Solvimus MBUS-PS6 User manual

MBUS-PS - USER MANUAL

MBUS-PS

Level converter

for the M-Bus

Version: 1.4

Date: 6 December 2022

Authors:

Remo Reichel, Frank Richter

solvimus GmbH

Ratsteichstr. 5

98693 Ilmenau

Germany

solvimus GmbH – Ratsteichstr. 5 – 98693 Ilmenau – Germany

MBUS-PS - User manual

Page intentionally left blank

Page 2/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Table of Contents

Table of Contents 3

1 Notes and conventions 4

1.1 Aboutthisdocument ....................................... 4

1.2 Legalbasis............................................. 4

1.2.1 Placingonthemarket................................... 4

1.2.2 Copyrightprotection ................................... 4

1.2.3 Personnelqualification .................................. 4

1.2.4 Intendeduse........................................ 4

1.2.5 Exclusionofliability.................................... 4

1.2.6 Disclaimer......................................... 4

1.3 Symbols .............................................. 5

1.4 Fontconventions ......................................... 5

1.5 Numbernotation ......................................... 5

1.6 Safetyguidelines.......................................... 6

1.7 Scope ............................................... 6

1.8 Abbreviations ........................................... 6

2 Introducing the device 9

2.1 Generalinformation ........................................ 9

2.2 Delivery variants and scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Connectors............................................. 9

2.4 StatusLEDs............................................ 11

2.5 Firststeps ............................................. 11

2.5.1 Configuration of the logical bus master . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.2 SignallingontheM-Bus ................................. 12

2.6 Specifictroubleshooting...................................... 13

2.6.1 Hardwareerrors ...................................... 13

2.6.2 Errors while meter reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Technicaldata........................................... 15

2.7.1 Generalspecifications................................... 15

2.7.2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Accessory 18

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 3/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

1 Notes and conventions

1.1 About this document

This manual provides guidance and procedures for a fast and efficient installation and start-up of the units

described in this manual. It is imperative to read and carefully follow the safety guidelines.

1.2 Legal basis

1.2.1 Placing on the market

Manufacturer of the MBUS-PS is the solvimus GmbH, Ratsteichstraße 5, 98693 Ilmenau, Germany.

1.2.2 Copyright protection

This documentation, including all illustrations contained therein, is protected by copyright. The author is

solvimus GmbH, Ilmenau. The exploitation rights are also held by solvimus GmbH. Any further use that

deviates from the copyright regulations is not allowed. Reproduction, translation into other languages, as

well as electronic and phototechnical archiving and modification require the written permission of solvimus

GmbH. Violations will result in a claim for damages. The solvimus GmbH reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical progress. All rights in the event

of the granting of a patent or the protection of a utility model are reserved by solvimus GmbH. Third-party

products are always mentioned without reference to patent rights. The existence of such rights can therefore

not be excluded.

1.2.3 Personnel qualification

The product use described in this documentation is intended exclusively for qualified electricians or persons

instructed by these. They must all have good knowledge in the following areas:

•Applicable standards

•Use of electronic devices

1.2.4 Intended use

If necessary, the components or assemblies are delivered ex works with a fixed hardware and software config-

uration for the respective application. Modifications are only permitted within the scope of the possibilities

shown in the documentation. All other changes to the hardware or software as well as the non-intended use

of the components result in the exclusion of liability on the part of solvimus GmbH. Please send any requests

for a modified or new hardware or software configuration to solvimus GmbH.

1.2.5 Exclusion of liability

Study this manual and all instructions thoroughly prior to the first use of this product and respect all safety

warnings, even if you are familiar with handling and operating electronic devices.

The solvimus GmbH accepts no liability for damage to objects and persons caused by erroneous operation, inap-

propriate handling, improper or non-intended use or disregard for this manual, especially the safety guidelines,

and any warranty is void.

1.2.6 Disclaimer

All products, company names, trademarks and brands are the property of their respective holders. Their use

serves only to describe and identify the respective company, product or service. Use of them does not imply

any affiliation with, commercial relationship with or endorsement by them.

Page 4/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Firefox is a trademark of the Mozilla Foundation in the U.S. and other countries.

Chrome™browser is a trademark of Google Inc.

Microsoft Excel is a trademark of the Microsoft group of companies.

7-Zip Copyright (C) 1999-2022 Igor Pavlov.

Wireshark: Copyright 1998-2022 Gerald Combs <gerald@wireshark.org> and contributors.

1.3 Symbols

Danger: It is essential to observe this information in order to protect persons from injury.

Caution: It is essential to observe this information in order to prevent damage to the device.

Notice: Boundary conditions that must always be observed to ensure smooth and efficient operation.

ESD (Electrostatic Discharge): Warning of danger to components due to electrostatic discharge. Observe

precautionary measures when handling components at risk of electrostatic discharge.

Note: Routines or advice for efficient equipment use.

Further information: References to additional literature, manuals, data sheets and internet pages.

1.4 Font conventions

Names of paths and files are marked in italics. According to the system the notation is using slash or backslash.

e. g.: D: \Data

Menu items or tabs are marked in bold italics.

e. g.: Save

An arrow between two menu items or tabs indicates the selection of a sub-menu item from a menu or a

navigation process in the web browser.

e. g.: File →New

Buttons and input fields are shown in bold letters.

e. g.: Input

Key labels are enclosed in angle brackets and shown in bold with capital letters.

e. g.: ⟨F5⟩

Programme codes are printed in Courier font.

e. g.: ENDVAR

Variable names, identifiers and parameter entries are marked in italics.

e. g.: Value

1.5 Number notation

Numbers a noted according to this table:

Numbering system Example Comments

Decimal 100 Normal notation

Hexadecimal 0x64 C-like notation

Binary ’100’ In apostrophes

’0110.0100’ Nibbles separated by dots

Table 1: Numbering systems

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 5/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

1.6 Safety guidelines

Observe the recognized rules of technology and the legal requirements, standards and norms, and other

recommendations.

Study the instructions for the extinction of fire in electrical installations.

