SOMNI C3 User manual

1

VETERINARY ANAESTHETIC

VAPORISER OPERATIONS MANUAL

SOMNI C3

SOMNI PRODUCT MANUAL

2

TABLE OF CONTENTS

User Responsibility

Warnings and Cautions

Principles of Operation

Examination and

Preparation For Use

Installation

Operating Instructions

Filling Instructions

Funnel Fill

Draining Instructions

Funnel Fill

Filling Procedure

Key Filled

Operating Instructions

Key Filled

Specications

Warranty and Service

3

4

5

6

7

9

11

12

13

15

17

20

3

USER RESPONSIBILITY

The SOMNI C3 is a precision medical vaporiser designed for Veterinary

Use Only. This vaporiser was designed to mix the vapours of specied

liquid anaesthetic gas agents with anaesthetic delivery gases. The

vaporiser will continue to provide reliable performance only if the

manufacturer’s operating and maintenance instructions are followed.

The vaporiser, as with any mechanical medical device, requires periodic

preventative maintenance and calibration. Any components, which

become worn, distorted, or contaminated should be replaced by a

factory authorised service centre. A vaporiser that requires service

should not be used until it has been accurately tested and veried by a

factory authorised service centre. Field-testing of vaporiser output using

portable test equipment, while valuable, is not a substitute for factory

authorised preventative maintenance. Factory service and calibration is

recommended every two years, eld-testing is recommended annually at

minimum. The user assumes full responsibility and liability of any use of

the vaporiser.

4

WARNINGS AND CAUTIONS

• This vaporiser is intended for Veterinary Use Only

• Do not ll the vaporiser with any agent other than the one specied on the front

label. Vaporisers are specically designed dependent on agent type. Therefore, any

other agent used can prove to be dangerous to a patient.

• Do not use this vaporiser until it is mounted upright, vertical and out of operation

for a minimum of (1) hour aer initial lling to allow for proper initial wick

absorption. Failure to allow wicking absorption time may result with inaccurate

output at the selected dial setting.

• Do not carry vaporiser by control dial. Handle and transport vaporiser with care

by grasping the vaporiser rmly with two hands.

• Do not modify, tamper, or disassemble the vaporiser. There is a probable

danger of damaging the vaporiser and altering the calibration accuracy.

• Do not put vaporiser into any liquid, including water.

• Do not attempt to sterilise vaporiser.

• Do not drain anaesthetic agent into any container other than a properly

marked container.

• Do not tilt or tip vaporiser beyond a 45-degree angle while lled with liquid

agent. If unit is accidentally tipped on its side, please call the manufacturer

for specic instructions.

• Do not have vaporiser serviced by anyone other than a SOMNI authorised

service centre.

• Do not operate vaporiser prior to leak testing the anaesthetic equipment,

ensuring secure connections to prevent unnecessary anaesthetic exposure

• Turn the vaporiser OFF when not in use.

• It is recommended that the vaporiser is kept upright at all times aer installation.

5

PRINCIPLES OF OPERATION

VAPORISER SUMP AND VALVE ASSEMBLY

This anaesthetic vaporiser is comprised of a vaporising chamber and duct

system (located within the sump cover), rotary valve and concentration dial. The

concentration dial is connected to the rotary valve underneath. The rotary valve

contains ducts and a vapour control channel. With the concentration dial in the

o position, the rotary valve links the inlet and outlet of the vaporiser, allowing

carrier gas to pass through. When the concentration dial is turned on, the carrier

gas is split in two: one stream owing into the bypass and the other owing into

the vaporising chamber.

The vapourising chamber contains two concentric wicks that are in contact

with the liquid anaesthetic agent. The wicks ensure the vapour is maintained at

saturation of concentration in the gas that leaves the vaporising chamber. The

ow through the vaporising chamber is controlled by the concentration dial.

