SOMMY SF Series User manual

Ⅲ.Specification

Ⅱ.Order Model Information

Ⅰ.Model Illustration

1

2 3

SF Sensor Meter User Manual

Features:

● The upper line red LED display real time,maximum & minimum value,and the lower line green

LED display measure unit or alarm value.

● Support 3 alarms output maximum

● Support many kinds of linear signal inputs or temperature sensor signals

● Optional 4-20mA DC transmition output , can modify the transmition range and make calibration.

●RS485 communication and Modbus-RTU protocol

●Power supply 100 ~240V AC/DC。

●Isolated DC24V voltage output(30mA)。

● Peak value hold function, easy to record the maximum and minimum measurement data

●easy to operate, economical and practical.

1)If the fault of the product or abnormal system lead to a serious accident, please set the appropriate circuit protection outside.

2)Before the connection completely, please do not power. Otherwise it may result in electric shock, fire, malfunction.

3)Do not use the product out of scope of specifications range. Otherwise, it may result in fire, malfunction.

4)Do not use in places with flammable and explosive gas.

5) Do not touch the site of high voltage power terminal site after power. Otherwise, there is danger of electric shock.

6)Do not disassemble, repair and modify this product. Otherwise,it may result in electric shock, fire, malfunction.

Caution

1)This product should not be used in a nuclear plant and medical equipment which associated with human life.

2)Some time,it will happen radio interference when the product uses in home environment.It should take adequate

countermeasures.

3)This product has electric shock protection through improved insulation.And when using the product and connecting,it

subject to compliance with specifications.

4)In order to avoid lighting surge,it should set appropriate surge suppression circuits when the product uses in the

environment where the total cable lengh more than 30 metre.

5)The product uses in disk,and avoid to touch the part of high voltage,please take the necessary measure on the final product.

6)Please observe the precautions in this manual, otherwise there is risk of causing significant harm or accident.

7)Please abserve the regulation when wiring.

8)To prevent to damage the machine and prevent to machine failure, the product is connected with power lines or large capacity input and

output lines and other methods please install proper capacity fuse or other methods of protection circuit.

9)Please don't put metal and wire clastic mixed with this product,otherwise it may lead to electric shock, fire, fault.

10)Please tighten screw torque according to the rules.If not,it may lead to electric shock and fire.

11)In order not to interfere with this products to dissipate heat, please don't plug casing around the cooling vent hole and equipment.

12)Please don`t knock or rub the panel with rigid thing.

13)The readers of this manual should have basic knowledge of electrical,control, computer and communications.

14)The illustration, example of data and screen in this manual is convenient to understand,instead of guaranteeing the result of

the operation.

15)In order to use this product with safety for long-term,regular maintenance is necessary. The life of some parts of the equipments

are by some restrictions, but the performance of some will change for using many years.

16)Without prior notice, the contents of this manual will be change. We hope these is no any loopholes, if you have questions or objections,

please contact us.

Caution of Install & Connection:

Warning

Safety Caution

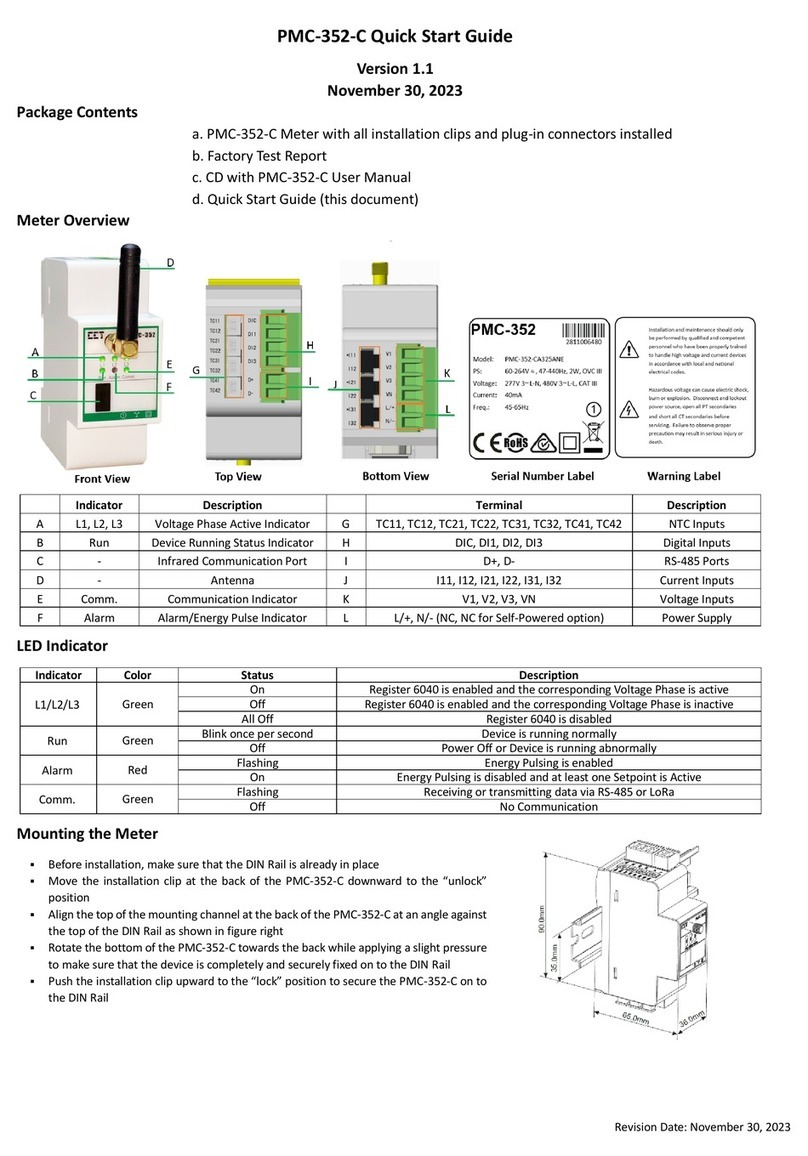

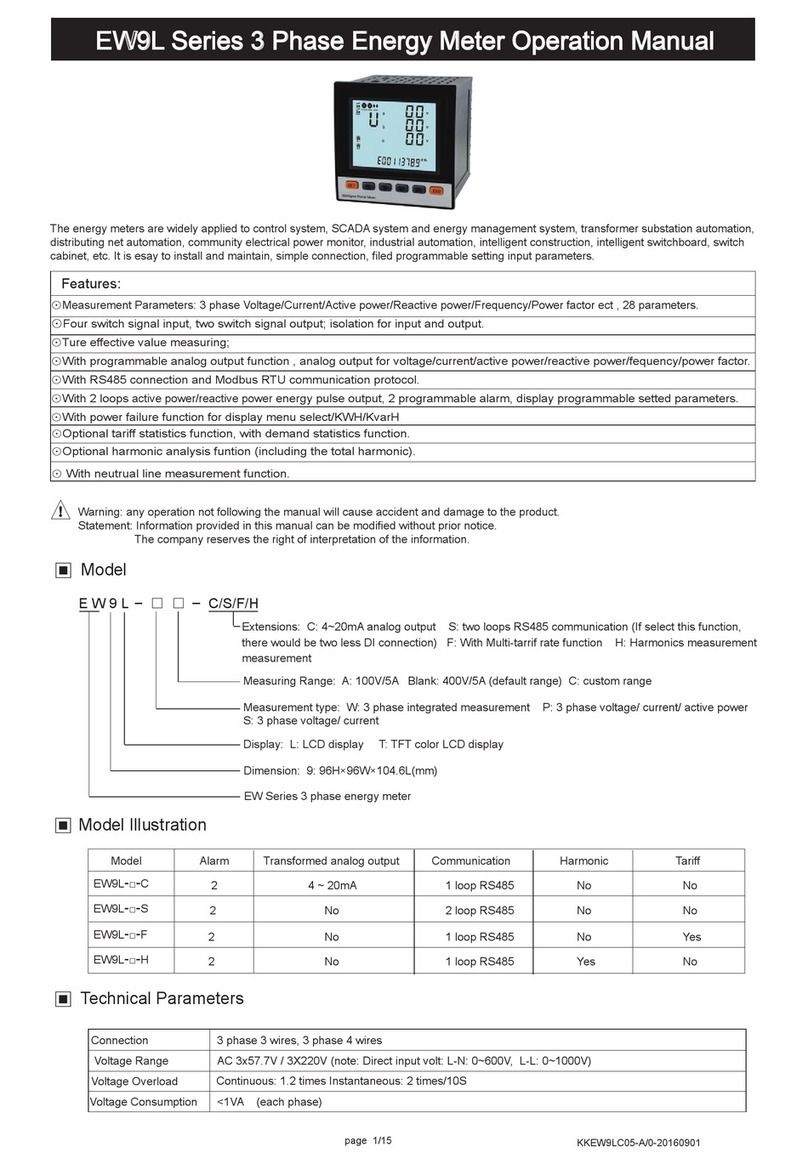

SF□-A0

SF□-R20B

SF□-IR20B

SF□-IR28B

SF□-A0-T

SF□-R20B-T

SF□-R28B-T

SF□-IR20B-T

SF□-IR28B-T

SF series sensor Indicator

C:Version

B: With DC 24V auxiliary voltage Blank:No auxiliary voltage

T: Temperature sensor input Blank:Voltage,current input

0: without RS485 8:with RS485 communication

I: With DC 4-20mA transmition output Blank: No transmition output

4: 48W*48Hmm 6: 48W*96Hmm 7: 72W*72Hmm 8: 96W*48Hmm

9: 96W*96H mm 16:80W*160Hmm 80:160W*80Hmm

Blank: No alarm 2: 2 alarms 3: 3 alarms

A: No alarm R: With alarm relay output

Signal input

mA、V

mA、V

mA、V

mA、V

mA、V

TC/RTD/mV/RT

TC/RTD/mV/RT

TC/RTD/mV/RT

TC/RTD/mV/RT

TC/RTD/mV/RT

2

2

2

2

2

2

2

2

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Alarm Auxiliary voltage

Transmition output

RS485

SF 8 - I R 2 8 B T - C

Model

1.Electrical parameters

Sample rate

Relay capacity

Power supply

Power consumption

Environment

Storage environment

4 Times/seconds

AC 250V /3A life of rateD load>100,000 times

<6VA

Indoor , temperature: -5 ~50℃ no condensation; Humidity:<85%RH; Altitude<2000m

-10 ~60℃,no condensation

AC/DC 100 ~240V (85-265V)

SF Series

KKSFE03-A/0-20160311

1.Installation:

1)This product is used in the following environmental standards.

(IEC61010-1)[Overvoltage categoryⅡ、class of pollution 2]

2)This product is used in the following scope:surrounding environment, temperature, humidity and environmental conditions.

Temperature:0~50℃;Humidity:45~85%RH;Environment condition:Indoor warranty,The altitude is less than 2000m.

3)Please avoid using in the following places:

The place will be dew for changing temperature;with corrosive gases and flammable gas;with vibration and impact;with water, oil, chemicals,

smoke and steam facilities with Dust, salt, metal powder;and with clutter interference, static electric and magnetic fields, noise;where has air

conditioning or heating of air blowing directly to the site.