The power supply must be switched off before replacing components and modules.

If the contacts are deformed, the affected module or connector must be replaced, as the function is not guar-

anteed in the long term.

The components are not resistant to substances that have creeping and insulating properties. These include

e.g. aerosols, silicones, triglycerides (ingredient of some hand creams). If the presence of these substances in

the vicinity of the components cannot be excluded, additional measures must be taken:

•Install the components in an appropriate casing.

•Handle components with clean tools and materials only.

Only use a soft, wet cloth for cleaning. Soapy water is allowed. Pay attention to ESD.

Do not use solvents like alcohol, acetone etc. for cleaning.

Do not use a contact spray, because in an extreme case the function of the contact point is impaired

and may lead to short circuits.

Assemblies, especially OEM modules, are designed for installation in electronic housings. Do not touch

the assembly when it is live. In each case, the valid standards and directives applicable to the construction

of control cabinets must be observed.

The components are populated with electronic parts which can be destroyed by an electrostatic discharge.

When handling the components, ensure that everything in the vicinity is well earthed (personnel, work-

place and packaging). Do not touch electrically conductive components, e.g. data contacts.

1.7 Scope

This documentation describes the device manufactured by solvimus GmbH, Ilmenau, and stated on the title

page.

1.8 Abbreviations

Abbreviation Meaning

2G Mobile radio standard, synonym for GSM or GPRS

3G Mobile radio standard, synonym for UMTS

4G Mobile radio standard, synonym for LTE

ACK Acknowledge

AES Advanced Encryption Standard

AFL Authentication and Fragmentation Layer

AI Analog Input

ANSI American National Standards Institute

AO Analog Output

APN Access Point Name

ASCII American Standard Code for Information Interchange

ASHRAE American Society of Heating, Refrigerating and Air-Conditioning Engineers

BACnet Building Automation and Control networks

BBMD BACnet Broadcast Management Device

BCD Binary-coded decimal numbers

BDT Broadcast Distribution Table

BMS Building Management System

CA Certification Authority

CHAP Challenge Handshake Authentication Protocol

CI Control Information

CLI Command line interface

COSEM COmpanion Specification for Energy Metering

CPU Central processing unit

CRC Cyclic redundancy check

CSV Character-Separated Values

Continued on next page

Page 6/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Table 2 – Continued from previous page

Abbreviation Meaning

CTS Clear to send

D0 D0 interface (optical interface, IEC 62056-21)

DDC Direct Digital Control

DHCP Dynamic Host Configuration Protocol

DI Digital Input, digital input terminal

DIF Data information field

DIFE Data information field extensions

DIN Deutsches Institut für Normung, German Institute for Standardization

DLDE Direct Local Data Exchange (EN 62056-21, IEC 1107)

DLDERS DLDE communication via RS-232 or RS-485

DLMS Device Language Message Specification

DNS Domain Name System

DO Digital Output, digital output terminal

EEG German Renewable Energy Sources Act

EIA/TIA Electronic Industries Alliance/Telecommunications Industry Association

ELL Extended Link Layer

EMC Electromagnetic compatibility

EN European norm

ESD Electrostatic Discharge

FCB Frame Count Bit

FCV Frame Count Valid Bit

FNN Forum Netztechnik/Netzbetrieb, subgroup of VDE

FSK Frequency Shift Keying

FTP File Transfer Protocol

FTPS FTP via TLS

GB Gigabyte

GMT Greenwich Mean Time

GPRS General Packet Radio Service

GSM Global System for Mobile Communications

HCA Heat cost allocator

HTTP Hypertext Transfer Protocol

HTTPS Hypertext Transfer Protocol Secure

I2C Inter-Integrated Circuit

I/O Input/Output

ICMP Internet Control Message Protocol

ID Identification, Identifier, unique marking

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

IoT Internet of Things

IP Internet Protocol or IP address

ISO International Organization for Standardization

JSON JavaScript Object Notation

LAN Local area network

LED Light-Emitting Diode

LSB Least significant byte

LSW Least significant word

LTE Long Term Evolution

M2M Machine-to-Machine

M-Bus Meter-Bus (EN 13757, part 2, 3 and 7)

MAC Medium Access Control or MAC-Adresse

MB Megabyte

MCR Multi Channel Reporting

MDM Meter Data Management

MEI Modbus Encapsulated Interface

MHz Megahertz

MQTT Message Queuing Telemetry Transport

MSB Most Significant Byte

MSW Most Significant Word

MUC Multi Utility Communication, MUC controller

NB-IoT Narrow Band Internet of Things

OBIS Object Identification System

OEM Original Equipment Manufacturer

OMS Open Metering System

PAP Password Authentication Protocol

PEM Privacy Enhanced Mail

PIN Personal Identification Number

PKI Public Key Infrastructure

PLC Programmable Logic Controller

PPP Point-to-Point Protocol

PPPoE Point-to-Point Protocol over Ethernet

PUK Personal Unblocking Key

Continued on next page

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 7/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

Table 2 – Continued from previous page

Abbreviation Meaning

RAM Random Access Memory

REQ_UD Request User Data (Class 1 or 2)

RFC Requests For Comments

RSP_UD Respond User Data

RSSI Received Signal Strength Indicator

RTC Real-Time Clock

RTOS Real-Time Operating System

RTS Request to send

RTU Remote Terminal Unit

S0 S0 interface (pulse interface, EN 62053-31)

SCADA Supervisory Control and Data Acquisition

SCP Secure Copy

SFTP SSH File Transfer Protocol

SIM Subscriber Identity Module

SML Smart Message Language

SMTP Simple Mail Transfer Protocol

SND_NKE Send Link Reset

SND_UD Send User Data to slave

SNTP Simple Network Time Protocol

SPST Single Pole Single Throw Relay (closing switch)

SRD Short Range Device

SSH Secure Shell

SSL Secure Sockets Layer

TCP Transmission Control Protocol

THT Through-Hole Technology

TLS Transport Layer Security

U Unit width of the housing (1 U = 18 mm)

