SOMMER SMA-2 User manual

9

SMA-2

Snow melt analyzer

User Manual

Setup version 3.10

2019-03-12

Sommer GmbH

All rights reserved.

The Copyrights for this manual are exclusively owned by

Sommer GmbH

A-6842 Koblach

This manual or parts of it may only be copied or passed on to third parties with written permission of Sommer GmbH. This applies to

printed as well as digital issues of this manual.

Sommer GmbH

Strassenhaeuser 27

6842 Koblach

Austria

http://www.sommer.at

Email: office@sommer.at

Tel.: +43 5523 / 55 989 - 0

Fax: +43 5523 / 55 989 - 19

Validity

This manual applies to the SMA-2 snow pack analyzer and is valid for the setup version 3.10 with all its

subversions.

The firmware version can be viewed with the function Device status and is listed in the boot message.

Created:

Last update:

Approved:

File:

jofri 2019-03-12

-

wosom 2019-03-12

manual_SMA-2_en.docx

CE compliance

This product is in conformity with the following standards

LVD Directive 2014/35/EU EN 62368-1

EN 61010

EMV Richtline 89/336/EEC EWG EN 61326

RoHS II Directive 2011/65/EU

RoHS III Delegated Directive (EU) 2015/863

Safety information

Please read this manual carefully before installing or operating this equipment. Non-compliance with the

instructions given in this manual can result in failure or damage of the equipment or may put people at

risk by injuries through electrical or mechanic impact.

-Installation and electrical connections must be carried out by qualified personnel familiar with the

applicable regulations and standards.

-Some parts of the device are heavy or long. For their handling contact your safety officer or consult

applicable safety regulations for precautions and proper personal safety equipment.

-Do not perform any installations in bad weather conditions, e.g. thunderstorms.

-Prior to installation of equipment inform the owner of the measurement site or the authority respon-

sible for it. Upon completion, secure the installation from trespassers.

-Maintenance and repair must be performed by trained personnel or an engineer of Sommer GmbH.

Only replacement parts supplied by Sommer GmbH should be used for repairs.

-Make sure that NO power is connected to the equipment during installation and wiring.

-Only use a power supply that complies with the power rating specified for this equipment.

-Keep equipment dry during wiring and maintenance.

-If applicable, it is recommended to use accessories of Sommer GmbH with this equipment.

Disposal

After this device has reached the end of its lifetime, it must not be disposed of with house-

hold waste! Instead, dispose of the device by returning it to a designated collection point

for the recycling of waste electrical and electronic equipment.

Content

1Introduction ................................................................................................................................. 6

2Unpacking .................................................................................................................................... 7

3Quick start.................................................................................................................................... 8

3.1 Installation ...................................................................................................................................... 8

3.2 Connection of the SMA-2 to a computer........................................................................................ 8

3.3 Sensor configuration....................................................................................................................... 8

4Specifications ............................................................................................................................... 9

5Principles of operation................................................................................................................ 10

6Installation................................................................................................................................. 11

6.1 Selection of the measurement site............................................................................................... 11

6.2 Assembly ....................................................................................................................................... 11

6.2.1 Tools.................................................................................................................................... 11

6.2.2 Supporting frame................................................................................................................ 11

6.2.3 Control cabinet ................................................................................................................... 12

6.2.4 Wiring ................................................................................................................................. 12

6.2.5 Power supply ...................................................................................................................... 13

6.3 Lightning protection...................................................................................................................... 13

6.4 Maintenance ................................................................................................................................. 13

7Communication .......................................................................................................................... 14

7.1 SMA-2 controller........................................................................................................................... 14

7.1.1 Connection terminals.......................................................................................................... 14

7.2 Communication with a PC............................................................................................................. 16

7.3 Connection to a data logger.......................................................................................................... 19

7.3.1 RS-485................................................................................................................................. 19

7.3.2 SDI-12.................................................................................................................................. 20

7.4 Connection to Modbus ................................................................................................................. 20

8Configuration ............................................................................................................................. 21

