Sollatek DSP-D User manual

THE SOLLATEK DISTRIBUTION SURGE PROTECTOR

DSP-D, DSP-S, DSP-M RANGE

AC Panel Transient Voltage Surge Suppressors

INSTRUCTION MANUAL

Important: This manual contains important safety instructions.

Keep this manual handy for reference.

TM

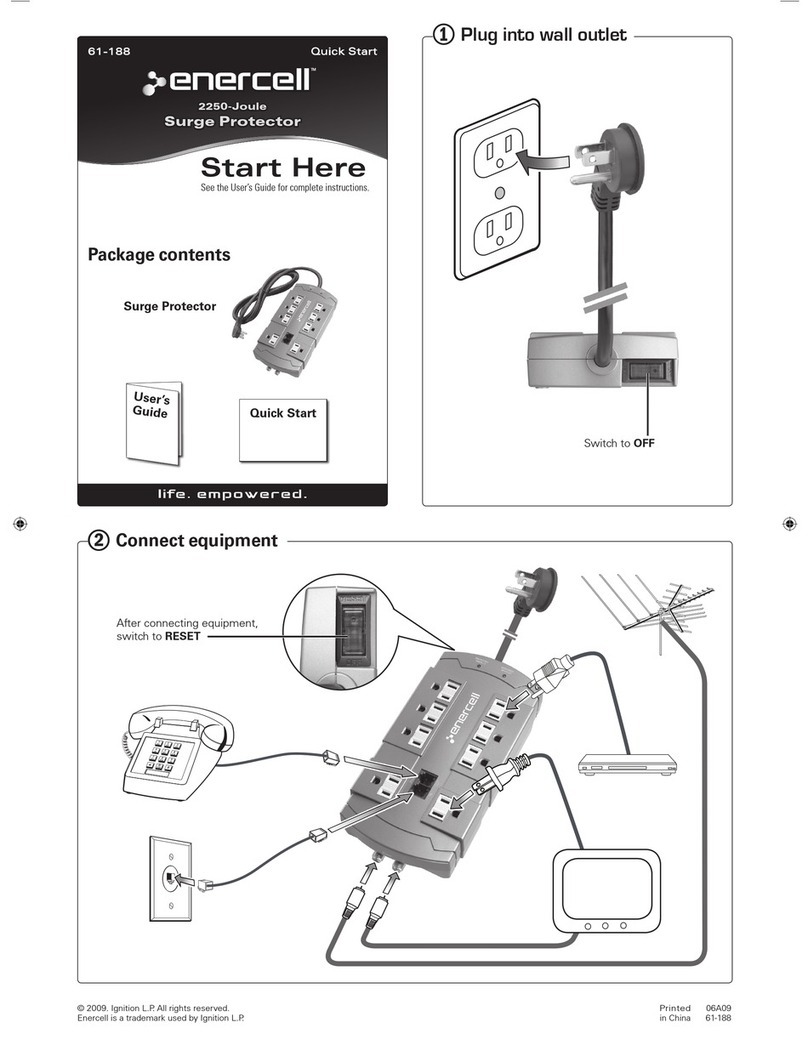

DSP-M

THREE PHASE

DSP-S

THREE/SINGLE PHASE

DSP-D

THREE PHASE

THREE PHASE

2

Without doubt, power interruptions cause major problems for home and business

computing. An unpredictable power supply can lead to worrying problems such as

surges, spikes, lightning strikes, brown-outs, power-cuts (black-outs), power-back

surges, mains over-voltage, and complete failure - all of which can damage electrical

and electronic equipment. If any of these should occur, there’s a strong chance you

will suffer

from loss of critical data, lowered productivity and even damage to your

expensive equipment.

Sollatek encompasses a wide range of power protection products for use in many

different industries where clean, regulated mains power is critical to their continued

operation.

For more information on our range of power protection products, contact us now.

SOLLATEK (UK) LTD

UNIT 10 POYLE 14 INDUSTRIAL ESTATE,

NEWLANDS DRIVE, POYLE,

SLOUGH SL3 0DX,

UNITED KINGDOM

Tel: International +44 1753 688300 National 01753 688300

Fax: International +44 1753 685306 National 01753 685306

E-mail: [email protected]

www.sollatek.com

TM

The

DSP-D

range offers high capacity protection in industrial applications, ten-mode

protection and a max surge handling capabilities of 80kA, 120kA or 160kA per phase.

