Sonder Allegro 576 Series Owner's manual

Allegro 576

Technical Installation & Operation Manual Energy control

Avenida la Llana Nº 93

P.I. La Llana 08191 RUBÍ

(Barcelona) - Spain

Tel.: +34 93 588 42 11

Fax: +34 93 588 49 94

www.sonder.es

SONDER REGULACIÓN S.A.

Allegro 576 RAIL code: 20.043

Allegro 576 BOX code: 20.054

5815VØ MAY-09

2 35

NOTES

CONTENTS

NOTES

34

Warnings

Presentation

Installation and connection

Description

Technical specifications

Dimensions

Connections

Operation

Getting started

Probe and relay test

Screen view

Configuration

Factory settings and resetting

Resource control

Menu

Statistics

Functions

Systems

Settings

33

4

5

6

...................................................................................6

..............................................................6

................................................................................6

................................................................................7

8

............................................................................8

...................................................................9

.............................................................................10

..............................................................................11

..................................................12

.......................................................................13

16

.....................................................................................16

.....................................................................................18

.....................................................................................22

.....................................................................................26

SAFETY INSTRUCTIONS

- Before installing the Allegro 576 regulator, ensure

that the environmental conditions (operating

temperature, humidity, pollution and gas emissions)

are suitable, as any of these factors can cause the

unit to malfunction.

- When handling the Allegro 576 regulator, whether

for installation or repairs, disconnect it from the

electricity mains.

- The Allegro 576 is an independent control device for

surface assembly with wiring through tubes for

correct installation.

- Electrical connections other than those indicated in

this manual and on the connection label on the side

of the device are not permitted. The connections

referred to in this manual are those of the regulator;

to connect the rest of the components, please

consult the corresponding instructions for each unit

(collectors, tanks, valves, etc.). For correct

operation of the installation, check that the technical

needs of the elements are compatible.

- This regulator is not a security device nor can it be

used as one; it is the responsibility of the installer to

provide the protection most suited to each type of

installation (officially authorised).

- The assembly, electrical connection, commissioning

and maintenance procedures must be carried out by

qualified personnel.

- Should you encounter any defects that could cause

damage or malfunctions, do not connect the device.

- Should you have any doubts regarding the operation

or correct installation of the device, do not connect it

to the electricity mains and consult a professional

technician.

- Sonder Regulación S.A. reserves the right to modify

the product, technical data and assembly and use

instructions without prior notification.

WARRANTY CONDITIONS

This device has Three-year warranty. The warranty

is limited to the replacement of faulty parts, which will

be restored to the same condition in which they were

received. No packaging, batteries, instructions or any

other accessories included with the product will be

replaced.

We cannot accept any responsibility for devices

damaged as a result of poor handling, omission of the

warnings provided in this manual or technical

ignorance with regard to the requirements of the

installation.

For repairs during the warranty period, customers

are required to provide proof of purchase and an

accurate description detailing the defect or the

anomalous behaviour of the product according to the

user.

In the event of repairs outside the warranty, the user

will be informed of their viability and cost.

Assessments carried out by our technical department

may incur an additional cost for the user.

The following cases are excluded from the warranty:

Devices whose serial number has been worn away,

erased or modified.

Devices which were not connected or used in

accordance with the instructions enclosed with the

device.

Devices that have been modified without prior

agreement with the manufacturer.

Devices damaged due to knocks, spills or gas

emissions.

Devices with normal wear and tear or which are

damaged from inappropriate use.

Shipment and reception costs.

Requests for compensation for loss of earnings,

usage compensation and indirect damage, unless the

company is deemed legally responsible.