Temperature compensation occurs automatically utilising a bi-metallic

strip to keep the output of the vaporiser constant during conditions of

changing temperature.

6

EXAMINATION AND PREPARATION FOR USE

1. Examine shipping carton for signs of external damage.

2. Remove contents from carton and inspect for visible damage

such as dents or missing parts.

3. If damage or missing parts are discovered or suspected, notify

customer service immediately at 0800 0129101.

4. Check that control dial operates freely.

5. Conrm the drain valve is completely closed .

6. Remove the mounting hardware (vaporiser spacer and 3-6mm bolts with

washers) and drain tube (*not shown) from package.

7

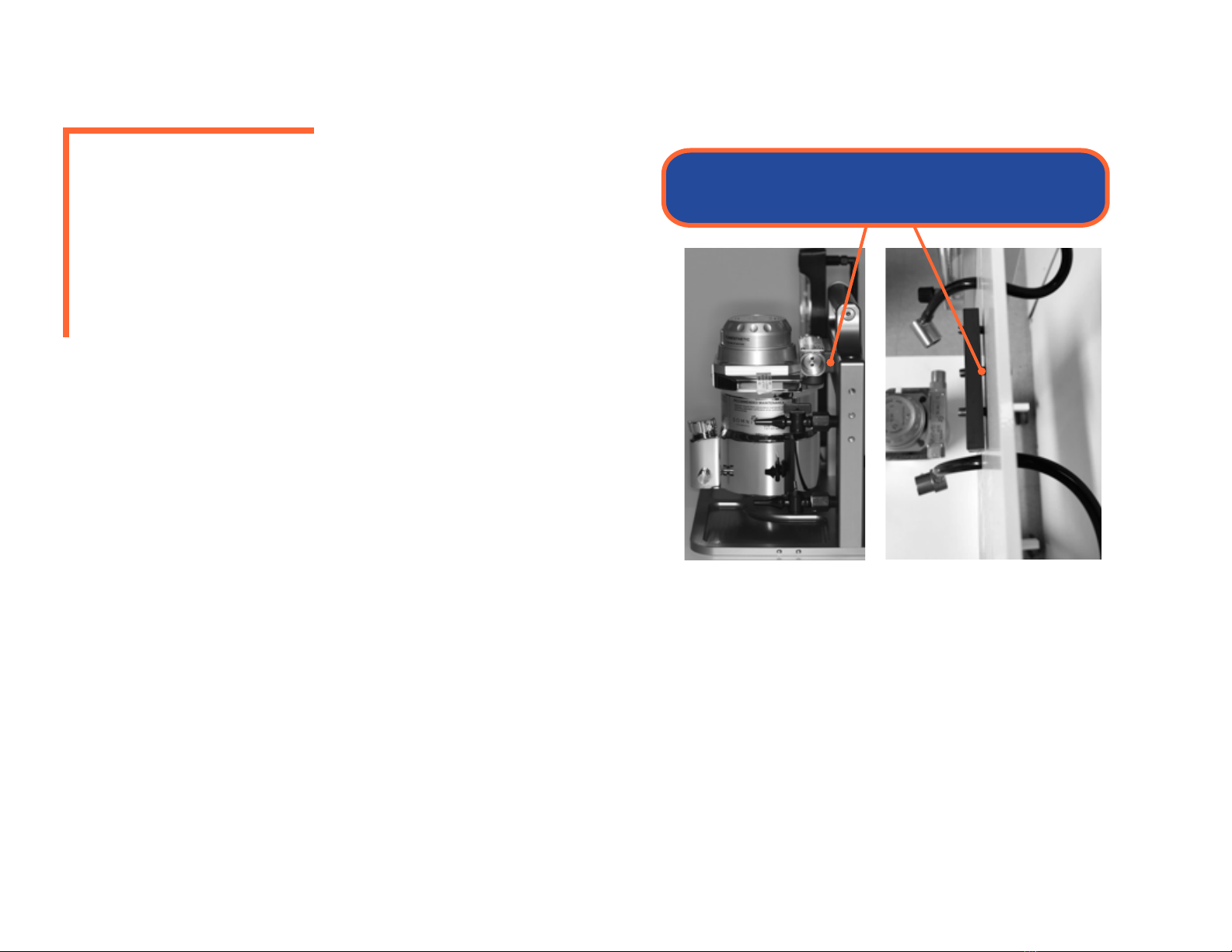

INSTALLATION

The standard mounting system requires bolting of the vaporiser directly

to a rigid back bar of an anaesthetic gas machine. The vaporiser should

always be mounted between the gas ow-metering unit and the

breathing circuit-always upstream of any absorber or humidier.

Ensure that emergency oxygen supplies or oxygen ush enter the

gas circuits downstream of the vaporiser.

The SOMNI C3 is supplied with mounting hardware consisting

of a spacer and 3-6mm bolts. While supporting the weight of

the vaporiser, install the spacer between the vaporiser and the

mounting surface and secure the vaporiser using the mounting

bolts provided. Ensure the bolts are tightly secured, but be sure

not to over-tighten.

Connect the 23mm inlet and outlet adapters to the corresponding

outlets on the cagemount. Twist and rmly push on for a secure,

leak-free connection. It may be necessary to connect the 23mm

adapters prior to mounting the vaporiser.

Complete a 10 second pressure test to conrm a leak free

installation. Instructions on Page 10.

8

INSTALLATION

• The direction of gas ow must be from “inlet to outlet”

(i.e. from le to right) when viewing the vaporiser from

the front.

• Ensure the liquid (which may accumulate in the

breathing circuit or the CO2 absorber) can not enter

the vaporiser while:

The vaporiser is tted with standard 23mm inlet and

outlet taper connections.

IMPORTANT! Vaporiser Spacer Placement

-in use

-during disassembly of the circuit

-when the machine is not in use

9

OPERATING INSTRUCTIONS

1. Observe all instructions and warnings on the vaporiser.

2. Fill only with agent indicated with vaporiser in OFF position.

3. Perform a leak test prior to rst use (See instructions

below- “10 Second Test”).