UART Universal Asynchronous Receiver Transmitter

UDP User Datagram Protocol

UL Unit load for M-Bus

UMTS Universal Mobile Telecommunications System

UTC Universal Time Coordinated

VDE Verband der Elektrotechnik Elektronik Informationstechnik e.V., German association

VHF Very high frequency

VIF Value information field

VIFE Value information field extensions

VLAN Virtual Local Area Network

VPN Virtual Private Network

WAN Wide Area Network

WLAN Wireless Local Area Network

wM-Bus Wireless Meter-Bus (EN 13757, part 3, 4 and 7)

XML eXtensible Markup Language

XSLT eXtensible Stylesheet Language Transformation

Table 2: Abbreviations

Page 8/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

2 Introducing the device

2.1 General information

The M-Bus (Meter-Bus) is an established and well-known interface for automated meter reading. Especially

the ease of installation (simple two-wire system with powering by the bus) and the robustness are important

features. These are also special attributes that are of interest for use in industrial environments.

The M-Bus is defined in the standard EN 13757. It establishes an own physics as well as an own protocol.

For connecting it to other systems, a translation is necessary.

The bit transmission in the M-Bus corresponds to the one in a UART interface. The data are transferred

according to the common time response. Exclusively the levels of voltage respectively current are characteristic

for the M-Bus. The levels are very robust and permit a continuous supply of the connected devices (slaves)

by the bus master.

Any UART is compatible to M-Bus by a conversion of the physical layer, that is the level. Hence, any PC with

an RS-232 interface can be made a (physical) bus master. This is the task of level converters (in the sequel

MBUS-PS for simplicity). They convert the typical RS-232 levels to M-bus levels. The M-Bus protocol can

thus be mapped in a PC software. This enables simple meter reading and meter configuration using a PC. In

automation, also a typical PLC can access meters via MBUS-PS, provided the PLC supports the protocol.

The MBUS-PS comes, depending on the model, in a housing 1 U (module) wide (MBUS-PS6, MBUS-PS20,

MBUS-PS32, MBUS-PS80) or 3 U wide (MBUS-PS125, MBUS-PS250, MBUS-PS500) and is intended for

top hat rail mounting (DIN rail 35 mm).

The serial number of the devices of the solvimus GmbH can be read from the housing.

2.2 Delivery variants and scope of delivery

The MBUS-PS is offered in a range of variants, and so can easily be adapted to the requirements of the

particular property.

Variant Order number M-Bus interface

MBUS-PS6 500374 max. 6 unit loads

MBUS-PS20 500330 max. 20 unit loads

MBUS-PS32 500375 max. 32 unit loads

MBUS-PS80 500331 max. 80 unit loads

MBUS-PS125 500359 max. 125 unit loads

MBUS-PS250 500360 max. 250 unit loads

MBUS-PS500 500351 max. 500 unit loads

Table 3: Delivery variants

The scope of delivery contains the device and a Quick Start Guide.