4

WARNINGS

Moderato-SR

33

Probes

- Radiation

- Temperature

New product

Versions to order

with probe

PTC2000

Remote adjustment probe

with range from 6 to 30 ºC

32

EQUIPMENT CONTAINED IN THE KIT

POSSIBLE ACCESSORIES

• 1 Allegro 576 solar regulator

• 3 contact terminals for probes

• 3 PT1000 1.5-metre probes

• Technical manual

• Quick start guide

L= 20mm

Landline telephone control

3 channels

3 alarms

Telephone control - landline / mobile

1 channel

1 alarm Water meter with pulse output

L= 50mm

L= 100mm

L= 200mm

Conductive

paste for sheaths

5

PRESENTATION

Stainless-steel sheaths

GSM

Consult us about models for remote

management and data storage with SD card

Visit our WEBSITE

New products

All our products

Technical documentation

Catalogues

www.sonder.es

Consult our wide

range of products BOX

RAIL

DESCRIPTION

First of all we would like to thank you for your purchase and we hope that the Allegro 576 meets the needs of

your installation.

The Allegro 576 is a thermal solar energy regulator with six 5A 250V~ relay outputs and seven PT1000 probe

inputs (three 1.5 metre probes are included, each with a range of -50 ºC to +200 ºC), in addition to a pulse input.

The relays are potential-free contacts, which means that they only act as switches and the devices connected to

the relay need to be powered.

When programming the Allegro 576 you will find different predefined installation systems that will help you to

quickly and easily configure your installation. Depending on the system you have chosen, you may activate

additional functions, such as unit heater, independent thermostat, return increase, double pump, anti-frost,

calorimeter and tubular sensors, provided that the resources (relays) required for the functions are not being

used by the system chosen to configure your installation.

Assembly on DIN rail

TECHNICAL SPECIFICATIONS

DIMENSIONS

R 1

(230 Vac)N L

105

90

Input power

Outputs

Inputs

Wiring

Environment

Operation

Tests

230 Vac +10% -15% 50/60 Hz max. 2 VA.

6 SPDT relays max. 250 V~, 5 A. Potential-free contacts (acting as switches).

7 PT1000 probes / Range: -50 ºC to +200 ºC + 1 calorimeter (pulses).

Min. power section = 0.75 mm² / Min. relay section = 1.5 mm² / Max. section = 2.5 mm² / Type = H05v-k.

Temperature = 0º C to 40 ºC / Humidity = 20% to 85% / Pollution = 2.

Software class A; Action type 1.B.

Assigned pulse voltage: 2500 V.

Temperatures for high-pressure ball valve: 100ºC (parts supporting voltage conductors).

75ºC (accessible plastic parts).

W 843 922 1000 1078 1155 1232 1309 1385 1461 1536 1611 1685 1758

ºC -40 -20 0 +20 +40 +60 +80 +100 +120 +140 +160 +180 +200

26 22 10

58

1414

45

62

ESC

OK

Allegro

576

Sonder

S

E

T

%

R 2 R 3 R 4 R 5 R 6

Probe1 Probe2 Probe3 Probe4 Probe5 Probe6 Probe7 Cal. / GND

INSTALLATION AND CONNECTION

6

Operation of the priorities

When an accumulator is below its priority temperature, it is charged

exclusively until it reaches the temperature. If another accumulator

falls below its priority temperature while the former is charging, both

become priority and are both charged at once until one of them

reaches its minimum temperature.

In winter

If the temperatures of AC1 and AC2 are below 65 and 40,

the installation heats them both at once. When AC2

reaches 40, only AC1 is heated until it reaches 65. Once it

reaches this temperature there are no other accumulators

in priority mode and it heats all three accumulators until

they reach 70, 45 and 35, respectively.

If one of them falls below its priority temperature, its priority

is activated again and only the one below its priority value

is heated.

In the case of excess heat: When AC1 has reached 70 and

AC has reached 45, the swimming pool is heated to

dissipate the excess heat instead of accumulating it in the

collectors, thus preventing the installation from

overheating.

Example with system 6.2

Accumulator priority ºC

AC 1 AC 2 AC 3

65 40 5

H. W. U. H. Swimming

pool

In summer

Tank alarm ºC

AL 1 AL 2 AL 3

70 45 35

Since the underfloor heating does not need to be activated

during the summer, its priority can be set to 5 ºC and its

alarm to 5 ºC to deactivate it, and AC3 can be set to 5 ºC

with its alarm to 35 ºC so it is not priority. The system then

heats AC1 until it reaches 65 ºC, and once it reaches this

temperature it heats AC1 and AC3 at the same time until

they reach their alarm temperature, at which point the

system stops charging the accumulators.