8.1 Setup using Commander............................................................................................................... 21

8.2 Setup using a terminal program ................................................................................................... 21

8.3 General settings ............................................................................................................................ 22

8.4 Calibration of SMA-ribbon-sensor ................................................................................................ 23

8.4.1 Zero test and adjustment ................................................................................................... 23

8.4.2 Span test and adjustment................................................................................................... 24

8.5 Serial data output ......................................................................................................................... 25

8.6 RS-485 interface............................................................................................................................ 26

8.6.1 System key and device number.......................................................................................... 26

8.6.2 Output time ........................................................................................................................ 26

8.6.3 Operation modes................................................................................................................ 26

8.6.4 Waking-up of a connected data logger .............................................................................. 27

8.6.5 Output protocols ................................................................................................................ 27

8.6.6 Commands.......................................................................................................................... 28

8.7 SDI-12 interface............................................................................................................................. 29

8.7.1 SDI-12 address (E-G-A)........................................................................................................ 29

8.7.2 Measurement commands................................................................................................... 29

8.7.3 Sensor configuration commands........................................................................................ 29

8.8 Modbus communication............................................................................................................... 30

8.9 Analog input.................................................................................................................................. 30

9Parameter definition .................................................................................................................. 31

Appendix A Measurement values.................................................................................................... 45

A.1 Error and exception values ........................................................................................................... 45

Appendix B RS-485 interface ........................................................................................................... 46

B.1 Protocols ....................................................................................................................................... 46

B.1.1 Sommer protocol ................................................................................................................ 46

B.1.2 Standard protocol............................................................................................................... 47

B.2 Commands and answers............................................................................................................... 47

B.3 Error codes.................................................................................................................................... 49

B.4 Sommer CRC-16 ............................................................................................................................ 49

Appendix C SDI-12 interface............................................................................................................ 50

C.1 Standard SDI-12 commands.......................................................................................................... 50

C.1.1 Sensor identification........................................................................................................... 50

C.1.2 Triggering a measurement.................................................................................................. 50

C.1.3 Requesting measurement values ....................................................................................... 50

C.1.4 Requesting continuous measurements .............................................................................. 51

C.2 Extended SDI-12 commands ......................................................................................................... 51

C.2.1 Reading and writing sensor configurations ........................................................................ 51

C.2.2 Adoption of settings ........................................................................................................... 52

Appendix D Modbus ....................................................................................................................... 53

D.1 Modbus default settings ............................................................................................................... 53

D.2 Modbus Configuration .................................................................................................................. 53

6

1Introduction

Determination of snowpack-properties can be very challenging as they vary significantly in space and

time. The SMA-2 snow melt analyzer measures the volumetric contents of ice and water and deter-

mines the snow density. This is achieved by recording the complex impedance of a ribbon-shaped sen-

sor that rests in the snow pack. This device provides an automatic measurement system to continu-

ously monitor the snowpack development for hydrological and other applications.

7

2Unpacking

When unpacking your SMA-2 please make sure that the following items are present:

ID

Description

Quantity

1

Base-profile right, L-shaped

1

2

Base-profile left, L-shaped

1

3

Cross-profile with winch

1

4

Cross-profile with pulleys

1

5

SMA ribbon-sensor with sensor cable

1

6

Tension spring for SMA ribbon-sensor

1

7

Stainless steel extension cable with shackle

1

8

Pair of plastic clips

4

11

Anti-twist support, pair

4

12

Control cabinet with SPA-controller

1

13

Peg for anchoring

4

Table 1: Parts list

Bolts and nuts are pre-mounted. In case of missing or damaged items please contact your Sommer

sales partner.

The following items are available as options:

-Commander software

-USB to RS485 converter cable

8

3Quick start

This section will guide you through the most important steps to set up a fully operating system to

measure snowpack properties with the SMA-2. It is divided into three main parts: installation, connec-

tion to a PC and sensor configuration.