4. Depress locking button to turn dial from OFF position.

5. Turn dial counterclockwise to desired concentration.

6. Then turn control dial counter clockwise to desired concentration.

7. Turn vaporiser to “OFF” position when not in use.

10

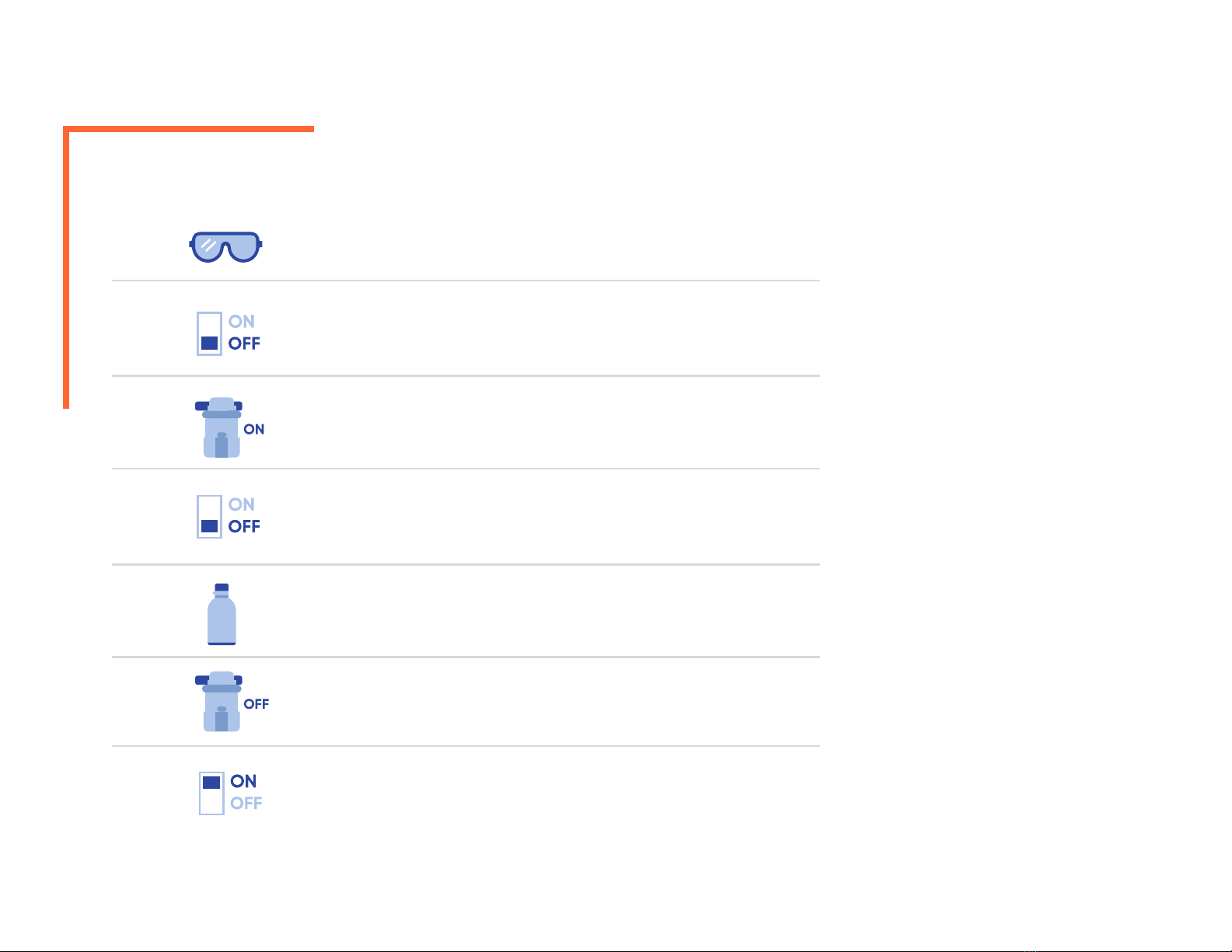

10 SECOND PRESSURE TEST

Before each use, “leak test” the anaesthesia system and ensure the waste gases have a

patent way through the evacuation system.

www.somniscientific.com | info@somniscientific.com | 1-877-637-3625

WARNING:

Anaesthetic Vaporiser Is

Under Pressure

1

2

3

4

5

6

7

Wear safety goggles or safety glasses.

Please Follow this protocol for refilling vaporiser

Turn O2 supply primary switch to “OFF”.

With vaporiser in “ON” position (2% concentration), drain oxygen from

line by turning “ON” fresh gas switch to induction chamber (be sure to

have evac for the induction chamber “ON”.

When oxygen stops flowing (flow meter will drop to zero and O2

pressure gauge will drop to zero), turn induction chamber fresh gas

supply to the “OFF” position.

Fill vaporiser with liquid anaesthetic.

Turn vaporiser dial to “OFF” position.

Turn O2 supply primary switch to the “ON” position.

11

FILLING INSTRUCTIONS-FUNNEL FILL

DO NOT ll vaporiser with any agent other than the one specied

on the front label. Vaporisers are designed specically to their

respective agents. Any agent other than specied could prove to

be dangerous to a patient.

CAUTION:

1. Verify that vaporsier dial and delivery gas owmeter(s) are

in the “OFF” position.

2. Verify that anaesthetic agent is the same as labeled on front

of vaporiser.

3. Verify that the drain valve on the right side of the ll assembly

is closed by turning clockwise until nger tight.

