SOMMER SPA User manual

SPA

Snow Pack Analyzer

Document version: 2012-Jan

Software version: 3.33

User Manual

S

ommer

M

easurement System

T

echnology.

All rights reserved.

User Manual SPA Snow Pack Analyser

Contents

1.

GENERAL INFORMATION...................................................................................................................................... 1

1.1.

P

RINCIPLE OF MEASUREMENT

..............................................................................................................................1

1.2.

M

EASUREMENT PARAMETERS

..............................................................................................................................2

2.

HARDWARE............................................................................................................................................................... 3

2.1.

SPA-

SENSORS

.....................................................................................................................................................3

2.2.

C

ORRECTION LENGTH SENSOR

(

POTENTIOMETER

).............................................................................................3

2.3.

S

NOW DEPTH SENSOR

..........................................................................................................................................3

2.4.

C

ONTROL UNIT

IASP............................................................................................................................................3

2.5.

F

RAMEWORK

.........................................................................................................................................................4

3.

INSTALLATION.........................................................................................................................................................5

3.1.

M

EASUREMENT SITE

.............................................................................................................................................5

3.2.

F

RAMEWORK

.........................................................................................................................................................5

3.3.

S

NOW DEPTH SENSOR

..........................................................................................................................................5

3.4.

S

LOPING

SPA-

SENSOR

........................................................................................................................................6

3.5.

C

ORRECTION LENGTH SENSOR

............................................................................................................................8

3.6.

H

ORIZONTAL

SPA-

SENSORS

................................................................................................................................9

3.7.

H

OUSING

.............................................................................................................................................................10

3.8.

P

OWER SUPPLY

..................................................................................................................................................10

3.9.

S

UMMARY

............................................................................................................................................................10

4.

PARAMETERIZATION...........................................................................................................................................11

4.1.

C

ONNECTION ESTABLISHMENT VIA TERMINAL

....................................................................................................11

4.1.1.

Local communication...............................................................................................................................11

4.1.2.

Connection affirmation............................................................................................................................. 11

4.2.

M

AIN

M

ENU

.........................................................................................................................................................12

5.

NECESSARY PARAMETER ADJUSTMENTS AFTER ASSEMBLY.............................................................13

5.1.

S

NOW DEPTH

......................................................................................................................................................13

5.2.

D

ISPLACEMENT OFFSET

/

L

ENGTH CORRECTION

...............................................................................................13

5.3.

G

EOMETRIC PARAMETERS

..................................................................................................................................14

5.4.

A

CTUAL

S

NOW DEPTH

........................................................................................................................................15

5.5.

M

EASUREMENT INTERVAL

...................................................................................................................................15

6.

DESCRIPTION OF THE PARAMETERS.............................................................................................................17

7.

DATA OUTPUT........................................................................................................................................................27

7.1.

P

ROTOCOL VALUES

.............................................................................................................................................27

7.2.

MIO

P

ROTOCOL

..................................................................................................................................................29

7.3.

S

TANDARD PROTOCOL

........................................................................................................................................31

8.

SUPPORT.................................................................................................................................................................32

9.

BASE SETTINGS AND DEFAULT VALUES......................................................................................................33

10.

TECHNICAL DATA.............................................................................................................................................35

User Manual SPA Snow Pack Analyser

Safety Information

Please read this entire manual before setting up or operating this equipment. The non-compliance of this

manual could result in damage to the equipment. Also in the case of non-compliance injuries of individuals

cannot be excluded totally.

To make sure that the protection provided of and by this equipment is not impaired, do not use or install

this equipment in any manner other than that specified in this manual.

User Manual SPA Snow Pack Analyser

- 1 -

1.General information

Snow has an enormous variability in space and time. Up to now mainly punctual measurements are

available for the relevant parameters. The Snow Pack Analysing System (SPA) constitutes an innovation

in snow measurement. It is a system for automatic and continuous measurement of all relevant snow

parameters like snow depth, snow density, snow water equivalent and contents of liquid water and ice.

There are several possibilities to install the system, depending on demand.

1.1. Principle of measurement

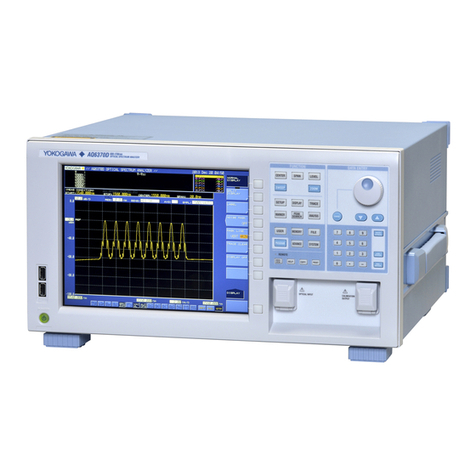

Fig. 1: Principle of measurement of the SPA-sensor

Snow consists of the three components ice, water and air. Referring to different measurement

frequencies, these components show different dielectric constants. Measuring the complex impedance

along a flat ribbon sensor (SPA-sensor) with at least two frequencies allows to estimate the volume

contents of the individual components. These specific volume contents equate the liquid water, ice and air

in the snow pack, which result in the snow density and the snow water equivalent.

User Manual SPA Snow Pack Analyser

- 2 -

1.2. Measurement parameters

Snow density

The SPA calculates the snow density of the snow surrounding the SPA-sensor.

