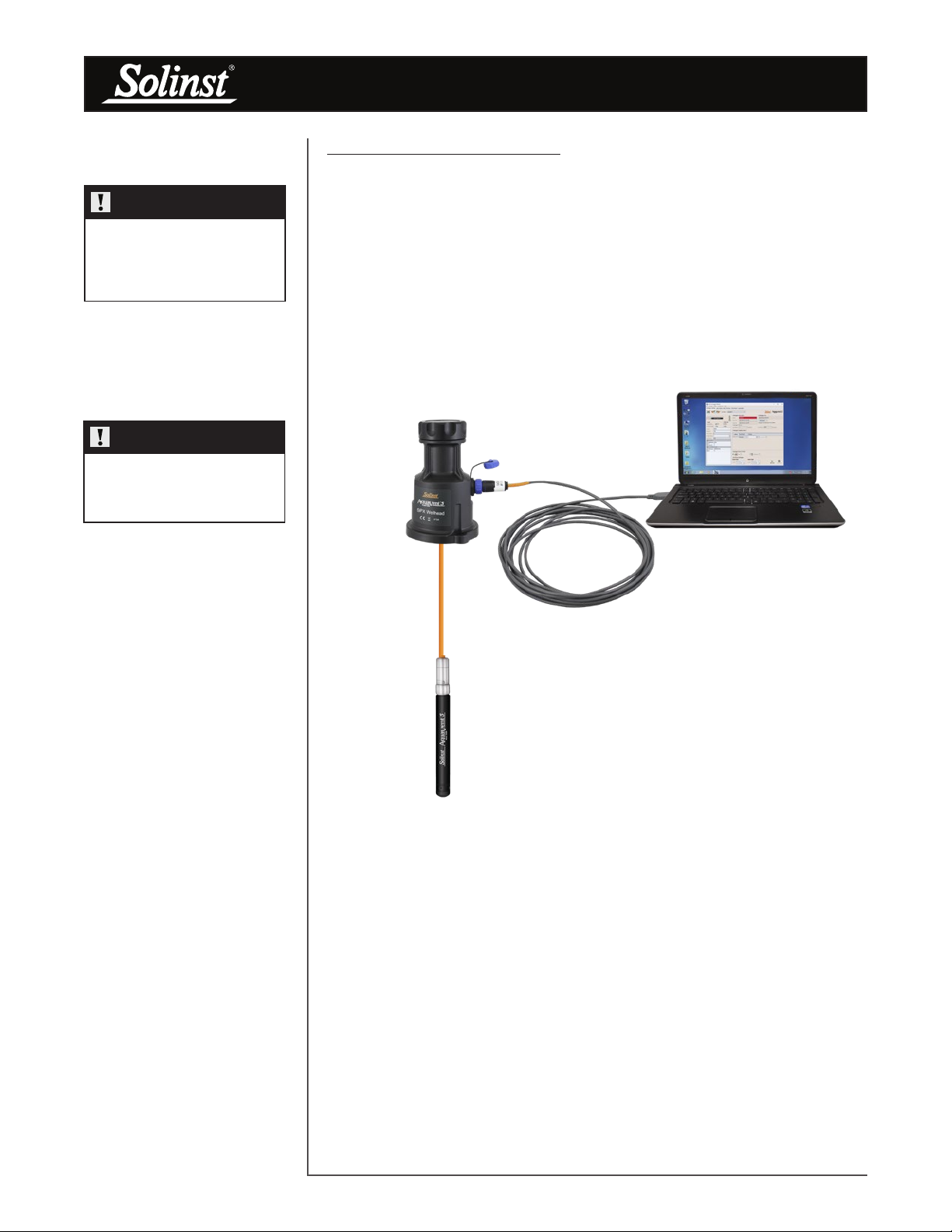

2 AquaVent Independent Recording Option

The AquaVent logger has the ability to record and store readings in its internal

memory, independent from the SDI-12 network, while connected to an SDI-12

master. Before connecting the AquaVent to the SDI-12 master, it can be

programmed and started using Solinst Levelogger PC Software (see Figure 3-1).

All standard sampling options provided by Solinst Levelogger PC Software are

available while the AquaVent is operating as an SDI-12 sensor. The AquaVent

logger can be set to record at a user-defined sampling rate; event, linear, and

scheduled sampling modes are available. This allows the AquaVent logger to

provide back-up data if the SDI-12 network fails. The AquaVent logger stores

the data in its internal memory, until it is downloaded.

If you program the AquaVent logger at a similar interval to the SDI-12 recorder,

it may require an occasional measurement retry by the recorder if the AquaVent

happens to be busy at that moment. You can change the schedule of either to

ensure this does not happen.

Each time the SDI-12 master asks the AquaVent for a current reading, the

Wellhead batteries are used to transmit the information from the logger to the

Wellhead. The AquaVent logger will also be using the batteries if programmed

to record independently – draining the batteries more quickly.

2.1 Data Downloading and Programming in Field

If the AquaVent logger has been programmed to record on its own independent

schedule, data can be downloaded from the AquaVent using a laptop and

USB Connector Cable in the field (see Figure 3-1). Temporarily disconnect the

AquaVent from the SDI-12 Connector Cable, preferably in between recordings

by the SDI-12 master. Connect a laptop and download the independently

recorded data.

If the AquaVent is disconnected from the SDI-12 network, and the SDI-12

master tries to communicate with the AquaVent, the SDI-12 master and the rest

of the sensors in the network are not disrupted.

After the data download is complete, the AquaVent is easily connected back into

the SDI-12 network without disruption. The AquaVent is automatically verified

when reconnected (see Section 4.2).

NOTE

See the Vented Dataloggers User

Guide for detailed AquaVent

operating instructions.

NOTE

Once you are finished

programming your AquaVent,

unplug the USB Connector Cable

from the Wellhead. The Wellhead

only communicates with the SDI-

12 network when just the SDI-12

Connector Cable is connected.

NOTE

The Wellhead batteries will drain

more quickly if the AquaVent logger

is also set to record independently.

NOTE

Other downloading options

are available using the Solinst

Levelogger App and DataGrabber.

See separate operating instructions.