4. Remove the funnel cap and pour agent slowly into opening.

Simultaneously, observe the agent level through the sight

glass. Note: If the vaporiser is dry, the level will fall slightly

as the wick absorbs the agent.

5. Replace cap by turning cap clockwise. Cap should be tight

to prevent leaks.

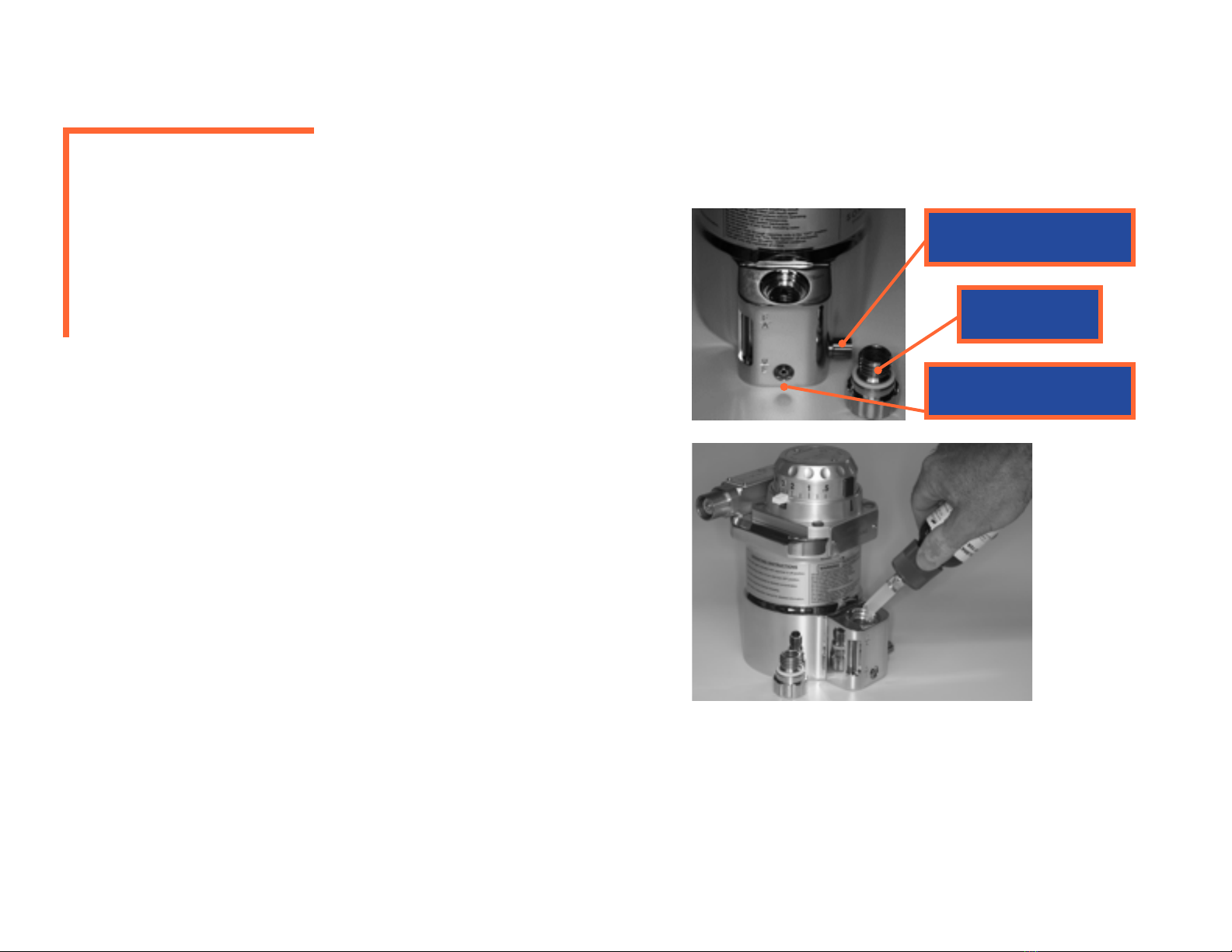

Drain Valve

Drain Port

Fill Cap

12

DRAINING INSTRUCTIONS-FUNNEL FILL

Liquid MUST be drained from the vaporiser into a properly labeled container.