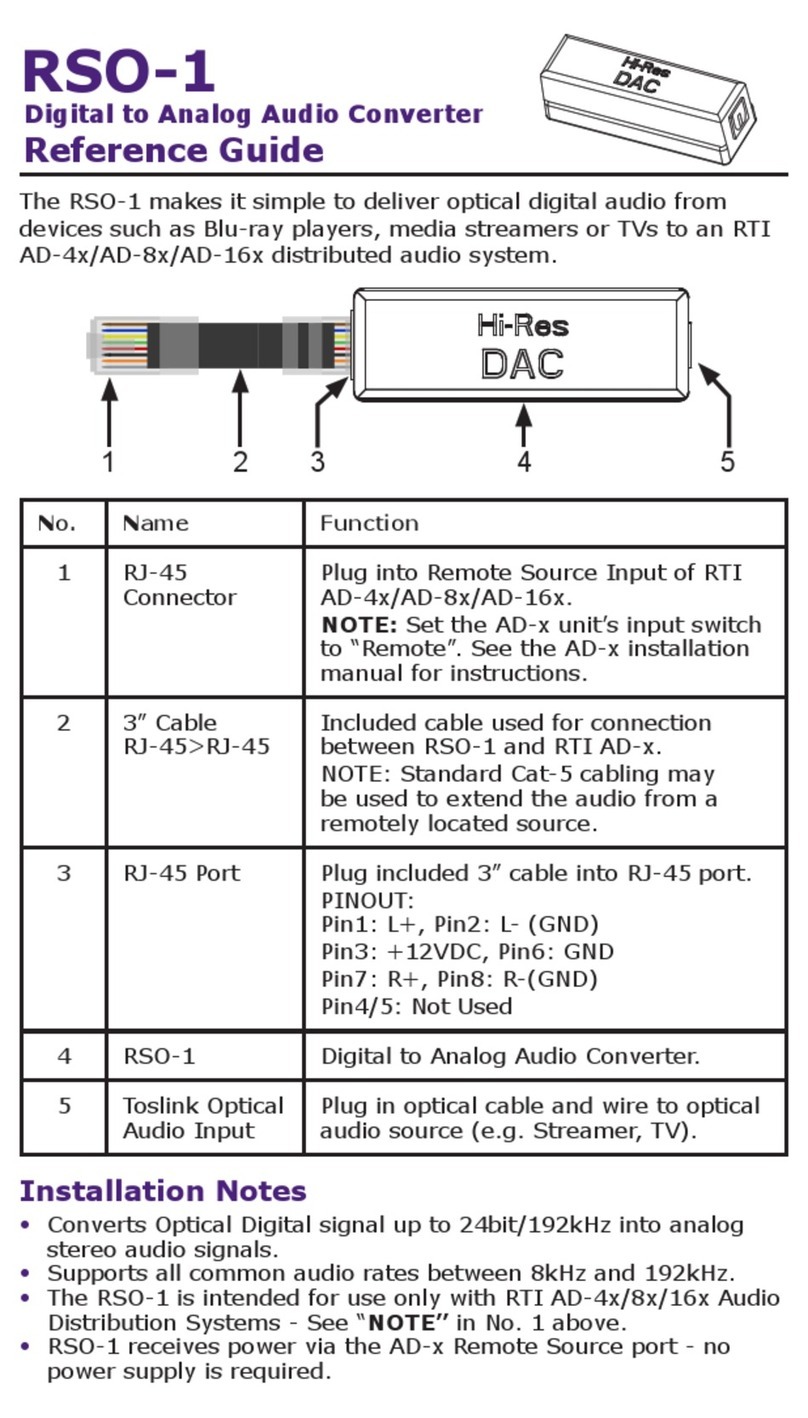

2.3 Connectors

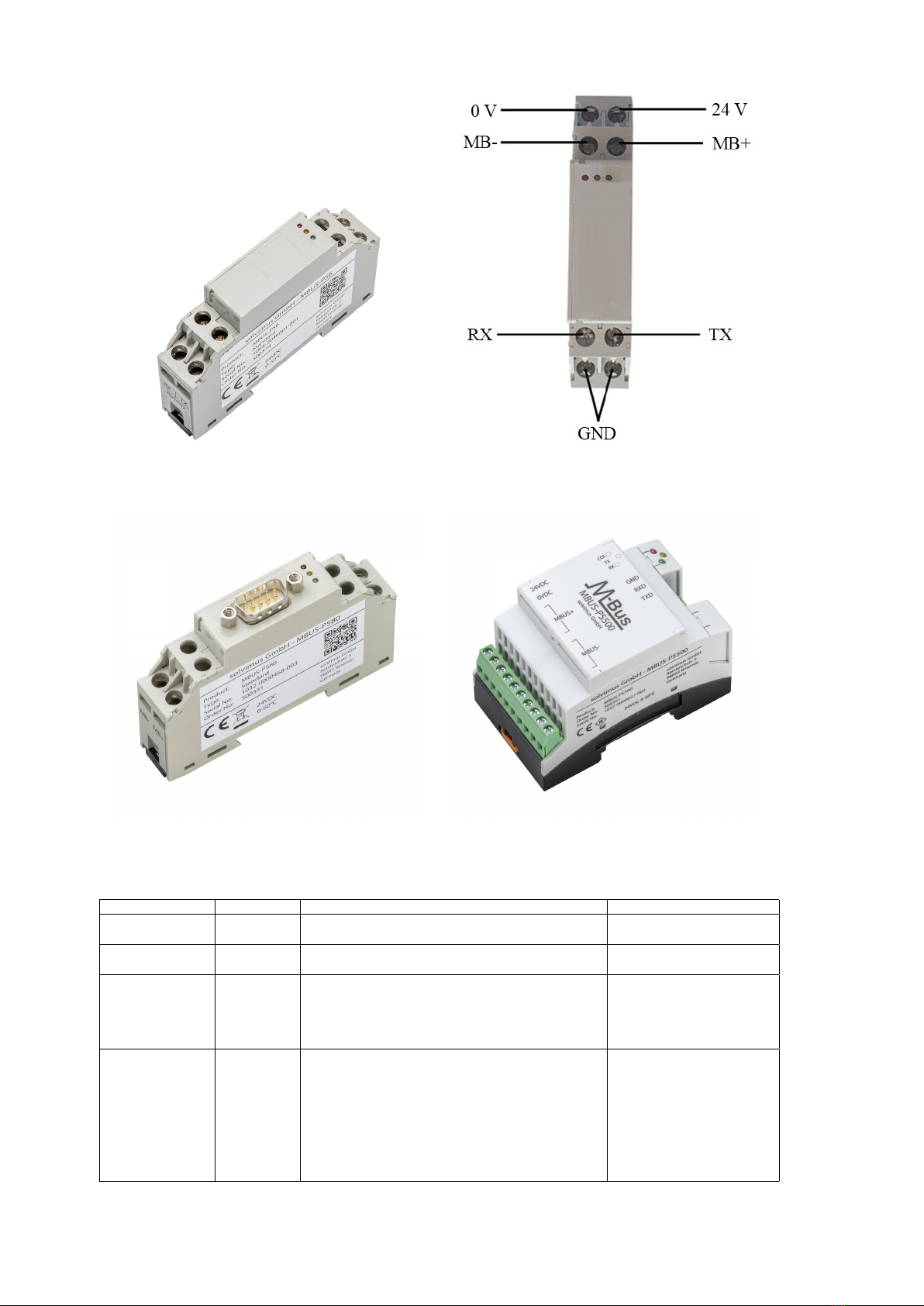

The connectors and interfaces of the MBUS-PS are on different sides of the device.