Snow water equivalent SWE

The SWE corresponds to the water column in mm resulting from the melting of the complete snow cover

on a defined area. It is calculated from the snow density of sloping sensors with respect to the snow

depth.

Contents of liquid water and ice in snow pack

The volumetric contents of ice and liquid water in the snow are output in %.

Snow depth

The snow depth is measured by an ultra sonic sensor. It is necessary to determine the SWE.

User Manual SPA Snow Pack Analyser

- 3 -

2.Hardware

Fig. 2: SPA-sensor

Fig. 3: IASP control unit

2.1. SPA-sensors

The SPA-sensor is a 6 cm wide flat ribbon sensor including three copper wires. The length varies between

3 and 10 m. Its ends are terminated by boxes including mounting rings. The connection cable is led out of

one box.

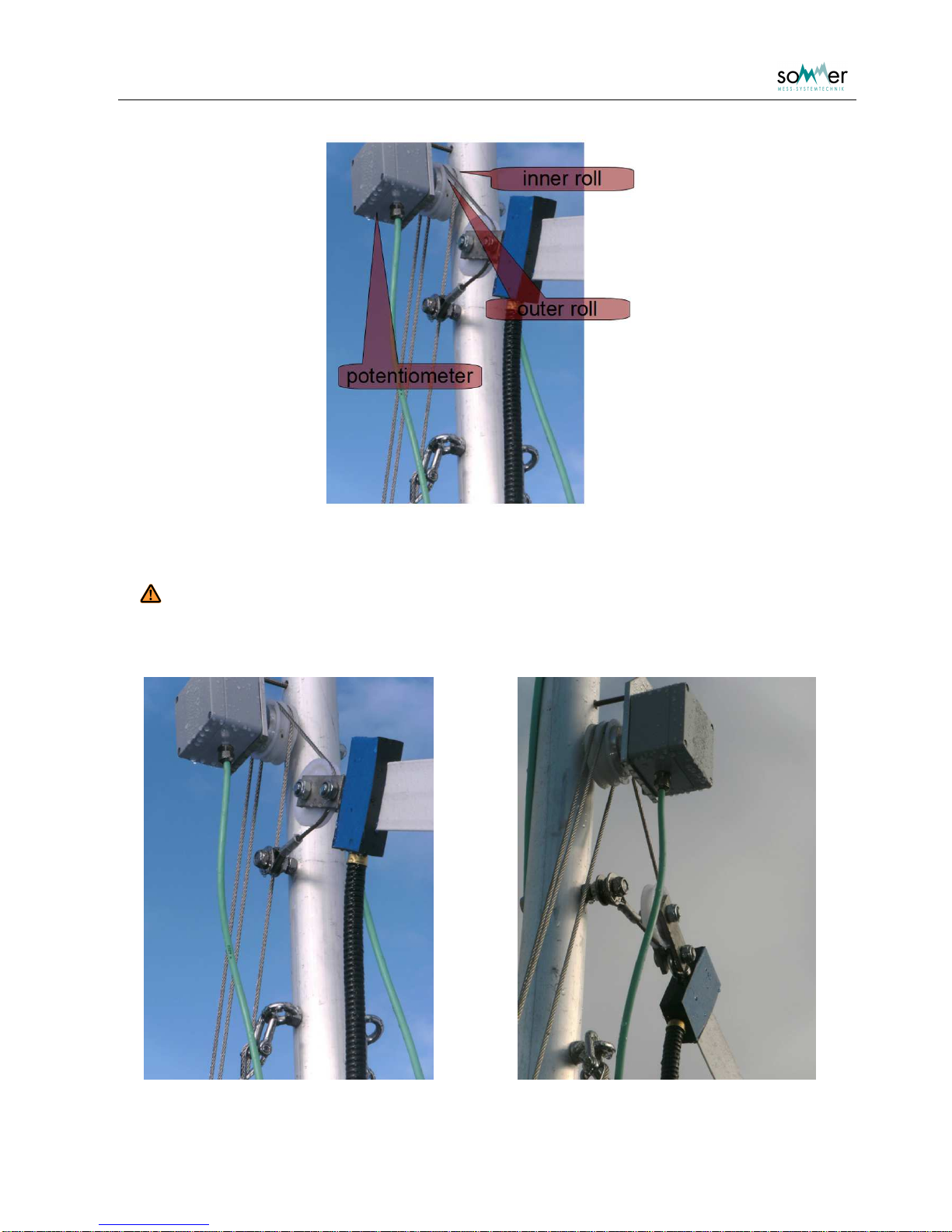

2.2. Correction length sensor (potentiometer)

The deforming of sloping sensors due to the snow pack can be corrected by measuring the additional

length of the sensor rope at the suspension. The sensor measures the rotation of the suspension roll and

converts the values into length. The correction is automatically included in the calculation.

2.3. Snow depth sensor

The snow depth sensor USH-8 is based on transit-time measurements of an ultrasonic pulse between the

sensor and the snow surface. It is mounted with an extension arm on a mast and is directly connected to

the control unit.

The snow depth is an essential parameter to calculate the snow pack parameters of sloping sensors. On

one hand the length of the sensor in snow is determined and on the other hand the total SWE is

calculated using the actual snow depth.