T3

T4

T2

T1

R3

R2

R1

AC3

AC2

AC1

Accumulator priority ºC

AC 1 AC 2 AC 3

65 5 5

Tank alarm ºC

AL 1 AL 2 AL 3

70 5 35

31

SETTINGS

Sequential priority OFF

When accumulator number 1 is below its priority temperature, it is

charged exclusively until it reaches its priority temperature. If

number 2 falls below its priority temperature while number 1 is

charging, it cannot be charged until accumulator 1 reaches its

minimum temperature (priority temperature).

Sequential priority ON

Example of operation

Sequential priority OFF

Sequential priority ON

If the temperatures of AC1 and AC2 are below 65 and 40,

the installation only heats AC1 (numerical order) until it

reaches 65 ºC. Once it has reached this temperature it is

no longer priority and the system then exclusively heats

accumulator 2 until it reaches 40. As there are no other

priority accumulators, the two accumulators are heated at

once until their temperature alarms are triggered.

Since the underfloor heating does not need to be activated

during the summer, its priority can be set to 5 ºC and its

alarm to 5 ºC to deactivate it, and AC3 can be set to 28 ºC

with its alarm to 35 ºC. The system then heats AC1 until it

reaches 65 ºC, and once it reaches this temperature it

heats AC3 until it reaches 28 ºC, then it charges AC1 and

AC3 at the same time. If AC1 falls below 65 ºC while AC3 is

charging, the system stops charging AC3 so it can charge

AC1 until it reaches 65 ºC.

H. W. U. H. Swimming

pool

MENU

When a system uses several accumulators (tanks, heating, swimming pools, etc.) it can set a priority for charging them

(accumulator priority setting on page 28). Their minimum temperature is configured and these temperatures are classified as

priority and non-priority when charging. The tanks with the lower temperatures are given priority until they reach the

temperature when they become non-priority.

When the sequential priority parameter is activated, it assigns the charge order in accordance with the numerical order and the

temperatures. The numerical order assigned to the accumulators is the numerical order of the relays.

Accumulator priority ºC

AC 1 AC 2 AC 3

65 5 28

Tank alarm ºC

AL 1 AL 2 AL 3

70 5 35

H. W. U. H. Swimming

pool

CONNECTIONS

Make the connections

of the installation before

connecting the power.

230 V~ 50 Hz max. 2 VA

INPUT POWER

INPUTS

CALORIMETER

The relay contacts are potential-free because they operate

as switches.

The application must be powered externally.

NO C (230 Vac)N L

Probe 1 Probe 2 Probe 3 Probe 4

+10%

- 15%

OUTPUTS 5A 250 V~ relays

R1

CONTROL KEYS

Up arrow

to move to another

menu or sub-menu.

ESC key

to cancel, exit or finish

without saving.

OK key

to confirm data and

settings.

Down arrow

to move to another

menu or sub-menu.

FLANGE FOR

INSTALLATION ON DIN RAIL

7 PT1000 probes

Range: -50 ºC to +200 ºC

Before making any electrical connections it is advisable to carefully read the whole manual and ensure

compliance with the technical requirements for correct operation of the installation.

Probe 5 Probe 6 Probe 7 Cal. / GND

NO C

R2 NO C

R3 NO C

R4 NO C

R5 NO C

R6

ESC

OK

576

Sonder

S

E

T

%

SCREEN

INSTALLATION AND CONNECTION

7

SETTINGS

For normal use of your installation the factory settings are considered to be the most common for each type of

system. If they are of use to you, the device is ready to control and regulate your installation. If, due to the needs

of your installation, you require other settings, read this section carefully.