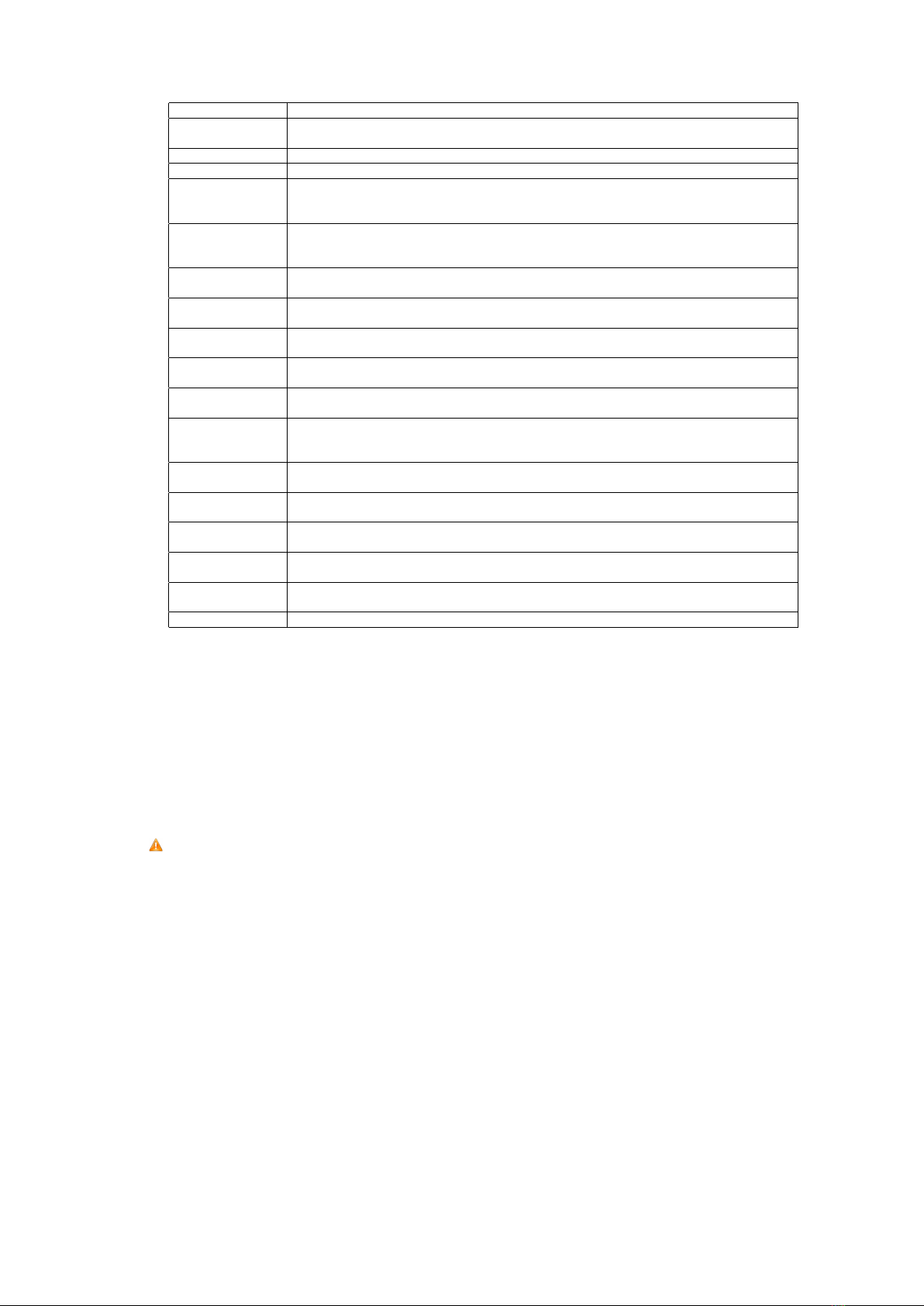

The following figures show the variants. Similar in outward appearance are:

•MBUS-PS6 and MBUS-PS32

•MBUS-PS20 and MBUS-PS80

•MBUS-PS125, MBUS-PS250 and MBUS-PS500

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 9/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

Figure 1: MBUS-PS6, views and connectors

Figure 2: MBUS-PS80 and MBUS-PS500

The following connectors are available at the MBUS-PS:

Connector Designation Pin assignment Comments

Power supply 24 V 24 V: positive power supply 24 VDC, screw terminal

0 V 0 V: negative power supply cross section 2.5 mm2

M-Bus connector MB+ MBUS+: positive bus line screw terminal

MB- MBUS-: negative bus line cross section 2.5 mm2

RS-232 connector RX RX: signal line for receiving data from the PC, according to

MBUS-PS6, TX signal line for transmitting data on the M-Bus ANSI EIA/TIA-232-F-1997

MBUS-PS32 GND TX: signal line for transmitting data to the PC, screw terminal

signal line for receiving data from the M-Bus cross section 2.5 mm2

GND: reference ground

RS-232 connector 1: according to

MBUS-PS20, 2: RX, as MBUS-PS6, MBUS-PS32 ANSI EIA/TIA-232-F-1997

MBUS-PS80 3: TX, as MBUS-PS6, MBUS-PS32 D-Sub male plug 9 contacts

4:

5: GND, as MBUS-PS6, MBUS-PS32

6:

7:

8:

9:

Table 4: Pin assignment MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80

Page 10/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Connector Designation Pin assignment Comments

Power supply 24 VDC 24 VDC: positive power supply 24 VDC: 12-36 VDC

0 VDC 0 VDC: negative power supply screw terminal

cross section 2.5 mm2

M-Bus connector MBUS+ MBUS+: positive bus line screw terminal

MBUS- MBUS-: negative bus line cross section 2.5 mm2

RS-232 connector RXD RXD: signal line for receiving data from the PC, according to

TXD signal line for transmitting data on the M-Bus ANSI EIA/TIA-232-F-1997

GND TXD: signal line for transmitting data to the PC, screw terminal

signal line for receiving data from the M-Bus cross section 1.5 mm2

GND: reference ground

Table 5: Pin assignment MBUS-PS125, MBUS-PS250, MBUS-PS500

2.4 Status LEDs

The MBUS-PS is equipped with 3 status LEDs. These indicate the following states:

LED* Colour Description

COL (a) red (flashing) Collision respectively too large capacitive load or overload

COL (b) red (flashing) Collision respectively too large capacitive load on the M-Bus

red (blinking) Overload of the M-Bus master

TX yellow Reception of data from the master (PC) and transmission to the M-Bus (slaves)

RX green Reception of data from the M-Bus (slaves) and transmission to the master (PC)

*Legend only on MBUS-PS125, MBUS-PS250, MBUS-PS500

(a) MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80

(b) MBUS-PS125, MBUS-PS250, MBUS-PS500

Table 6: Status LEDs

2.5 First steps

The MBUS-PS is operational after connection to the supply voltage. After switching on the power supply all

LEDs should flash briefly and then go out again.

The following figure shows a typical usage of a MBUS-PS:

Figure 3: Typical usage of the MBUS-PS, exemplified here with a MBUS-PS6 respectively a MBUS-PS32 and a PC

Further steps are not required for commissioning the device. All other settings must be performed on the

logical master, e.g. a PC.

The MBUS-PS is fully transparent to the data communication on the M-Bus. This means that the device is

not visible as an M-Bus slave and baud rate changes of the M-Bus master do not need any user interaction.