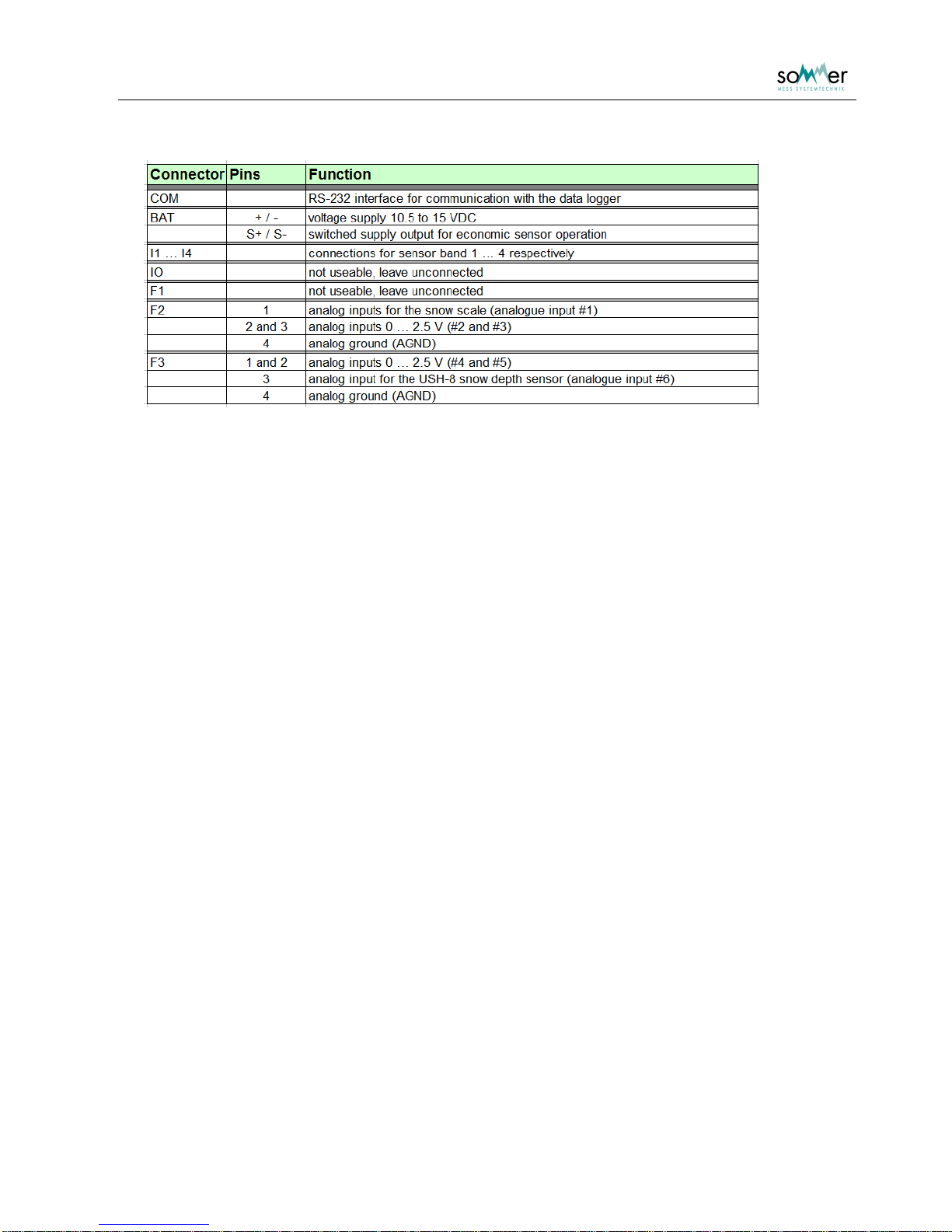

2.4. Control unit IASP

The control unit IASP performs all measurements, switches between sensors and calculates the snow

parameters with respect to snow depth, length correction and geometric parameters. The data is output

via a RS-232 interface.

The analogue input F2-1 (#1) is preadjusted for the length correction. The analogue input F3-3 (#6) is

preadjusted for the USH-8 snow depth sensor.

User Manual SPA Snow Pack Analyser

- 4 -

Tab. 1: Connector assignment for Fig. 3;

the analogue input F3-3 (#6) is reserved for the USH-8 snow depth sensor

2.5. Framework

The framework enables the installation of one sloping and up to three horizontal sensors and secures a

tight and upright positioning of the sensors. It includes the basement framework, a mast for the installation

of the sloping sensor, the snow depth sensor and the housing and suspension equipment for the SPA

sensors consisting of springs, levers and stretching devices.

User Manual SPA Snow Pack Analyser

- 5 -

3.Installation

3.1. Measurement site

A representative measurement site is horizontal and is not located in a basin or on a ridge. It is free of

influences from trees or rocks and is not exposed to intensive winds. An undisturbed accumulation of the

snow pack has to be guaranteed.

3.2. Framework

Fig. 4: SPA framework Fig. 5: Connection construction with foot

First the basement framework is placed on the ground. It is delivered separated in two parts each with

about two 3 m long beams connected with cross-beams. The side with the two round cross-beams is for

the installation of the mast and the fixation of the suspension, the side with the rectangle cross-beam is

used for fixing the sensors. The inner L-shaped cross-beam can be located at three position, depending

on the installation height of the sloping sensor of 1.5, 2 or 2.5 m.