In the menu you can adjust the parameters that define how the installation will operate.

default values and setting ranges

SETTING RANGE ADJUSTED

Adjustment mode

Activation differential

Deactivation differential

Tank temperature alarm *

Temperature differential

Minimum setting limit

Maximum setting limit

Minimum ambient limit

Maximum ambient limit

Probe calibration

Priority in the accumulator *

Accumulator cooling (1…6):

Sequential priority

Display light

Password

Winter / Summer

4.0 to 20.0 ºC

1.0 to 4.0 ºC

5 to 130 ºC

0.3 to 9.0 ºC

5 to 80 ºC

90 to 130 ºC

6 to 17 ºC

18 to 30 ºC

-10.0 to +10.0 ºC

5 to 130 ºC

5 to 130 ºC

ON/OFF

ON/OFF

OFF (0) / ON (1...9999)

Winter

6.0 ºC

2.0 ºC

85 ºC

2.0 ºC

10 ºC

90 ºC

6 ºC

30 ºC

0.0 ºC

5 ºC

130 ºC

OFF

OFF

OFF

* The values of the tank alarm and accumulator priority settings are interrelated in such a way that the alarm

cannot be set below the value of the tank priority and the tank priority value cannot be set above that of the

alarm, since this can block the setting adjustment range.

30

MENU

GETTING STARTED

- If you wish to activate one of the functions, first

make sure you know what resources the function

needs, the type (fixed, exclusive or shared) and

check that the configured system leaves the

required resources available:

- Seven PT1000 probes (S1, S2, ..., S7)

- Six 5A 250 V~ relays (R1, R2,..., R6)

- 1 pulse input (Calorimeter).

These resources are shared by systems and

functions in different ways.

The probes and relays in the systems are pre-

assigned and non-configurable. The probes can be

shared by the systems and the functions

The relays cannot be shared between systems and

functions (except the OR and AND functions).

The screen only shows the available systems, relays

and probes, depending on the activated functions and

systems.

If you need a function or system which is not shown,

you will have to free the required resources first.

The Allegro 576 is a thermal solar regulator.

On the screen you can see diagrams showing all the

information required to quickly and easily configure

and adjust your installation.

In normal operation mode, the screen shows the

status of the devices (pumps, relays, alarms, etc.)

and the probe temperatures.

For optimal operation carefully read this section,

which indicates the steps to follow to adapt the

Allegro 576 to your installation.

Steps to follow:

- Once installed and once the connections have

been made, you can connect the Allegro 576 to the

mains.

- Before configuring the system values and settings

it is advisable to test the probes and relays to

check the correct operation of the installation.

(This step is explained on page 9.)

- Once you have verified the operation, choose the

system that best suits your installation type from

among the available configurations (pages 22 and

23). Remember that System 1 has 6 variants

depending on the number of accumulators to be

configured, although only 1 symbol is shown on

the screen.

- All the settings are preset to factory default values.

If these values do not suit the needs of your

installation, consult page 26 to configure them.

8

OPERATION

ESC

OK

576

Sonder

Accumulator cooling

This parameter allows you to reduce the temperature of the accumulator by

recirculating the collector, when it detects that the collector temperature is

lower than the accumulator temperature.

- In the SETTINGS menu press until the

REFRIG ACUMULADOR screen appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 5 ºC to 130 ºC / Default: 130 ºC

ESC

OK

576

Sonder

29

SETTINGS

Display light

Parameter that defines the type of display lighting: timer (15 minutes without

keyboard activity) or always on.

- In the SETTINGS menu press until the LIGHT screen appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: OFF(15 min. and when a key is touched)

ON (always on) / Default: OFF

ESC

OK

576

Sonder

Password

This parameter denies unauthorised access to the Allegro 576

configuration. The user can only view statistics, screen light, change

summer/winter and perform the probe and relay tests.

- In the SETTINGS menu press until the PASSWORD screen

appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: ( ) to ( ) / Default: ( )OFF 0 ON 1...9999 OFF 0

ESC

OK

576

Sequential priority

This parameter defines the charging priorities according to the accumulator

number, if the installation has more than one. (see page 31).

- In the SETTINGS menu press until the PRIO SECUENCIAL screen

appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: OFF to ON / Default: OFF

ESC

OK

576

Sonder

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

MENU

- You will see the current temperature of each probe (its

shows which probe it belongs to).

- Press OK to move on to the next probe (S1 to S7).