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 11/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

2.5.1 Configuration of the logical bus master

Whereas the MBUS-PS provides the physics of the M-bus master, the protocol, which is the logic of the

M-bus, needs to be implemented via software on a PC or PLC.

The range of functions of such a software can be very diverse, stretching from a simple terminal programme up

to a complete MDM system. In all cases the M-Bus must be driven physically. To achieve that, the MBUS-PS

is connected to the RS-232 interface of the logical master. The latter one needs to be parameterised for that.

The following parameters are to be used for the M-Bus:

Parameter Value Hint

Baud rate 2400 bps Common are 300, 2400 and 9600 bps, 2400 bps is most widespread.

Data bits 8 The M-Bus uses 8 data bits.

Parity Even The M-Bus uses even parity.

Stop bits 1 The M-Bus uses 1 stop bit.

Table 7: Parameter for the RS-232 interface

Consult your supplier regarding the parameterisation of your particular software solution.

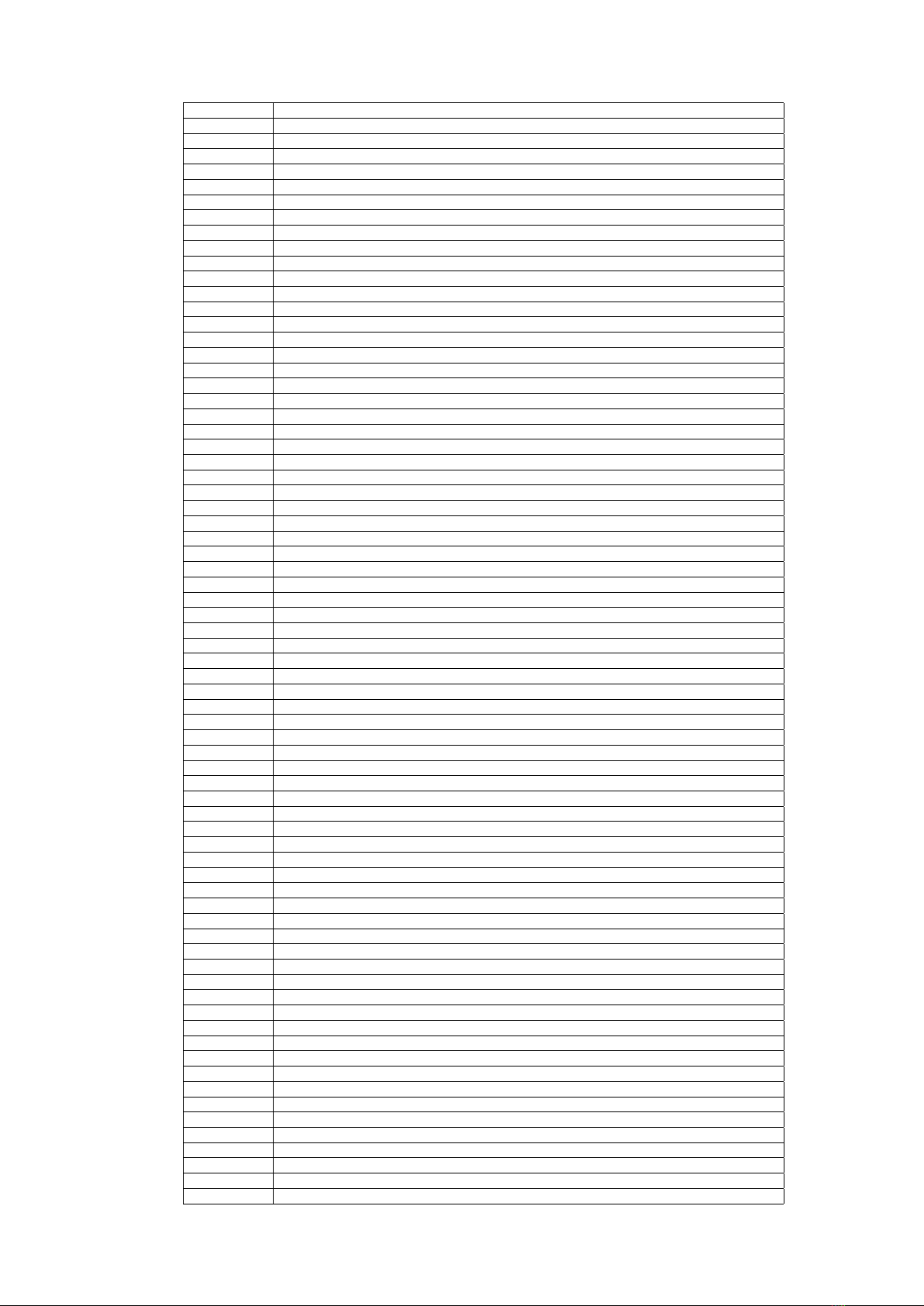

2.5.2 Signalling on the M-Bus

The M-Bus is a single master multiple slave bus. Therefore, a single bus master controls the bus and the data

traffic on the bus. Several slaves, i.e. meters, can be connected to the bus.

A second physical master is not allowed on the M-Bus.

On a physical level, the M-Bus uses voltage and current modulation to transmit data. The master transmits

telegrams by modulating the bus voltage, the slave transmits telegrams by modulating the current through

the bus. This is shown schematically in the following figure (values of current and voltage may deviate):

Figure 4: Signalling on the M-Bus

The M-Bus follows the principle of request-response, i.e. the master initiates the communication by a re-

quest/command which is then answered/confirmed by the slave. Spontaneous data transmission on the part

of the slaves is not allowed.

Certain terms are used in the M-Bus standard. The basics of communication are taken from IEC 60870-5-101.

Key terms are explained in the table below:

Term Description

ACK ACKnowledge, confirmation of a command, transmitted over the M-Bus as a single char-

acter telegram with content 0xE5.

Application reset Reset of the application layer, command to reset the meter to the default state and to

reset the meter for consecutive telegrams (multipaging).

Broadcast Broadcast, command or request is sent to all slaves, special addresses 0xFE and 0xFF are

used.