The two parts of the framework are connected with a connection construction consisting of a u-profile,

screws and a foot. It is important to install the framework with an initial tension to resist the forces of the

spanned sensors. This is achieved by connecting the two parts of the framework in a small angle, support

it with the foot and fix it with the screws. The height of the foot should be at least 10 cm.

After the installation of the basement the mast is installed on the inner cross-beam. The mast holds the

snow depth sensor, the rolls for the sloping SPA-sensor and the housing for the measurement and

communication devices. It is recommended to install the snow depth sensor before erecting the mast. The

mast is supported with two steel wires to be spanned to the near edges of the basement.

3.3. Snow depth sensor

The snow sensor is an ultra sonic sensors using transit time measurement. It is installed on the top of the

mast using the extension arm. The installation height has to be 1 m above the expected maximal snow

depth. The extension arm should be orientated on one side of the framework to guarantee a snow

measurement free of influences. Ensure that the area of the snow depth measurement is free of

constructions, sensors or cables and that it will be undisturbed during the complete winter season. Use

barrier tapes to prevent accidental entering of the area.

User Manual SPA Snow Pack Analyser

- 6 -

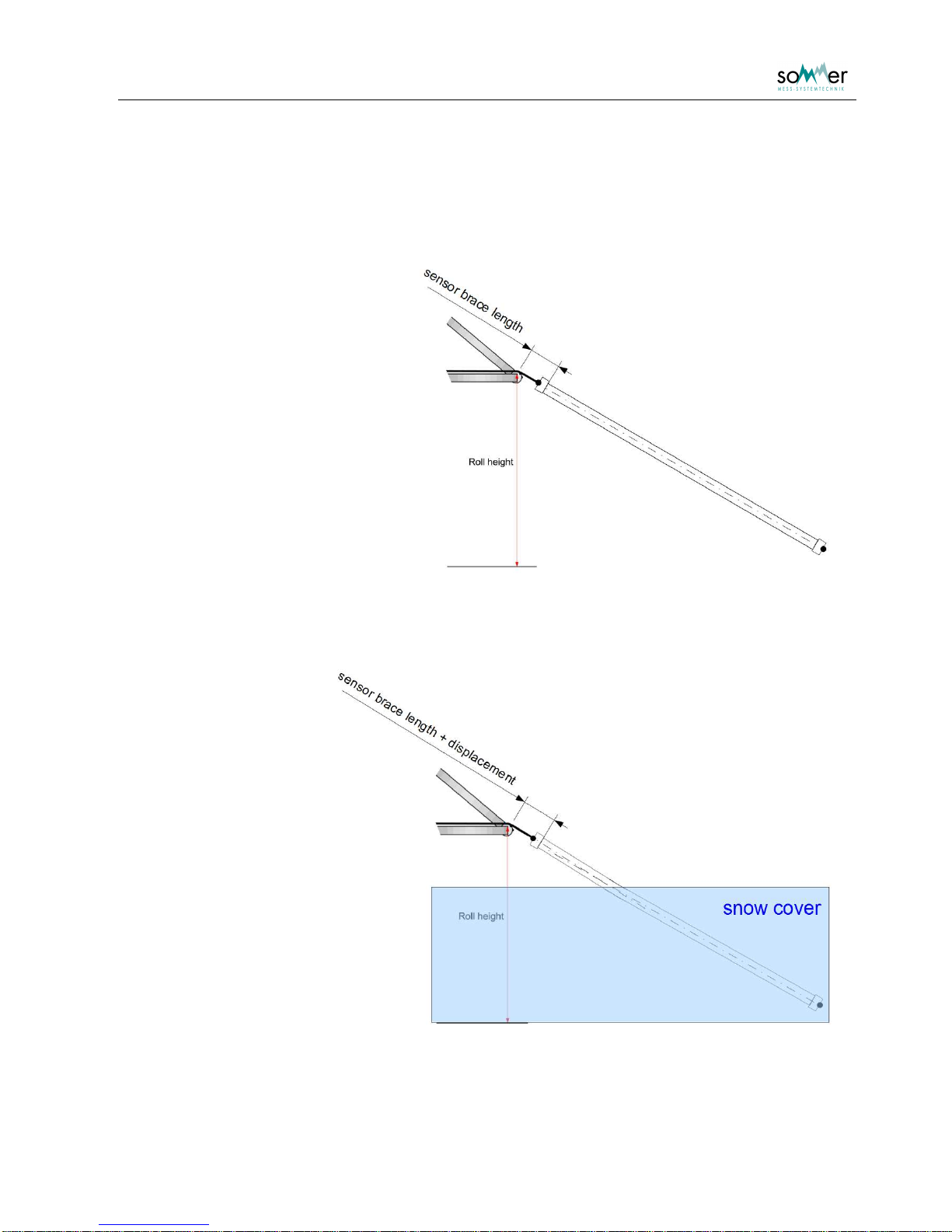

3.4. Sloping SPA-sensor

At the skew SPA the bend of the sensor which is also with strong tension not preventable at snow cover

has to be considered.

Without snow cover the sensor

has, caused by the tension, a

straight course.

Fig. 6: Sketch of the sloping sensor, the

tensioner part differs for simplicity from reality

With snow cover it is

possible that the

sensor has at the air /

snow boun-dary a

slight bend.