ESC

OK

576

S

E

T

9

PROBES

- It is advisable only to use original probes (1.5m

PT1000). Should they need to be extended, they

must be welded together avoid losing the reading

value and the joint must be shrink wrapped to

insulate against humidity.

- The probes of the panels must be installed at the

output leading to the installation.

- The accumulator probes must be installed inside the

accumulator.

- Under no circumstances should the probe cables be

laid in the same channel as the electrical cables.

RELAYS

- The relays that activate the devices of your

installation supply a voltage of 230 V~ and a

maximum current of 5(3) A (max. charge of 10A from

the three relays) so there is no need to

independently power valves, pumps, etc.

- Ensure that electrical connections from the devices

to the contacts of the relays have been made

correctly before connecting the Allegro 576

terminal to the mains .

TIPS

It is very important to press ESC to exit manual mode when you finish,

since system regulation is deactivated this mode and operations are limited

to the established manual orders

PROBE, RELAY AND METER TEST

OPERATION

This menu allows you to:

- View the current temperature of each of the probes, their assignment and operation. If the reading is not

correct, check that the probe is correctly connected and its cables are not cut.

- Enter forced manual mode: Manually connect and disconnect the relays to check that the installation is

working correctly.

- Finally, you will find the flow meter (l/min), showing whether there is a flow in the circuit and whether the Allegro

576 is receiving the pulses from the meter.

- When you exit TEST mode all the relays will update their status to system regulation status.

S

S

S

S

Sonder

ESC

OK

576

Sonder

S

E

T

With the password ON: After 15 minutes without touching a

key, the system returns to normal operation and the relays

return to the status required by the system at that time.

With the password OFF: The system does not exit the test

menu until the ESC key is pressed (forced manual mode).

- Then move on to the relays (forced manual), where you

can manually activate/deactivate each relay.

• Press OK to activate/deactivate relay R1.

• Press to move on to the next relay.

Press ESC for 6 seconds to enter test mode from

normal operation mode:

ESC

OK

576

Sonder

S

E

T

Tank priority (1 to 6)

This parameter determines the order in which the accumulators will be

charged, if the installation has more than one. (see page 31).

- In the SETTINGS menu press until the PRIO DEPOSITO screen

appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 5 ºC to 130 ºC / Default: 5 ºC

ESC

OK

576

Sonder

28

Probe calibration (T1 - T7)

With this parameter you can adjust the reading for each of the probes. Use a

precision master thermometer to take the reading and then adjust the probe to

this temperature.

- In the SETTINGS menu press until the CALIBR SONDAS screen

appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: -10.0 ºC to +10.0ºC / Default: 0.0 ºC

ESC

OK

576

Sonder

SETTINGS

WARNING: The range of this parameter can be affected by the configuration of the

accumulator temperature alarm.

FOR EXAMPLE: If AC1 has its alarm set to 70 ºC, you cannot set the priority above

this value. If the priority is set to 60 ºC and you try to reduce the

alarm to 50 ºC, the same thing happens and the range of the

alarm is blocked.

S

S

S

S

S

S

S

S

MENU

Maximum ambient limit

This parameter limits the maximum value for the ambient thermostat function

temperature setting.

- In the SETTINGS menu press until the LIM MAX AMBIENTE screen

appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 18 ºC to 30 ºC / Default: 30 ºC

ESC

OK

576

Sonder

S

S

S

S

SCREEN DISPLAY

touching a key it switches off and comes back on when

any key is pressed).

From this screen you can access:

- The menu to configure the settings, functions,

systems and to see the statistics, by pressing

both keys together for 5 seconds.

- The probe, relay and meter test, by pressing ESC for

6 seconds (page 9).

- The reset values function for the parameters,

functions and systems, provided that the password is

deactivated (value = 0). All the values are reset except

the total operating time of the relays and the total MWh

of the meter; these values belong to the statistics menu

(page 12).

- The manual mode to force operation of the

installation. To start this mode the password must be

deactivated and you have to enter in probe and relay

test mode (page 9).

If you are in configuration mode in a menu and do not

touch any keys for 15 minutes, the device will return to

normal operation without saving the changes.