C-field Command field, code that indicates the direction in which a telegram is exchanged and the

meaning of the telegram.

Checksum Check number for checking transmission errors, the checksum the M-Bus uses, results from

the addition of the transmitted data (without telegram header, up to checksum).

Single character One of the three telegram formats the M-Bus uses with a length of exactly 1 byte, telegram

header and end, consisting of checksum and 0x16, are not present, used on the M-Bus for

ACK.

Continued on next page

Page 12/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Table 8 – Continued from previous page

Term Description

FCB Frame Count Bit, bit in the C field, which is alternately set to 1 or 0 in consecutive

telegrams, consecutive telegrams can be retrieved when the bit changes in the request.

Imark Transmit current of the slave at logical 1, usually 1 UL.

Ispace Transmit current of the slave at logical 0, usually 12.5-21.5 mA.

Short frame One of the three telegram formats the M-Bus uses with a length of exactly 5 bytes, is only

sent from the master to the slave (e.g. commands and instructions), the telegram header

is 0x10 and the telegram ends with the checksum and 0x16.

Long frame One of the three telegram formats the M-Bus uses with a variable length, the telegram

header consists of 0x68 LL LL 0x68 (LL is the length of the telegram in each case), the

telegram ends with the checksum and 0x16.

Multipaging M-Bus method of distributing large amounts of data into several logically consecutive

telegrams, use of the FCB for sequence control.

Primary address M-Bus Link layer Address, this is used to address the requests/commands, address space

0-250, special addresses 253 (0xFD), 254 (0xFE) and 255 (0xFF).

REQ_UD2 REQuest User Data type 2, request for consumption data, transmitted over the M-Bus by

the master as a short frame telegram.

RSP_UD ReSPond User Data, response of the meter to a request for data, transmitted over the

M-Bus by the slave as a long frame telegram.

Secondary address Worldwide unique identification number of the meter, consisting of manufacturer code,

8-digit serial number, medium ID and version number.

Slave select Procedure for extending the address space to the secondary address of the meter, use of

the SND_UD for selecting the meter via the application layer, then selected meter can be

addressed via special address 0xFD.

Standard load Defined idle current that a meter may draw from the M-Bus, according to the standard

1 UL=1.5 mA.

SND_NKE Send Link Reset, initialization command to the slave (reset FCB bit and selection), trans-

mitted by the master as a short frame telegram on the M-Bus.

SND_UD SeND User data, sending data or commands to the meter, transmitted by the master as a

long frame telegram on the M-Bus.

Umark Mark voltage, upper voltage of the M-Bus signals at the master, representation of the

logical 1, idle state, usually 24-42 V.

Uspace Space voltage, lower voltage of the M-Bus signals at the master, representation of the

logical 0, usually 12-30 V.

UL Unit of standard load (see above)

Table 8: M-Bus specific terms

2.6 Specific troubleshooting

In case the MBUS-PS does not work as described in this document, it is useful to locate the malfunction in

order to resolve the issue and to recover the full functionality again.

2.6.1 Hardware errors

The device does not respond.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

The device does not respond after powering on. The current consumption remains at approx. 0 mA or none

of the LEDs flashes briefly about powering on.

Check the power supply:

•Is there a voltage of approx. 24 VDC between the connectors 24 V and 0 V, respectively 24 VDC and

0 VDC?

•Is the polarity of the power supply correct?

•Is there a voltage of approx. 36-40 VDC (see Section 2.7.2) between the connectors MB+ and MB-

respectively MBUS+ and MBUS-?

If errors could not be eliminated, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 13/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

The current consumption is too high.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

After powering on, the current consumption rises to values beyond 500 mA (MBUS-PS6, MBUS-PS20, MBUS-

PS32, MBUS-PS80) respectively 1000 mA (MBUS-PS125, MBUS-PS250, MBUS-PS500).

Check the M-Bus connector:

•Is there a voltage of about 36-40 VDC (see Section 2.7.2) between the connectors MB+ and MB-

respectively MBUS+ and MBUS-?

•Disconnect the M-Bus from the device. Is the current consumption reduced? Can you now measure the

36 VDC (MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80) respectively 40 VDC (MBUS-PS125,

MBUS-PS250, MBUS-PS500)?

•Are the LEDs briefly lit after powering on?

If errors could not be eliminated, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

2.6.2 Errors while meter reading.

The transmission LED remains off while sending.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

Check the cable between MBUS-PS and the PC, and replace faulty cables if necessary. The connectors RX

and TX must be crossed between the PC and MBUS-PS if need be.

If errors could not be eliminated, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

The reception LED remains off after sending.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

Check the cable between MBUS-PS and the meter, and replace faulty cables if necessary. Measure the M-Bus

voltage at the device and at the meter, it should be approximately 36 VDC (MBUS-PS6, MBUS-PS20, MBUS-

PS32, MBUS-PS80) respectively 40 VDC (MBUS-PS125, MBUS-PS250, MBUS-PS500).

If this voltage can not be detected, check the M-Bus for a short circuit:

•Disconnect the M-Bus from the device and measure the voltage at the device again.

•Is it now the desired voltage? An internal fuse may have switched off the bus because of overload.

•Is the current consumption of the M-Bus proportionate to the number of connected slaves?

If no data are received, the cause might as well be the protocol, that is the software on the PC, or the baud

rate. Check above all the logical settings.

If errors could not be eliminated and if all logical settings are correct, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

Page 14/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

The reception LED begins to light up sporadically.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

Check the cable between MBUS-PS and the meter, and replace faulty cables if necessary. Disturbances may

be present on the M-Bus and be interpreted like received data. The reception LED should be reset at the next

reading (request from the master, sending from the slaves).

If errors could not be eliminated and if all logical settings are correct, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

The collision LED is blinking regularly without communication.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

The devices MBUS-PS125, MBUS-PS250 and MBUS-PS500 detect an overload if the maximum number of

connected unit loads is surpassed. This is indicated by a regularly blinking collision LED. A reception of data

is no longer possible then.