4)On the occasion of the installation, please consider the following before installing several.

In order to protect heat saturated, please ensure adequate ventilation space.

Please consider connections and environment,and ensure that the products below for more than 50mm space.

Please avoid to installed over the machine of the calorific value(Such as heaters, transformer, semiconductor operations, the bulk resistance).

When the surrounding is more than 50℃, please using the force fan or cooling fans.But don't let cold air blowing directly to the product.

In order to improve the anti - interference performance and security, please try to stay away from high pressure machines, power machines to install.

Don`t install on the same plate with high pressure machine and the product.

The distance should be more than 200mm between the product and power line.

2.Cable caution:

1)Please use specified compensation wire in the place of TC input;Please use insulated TC if the measured device is heated metal.

2)Please use the cable of lesser resistance in the place of RTD input,and the cable(3 wire) must be no resistance difference,but the total

length is within 5m.

3)In order to avoid the effect of noise,please put the input dignal away from meter cable,power cable,load cable to wiring.

4)In order to reduce the power cables and the load power cables on the effect of this product,please use noise filter in the place

where easy to effect.You must install it on the grounding of the disk if you use the noise filter,and make the wiring to be shortest

between noise filter output side and power connectors.Don`t install fuse and switch on the wiring of noice filter output side,otherwise it

will reduce the effect of noise filter.

5)It takes 5s from input power to output.If there is a place with interlocking actions circuit signal,please use timer relay.

6)Please use twisted pair with a shield for analog output line,to ensure the reliabilty of signal.

7)Please use twisted pair with a shield for remote RS485 communication cable,and deal with the shield on the host side earth,

otherwise it will reduce the effect of noise filter.

8)This product is not the fuse;please set according to rated voltage 250V,rated current 1A if you need;fuse type:relay fuse.

9)Please use the suitable screw force and crimp terminal.

The screw terminal size:M4X8(with 7.0X7.0 square base)

Recommended tightening torque:0.7N.m

Proper cables:0.25~1.65mm single cable/multiple core cable

10)Please don`t put the Crimp terminal or bare wire part contact with adjacent connector.

The instruction explain instrument settings,connections,name and etc,please read carefully before you use the temperature controller.

SF□-R28B

2.Signal parameters

Current output

Communication port

Insulation impedance

ESD

Pulse traip anti-interference

Lightning surge

Frequency drop

Dielectric strength

Total weight

Material of case

Material of panel sticker

Power-off data protection

Protection level of panel

Safety Standard

DC 4 ~20mA load < 500Ω

RS485 port Modbus-RTU procotol

Input,output,power cabinet>20MΩ

IEC/EN61000-4-2 Contact ±4KV /Air ±8KV perf.Criteria B

IEC/EN61000-4-4 ±2KV perf.Criteria B

IEC/EN61000-4-5 ±2KV perf.Criteria B

IEC/EN61000-4-29 0% ~70% perf.Criteria B

Signal input & output & power 1500VAC 1min,below 60V Low voltage circuit between DC500V,1min

About 400g

The case and panel frame PC/ABS (Flame Class UL94V-0)

PET(F150/F200)

10 years,times of writing:100w times

IP65(IEC60529)