3.1 Installation

1. Select a representative measurement site (Section 6.1)

2. Install the SMA-2 frame, sensors and control cabinet (Section 6.2)

3.2 Connection of the SMA-2 to a computer

1. Install the Commander software

2. Connect the SMA-2 to your computer using the USB to RS485 converter cable (Section 7.2)

3. Connect a 9…28 VDC power supply to the SMA-2 data cable

4. Start the Commander software and establish a connection with the SMA-2 (Section 7.2)

3.3 Sensor configuration

1. Select language and decimal character (Section 8.3)

2. Select the measurement trigger and measurement interval (Section 8.3)

3. Calibrate the SMA-2 by measuring the capacities of the ribbon sensors in air (Section 8.4)

4. Optional: measure the capacities of the ribbon sensors with a reference plate (Section 8.4))

5. Define the format and timing of the data output (Section 8.6)

Upon successful configuration the SMA-2 may be connected to a data logger for continuous monitoring

(Section 7.3).

9

4Specifications

Physical and environmental

Power supply

9…28 VDC; Reverse voltage protection, overvoltage protection

Power consumption at 12 V

max. 65 mA active; 1 mA in sleep mode

Operating temperature

-35…60 °C (-31…140 °F)

Storage temperature

-35…60 °C (-31…140 °F)

Protection rating

IP 54; IP66 with SMA-2 controller in electrical cabinet

Lightning protection

Integrated protection against indirect lightning with a discharge

capacity of 6 kA Ppp

Frame material

Aluminium

Size L x W

3000 x 600 mm (118.11 x 23.62 in)

SMA-sensor

Size L x W

2600 x 60 mm (102.36 x 2.36 in)

Material

weatherproof, UV resistant ribbon, reinforced with Kevlar cords

SPA-controller

Inputs

up to 4 SMA ribbon-sensors (only applicable for SPA-2)

4x Analog 0 ... 2.5 V, 16 bit

2x Trigger input, low: 0…0.6 V, high: 2…26 V

1x RS-485

1x SDI-12

Outputs

4x Switched power supply, max. 0.2 A each

1x RS-485

1x SDI-12

Measurement range and accuracy

Snow density

0 … 1000 kg/m3(±5% FS)

Volumetric water content

0 … 100 % (±2% FS)

Volumetric ice content

0 … 100 % (±2% FS)

Table 2: Specifications

10

5Principles of operation

A snowpack has strong spatial variability and transforms considerably over time. The evaluation of

snow properties and the assessment of snow conditions mostly relies on spot observations. The snow

melt analyzer SMA-2 breaks these limitations and provides information about the snow pack by meas-

uring the dielectric properties of a large snow volume. It provides relevant snow properties like density

and contents of liquid water and ice.

Snow consists of ice, water and air, which have distinctly different dielectric properties. By measuring

the complex impedance along a ribbon sensor (SMA-sensor) at two different frequencies, ice, water