CAUTION:

1. Attach small drain tube to the hole in the front of the vaporiser

ll assembly.

2. Hold an empty, properly labeled container under the tube.

3. Open the drain valve located on the right side of the ll assembly.

Aer all liquid is drained, close the valve nger tight to seal.

4. Discard used anaesthetic agent per proper protocol.

13

FILLING INSTRUCTIONS - KEY FILLED

CAUTION:

The vaporiser may be pressurised. Open the dial to

relieve internal pressure and then close. Unscrew

the top key retaining screw slowly when removing

the replica key plug on vaporisers tted with key

ll design.

Drain Screw Valve

Replica Key Plug

Key Retaining Screw

Fill Socket

Sight Glass

Drain Nozzle

A. Remove the cap and seal from the anaesthetic bottle. Check

that the bottle is not damaged and attach the tted keyways of

the bottle adapter to the keys of the bottle collar. Screw them

together until fully secured and tightened. The bottle is now

ready to ll the vaporiser. Only the correct agent-keyll adapter

can be tted to the respected anaesthetic agent bottle.

B. Ensure that the vaporiser dial control is set to the “OFF” position.

Loosen the top key retaining screw on the ller assembly counter-

clockwise and withdraw the replica key plug.

C. Insert the keyll bottle adapter into the ll socket.

14

FILLING INSTRUCTIONS - KEY FILLED

Because the SOMNI C3 vaporiser sump can hold 125 ml capacity, there may be no excess agent.

If there is any excess liquid agent, allow this to escape from the ller socket completely, then

insert and fully tighten the replica key plug to prevent gas from escaping through the ller.

Note: If the vaporiser was dry before lling, the level will decrease as the wicks absorb the agent.

D. Aer insertion, tighten the key retaining screw clockwise to tighten and seal the keyll

adapter in the ller socket.

E. Raise the bottle above the level of the ll socket, avoiding kinking the adapter tube. The

agent should begin owing into the vaporiser from the anaesthetic bottle within a few

seconds. If this does not occur, remove the bottle and adapter from the vaporiser and

remove the adapter from the bottle. Carefully shake the adapter two or three times to clear

the tube, then repeat steps A through E.

F. When the vaporiser is lled to the maximum level mark in the sight glass, lower the bottle

below the level of the ller socket and wait for ve seconds to allow any agent in the adapter

to drain back into the bottle, then unscrew the top key retaining screw and remove the

adapter from the ll socket.

15

DRAINING INSTRUCTIONS - KEY FILLED

CAUTION:

DRAINING PROCEDURE:

Ensure the dial is in the “OFF” position, that the recovery bottle is below the drain

nozzle. The vaporiser may be pressurised, open and close the vaporiser to help

relieve internal pressure.

A. Remove cap from recovery bottle and position under the drain nozzle.

B. If needed, to allow air to vent, unscrew the top retaining screw and remove the replica key

plug from the ller socket.

C. Open the drain screw valve by turning knob counterclockwise to initiate the agent

draining process. Allow agent to pour into recovery bottle.

D. When draining has been successfully completed, close the drain screw valve by turning

the knob clockwise and insert replica key plug back into ller socket and secure.

16

ASSURING PERFORMANCE OF YOUR VAPORISER

To assure the continued performance of your vaporiser, the manufacturer

recommends full factory preventative maintenance be performed

every 2 years. Accurate and eicient anaesthetic gas delivery is a primary

consideration in patient care. Anaesthetic agent vapours are extremely

potent, and a very small error in concentration could be hazardous.