Ensuring protection at distribution boards, lighting systems and equipment panels and

cabinets. Featuring; solid-state diagnostics, LED indication of protection level status,

IP66 and UL 1449 rated. International three phase supply versions only.

The

DSP-S

range with ten-mode protection, maximum surge handling capacity of 90kA

per phase, when used in conjunction with a Sollatek DSP-M series at the main service

entrance provides the ultimate in complete high-capacity surge suppression. Requiring

no operator intervention, LED indicators allow each MOV network to be constantly

monitored. Remote monitoring by means of normally closed contacts. IP66 and UL 1449

approved. Single / three phase versions for all international supply voltages.

Designed for main service entrance locations, the

DSP-M

range gives ten-mode

protection, surge max surge current of 150kA or 180kA per phase. Visual or remote

warning alerts the operator of varistor network failure while a redundant unit keeps

protecting the site, even after a direct strike. Silicon avalanche diode versions are

available (DSP-150-SD) incorporating both SAD and MOV technology for a lower limiting

voltage. Remote monitoring by means of normally closed contacts. IP66 and UL 1449

approved. Three phase versions for all international supply voltages.

Contents

Sollatek DSP-D Series

p.3

Sollatek DSP-S Series

p.4

Sollatek DSP-M Series

p.6

Power problems p.10

Comparison chart p.11

THE SOLLATEK DISTRIBUTION SURGE PROTECTOR (DSP)