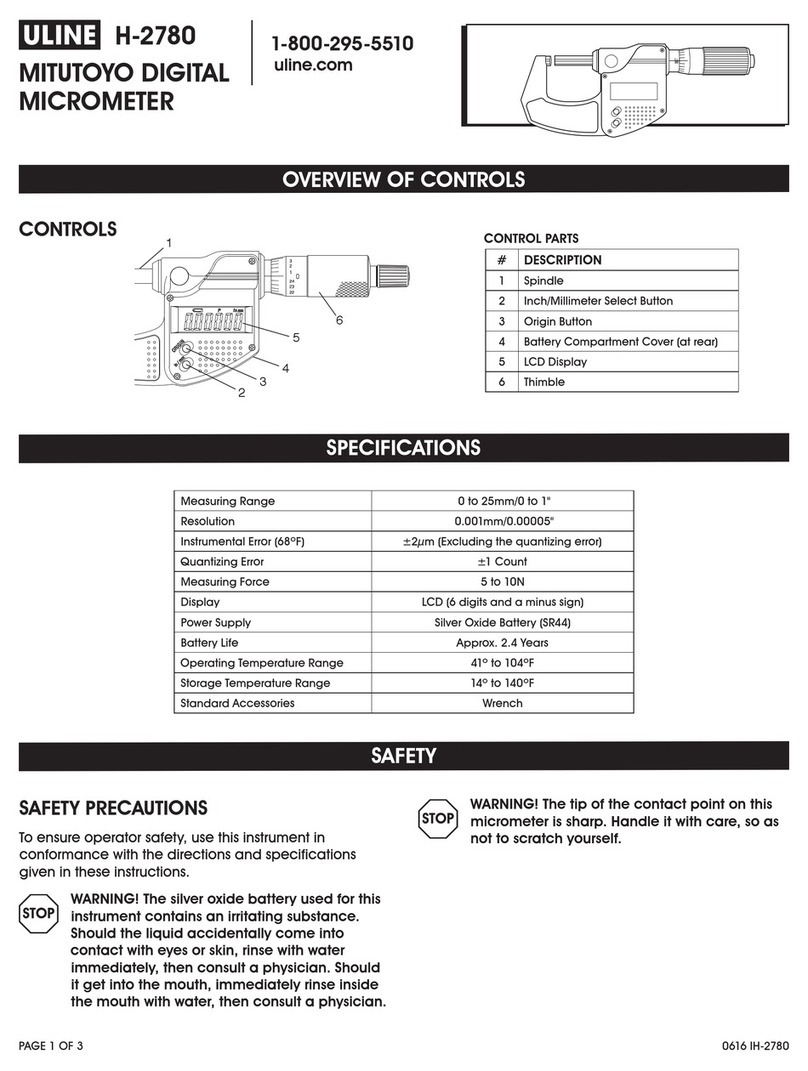

and air can be distinguished and their relative volume contents can be determined. In Figure 1 the

cross section of a SMA-sensor and its surrounding electric field are illustrated.

Figure 1: Measurement principle of a SMA-sensor

The SMA-sensor is a 60 mm wide, reinforced rubber ribbon containing three parallel copper wires. As

soon as an alternating current flows through the wires, an electric field builds up that penetrates up

to 4 cm into the surrounding snowpack.

11

6Installation

6.1 Selection of the measurement site

The selection of a suitable site is crucial to gain information of the snowpack that is representative of

the monitored area. Several aspects have to be considered when choosing a measurement site:

1. The selected site should be flat with no dips and rises.

2. The measurement spot should be representative of the monitored area.

3. There should be no boulders, trees, fences or other objects in the vicinity of the measurement

spot. Any obstacle can cause snow drift and thus affect the measurement results.

4. If feasible, the SMA-2 should be installed in the direction of the main wind. This minimizes disturb-

ances by snow drifts.

5. The site must be safe from avalanches.

6.2 Assembly

!

Attention

To avoid erroneous measurements, the SMA-2 must be installed on firm

ground. If there is a risk of subsiding ground, reinforce the surface with logs or

concrete slabs and install the SMA-2 on top of it.

6.2.1 Tools

Prepare the following tools for installation of the SMA-2:

-1x flat spanner 19 mm

-1x flat spanner 13 mm

-1x flat spanner 10 mm

-Allen-keys 3 mm

-Side cutter

-Folding rule

6.2.2 Supporting frame

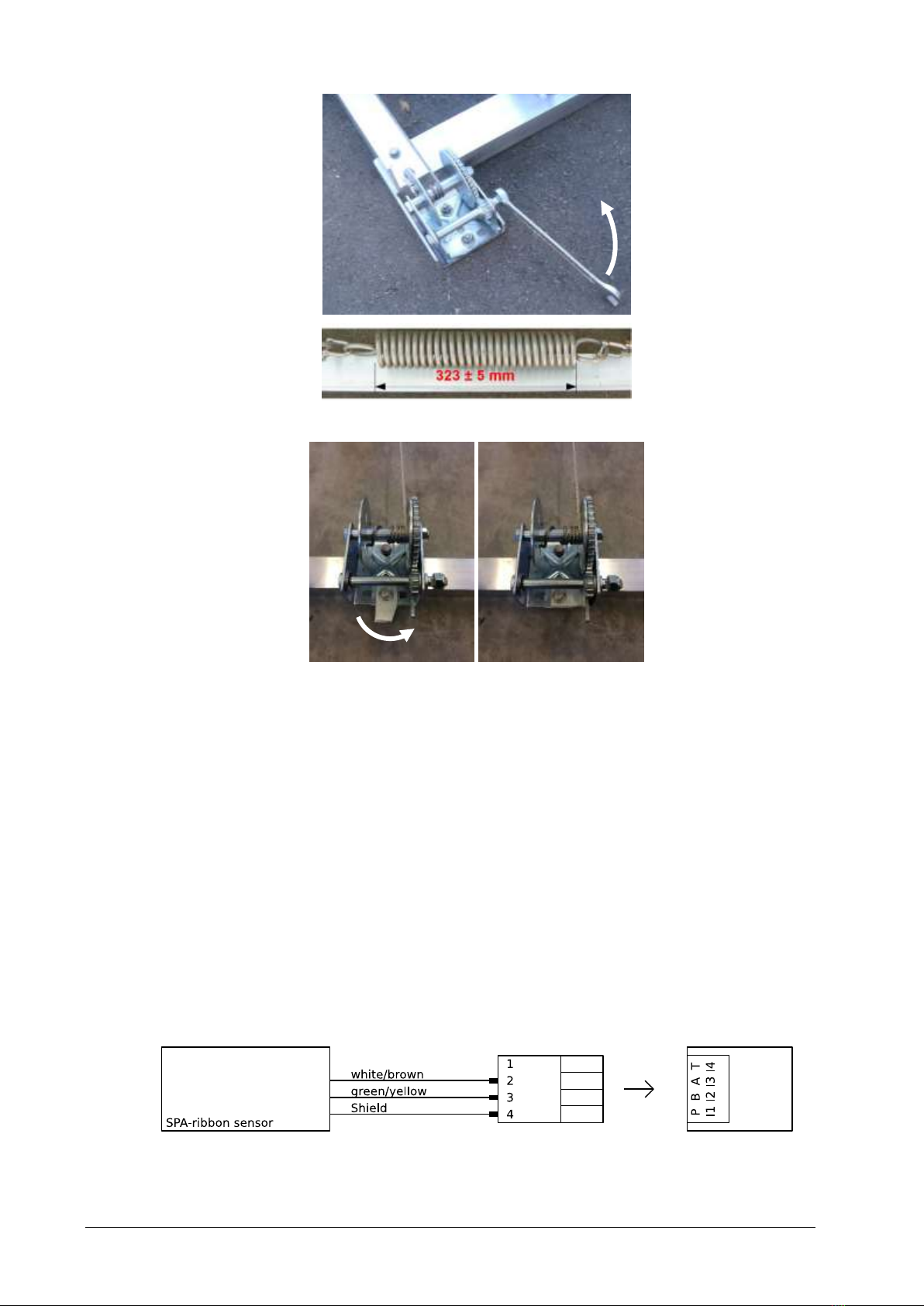

Follow the steps below to assemble the supporting frame:

1. Join the base- and cross-profiles with the provided bolts.

2. Attach the ribbon-sensor to the clamp of the cross-profile. Make sure that the sensor cable is

pointing upwards and that the ring-nut can turn in the clamp-gap!

3. Hinge one end of the extension cable to the far end of the ribbon-sensor and guide it around the

pulleys of the cross-profile. Make sure that the ribbon-sensor is not twisted!

4. Hinge the tension spring to the other end of the extension cable and to the cable of the winch.

5. Tighten the spring to a length of 323 ±5 mm by operating the winch in clockwise direction.

12

6. Secure the winch by turning the lug into its right position.

7. Secure the sensor cable with the provided clamp.

8. Attach the 4 plastic clips onto the ribbon-sensor with the supplied bolts. The spaces between the

clips should be equal along the ribbon (65 cm). Make sure the thickened edges of the ribbon are

placed in the notches of the clips.