IEC61010-1 Overvoltage category Ⅱ

Range Accuracy

Input impedance/

auxiliary current

Code

K

J

E

T

N

B

R

S

PT100

CU50

CU100

0~50mV

0 ~ 400Ω

0~10V

4~20mA

0~5V

1~5V

0~20mA

-50 ~ 1200℃

0 ~ 1200℃

0 ~ 850℃

-50 ~ 400℃

-50 ~ 1200℃

600 ~ 1800℃

0 ~ 1600℃

-10 ~ 1600℃

-200.0 ~ 600.0℃

-50.0 ~ 150.0℃

-50.0 ~ 150.0℃

-1999~9999

-1999~9999

-1999~9999

-1999~9999

-1999~9999

-1999~9999

-1999~9999

1℃

1℃

1℃

1℃

1℃

1℃

1℃

1℃

0.1℃

0.1℃

0.1℃

0.01%FS

0.01%FS

0.01%FS

0.01%FS

0.02%FS

0.02%FS

0.01%FS

0.5%FS±3digits

0.5%FS±3digits

0.5%FS±3digits

0.5%FS±2℃

0.5%FS±3digits

0.5%FS±2℃

0.5%FS±2℃

0.5%FS±2℃

0.5%FS±3digits

0.5%FS±3℃

0.5%FS±1℃

0.5%FS±3digits

0.5%FS±3digits

0.5%FS±3digits

0.5%FS±3digits

1%FS±3digits

1%FS±3digits

0.5%FS±3digits

>500KΩ

>500KΩ

>500KΩ

>500KΩ

>500KΩ

>500KΩ

>500KΩ

>500KΩ

0.2mA

0.2mA

0.2mA

>500KΩ

0.2mA

>500KΩ

100Ω

>500KΩ

>500KΩ

100Ω

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

K.0 -50.0 ~ 500.0℃ 0.1℃ 0.5%FS±3digits >500KΩ

Input Symbol ratio

4

6 7

2.Directions of meu

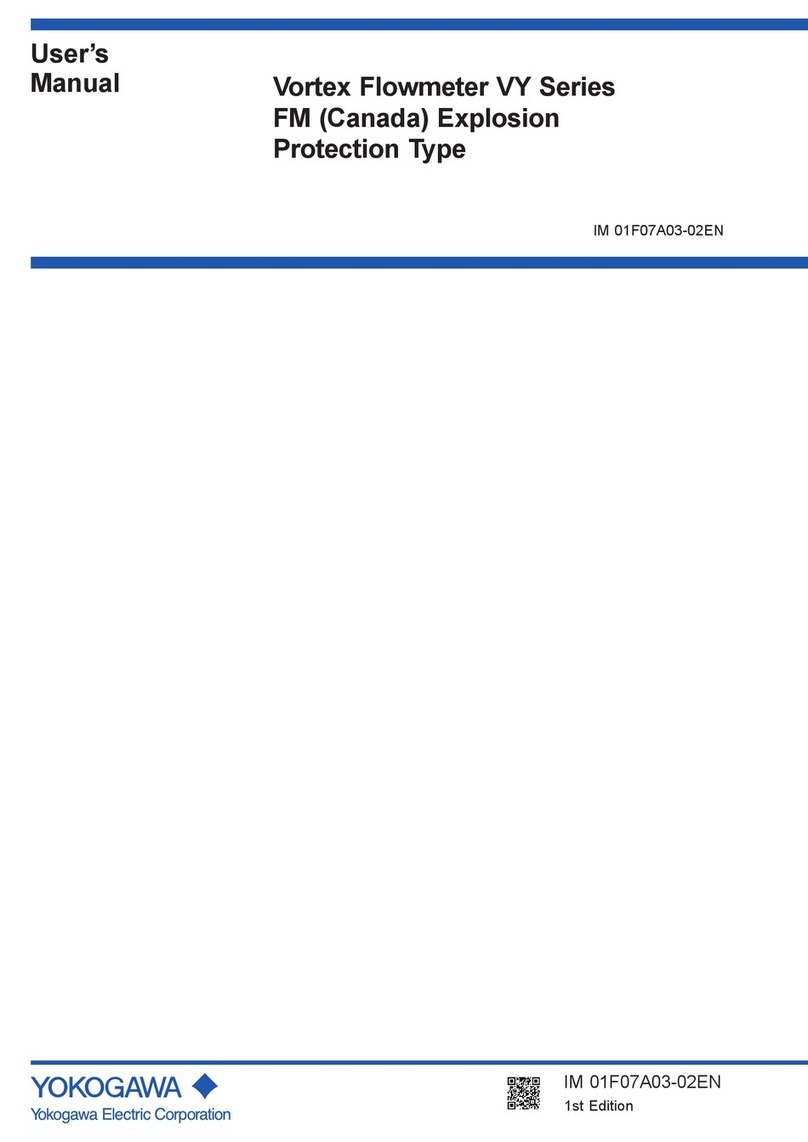

3.Isolation diagram

MCU(Ⅱ)

Measure input

Relay

alarm output

transmition output

Communication port

(Ⅰ) Auxiliary voltage

“ ”:Isolation

Note:when the auxiliary voltage used for power supply of external sensor and if the sensor is non-isolated, then it is not isolated

between (Ⅰ) and (Ⅱ)

Ⅳ.Name of universal panel

Ⅴ.Unit symbol comparision

No. Symbol Name Function

1

2

AL1

AL2

AL3

3

5

4

6

7

20

21

Alarm 1 indicator light

Alarm 2 indicator light

Alamr 3 indicator light

Light of max value

Light of min value

Light of hold value

SET key

Shift key

Add/hold key

Reduce/reverse key

Upper display window

Lower display window

1st alarm output indication,alarm output with lighting , no alarm output without lighting

2nd alarm output indication,alarm output with light,no alarm output without light

3rd alarm output indication,alarm output with light,no alarm output without light

when the MAX value indicator lighting , PV display the maximum value

when the MIN value indicator lighting , PV display minimum value.

when HOLD value indicator lighting , PV display hold value.

Menu browse key / ensure key, max/min/current value shift key.

Parameters modify activating , modify bit moves to left

Increase the flashing bit value, hold measurement instantaneous value

Reduce the flashing value, browse menu in backward sequence.

Display current/max/min value and parameter symbol,error remind

Display measure unit,parameter and alarm value

HOLD

PV

SV

MIN

MAX

0

1

2

3

4

5

6

7

8

9

10

no

M

cm

mm

kg

g

mg

Mpa

pa

ba

mba

12

11

13

14

15

16

17

18

19

20

21

N

W

KW

RPM

RPS

MPM

MPS

Hz

KHz

mV

V

22

23

24

25

26

27

28

29

30

KV

mA

A

KA

Ω

KΩ

℃

℉

K

No. Symbol Unit No.

Symbo

Unit No.

Symbo

Unit

Menu shield function, function symbol and its according parameters are as below:

AL1:AD1,AL1,HY1,AE1,DL1A,DL1B;

AL2:AD2,AL2,HY2,AE2,DL2A,DL2B;

AL3:AD3,AL3,HY3,AE3,DL3A,DL3B;

BS:BRL,BRH,OLL,OLH,TEST;

When it display one function symbol , lower line will display “Y” or “N” (Y means start the function; N means stop the function)

For example:if the meter have no first alarm , please set the AL1 to “N” and then exit menu.

Then the menu and submenu will not display AD1,AL1,HY1,AE1,DL1A,DL1B and the alarm function stop to work.

COMM:BAUD,ADDR,DTC;

SF1:CAS, CAK , SQRT;

SF2:DREF,STEP,CJC,RLMR;

Measured high limit, setting value must larger than measured low limit

-1999~9999

1000/1200

0

HY1

AL2

HY2

AD2

1st alarm backlash value

2nd alarm setting value

Optional 4 types alarm , set as 0 , alarm close

Optional 4 types alarm , set as 0, alarm close

2nd alarm backlash value

3rd alarm setting value

3rd alarm backlash value

lower line led display choice : no display, measuring unit ,

1st /2nd/3rd alarm value.

filter coefficient of digital filters.

The higher of value, the larger the filter effect.