In normal operation, the screen cyclically (5

seconds each screen) displays the chosen system,

the activated functions, and the readings of the

probes for this system (identified by flashing name

and symbol).

Moreover, you can see if the pumps are operating,

the direction of the three-way valves and whether

there are any temperature alarms, given that they

are indicated by flashing the symbol of the device.

On the screen a sun appears above the panels. This

symbol indicates that:

- the temperature is tending to rise,

- the temperature of the panels is higher than the

average temperature.

- the panels are currently transferring heat to the

accumulator.

The titles move to show the full name and the start is

shown by an asterisk.

The screen can be lit permanently or the timer

function can be activated (after 15 minutes without

• If you do not touch any keys for 15 minutes, the screen light will switch off

• Press any key to switch it back on

Screen: Normal Operation Mode Normal Operation Mode with probe error

ESC

OK

576

Sonder

This screen informs you that:

1 - The chosen system is 2.2

2 - The temperature reading is from the collectors

(COLE name and flashing probe symbol)

3 - The temperature is tending to rise

2

3

SCREEN LIGHT TIMER (LIGHT parameter OFF)

10

ESC

OK

576

Sonder

This screen informs you that:

- The probe assigned to the radiator

has a reading error

S

S

OPERATION

SETTINGS

27

Tank temperature alarm

This parameter defines a temperature alarm for each accumulator;

depending on the system, a unit heater or cooling system is activated, another

accumulator is charged or circulation is stopped.

- In the PARÁMETROS menu press until the AL TEMP DEPÓSITO

screen and the number corresponding to the tank appear.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 5 ºC to 130 ºC / Default: 85 ºC

ESC

OK

576

Sonder

Temperature differential

This parameter allows you to configure the temperature differential for the

settings of all the functions (except ambient thermostat, which has its

differential set to 0.3 ºC).

- In the PARÁMETROS menu press until the DIF TEMPERATURA

screen appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 0.3 ºC to 9.0 ºC / Default: 2.0 ºC

ESC

OK

576

Sonder

Minimum setting limit

This parameter limits the minimum value for the support function temperature

setting.

- In the PARÁMETROS menu press until the LIM MIN CONSIGNA

screen appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 5 ºC to 80 ºC / Default: 10 ºC

ESC

OK

576

Sonder

S

S

S

S

S

S

S

S

S

S

S

S

MENU

Maximum setting limit

This parameter limits the maximum value for the support function temperature

setting.

- In the PARÁMETROS menu press until the LIM MAX CONSIGNA

screen appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 90 ºC to 130 ºC / Default: 90 ºC

ESC

OK

576

Sonder

S

S

S

S

Minimum ambient limit

This parameter limits the minimum value for the ambient thermostat function

temperature setting.

- In the PARÁMETROS menu press until the LIM MIN AMBIENTE

screen appears.

- Press OK to enter the function settings, and use to define the desired

value.

- Press ESC to go back and press OK to save the adjusted values.

ESC

OK

576

Sonder

S

S

S

S

Range: 6 ºC to 17 ºC / Default: 6 ºC

CONFIGURATION

Once all the connections have been made and

the device is connected to the mains, the device

shows the screen operating in normal mode with the

factory settings (page 12).

Press both keys together for 5 seconds

to show the main menu on the screen. Here you can

use the keys to choose a sub-menu.

Press OK to enter the chosen sub-menu, such as

Functions.

Press the keys to move around the sub-

menu until you find the function you want to configure.

These screens indicate the status of the function.

Press OK in the desired function to configure the

values (the value to be changed flashes). When

you have changed the value, press OK to

save and move on to the next value. When all the

values for this function have been changed, save the

changes and return to the sub-menu.

Press ESC to return to the functions sub-menu

without saving the changes.

Press ESC again to return to the main menu.

Press ESC again to return to normal regulation

operation and after 15 minutes without touching any

keys the screen light will switch off. Press any key to

return to normal mode.

This method is applicable to all configuration

menus and sub-menus.