INTRODUCTION

3

SOLLATEK DSP-D SERIES

SOLLATEK DSP-D SERIES

AC Panel Transient Voltage Surge Suppressors

AC Panel Transient Voltage Surge Suppressors

INTRODUCTION

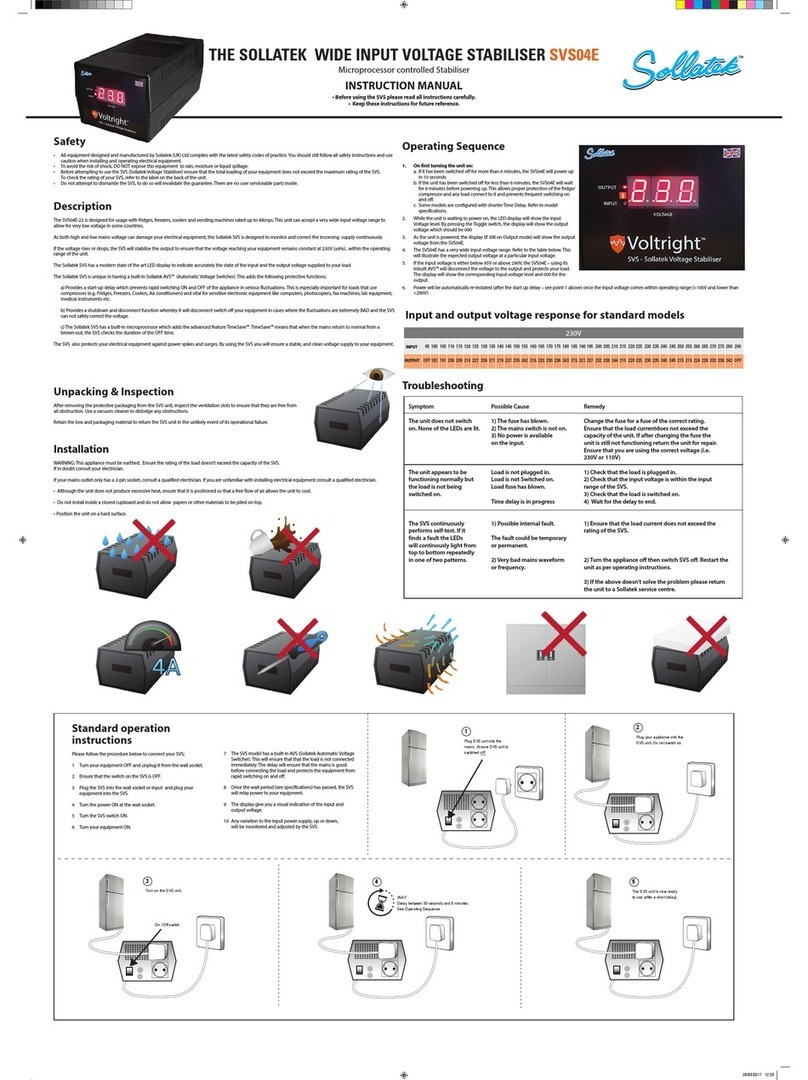

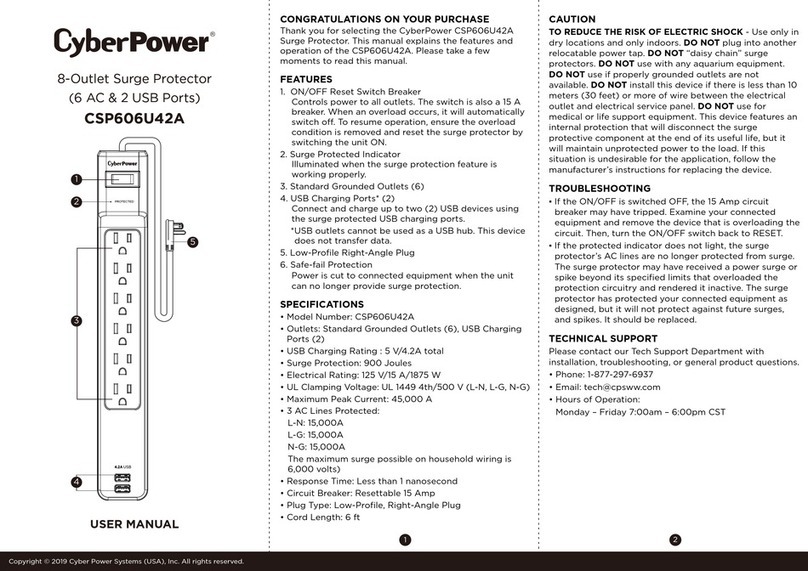

This document explains how to install the Sollatek DSP-D Series of AC Panel Surge

Protective Devices.

INSTALLATION INSTRUCTIONS

The suppressor should be mounted on or near the panel as close as possible to the

wire connection point. The suppressor has three mounting possibilities: surface, fl ush

or close nipple. In all three mounting possibilities connect the BLACK #12 AWG solid

wires to the phase conductors, connect the WHITE #12 AWG solid wire to the neutral

bus and connect the GREEN #12 AWG solid wire to the ground bus. At the installation

stage, cut each conductor AS SHORT AS POSSIBLE. Avoid large loops of wire and

sharp bends in the wires. Bind all connecting cables tightly together throughout the

wire run from the Sollatek DSP-D to the panel.

MOUNTING

Close Nipple Mounting:

Choose a location on the panel that will give the most direct connection to the phase

conductors and neutral-ground busses. Use a pre-existing ½ inch conduit knock-

out or drill a new ½ inch conduit hole in the panel. Remove the conduit nut from the

Sollatek DSP-D and slide the wires and conduit nipple into the panel. Reconnect the

conduit nut to the Sollatek DSP-D.

CAUTION: the conduit connection is plastic, DO NOT OVER-TIGHTEN. Connect wires

as described above.

Surface Mounting:

Choose a location near the panel that will give the most direct connection to the phase

conductors and neutral-ground busses. Use a pre-existing ½” conduit knock-out or

drill a new ½” conduit hole in the panel. Remove the conduit nut from the Sollatek DSP-

D Series and slide the wires and conduit nipple into the panel. A short piece (less than

3”) of plastic conduit may have to be added to the Sollatek DSP-D. Connect either the

close nipple on the Sollatek DSP-D or the short additional piece of conduit to the panel.

Use the four 0.20” mounting holes on the Sollatek DSP-D Series and secure it to the

wall using appropriate hardware (not supplied). Connect wires as described above.

Flush Mounting:

The fl ush mount Sollatek DSP-D Series is installed into a suitably sized hole in the wall.