Display refresh cycle, unit:s

decimal point setting for linear signal

Input signal types

0~1000

FL~FH

0、L、H、Int、Out

0~1000

FL~FH

0~1000

Non、Unit、AL1、

AL2、AL3

1~255

0~5

0~3

Refer signal sheet page 3

1

2

3

4

Symbol Menu name Directions Setting range Factory

9

10

11

12

13

14

15

16

AL1

MME

AD1

6

7

8

5

Max/min value starting record function. Y: start , N:close

1st alarm setting value

Optional 4 types alarms : 0:alarm close; L:low limit alarm;

H: high limit alarm; Int:interval alarm;

Out: outside the interval alarm

0(N) 1(Y)

FL~FH

0、L、H、

Int、Out

N

200

L

1

600

H

1

800

H

1

Unit

10

0

0

0~10V/K

0/-50

AL3

AD3

HY3

LDSP

FT

DREF

DP

INP

FL

FH

PS

26

28

27

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Display mode choice. o_SL=0 , no function .

o_SL=1, measured value <FL, display FL value ; measured value >FH,

display FH vlaue.

o_SL=2, measured value < SCUT/FL , display FL value;

measured value>FH, display FH value

o_SL=3,measured value <SCUT, display the smaller value of FL&SCUT;

if measured value >FH,display FH value.

Max/min value power failure protection.Y:open;N:Close

linear signal Square root

Display jumping interval

transmition output low limit

transmition output high limit

Adjust transmition output low limit OLL= (preset transmition low limit

- actual transmition low limit)/ actual transmition range*1000

Adjust transmition output high limit OLH=(preset transmition high limit -actual

transmition high limit)/ actual transmition range *1000+1000

Communication baud rate

Meter communication address

Communication delay time

AL1 extensions

AL2 extensions

AL3 extensions

0~3

-1999~9999

0(N)1(Y)

1~10

FL~FH

FL~FH

-500~1000

0~1050

4.8K、9.6K、19.2K

1~255

Refer

Communication

procotol remark

0~11

0~11

0~11

o_SL

PSb

MEMO

SQRT

STEP

BRL

BRH

OLL

OLH

BAUD

ADDR

DTC

AE1

AE2

AE3

DL1A

DL1B

DL2A

0

0

N

N

1

FL

FH

0

1000

9.6K

1

0

0

0

0

0.0

0.0

0.0

44

45

46

close the function of AL2 delay (unit:s)

start the function of AL3 delay(unit:s)

start the function of AL2 delay (unit:s)

close the function of AL1 delay(unit:s)

start the function AL1 delay(unit:s)

close the function of AL3 delay(unit:s)

0~999.9

0~999.9

0~999.9

DL2B

DL3A

DL3B

0.0

0.0

0.0

1.Operation of normal menu and shielding menu

Press SET key for 3s

PRE

SET

PRE

SET

PRE

PRE

PRE

PRE

SET

SET

PRE

SET

SET

SET

Press SET key for 3s

Ⅵ.Operation and Menu Direction

22

23

25

Password, LCK=01, unit lock ; LCK=10, menu lock;

LCK=11,unit&menu lock; LCK=33, it can enter class 2 menu;

LCK=5555, reset to factory setting.

Small signal elimination function. please refer to description of o_SL

0~9999

-1999~9999

0

5

LCK

SCUT

LCK=66

Press SET key for 3s

SET

Zero function, long press + , display will show zero. And then zero value

is stored in PSb. If you want to reset the value, long press

1) In the normal measurement mode and when the MME=Y, press key can shift display of max/min/current value in cycle.

2) Enter MME menu, and set it as displays “Y” , press key to restart to record max/min value.

3) In the normal measurement mode, short press key can lock current display value, and press again to unlock.

4) Before using CAS , CAK calibration function , long press

AH1 1st alarm interval high limit value

FL~FH

1000

AH2

FL~FH

1000

0、L、H、Int、Out

AH3

FL~FH

1000

17

18

19

Refer signal sheet page 3

Refer to input signal tabel

0~999.9

CAS

CAK

Displayed value of low limit input signal. set corresponding value of

low limit input , press to decrease CAS value. when CAS= OFF ,

this function is disabled.

OFF, FL~FH OFF

Displayed value of high limit input signal . Set corresponding value of

high limit input , press to decrease CAK value, when CAK= OFF ,

this function is disabled.

OFF, FL~FH OFF

24

0~999.9

0~999.9

1

6

27 3 54

SET

PRE

PRE

SET

PRE SET

PRE SET

PRE SET

PRE SET

PRE SET

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

PRE

SET

PRE

SET

PRE

SET

SET

PRE

SET

PRE

SET

PRE

SET

PRE

SET

PRE

SET

PRE

SET

PRE

SET PRE

SET

PRE

SET

PRE SET

PRE SET

PRE SET

PRE SET

LCK≠33 时LCK=33 时

PRE SET

5

Power supply

+, (make sure PSB=0)

2nd alarm interval high limit value

3rd alarm interval high limit value

measure range low limit ,setting value must be less than

range high limit

Amend value,display value=actual measured value+ amend value

+or set Psb

as 0 .(Temperature input signal without this function)

0(N)1(Y)

8

10

9

11

Ⅹ.Connection drawing

47

Thermocouple low temperature compensation mode :

auto-compensation, close compensation, input

compensation temperature by manual

-1(Auto),0(Off),

1~50

CJC Auto

49

51

50

52

53

48

RLMR

TEST

CAL

CAE

CAH

VER

linear resistance value, can use it when linear resistance is

large (Unit: mΩ)

Simulating input test, used to test output function

Operation of user calibrating low limit input, after

adding the low limit signal to signal input terminal, flash

display YES, press “ ” to confirm. When it displays

OK, it finishing calibrate low limit input signal.