9. Attach the positioning supports to the clips.

6.2.3 Control cabinet

1. Mount the control cabinet to its dedicated place (frame of SMA-frame or mast in the vicinity).

2. Feed the sensor cable of the SMA ribbon-sensor and the cable of the power supply through the

cable glands into the cabinet and secure them with the provided nuts.

6.2.4 Wiring

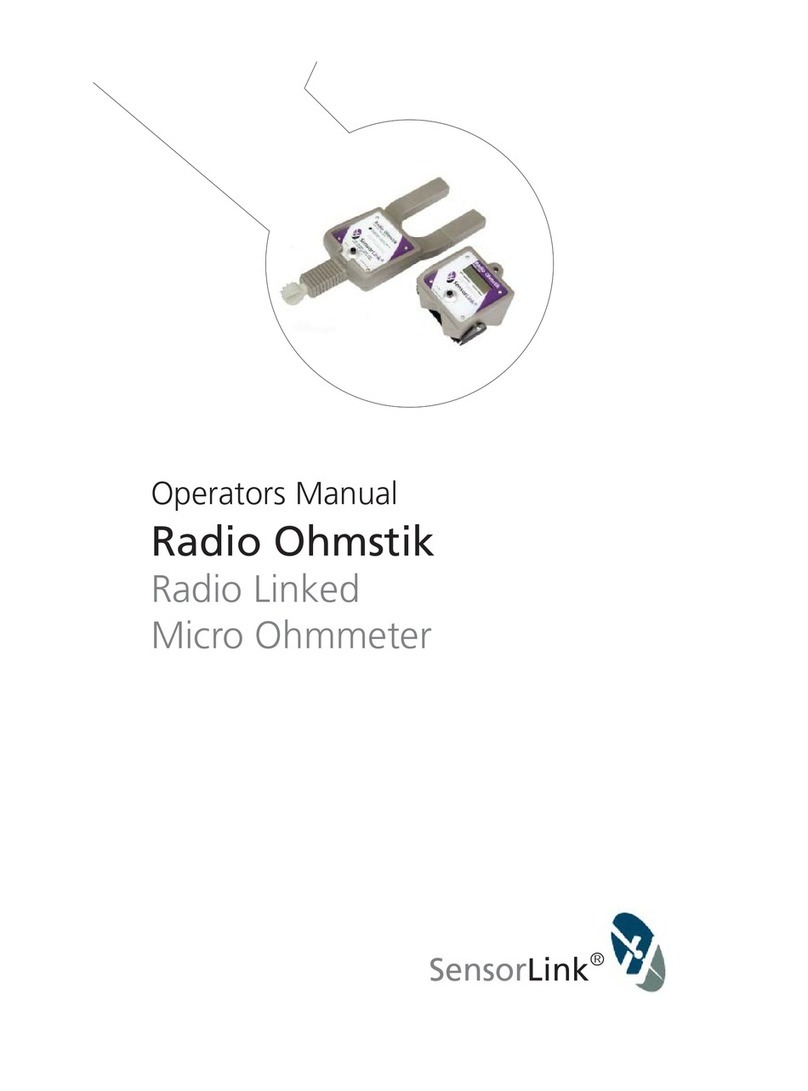

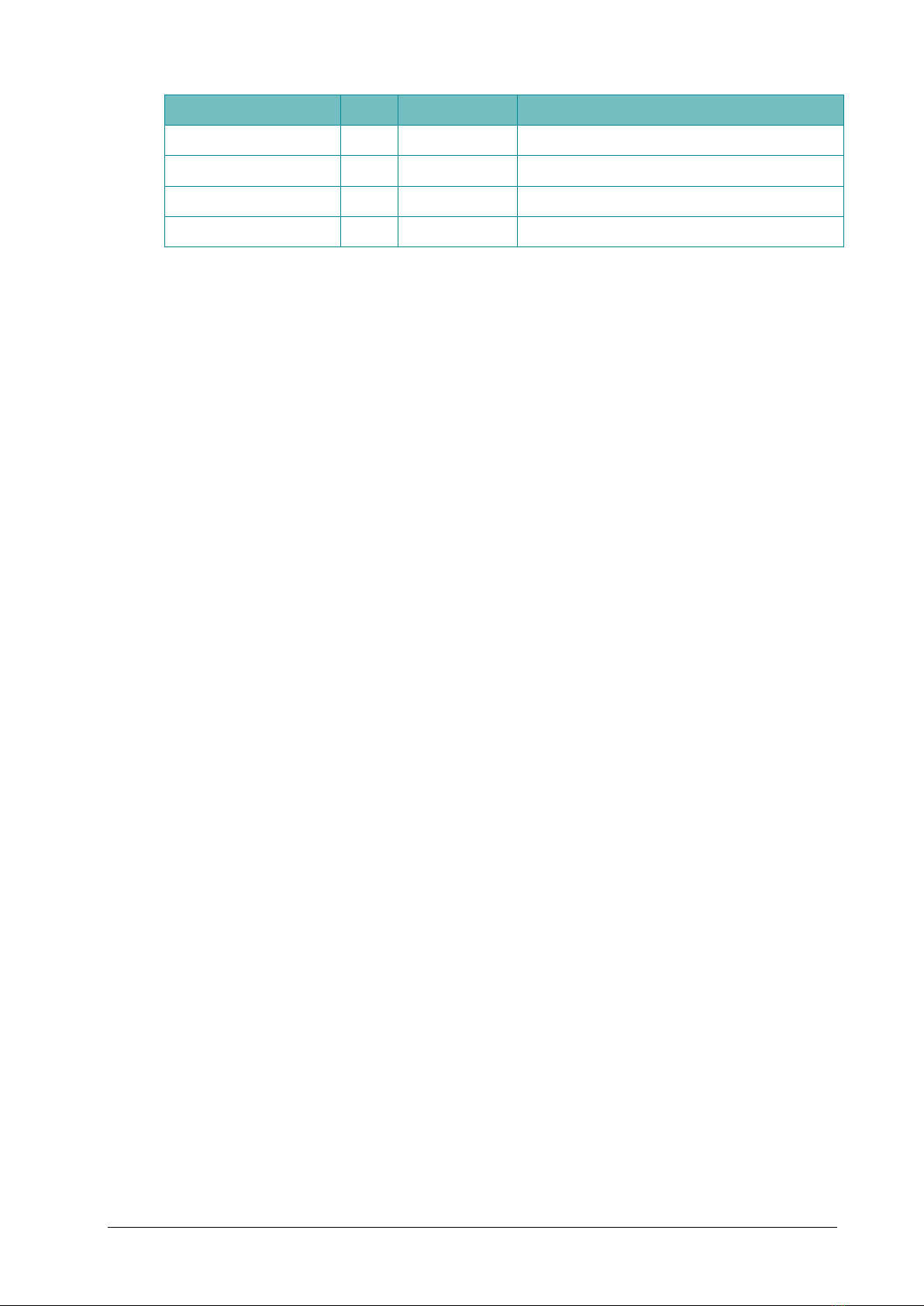

1. Connect the SMA-sensor cable to the I1 terminal of the controller. The sensor wires are connected

to the SMA-2 controller as illustrated below.

Figure 2: Wiring of SMA ribbon-sensor

13

Wire color

Pin

Function

Description

-

1

-

not connected

white/brown

2

Receive

Received signal

green/yellow

3

Transmit

Transmitted signal

shield

4

-

cable shield

Table 3: Connection wires of SMA ribbon-sensor

6.2.5 Power supply

The SMA-2 is designed for extreme environmental conditions at remote sites with no grid connection.

The sensor switches automatically into standby-mode between measurements and thus consumes

only approx. 0.1 Ah per day at a typical measurement interval between 5 to 10 minutes. Thus, the

device can be powered by a 12V-solar-generator mounted in the vicinity.

The installation of the SMA-2 is now complete. Please follow the instructions in Configuration to com-

plete the setup.