Check the M-Bus installation. How many meters are connected? Reduce the number of meters, if possible.

Is the current consumption of the M-Bus proportionate to the number of connected slaves?

If errors could not be eliminated, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

The collision LED lights up when sending respectively when receiving.

Only trained and appropriately qualified personnel are allowed to check the electric power supply (see

Section 1.2.3).

Check the M-Bus installation. How many meters are connected? Reduce the number of meters, if possible.

Do several meters have identical bus addresses? What is the overall capacity of the bus? Replace the faulty

cable if necessary or parameterise the meters correctly.

In case of a high capacity on the bus (e.g. long cables, many meters) the data transmission remains

undisturbed even though the collision LED lights up; this can be ignored.

If errors could not be eliminated, please contact our customer support:

E-Mail: suppo[email protected]

Phone: +49 3677 7613065

2.7 Technical data

2.7.1 General specifications

Dimensions/Weight

The devices have the following dimensions and the following weight:

Variant Width (mm) Height (mm) Depth (mm) Weight approx. (g)

MBUS-PS6, MBUS-PS32 18 89 60 58

MBUS-PS20*, MBUS-PS80* 18 89 64 70

MBUS-PS125, MBUS-PS250, MBUS-PS500 54 90 60 130

*Depth with D-Sub male plug, depth without D-Sub male plug: 60 mm

Table 9: Dimensions and weight

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 15/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

Mounting

The devices are intended for control cabinet mounting:

•MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: Temperature range 0-55 °C

•MBUS-PS125, MBUS-PS250, MBUS-PS500: Temperature range -20-70 °C; uninterrupted service 0-55 °C

•Air humidity: 0-95 % relH

•Degree of protection: IP20 (IEC 60529)

•Top hat rail mounting (DIN rail 35 mm, IEC 60715)

2.7.2 Electrical specifications

Power supply

The devices are powered by an external power supply (pin assignment see Section 2.3):

•MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: voltage 21.6-24.5 VDC

•MBUS-PS125, MBUS-PS250, MBUS-PS500: voltage 12-36 VDC

•Screw terminals (≤2.5 mm2, tightening torque 0.5-0.6 Nm)

•Power consumption:

–idle state: 1 W (all variants)

–MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: max. 10 W

–MBUS-PS125, MBUS-PS250, MBUS-PS500: max. 40 W

•Safety: reverse polarity protected M-Bus, overvoltage protection (transients), protection class III (IEC 61140)

•Peak inrush-current: approx. 3 A

Meter interfaces

The devices have an M-Bus meter interface (pin assignment see Section 2.3):

•M-Bus:

–compliant to EN 13757-2, screw terminals (≤2.5 mm2, tightening torque 0.5-0.6 Nm)

–MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: Umark=36 V, Uspace=24 V

–MBUS-PS125, MBUS-PS250, MBUS-PS500: Umark=40 V, Uspace=27 V

–max. 6 unit loads (UL) for MBUS-PS6

–max. 20 unit loads (UL) for MBUS-PS20

–max. 32 unit loads (UL) for MBUS-PS32

–max. 80 unit loads (UL) for MBUS-PS80

–max. 125 unit loads (UL) for MBUS-PS125

–max. 250 unit load (UL) for MBUS-PS250

–max. 500 unit loads (UL) for MBUS-PS500

•Max. current rating permanent:

–MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: approx. 140 mA

–MBUS-PS125, MBUS-PS250, MBUS-PS500: 1500 mA

•Max. baud rate:

–MBUS-PS6, MBUS-PS20, MBUS-PS32, MBUS-PS80: 19200 bps

–MBUS-PS125, MBUS-PS250, MBUS-PS500: 9600 bps

Page 16/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

MBUS-PS - User manual

Communication interfaces

The devices have an RS-232 communication interface (pin assignment see Section 2.3):

•compliant to ANSI EIA/TIA-232-F-1997

•MBUS-PS6, MBUS-PS32, MBUS-PS125, MBUS-PS250, MBUS-PS500: screw terminals (≤1.5 mm2,

tightening torque 0.5-0.6 Nm)

•MBUS-PS20, MBUS-PS80: D-Sub male plug, 9 contacts

•No handshake

Galvanic isolation

The RS-232 communication interface is separated from the meter interface and the supply:

•Galvanic isolation: 1000 V

Frank Richter, 6 December 2022

©solvimus GmbH

Version: 1.4

Released

Page 17/18

UG_EN_MBUS-PS.pdf

MBUS-PS - User manual

3 Accessory

The solvimus GmbH recommends the external power supplies in the following table:

Module width (U) External power supply Order number of the solvimus GmbH

1 PHOENIX CONTACT STEP-PS/1AC/24DC/0.5 103501

3 PHOENIX CONTACT STEP-PS/1AC/24DC/1.75 103960

Table 10: External power supplies

The usage of accessories not recommended is at your own risk. It is imperative to mind Section 1.2.5.

Page 18/18

UG_EN_MBUS-PS.pdf

Version: 1.4

Released

Frank Richter, 6 December 2022

©solvimus GmbH

This manual suits for next models

8

Table of contents

Other Solvimus Media Converter manuals

Popular Media Converter manuals by other brands

Gefen

Gefen GEF-HDMI1.3-2-3GSDI user manual

Nice

Nice MORX Instructions and warnings for installation and use

CTC Union

CTC Union FRM220-1000ES-2F user guide

Patton electronics

Patton electronics 2020RC user manual

Jolida

Jolida Glass FX series owner's manual

LG

LG CodePlus OAT100R Installation & setup quick reference

Baumer

Baumer HUBNER BERLIN Proibus DP HMG 10 Installation and operating instructions

Bonart

Bonart ART-M1 instruction manual

Ganz

Ganz ZN-S1000V installation manual

Seneca

Seneca Z-SG2 user manual

B&B Electronics

B&B Electronics RS-232 Baud Rate Converter CE 232BRC product manual

SOUNDLIGHT

SOUNDLIGHT 3603PWM-H Mk3 RDM operating manual