Display the software version;

FL~FH

YES/OK

YES/OK

Unable to set

OFF

YES

YES

V1.0

1、High & low limit display setting function

Example: use electronic ruler or others to measure , if want position 5mm display 500, position 6mm display 600, firstly enter into

function shield menu, make SF1= Y( open the functionof CAS, CAK parameter), then enter menu to set CAS=500 at 5mm postion,

and set CAK=600 at position 6mm, exit to the measure measure interface after finishing settting.

2、Linear signal self-calibration function

a)Set INP type, and make sure that it is one of the linear signals.

b)The input signal should input to correct input channel.

c)Enter low limit calibration menu CAL, press “ ” to flash “YES” ; and adjust the input signal to the minimum value.

d)When “YES” flashing, and the minimum value of input signal is inputed into the meter; press “ ” to confirm and save

calibration value.

e)After the low limit is calibrated, enter high limit calibration menu CAH, and flash “YES” in the same way.

f)Adjust the input signal to the maximum value, and input it into the meter. And when “YES” flashing, press “ ” to confirm

and save calibration value of high limit.

g)After calibration, enter CAE to change “N” into “Y” to enable calibration; otherwise, it will use the default calibration value.

h)The calibrated high limit input value of linear signal should not beyond the ±10% of the standard signal

i)After the calibration, if the result is not satisfactory, it can be recalibrated.

3、Transmition range calibration function

Example: actual high limit is 20.4mA, low limit is 3.97mA. To calibrate the transmition range through modification of OLL, OLH.

OLL= (Preset transmit low limit - actual transmit low limit)/ actual transmit range*1000 =( 4.0 - 3.97)/(20.4 - 3.97) * 1000 = 2

OLH= (Preset transmit high limit - actual transmit high limit)/ actual transmit range*1000+1000 = (20.0 - 20.4)/( 20.4 - 3.97) * 1000

+ 1000 =976

Ⅶ.Alarm parameters and output logic diagram

Alarm code Type

High limit

absolute value

alarm

Low limit

absolute value

alarm

Interval alarm

HY

AL1 AL2

AL1 AL2

HY

HY

HY

AL

AL

HY

HY

Deviation alarm

Logic diagram

Alarm extension function table

0

1

2

5

3

4

Alarm handling mode

when display is over limit

AE1/AE2/AE3 value inhibits alarms or not when power on

Do not inhibit

(As long as it meets the requirement of alarm,

alarm output)

Inhibit

(Forced alarm close when power on;alarm

does not output until PV meet alarm condition)

Status maintained

Forced alarm output

Forced alarm close

Forced alarm output

Forced alarm close

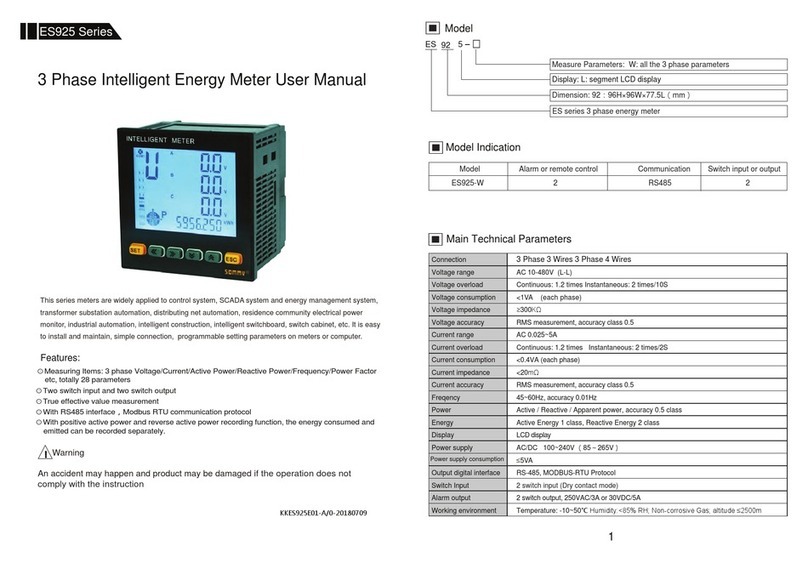

Ⅸ.Dimension

Panel Size Side Face Size Mounting Size

Operation of user calibration high limit input, after

adding the high limit signal to signal input terminal, flash

display YES, press “ ” to confirm .When it displays

OK, it finishing calibrate high limit input signal.

0~9999 0

User calibration function,this parameter is only for

linear signal; Y: use user calibration parameters;

N: No user calibration function N

0(N),1(Y)

OFF

OFF OFF

OFF

OFF

PV

PV

PV

PV

ON

ON

ON

ON ON

Function

code

Start ADD

High bit

Start ADD

Low bit

Data byte

length

high bit

CRC code

low bit

CRC code

high bit

Host request(Read multi-register)

1 2 3 4 5 6 7 8

0x01 0x03 0x32 0x01 0x00 0x01 0x DB 0x72

1 Read register(0x03)

For example: Host reads integer AL1(AL1=200)

The address code of AL1 is 0x3201, because AL1 is integer( 2 byte), seizes 1 data register. The memory code of decimal integer

200 is 0x00C8.

Note:It should read DP value or confirm DP menu value first to ensure the decimal point postion when reading data,and converse

the reading data to get the actual value. On the contrary ,it should converse the data to corresponding ratio first before writing the

data into meter.