This hole needs to be large enough for the body of the suppressor, yet not exceed the

fl ush mount plate mounting holes. Choose a location near the panel that will give the

most direct connection to the phase conductors and neutral-ground busses. Use a

pre-existing ½” conduit knock-out or drill a new ½” conduit hole in the panel. Remove

the conduit nut from the Sollatek DSP-D Series and slide the wires and conduit nipple

into the panel. A short piece (less than 3”) of plastic conduit may have to be added

to the Sollatek DSP-D Series. Connect either the close nipple on the Sollatek DSP-D

Series or the short additional piece of conduit to the panel. Use the four mounting holes

on the Sollatek DSP-D Series fl ush plate and secure it to the wall using appropriate

hardware (not supplied). Connect wires as described above.

INCORRECT INSTALLATION WILL IMPAIR THE EFFECTIVENESS OF AC PANEL SURGE

PROTECTORS. Particularly important is the length and routing of the connecting

leads.

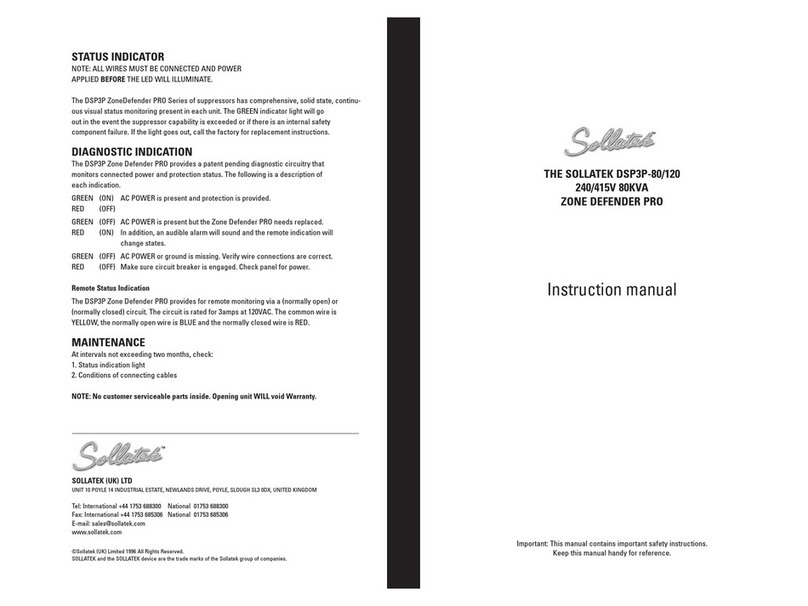

STATUS INDICATOR

NOTE: ALL WIRES MUST BE CONNECTED AND POWER APPLIED BEFORE THE LED

WILL ILLUMINATE.

The Sollatek DSP-D Series of suppressors has comprehensive, solid state, continuous

visual status monitoring present in each unit. The GREEN indicator light will go out

in the event the suppressor capability is exceeded or if there is an internal safety

component failure. If the light goes out, call the factory for replacement instructions.

Panel LED Mount Models only:

Specifi c Sollatek DSP-D Series models have the

capability of panel indication. Drill a 0.280” hole in the panel in the desired location.

Maximum panel thickness is 0.125”. Remove the lens from the LED holder and snap

it into the panel. While holding the lens in place, snap the LED holder onto the lens.

Use the supplied wire nut to connect the wires, matching the color codes on the

suppressor to those on the LED holder.

REMOTE STATUS INDICATION

Each Sollatek DSP-D Series has remote indication of the protector status. This is

available as a normally closed dry contact. To utilize this feature, connections are

made to the pair of stranded RED #18AWG wires. If this loop opens, it indicates a

failure of the Sollatek DSP-D Series. Call the factory for replacement instructions. If

remote indication is not used, RED wires can be cut and taped off.

MAINTENANCE

At intervals not exceeding two months, check:

1. Status indication lights

2. Conditions of connecting cables and terminals

NOTE: No customer serviceable parts inside. Opening module WILL void warranty

CONNECTION DIAGRAMS

Note: Circuit breaker (15-30A) is optional

INTRODUCTION

This document explains how to install the Sollatek

DSP-S AC Panel Surge Protection Devices.