The sensor is not

stretchable but

nevertheless the bend

leads to an extension

of the fractional part of

the sensor which is

covered by snow.

This increase can be

determined over the

length change in the

sensor brace length.

Fig. 7: Sketch of the sloping band with a snow cover; the slight

bend in the sensor is best noticeable at the symmetry

lines

User Manual SPA Snow Pack Analyser

- 7 -

Fig. 8: Upper end of the sloping sensor with the upper part of the tensioner; consider that

the potentiometer is not included at every SPA

Attention: The inner and outer roll rotate at a length displacement with different extent.

The rotation is only measured at the outer roll. So it is very important that the

ropes are not interchanged during the assembling.

Fig. 9: Upper end of the sloping sensor with the upper part of the tensioner from different

views

User Manual SPA Snow Pack Analyser

- 8 -

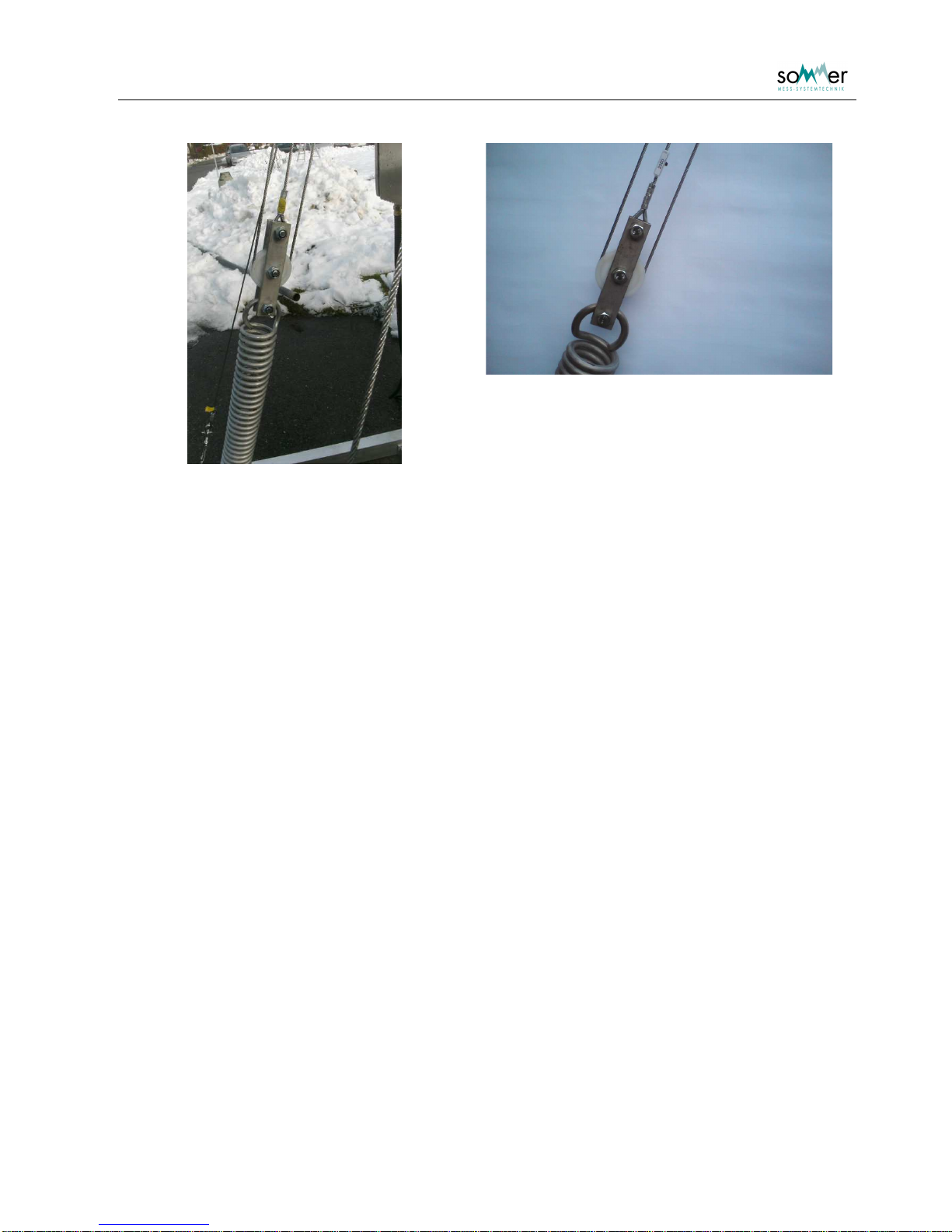

Fig. 10: Suspension at top of the spring with the pulley sytem (overview and detail)

The installation height of the sloping SPA-sensor should be higher than the maximum expected snow

depth. On the mast are three predrilled positions at heights of about 1.5, 2 and 2.5 m. Depending on the

selected height the L-shaped cross-beam is installed at the predefined positions at the far end of the

framework. The higher the sensor is spanned, the nearer the cross-beam is located, where the bottom

end of the SPA-sensor is fixed.

To span the sensor a spring and pulley system is used, that is spanned by a stretching device. The

stretching device is fixed at the near end of the framework and connected to the spring. The small bar with

the lower roll of the pulley system is connected to the opposite side of the spring. The rope of the pulley

system is fixed at the top screw of the bar connected to the spring. Then it is guided to the inner roll fixed

on the mast, back to the roll on the pulley system, up to the outer roll on the mast and through the roll of

the sensor. Finally it is connected to the screw located bellow the rolls on the mast. Then the sensor is

spanned using the stretching device.