Address error abnormal answer: (For example, host request address is 0x2101)

1 2 3 4 5

0x01 0x83 0x02 0xC0 0xF1

Slave error answer

CRC code

low bit

CRC code

high bit

1 2 3 4 5 6 7

0xC8 0xB9 0xD2

Data

low bit

Slave normarl answer(

Read multi-register

)

0x01 0x03 0x02

0x00

2 Write multi-register (0x06)

For example: Host writes AL1(First alarm set value 100)

The address code of AL1 is 0x3201, because AL1

is integer ( 2 dyte), seizes 1 data register. The hexadecimal memory code of decimal

integer 100 is

0x0064.

Meter ADD

Data byte

length

low bit

Function

code

Meter ADD Data byte

number

Data

high bit

CRC code

low bit

CRC code

high bit

Meter ADD

Function code Error code

87654321

0x590xD70x640x000x010x320x060x01

CRC code

high big

CRC code

low bit

87654321

0x590xD70x640x000x010x320x060x01

Host request(Write single-register)

Meter ADD

Function

code

Data ADD

High bit

Data ADD

Low bit

Data

High bit

Data

Low bit

Slave normarl answer(

Write single-register

)

Meter ADD

Function

code

Data ADD

High bit

Data ADD

Low bit

Data

High bit

Data

Low bit

CRC code

low bit

CRC code

high big

SF7 SF9/16/80

SF4 SF6/8

4:(48*48)

6:(96*48)

7:(72*72)

8:(48*96)

9:(96*96)

80:(80*160)

16:(160*80)

48

48

72

96

96

160

80

Model

3:(72*36) 72 36 70.5 6.5 64 32 68 25 33 25

A H(Min)

GB C D E F

J

48

96

72

48

96

80

160

101

100

100

100

100

102

102

10

6

10

6

10

10

10

91

94

90

94

91

92

92

45.5

45.5

68

91.5

91

154

76.5

25

25

25

25

25

30

30

45.5

91.5

68

45.5

91

76.5

154

45

91

67.5

45

90.5

76

153.5

K

(Min)

25

25

25

25

25

30

30

H

G

K

J

A

B

C

E

D

F

+0.5

-0

+0.5

-0

Meter adopt Modbus RTU communication protocol, RS485 half duplex communication.Read function code:0x03,

write function code 0x06 or 0x10. Adopts 16 digit CRC check, the meter does not return for error check.

Data frame format:

Display

HHHH/LLLL

Methods

Start bit

Data bit

181No

Stop bit Check bit

XⅠ.Methods of simple fault

XⅡ.Communication procotol

Abnormal communication processing:

When abnormal response,put 1 on the highest bit of function code. For example: when host request function code is 0x03, slave

response function code should be 0x83.

Error code:

0x02---Illegal address: the register address designated by host beyond the address range of meter.

Communication cycle:

Communication cycle is the time from host request to slave response data . ie: communication cycle= time of request data sending

+slave preparation time + response delay time + response return time.

Eg: 9600 Baud rate: communication cycle of single measured data ≥ 250ms.

Note: If there is any change, please subject to the drawing on the meter

Checks whether the input disconnection and whether normal of FH value,FL value,working

environment temperature and whether input signal is selected correctly.

Status maintained

12

14

13

15

Address error abnormal answer:( for example, host request address is 0x2101)

1 2 3 4 5

0x01 0x86 0x02 0xC3 0xA1

Error code

3、Write register(0x10)

For example: host writes AL1 (First alar set value 100)

0x01 0x10 0x32 0x00 0x00 0x01 0x02 0x00 0x64

0xB5 0xA9

42

43

44

45

46

47

48

49

HY3 3rd alarm backlash value

TESE similate input test enable

TEST simulate input test

LCK Lock

ADDR Meter communication address

0x3211

0x3210

0x3212

0x3213

0x3214

0x3301

0x3302

0x3303

0x3304

2

2

2

2

2

2

2

2

R/W

R/W

R/W

R/W

R

R

R/W

R/W

Refer to measure signal parameter

table(Page 3)

Effective for all quantities-related

parameter

Note①(Page 14)

0:close、1:open

simulate display input, test output

function

※16 digit CRC check code to get C program

unsigned int Get_CRC(uchar *pBuf, uchar num)

{

unsigned i,j;

unsigned int wCrc = 0xFFFF;

for(i=0; i<num; i++)

{

wCrc ^= (unsigned int)(pBuf[i]);

for(j=0; j<8; j++)

{

if(wCrc & 1){wCrc >>= 1; wCrc ^= 0xA001; }

else

wCrc >>= 1;

}

}

return wCrc;

}

50

51

52

53

54

BAUD Baud rate

DTC Communication configuration

byte

NAME meter name

VER Software version code

0x3305

0x3306

0x3400

0x3401

2

2

2

2R/W

When LCK=11, other parameter can

not be written

0~1050

0:4.8K、1:9.6K、2:19.2K

R/W

2R/W

R

R

Note②(Page 15)

208: SD8

10 : V1.0

1 2 3 4 5

0x01 0x90 0x02 0xCD 0xC1

87654721

12345678910 11

0x000x010x320x100x01 0xB10x5E0x01

No. ADD mapping Variable name Register

number Read/write Remark

2

3

4

6

7

8

0x3001

0x3002

0x3003

0x30045

0x3100

0x3101

0x3102

MAX Maximum measure value

MIN Minimum measure value

HOLD Hold measured value

STA Output status

FL Measuring range low limit

FH Measuring range high limit

INP Input signal type

Reserve

Reserve

Reserve

2

2

2

2

2

2

2

R

4、Address Mapping Table of Meter Parameters

10x3000 PV Measure value 2R

R

R

R

0x31039DP Decimal point 2R/W

R/W

R/W

R/W

Data location error response:(For example:Host request write ADD index is 0x2100)