INSTALLATION INSTRUCTIONS

Warning: Terminals marked L1, L2, L3, N, GND

(where relevant) must be connected respectively to

phase(s) neutral and ground. Failure to comply may result in danger or damage. See

corresponding diagrams for proper connections.

INSTALLATION DESCRIPTION

Sollatek DSP-S units are connected in parallel (or in “shunt”) across the supply to be

protected. The connecting cable does not carry the supply current, only the current

associated with suppressing the transient overvoltage.

MOUNTING

The units should be mounted as close as possible to the panel to be protected. See

Connecting Lead lengths opposite. Conduit, preferably metallic, is to be installed from

the suppressor to the panel. Drill holes in the Sollatek DSP-S enclosure only in the

designated areas as shown in recommended cable dressing illustrations (page 6).

Mount the unit in the appropriate location using the mounting holes provided on the

enclosure.

FLUSH MOUNT

The fl ush mount Sollatek DSP-S is installed into a suitably sized hole in the wall.

Remove the four snap-in screw covers and remove the cover, temporarily disconnect

the cover ground wire. Choose a location such that the recessed part of the Sollatek

DSP-S enclosure can be fi xed to a wall stud or suitable upper or lower support. Be

sure that the Sollatek DSP-S enclosure is fl ush with the wall. Follow the standard

instructions for location and connecting leads. Reconnect the cover ground wire and

install the cover plate. Replace the four snap-in screw covers.

INCORRECT INSTALLATION WILL IMPAIR THE EFFECTIVENESS OF THE AC PANEL

PROTECTORS. Particularly important is the length of the connecting leads (see

opposite).

STATUS INDICATORS

The DSP-S units have comprehensive, continuous visual status monitoring present on

each module. NOTE: Indicator windows do NOT illuminate.

Status Full Reduced No No Power To

Indicated Protection (Standby) Protection Protector

Indication Both Windows One Window Both Windows Both Windows

Windows Show Green Shows Black Show Black Show Green

LED Green Green Green Green

Indicator LED Lit LED Lit LED Out LED Out

Note: 240V 3 Phase Delta Systems and 480V 3 Phase Delta Systems do not have LED

indication.

REMOTE INDICATORS

A remote indication of the reduced protection

state is available as a normally open or normally

closed dry contact. Pluggable connectors must be

wired as shown below.

WARNING: of high neutral to ground voltage On

certain models, a RED warning light is provided.

Should this light glow RED at any time, consult

a qualifi ed electrical contractor to check the

integrity of the building wiring. This RED light does

not indicate suppressor failure; however, a RED

glowing light is indicative of potentially hazardous

site wiring.

CONNECTING LEADS

Connect the suppressor as shown in the installation diagram. Refer to diagrams below

for recommended cable dressing. Connect the terminals within the suppressor to the

load side of 30A breakers within the panel.

RECOMMENDED WIRE GAUGE

Minimum of 10 AWG. Maximum of 4 AWG ( for ease of dressing)

LENGTH OF CONNECTING LEADS

The longer the connecting leads between the the DSP-S and power panel, the higher

the residual transient voltage.

RECOMMENDED MAXIMUM: 500mm (19”). IDEALLY: 250mm (10”)

Each 250mm increase in cable length; increases clamping voltage by 25V per 1000A

surge current discharged.

• BIND THE PHASE NEUTRAL AND GROUND CONDUCTORS TIGHTLY, OVER THE

ENTIRE RUN FROM THE SUPPRESSOR TO THE SERVICE PANEL.

• ALWAYS USE THE SHORTEST LENGTH OF CONNECTING CABLE POSSIBLE.

4

pluggable connector

pluggable connector

customer

customer

supplied

wires

normally closed

normally open

end

end

view of

view of

module

module

SOLLATEK DSP-S SERIES

AC Panel Transient Voltage Surge Suppressors

power/

protection

LED

indicator

indicator

windows

RECOMMENDED CABLE DRESSING

5

Sollatek DSP3P-S90 Confi guration and Schematic Connection Diagrams

120/208V THREE PHASE 4W WYE

240/415V THREE PHASE 4W WYE

277/480V THREE PHASE 4W WYE

220/380V THREE PHASE 4W WYE

Sollatek DSP3P-S90 Confi guration and Schematic Connection Diagrams

240V THREE PHASE 3W DELTA

480V THREE PHASE 3W DELTA

277/480V THREE PHASE 3W DELTA

Note: these models have no LEDs

Sollatek DSP1P-S90 Confi guration and Schematic Connection Diagrams

240V or 120V SINGLE PHASE 2W

Maintenance

At intervals not exceeding two months, check:

1. Status indication lights

2. Conditions of connecting cables and terminals

Module Replacement

WARNING

: Before opening the access panel, ensure that the AC supply has been disconnected.