3.5. Correction length sensor

If a correction length sensor (potentiometer) is used for the sloping sensor, it is installed at the deflector

roll located on the mast (Fig. 8). The bolt of the sensor has two rotary stop positions. Make sure that the

bolt is in the correct position to react to extensions of the suspension rope.

User Manual SPA Snow Pack Analyser

- 9 -

3.6. Horizontal SPA-sensors

Fig. 11: Spring connection for horizontal sensor

Fig. 12: Far end of framework

Fig. 13: Same as Fig. 11 but from the other side

User Manual SPA Snow Pack Analyser

- 10 -

The horizontal SPA-sensors are installed at predefined levels on the installation rack. The far end of the

sensors are connected at the far end of the framework. Then they are connected to the levers located on

the crossbeam of the mast. The stretching devices are fixed to the round cross-beam at the other end of

the framework. The springs are positioned directly at the levers and connected to the wires of the

stretching devices. Afterwards the sensors are spanned using the stretching devices until the spring has

elongated by about 100 mm and the sensor is 5000 mm long. The horizontal sensors are supported with

about 5 forks to ensure an upright and stable position.

3.7. Housing

Mount the housing on the mast and connect the cables of the SPA-sensors, the snow depth sensor and

the correction length sensor at the marked inputs.

3.8. Power supply

The supply voltage of the complete system is 10,5 to 15 VDC.

3.9. Summary

•Install framework with an initial tension.

•Locate snow depth sensor 1 m above the maximal expected snow depth.

•Install the sloping SPA-sensor higher than the maximal expected snow depth.

•Span the sensor using the stretching device.

•Install correction length sensor and set rotary bolt to correct position.

•Install and Span horizontal sensors by elongating the spring by about 100 mm.

User Manual SPA Snow Pack Analyser

- 11 -

4.Parameterization

4.1. Connection establishment via terminal

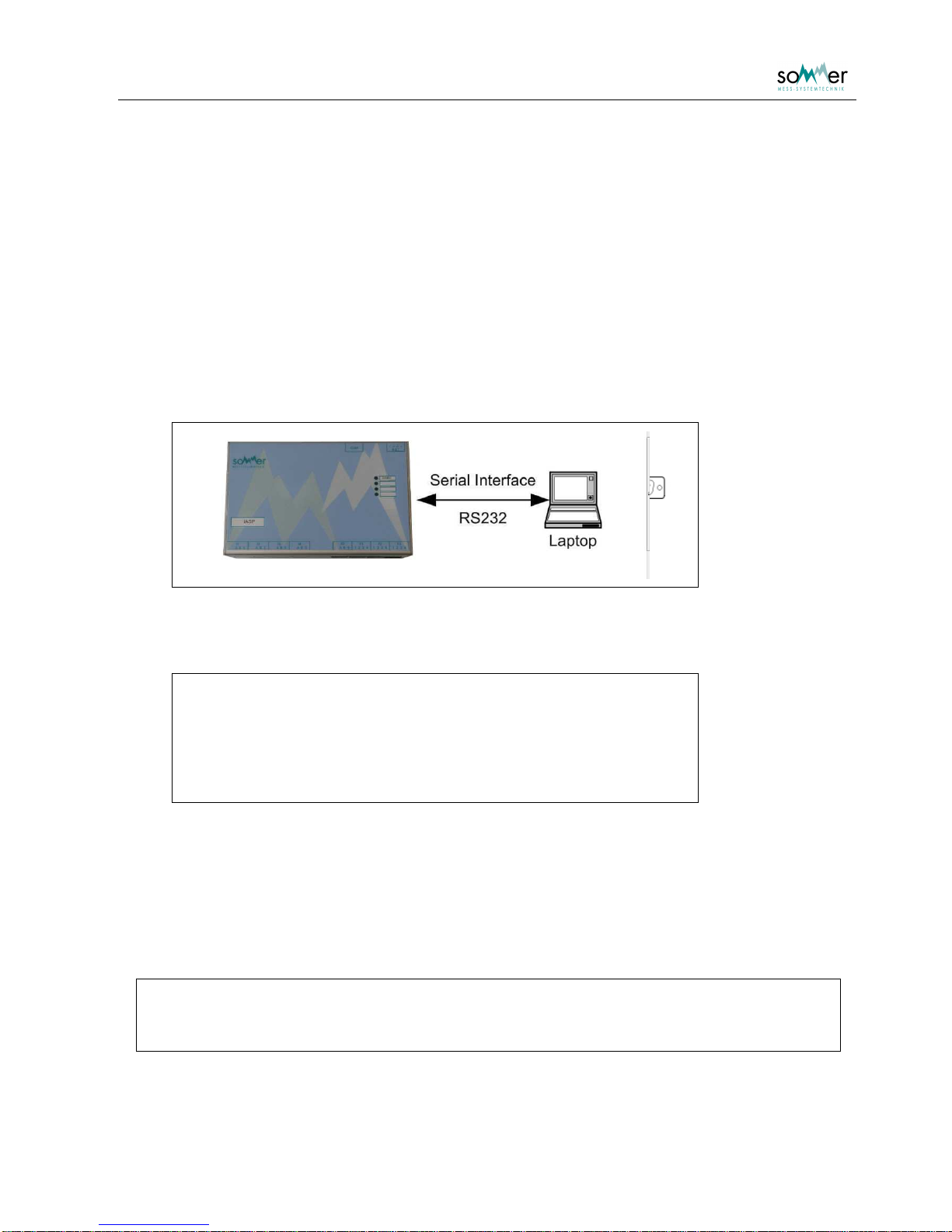

4.1.1. Local communication

The parameterization of the IASP can be performed by directly connecting the serial interface with a PC or

laptop. Any communication program can be used.