Preventative Maintenance Includes:

• Disassembly of the vaporiser

• Cleaning and inspection of all components

• Replacement of internal wick and seals

• Testing of thermostat and adjusting or replacing if needed

• Reassembly and leak test

• Calibration using industry standard laser refractometer

Preventative Maintenance Ensures:

o Worn components are replaced when necessary and

calibration is veried.

o Wicks are replaced to prevent the accumulation of contaminants

which can hinder anaesthetic vapourisation and interfere with eicient

anaesthetic gas delivery.

o Inspection and service can reveal accidental damage that could alter

performance and allows correction.

o Correction of vaporiser leaks and prevents the vaporiser from

contributing to unnecessary personnel exposure to waste anaesthetic

gas pollution.

17

Calibration

Vaporisers are calibrated at 21° C. The variation in output

with temperature, ow rate and duration of use is small, and

the variation in output when used with Intermittent Positive

Pressure Respiration is negligible.

Resistance to Gas Flow

5cm.wg at the “OFF” setting at 5 liter/min O2 at 22° C

Duration of Use

The rate of consumption of anaesthetic agent depends

primarily on ow rate and vapour output concentration. As

an approximate working gure, 1.0 ml of liquid anaesthetic is

required to provide 200 ml of vapour.

The rate of evapouration of anaesthetic agent may be used

(with caution) as an approximate method of checking that

the delivered output is not grossly in error. It may also be

used as a means of estimating how oen the vaporiser is

likely to need relling.

The approximate hourly consumption of anaesthetic agents

can be expressed as follows:

3 x % x F

Where % represents the setting of the vaporiser output

percentage, F represents the input ow rate in liter/min.

Example: If a vaporiser is set to deliver 2% at 6 liter/min total

input gas ow rate.

SPECIFICATIONS

Approximate rate of agent consumption = 3 x 2 x 6 = 36 ml/hour.

The above gures are approximate and intended for clinical

guidance only. Figures will vary depending on ow meter type

(and other varying factors). Results will be grossly in error if the

vaporiser drain port is not fully closed.

Liquid Capacity

Amount of anaesthetic agent to fully charge the vaporiser =125 ml.

Amount retained by Wick System = ml.

Weight and Dimensions

Weight 6.1kg / 13.5 lb

Height 181.6 mm / 7.15 in

Depth 134.6 mm / 5.35 in

Width 109.2 mm v/ 4.3 in

Capacity 125 ml

Wicking Capacity 50 ml

Some ventilators may impose higher, steady back pressures

(around 100 mmHG), producing more signicant depression of

the v/v percentage. Increased patient uptake of agent, along with

improved ventilation can oen mitigate these eects, eliminating

the need to compensate for increased back pressure at the

vaporiser.

High Back Pressures

Pressures in excess of 400 mmHg could conceivably occur during

procedures similar to bronchoscopy or because of occlusion of

downstream tubing and piping or for other reasons. These eects

on v/v percentage cannot be precisely predicted but the most likely

eects will be reductions in concentration (or small increases).

18

Back Pressure Fluctuating

Fluctuating backpressures may be imposed on the

vaporiser by downstream components and assisted

or controlled ventilation to the patient. This can

aect the vaporiser and increase the concentration by

intermittently altering the pressures, therefore altering

ow distribution within the vaporiser. The greatest

eects are observed in combinations of very low ow

rates and low dial settings, with large and rapid pressure

uctuations. These eects become progressively less

notable as the dial setting and ow rates increase,

causing the magnitude and rate of cycling pressure

uctuations to decrease.

In clinical use, vaporisers are considered unaected

by uctuating back pressures which occur frequently

in most typical, clinically encountered conditions

appertaining to human anaesthesia.

Carrier Gas Composition

Small eects can occur when the carrier gas

composition is changed (i.e., from Oxygen to air, or in a

Nitrous Oxide and Oxygen mixture). As a general rule,

variation of output with carrier gas compilation should

be considered of low clinical signicance, since the side

eects (if any) are typically less than 10% of the setting.