Unplug the remote contact connector at the top of the module. Remove the mounting nuts at the top and bottom of the module. The protection module can now be removed.

WARNING

: Replace the defective module with a module having the same color label and voltage rating.

Installation of the replacement module is the reverse of the above procedure. Final step, check that all cable connections are secure and nuts are tightened. Do not overtighten.

NOTE

: No customer serviceable parts inside. Opening module will void warranty.

6

INTRODUCTION

This document explains how to install the Sollatek

DSP-M Series of AC Panel Surge Protection

Devices.

INSTALLATION INSTRUCTIONS

Warning: Terminals marked L1, L2, L3, N, GRD (where

relevant) must be connected respectively to phase(s) neutral and ground. Failure to

comply many result in danger or damage. See corresponding diagrams for proper

connections.

INSTALLATION DESCRIPTION

Sollatek DSP-M units are connected in parallel (or in “shunt”) across the supply to be

protected. The connecting cable does not carry the supply current, only the current

associated with suppressing the transient overvoltage.

MOUNTING

The units should be mounted as close as possible to the panel to be protected. See

opposite on Connecting Lead lengths. Conduit, preferably metallic, is to be installed

from the suppressor to the panel. Drill holes in the Sollatek DSP-M enclosure only in

the designated areas as shown in recommended cable dressing illustrations (below).

Mount the unit in the appropriate location using the mounting holes provided on the

enclosure.

INCORRECT INSTALLATION WILL IMPAIR THE EFFECTIVENESS OF THE AC PANEL

PROTECTORS.

Particularly important is the length of the connecting leads (see section opposite).

STATUS INDICATORS

The Sollatek DSP-M units have comprehensive, continuous visual status monitoring

present on each module.

Status Full Reduced No No Power To

Indicated Protection (Standby) Protection Protector

Indication Both Windows One Window Both Windows Both Windows

Windows Show Green Shows Black Show Black Show Green

LED Green Green Green Green

Indicator LED Lit LED Lit LED Out LED Out

Note: 240V 3 Phase Delta Systems and 480V 3 Phase Delta Systems do not have LED

indication.

REMOTE INDICATORS

A remote indication of the reduced protection state is available as a normallyopen or

normally closed dry contact.

WARNING: HIGH NEUTRAL TO GROUND VOLTAGE

On certain models, a RED warning light is provided. Should this light glow RED at any

time, consult a qualifi ed electrical contractor to check the integrity of the building

wiring. This RED light does not indicate suppressor failure, however a RED glowing

light is indicative of potentially hazardous site wiring.

CONNECTING LEADS

Connect the suppressor as shown in the installation diagram. Refer to diagrams

below for recommended cable dressing. Connect the terminals within the suppressor

to the load side of 60A breakers or fuses withing the panel. See specifi c connection

diagrams for more details and markings on unit if provided.

RECOMMENDED WIRE GAUGE

Minimum of 8 AWG

Maximum of 4 AWG (for ease of dressing)

LENGTH OF CONNECTING LEADS

The longer the connecting leads between the DSP-M and power panel the higher the

residual transient voltage.

RECOMMENDED MAXIMUM: 19” (500mm)

IDEALLY: 10” (250mm)

Each 10” (250mm) increase in cable length, increases clamping voltage by 25V per

1,000A surge current discharged.

• BIND THE PHASE NEUTRAL AND GROUND CONDUCTORS TIGHTLY OVER THE

ENTIRE RUN FROM THE SUPPRESSOR TO THE SERVICE PANEL.

• ALWAYS USE THE SHORTEST LENGTH OF CONNECTING CABLE POSSIBLE.