Collocate with DP value to read value

Collocate with DP value to read value

Collocate with DP value to read value

Collocate with DP value to read value

Collocate with DP value to read value

Collocate with DP value to read value

DL3B 3rd alarm close delay

Slave answer error code

CRC code

high big

CRC code

low bit

Meter ADD

Function

code

Host request(Write register)

Function

code

Start ADD

High bit

Start ADD

Low bit

Data byte

length

high bit

CRC code

low bit

CRC code

high bit

Meter

ADD

Data byte

length

low bit

Data byte

length

Data

high bit

Data

low bit

Slave normarl answer(

Write register

)

Function

code

Start ADD

High bit

Start ADD

Low bit

Data byte

length

high bit

Meter

ADD

Data byte

length

low bit

CRC code

low bit

CRC code

high bit

Slave answer error code

Meter ADD

Function

code

Error code

CRC code

low bit

CRC code

high bit

FL~FH Collocate with DP value

to read value

DL3A 3rd alarm start delay

AE 3rd alarm expand function

Collocate with DP value

to read value

0~1000

refer alarm expand photo(page 9)

10 corresponding to 1.0 second

10 corresponding to 1.0 second

BRL transmit output low limit

BRH transmit ouptut high limit

OLL transmit output low limit adjust

OLH transmit output low limit adjust

FL~FH Collocate with DP value

to read value

FL~FH Collocate with DP value

to read value

-500~1000

55

56

57

58

R/W

R/W0x3402

0x3403

0x3404

0x3405

2

2

2

2

R

R

1~255

R:Read only; R/W:Read/Write

Note①:measurement status indication, when data byte is 1, it means execution; when data byte is 0, it means no execution.

D7 D6 D5 D4 D3 D2 D1 D0

AL3 AL2 AL1HHHH LLLL MIN HOLD MAX

Hundreds place, reserve

Tens place, byte transfer sequence: when it is 0, from high to low; when it is 1, from low to high

One place, respon delay: 0 ~9 respectively stand for 10 ~100ms

□ □ □

DTC:

Note②:DTC communication configuration byte illustration

30

32

31

33

34

35

36

AL2 2nd alarm value

AD2 2nd alarm type

HY2 2nd alarm backlash value

AE2 2nd alarm extended mode

DL2A 2nd alarm start delay

DL2B 2nd alarm close delay

AL3 3rd alarm value

0x3206

0x3207

0x3208

0x3209

0x320A

0x320B

0x320C

2

2

2

2

2

2

2

R/W

R/W

R/W

R/W

R/W

R/W

R/W

37

38

AD3 3rd alarm type

0x320D

0x320E

2

2

R/W

R/W

39

40

41 0x320F 2R/W

20

21

22

23

24

25

26

27

28

29

0x310E

0x310F

0x3110

0x3111

0x3112

0x3201

0x3200

0x3202

0x3203

0x3204

0x3205

MME Maximum/minimum value

record function

MEMO Power failure memory

SQRT Linear signal square root

CJC Thermocouple cold end

compensation method

Reserve

AD1 1st alarm type

HY1 1st alarm backlash value

AE1 1st alarm extended mode

DL1A 1st alarm start delay

DL1B 1st alarm close delay

FL~FH

0:no alarm、1:L、2:H

Refer to alarm extention table

(Page 9)

10 corresponding to 1.0 second

10 corresponding to 1.0 second

FL~FH

0:no alarm、1:L、2:H

0~1000

10 corresponding to 1.0 second

2

2

2

2

2

2

2

2

2

2

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

10 0x3104 UNIT Unit setting 2R/W

0x3105 PS Translation correct 2R/W

11

0x3106

0x3107

0x3108

0x3109

0x310A

0x310B

0x310C

0x310D

CAS limit point display value

setting

FT Filter constants

DREF Display refresh cycle

SCUT Small Signal Elimination

PSb Zero clearing value

oSL Display method option

LDSP Lower line display content option

STEP Display stepping interval

2

2

2

2

2

2

2

2

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

12

13

14

15

16

17

18

19

Refer to symbol table (Page 4)

Set the low input point

corresponding display value

1~255

Unit: second

Set the minimum step value of

display change

0:N;1:Y

0:N;1:Y

0:N;1:Y

Unit: mOhm

0:no alarm、1:L、2:H、

3:Int、4:Out

0~1000

Refer to alarm extention table

(Page 9)

10 corresponding to 1.0 second

Non(0)、Unit(1)、AL1(2)、

AL2(3)、AL3(4)

-1: Auto compensation、0: No

compensation、(1~50) Manual

input cold end temperature

Collocate with DP value to

read value

Refer to menu illustration (Page 7)

AL1 1st alarm value FL~FH Collocate with DP value

to read value

Collocate with DP value

to read value

Collocate with DP value

to read value

Collocate with DP value

to read value

Collocate with DP value

to read value

Collocate with DP value to

read value

Collocate with DP value to

read value

0x3113 RLMR linear resistance value

CAK high point display value

setting 2R/W Set the high input point

corresponding display value

AH1 1st interval alarm high limit value 2R/W FL~FH cooperate DP value to Read value

FL~FH cooperate DP value to Read value

AH2 2nd interval alarm high limit value

AH3 3rd interval alarm high limit value

Other SOMMY Measuring Instrument manuals

SOMMY

SOMMY ES925 Series User manual

SOMMY

SOMMY SG8-SVA User manual

SOMMY

SOMMY SF Series User manual

SOMMY

SOMMY EW9L Series User manual

SOMMY

SOMMY EP8 SVA Series User manual

SOMMY

SOMMY SF Series User manual

SOMMY

SOMMY SF Series User manual

SOMMY

SOMMY ER9 Series User manual

SOMMY

SOMMY EL801 Series User manual