6.3 Lightning protection

If the underground at the measurement site permits sufficient current dissipation it is strongly recom-

mended to equip the device with properly dimensioned lightning protection. Consult an expert for

advice.

6.4 Maintenance

The SMA-2 generally does not require any special maintenance. However, we recommend to check

the following regularly:

-Sits the installation firmly on the ground?

-Is the SMA ribbon-sensor damaged and tightly stretched? Are the clips in the upright position?

-Is the sensor cable and its protection tubing intact or broken, e.g. damage by rodents?

14

7Communication

7.1 SMA-2 controller

The controller of the SMA-2 triggers the measurements of the connected sensor, acquires data and

calculates the snow parameters. It returns the data via RS-485 or SDI-12.

7.1.1 Connection terminals

All available connection terminals are listed in Table 4.

Figure 3: Connection terminals of SP-2 controller

Terminal

PIN

Description

TRIG

2

Trigger input 2 (not available)

G

Ground

1

Trigger input 1

G

Ground

BUS 1

B

RS-485 B (to data acquisition device)

A

RS-485 A (to data acquisition device)

S

SDI-12 (to data acquisition device)

G

Ground

BAT

-

Supply voltage (-)

-

Supply voltage (-)

+

Supply Voltage (+), 9.0 to 24.0 VDC

+

Supply Voltage (+), 9.0 to 24.0 VDC

15

I1

T

Optional temperature input

A

SMA ribbon-sensor

B

SMA ribbon-sensor

P

Shield of SMA ribbon-sensor

I2

T

Optional temperature input

A

Used with SMA-2 (ribbon sensor)

B

Used with SMA-2 (ribbon sensor)

P

Used with SMA-2 (ribbon sensor)

I3

T

Optional temperature input

A

Used with SMA-2 (ribbon sensor)

B

Used with SMA-2 (ribbon sensor)

P

Used with SMA-2 (ribbon sensor)

I4

T

Optional temperature input

A

Used with SMA-2 (ribbon sensor)

B

Used with SMA-2 (ribbon sensor)

P

Used with SMA-2 (ribbon sensor)

AIN 1,2

G

Ground

1

Analog input 1

2

Analog input 2

AIN 3,4

G

Ground

3

Analog input 3

4

Analog input 4

BUS 2

G

Ground

S

SDI-12 (from sensor)

A

RS-485 A (from sensor)

B

RS-485 B (from sensor)

OUT 1,2

G

Ground

1

Switched supply voltage 1

2

Switched supply voltage 2

OUT 3,4

G

Ground

3

Switched supply voltage 3

4

Switched supply voltage 4

Table 4: Connection terminals of SMA-2 controller

16

7.2 Communication with a PC

Communication between the SMA-2 and a PC can be established with a USB to RS-485 converter. Per-

form the following steps to set up the communication between the SMA-2 and your PC:

1. Install the Commander software on your PC.

2. If not already done, install the driver of the USB to RS-485 converter.

3. Connect the USB to RS-485 converter to a USB-port on your PC and the BUS 1 terminal of the SMA-

2 as illustrated in Figure 4.

Figure 4: Connection of USB to RS-485 converter

4. Start the Commander Software.

5. Click on Communication assistant on the right-hand side of the Commander window.

6. Select Serial Connection and press Next.

17

7. Make sure the SMA-2 is powered and press Next.

8. Select Sensor (9600 Bd) and press Next.

9. Tick Select port and select the COM port that was assigned to the USB/RS-232 converter; then click

Next.

18

If more than one COM ports are listed and you are not sure which one to select, open the Windows

Device Manager (press and type device manager) and expand the menu Ports (COM & LPT). By

unplugging and re-plugging your USB/RS-232 converter you can identify the number of the desired

port.

10. The Commander now searches for connected devices. This may take a few minutes. Upon comple-

tion, press No to the question “Do you want to save the station?”.

11. Click Finish. Upon completion, the newly created connection is displayed in the Communication

section of the Commander.

12. Open the Parameters (F2) tab and click Download parameters from device.

Table of contents

Other SOMMER Measuring Instrument manuals