SOLLATEK DSP-M SERIES

AC Panel Transient Voltage Surge Suppressors

indicator

windows

power/

protection

LED

indicator

windows

RECOMMENDED CABLE DRESSING

7

Sollatek DSP3P-M Confi guration and Schematic Connection Diagrams

120/208V THREE PHASE 4W WYE

Sollatek DSP3P-M Confi guration and Schematic Connection Diagrams

120/240V THREE PHASE 4W HIGH LEG DELTA

Note: L2 is designated as the "high leg"

Sollatek DSP3P-M Confi guration and Schematic Connection Diagrams

240V THREE PHASE 3W DELTA

Sollatek DSP3P-M Confi guration and Schematic Connection Diagrams

277/480 THREE PHASE 4W WYE

220/380 THREE PHASE 4W WYE

240/415 THREE PHASE 4W WYE

Sollatek DSP3P-M Confi guration and Schematic Connection Diagrams

480V Three Phase 3W Delta

8

Maintenance

At intervals not exceeding two months, check:

1. Status indication lights

2. Conditions of connecting cables and terminals

Module Replacement

WARNING

: Before opening the access panel, ensure that the AC supply has been disconnected.

Unplug the remote contact connector at the top of the module. Remove the mounting nuts at the top and

bottom of the module. The protection module can now be removed.

WARNING

: Replace the defective module with a module having the same color label and voltage

rating.

Installation of the replacement module is the reverse of the above procedure. Final step,

check that all cable connections are secure and nuts are tightened. Do not overtighten.

NOTE

: No customer serviceable parts inside. Opening module will void warranty.

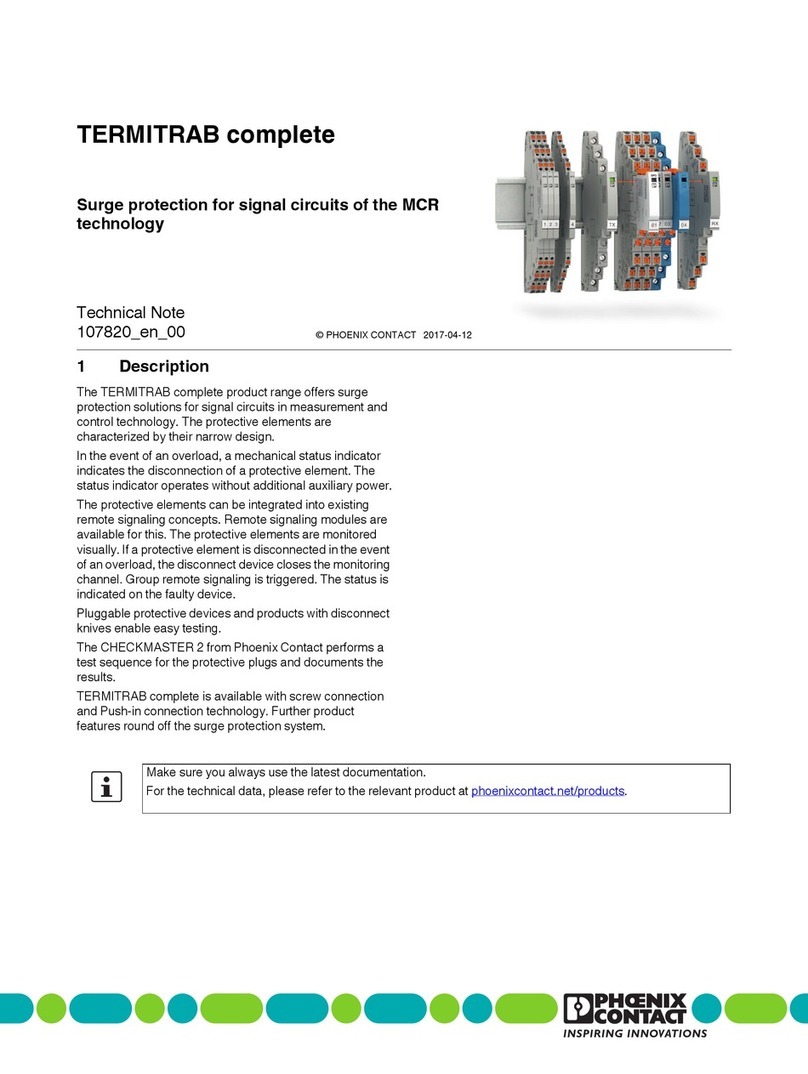

POWER PROBLEMS AND THEIR ASSOCIATED CAUSES

All electrical and electronic equipment, connected to the mains supply is at

risk of being damaged from spikes, surges, lightning, brown-outs, power-

cuts (blackouts), power back surges, and over-voltage.