Until Windows XP the terminal program HyperTerminal was included in the Windows operating systems under Start

Programs

Accessories

Communications

HyperTerminal.

The connection cable is a serial data cable with a 1:1 connection (not crossed).

Fig. 14: Connection of the IASP via serial interface

To communicate with the sensor in delivery state the following settings are required:

Baud rate: 9600

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

Tab. 2: Parameter settings for serial connection

4.1.2. Connection affirmation

If a connection is established and the sensor is switched on, a connection affirmation is sent.

IA-SPA

(c)2006-2012 Sommer GmbH&CoKG

Software version : wdV3.33r01

User Manual SPA Snow Pack Analyser

- 12 -

4.2. Main Menu

The main menu is opened by quickly entering three question marks ??? in the terminal

program.

Fig. 1: Main menu

The menu items are accessed by entering the menu key display left of the menu item. Either sub menus

are opened or the specific parameter is displayed with the corresponding unit. Changes are verified with

Enter

, editing is aborted with

Esc

. Sub menus are closed with

X

. The menu is not case sensitive. If the

main menu is closed, the sensor starts the measurement mode and returns the message Run! .

User Manual SPA Snow Pack Analyser

- 13 -

5.Necessary parameter adjustments after assembly

5.1. Snow depth

The actual snow depth offset is adjusted in Main menu

Analog input

Snow depth adjustment.

5.2. Displacement offset / Length correction

This step applies only for SPA's which include a potentiometer.

Fig. 15: SPA with potentiometer

Fig. 16: SPA without potentiometer

A sloping SPA-sensor is installed with a spring to ensure a tight spanning and to prevent the

sensor from damages due to compression of the snow pack. This non static installation may

cause changes in the sensor position, that can be corrected by measuring the extension

length of the sensor suspension.

In delivery state the length measurement for SPA-sensor 1 is connected to the analog input 1. This

analogue input (channel) is defined for the SPA-sensor in

Main menu

Sensor_01

Input length corr .

Horizontal sensors are operated without length correction by setting the value of the Input length corr. to

“0”.

User Manual SPA Snow Pack Analyser

- 14 -

It is then necessary to adjust the potentiometer which measures the length displacement. Instantly after

the assembling process there is no snow cover on the sensors. Therefor the right offset adjustment is

zero:

Main menu

Analog input

Target value adjustment input_01

0

The actual value is checked with Main menu

8 Sensor_01

6 Input check

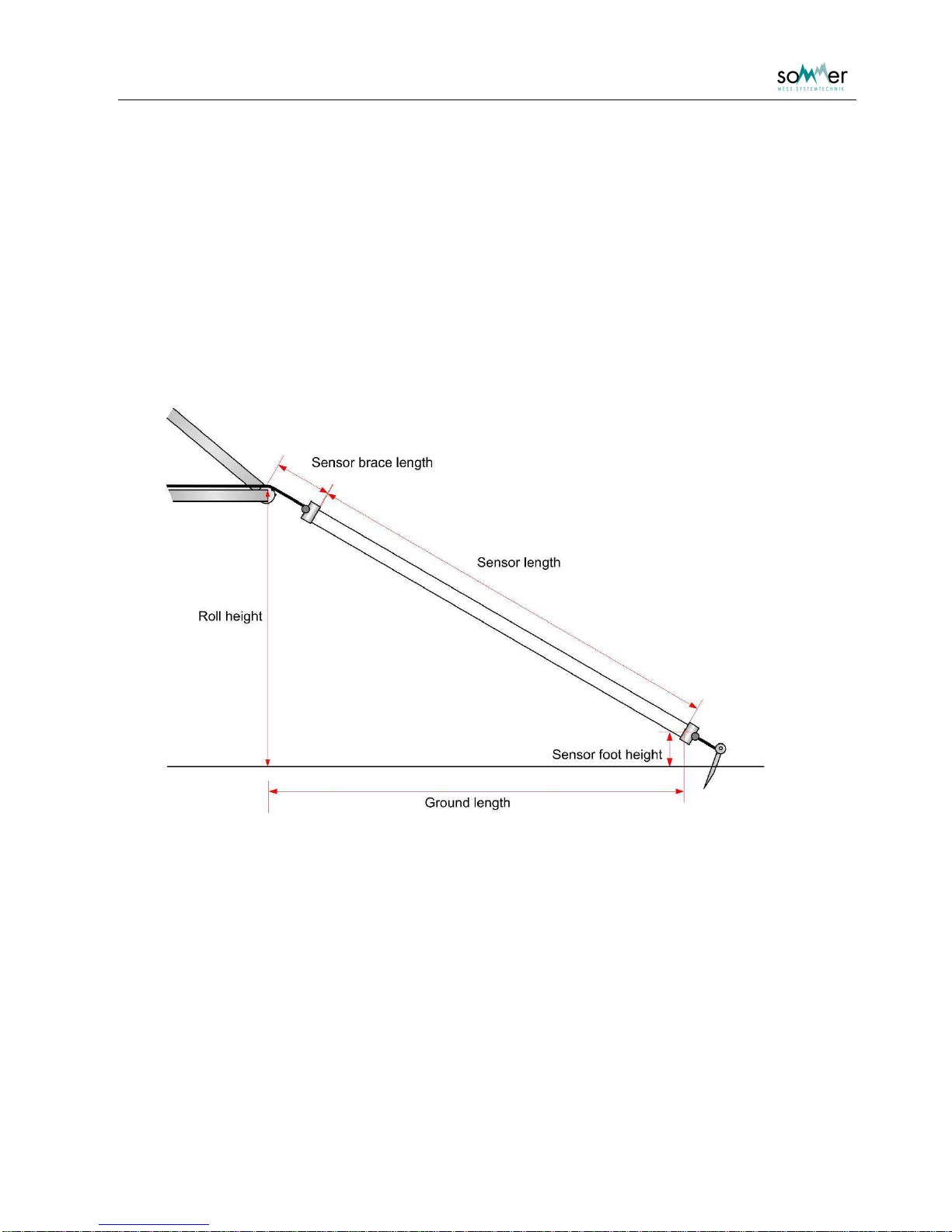

5.3. Geometric parameters

The correct calculation of the snow parameters demands the geometric situation of all included sensors.

Especially for the sloping SPA-sensor these settings are used to determine the length of the sensor in the

snow and to correct a smooth inclination of the measurement site.

Abb. 2: Geometric parameter of SPA-sensor

Numbering of the sensors

The four in different position mounted sensors are indicated with numbers from 1 to 4. For the standard

SPA the assignment is as following:

odiagonal/slope sensor = sensor 1

ohorizontal, at the lowest level height (100 mm) sensor = sensor 2

ohorizontal, medium level height (300 mm) sensor = sensor 3

ohorizontal, at the highest level (500 mm) sensor = sensor 4

User Manual SPA Snow Pack Analyser

- 15 -

Adjustment

The following geometric parameters are necessary:

•Sensor length: Length of the sensor from one box to the other.

•Roll height: Plumb line height of the top of the roll and the ground

•Foot height: Plumb line height of the middle of the sensor at the lower box and the ground

•Brace length: Distance between the middle of the roll and the sensor at the upper top box.

•Ground length: Distance on the ground between plumb line of roll and plumb line of sensor foot.

For horizontal sensors the roll height and the foot height have to be equal. The brace length is set to “0”

and the ground length is equal to the sensor length.

The geometric parameters are measured with a measuring tape and should be of about 1 cm accuracy.

The geometric parameters are entered into

Main menu

Sensor_01

Main menu

Sensor_02

Main menu

Sensor_03

Main menu

Sensor_04

5.4. Actual Snow depth

The snow depth measurement offset has to be adjusted in the control unit IASP by entering the actual

value in Main menu

6 Analog input

7 Snow depth adjustment

A test measurement of the snow depth is performed with Main menu

6 Analog input

Snow depth

5.5. Measurement interval

The minimum recommended interval is 5 minutes (= 300 s) ( Main menu

2 Meas. interval )

Attention: If the interval is adjusted to a lower value eventually temporary problems in

the meausurement process can occur.

The adjusted default interval is 10 minutes.

User Manual SPA Snow Pack Analyser

- 16 -

Attention: Approximately the first 7 minutes after connecting the SPA to the power

supply the measured values are not reliable if the SPA was disconnected for

more than a moment.

During this startup time invalid measurements are indicated with a value of

9999 pF for the measured low frequency capacity and 0000 pF for the

measured high frequency capacity.

example extened MIO protocol output:

I000000000000000000000409;

I0100-999-008-9990000043F;

I020099990000-9999999046B;

The 7 minutes is the time the internal high capacity electrolytic capacitors need to load. These capacitors deliver the

power for the measurement.

User Manual SPA Snow Pack Analyser

- 17 -

6.Description of the parameters

1 Device identifier

The device identifier is included in the output protocol to identify the data values. The first output string is

assigned with the device identifier. For every following string the device identifier is increased by 1 (see

chapter 7). It is recommended to set the device identifier to

0

.

Value range: 0 to 9999 (default: 0)

Example:

oif Device identifier is adjusted as 0:

I000000000000000000000409;

I0100-999000002510000042A;

I020000100013-862-8860430;

oif Device identifier is adjusted as 3:

I03000000000000000000040C;

I0400-999000002510000042D;

I050000100013-862-8860433;

More details regarding the output strings you can find in chapter 7.

2 Meas. Interval

The measurement interval controls the time for the measurements. For permanent monitoring it is

important, not to set a to short interval. The measurements are performed using a measurement battery. A

to short measurement interval will prevent the battery from charging and the measurement will be invalid.

The recommended interval is 10 minutes (600 s).

Unit: [s]

Value range: 5 to 13980

(default: 600; values greater than 240 are rounded to multiples of 60)

3 Output time

The output of the data is either performed directly after the measurement or the data strings are requested

by a exclamation mark sent via the RS-232 interface.

Table of contents

Other SOMMER Measuring Instrument manuals