SPECIFICATIONS

In an instance where signicant changes do occur, the usual

eect is a slightly depressed output once nitrous oxide is

employed (compared to the output when oxygen is the carrier

gas).

Other Variables

Ambient temperature, input ow rate and duration can oen

aect delivered concentrations, particularly when vaporisers

are used at the clinical extremes of such variables.

The valve design and temperature compensation system of

the SOMNI C3 vaporisers work to reduce the eects to levels

considered not signicant by clinical standards.

19

SPECIFICATIONS

Temperature variation eects are typically negligible

at common dial setting and ambient temperature

combinations.

The vaporiser responds very slowly to change in ambient

temperate to prevent the valve from closing completely. As

an additional safety feature, the temperature sensitive valve

does not respond to temperatures below the approximate

range of 12-15° C.

Should the vaporiser temperature be lower than this, the

output can be expected to be lower than that indicated on

the dial.

At temperatures above the range shown on the performance

curves, the vaporiser output may be unpredictably high-

particularly if the temperature approaches the boiling point

of the anaesthetic agent.

To avoid any inaccuracies due to extreme temperatures, the

vaporiser should be allowed to reach a temperature within

the suggested range (of the performance curves) prior to use.

Pressure

Vaporisers are graduated in v/v percentage at 760 mm Hg.

Equation 1 D = % x 760

Where % is the nominal setting of the vaporiser.

It is generally accepted that the depth of anaesthesia depends on

the inspired partial pressure of agent and not the concentration by

volume of agent.

To obtain a consistent depth of anaesthesia when gross changes

of barometric pressure occur, it is necessary to change the v/v

percentage in inverse proportion to the barometric pressure.

The vaporiser automatically performs this action. For practical

and clinical purposes, the eects of barometric pressure can be

ignored.

The vaporiser automatically does this and for practical clinical

purposes the eects of the barometric pressure

can be ignored.

P

20

Limited Warranty

Somni Scientic warrants to the original purchaser that

the products, not including accessories, shall be free from

defects in materials and workmanship under normal use, if

maintained in accordance with our companies guidelines

and used according to its labeling, for the period specied

in the manual.

Warranty period is 5 years.

THIS LIMITED WARRANTY, IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES WHETHER EXPRESSED OR IMPLIED,

BY OPERATION OF LAW OR OTHERWISE, INCLUDING

BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

This warranty is void if the product has been altered,

misused, damaged by neglect or accident, tampered with,

not properly maintained, not installed in strict compliance

with applicable codes and ordinances, or repaired by

persons not authorised by Somni. This warranty does

not cover normal wear and tear and maintenance items

and specically excludes accessory items and any other

equipment used with the product.

WARRANTY AND SERVICE

Limitation of Remedies

The only obligation under this limited warranty is the repair or

replacement of the product. THIS IS THE EXCLUSIVE REMEDY. We

shall not be liable for and hereby disclaims any direct, incidental,

consequential or special damages or delays, including but not

limited to loss of use, downtime, lost business, revenues and

prots.

Warranty Procedure

To obtain warranty service, contact Somni Scientic

enquiries@somniscientic.com

(M) 07798 969805

(T) 0800 0129101

(D) 01872 248890

enquiries@somniscientic.com www.somniscientic.co.uk

Table of contents

Other SOMNI Vaporizer manuals

Popular Vaporizer manuals by other brands

Boundless

Boundless VEXIL user manual

Neta

Neta RUBI quick start guide

GRAVEDA

GRAVEDA GRASPRESSO ERIG DABTON V2 instruction manual

VapeOnly

VapeOnly PORTO PCC STARTER KIT manual

STORZ & BICKEL

STORZ & BICKEL Volcano Hybrid Instructions for use

Storz & Bickel GMBH

Storz & Bickel GMBH Crafty Instructions for use