The following is a summary of the main types of power problems, causes

and how these affect electrical and electronic equipment.

Spikes/Surge:

Very short, (one millisecond) event of very high surge in voltage to thousands of volts and amps. Spikes are common in all parts of the world and

repeated exposure to spikes will damage electronic equipment and corrupt data.

What causes it?

Switching on/off of nearby equipment, lightning, motors starting etc.

RFI (Radio Frequency Interference)/Noise:

High frequency disturbances that occur within a short period of time (milliseconds). RFI & noise are very common in

all parts of the world and are the main cause of data corruption.

What causes it?

Generated by high frequency noise from nearby equipment like TV, radio equipment, transmitters, mobile phones, switching on/off of certain

loads, fluorescent lights, motor speed controls, light dimmers.

Over-Voltage:

Long duration (milliseconds, seconds, minutes, hours or days) rise in the voltage above acceptable limits. Depending on the level of the over-

voltage, the damage can be instantaneous, severe and irreparable.

What causes it?

On return of mains supply after power cuts, under-sized utility oscillating between periods of brown-outs and over-voltage or accidental (e.g.

accidental connection between two phases).

Brown-Out:

Long duration of low voltage (milliseconds to seconds, minutes, hours or days). Very common in parts of the world especially where the power

utilities are over-stretched. Prolonged and frequent brownouts cause the equipment to malfunction or not work at all. Repeated episodes are certain to cause

damage. Motors and compressors (and therefore fridges, freezers, coolers, air-conditioners and pumps) are especially at risk. In time, damage is certain.

What causes it?

Most commonly an over-stretched utility, especially in areas of poor power distribution infra-structure and remote areas. Common in dry

seasons where water is used for electricity generation.

Lightning:

Direct or nearby strikes can cause minor problems or severe disturbances and damage. Lightning produces spikes/surges, over-voltage or power

cuts.

What causes it?

The surge is generated by either a direct hit, or indirectly striking underground or overhead lines and transmitting high surges to connected

equipment in nearby buildings.

Power-cuts:

Common in many countries in the world, especially in areas of frequent voltage problems. Sudden loss of power can cause damage ranging from

corruption of data to mechanical faults as equipment is stopped while in operation.

What causes it?

Power or sub station failure, breakdown in the distribution network, or simply a plug being pulled out accidentally.

Power-Back Surges:

These typically occur when power returns after a power-cut and connected equipment receives a surge of electricity at an over-voltage

level, which can be very damaging (see above).

What causes it?

Power back surges are created by the utility, when it restores supply at an above normal voltage in order to compensate for the demand as

connected equipment re-starts simultaneously.

Telecom surges, spikes and lightning:

Short term, high voltage and current phenomena occurring on the telephone lines. Can cause irreparable damage to any

piece of equipment connected to the incoming line. The telephone line itself may even be damaged or destroyed in severe cases.

What causes it?

Telecom spikes are caused by lightning striking either the telephone line directly or an object near it.

9

SOLLATEK PRODUCT RANGE COMPARISON CHART

The following chart gives an overview of most of the Sollatek range of products and the protection they offer.

10

©Sollatek (UK) Limited 1996 All Rights Reserved.

SOLLATEK and the SOLLATEK device are the trade marks of the

Sollatek group of companies.

DSP-D, DSP-S, DSP-M RANGE

Dec 05 Version 1.0

SOLLATEK (UK) LTD

UNIT 10 POYLE 14 INDUSTRIAL ESTATE,

NEWLANDS DRIVE, POYLE,

SLOUGH SL3 0DX,

UNITED KINGDOM

Tel: International +44 1753 688300 National 01753 688300

Fax: International +44 1753 685306 National 01753 685306

E-mail: [email protected]

www.sollatek.com

TM

This manual suits for next models

5

Other Sollatek Surge Protector manuals