11

ESC

OK

576

Sonder

ESC

OK

576

Sonder

ESC

OK

576

Sonder

ESC

OK

576

Sonder

ESC

OK

576

Sonder

OPERATION

S

S

S

S

S

S

S

S

For normal use of your installation the factory settings are considered to be the most common for each type of system. If they

are of use to you, the device is ready to control and regulate your installation. If, due to the needs of your installation, you require

other settings, read this section carefully.

To access the menu from normal operation mode, press any key (except ESC), use the arrows to move to PARÁMETROS, and

then press OK.

In the menu you can adjust the settings that will define the operation of the installation.

Winter or summer mode

Activation differential

Deactivation differential

Temperature alarm in tanks 1 to 6

Temperature differential (general for all settings)

Minimum setting limit

Maximum setting limit

Minimum ambient limit

Maximum ambient limit

Separate calibration for each probe (T1 to T7)

Priority of tanks 1 to 6

Cooling of accumulators 1 to 6

Sequential priority

Display light

Password (programming protection)

Summer / Winter mode

This parameter allows you to choose between two different settings for tank

priorities and alarms without having to change them one by one.

- In the PARÁMETROS menu press until the MODE screen appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: SUMMER or WINTER / Default: WINTER

ESC

OK

576

Sonder

Activation differential

This parameter defines the temperature difference required between the

accumulator and the solar collector for the pump to activate.

- In the PARÁMETROS menu press until the DIF ACTIVACIÓN

screen appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 4.0 ºC to 20.0 ºC / Default: 6.0 ºC

S

S

ESC

OK

576

Sonder

Deactivation differential

This parameter defines the temperature difference required between the

accumulator and the solar collector for the pump to deactivate.

- In the PARÁMETROS menu press until the DIF DESACTIVACIÓN

screen appears.

- Press OK to enter the function settings, and use to define the

desired value.

- Press ESC to go back and press OK to save the adjusted values.

Range: 1.0 ºC to 4.0 ºC / Default: 2.0 ºC

ESC

OK

576

Sonder

26

SETTINGS

S

S

S

S

S

S

S

S

S

S

MENU

From operation in normal mode with the screen switched on (the password must be OFF, value =0)

Press ESC to enter the probe and relay test menu, continue pressing it until you see that all segments of the screen light up and

the system returns to normal mode.

ESC

OK

576

Sonder

ESC

OK

576

Sonder

S

E

T

ESC

OK

576

Sonder

S

E

T

%

All the statistical values, parameter settings, function activations and the installation type are reset, but the

total operation hours of the relays and the megawatts/hours of the calorimeter are not reset.

Press ESC 10 secondsKeep it pressed for

RESETTING VALUES AND RESTORING FACTORY SETTINGS

FACTORY SETTINGS

SETTINGS

FUNCTIONS (all the functions are switched off and there are no factory settings)

Probe calibration (S1…S7):

Tank priority (1…6):

Sequential priority:

Tank cooling (1…6):

Light:

Password:

0.0 ºC

5.0 ºC

OFF

130 ºC

OFF

OFF

winter

6.0 ºC

2.0 ºC

85 ºC

2.0 ºC

10 ºC

90 ºC

Ambient thermostat 1

Ambient thermostat 2

Anti-frost

SYSTEMS

Double pump

Calorimeter

Tubular sensors

Return increase

Unit heater

OR function

AND function

Independent thermostat 1

Independent thermostat 2

Independent thermostat 3

Regulation mode:

Activation differential:

Deactivation differential:

Tank temperature alarm (1…6):

Temperature differential:

Minimum setting limit:

Maximum setting limit:

Active system: 1.1 (1 tank + 1 pump)

If the password is activated it is impossible to reset the values and restore the factory settings. To do so, it is

necessary first to deactivate the password (value =0) in the settings menu.

If an unauthorised user tries to reset the values, he would press the ESC key for 10 seconds and only be able

to enter the probe and relay test. When you exit the test, the relays return to their original status.

12

OPERATION

S7

Hot water

R6

R4

R2

S2

R5 S3S2S1 S4

POWER SUPPLY S4 S5 S6

S4

S5

R1 R3 S7

S1

N L

230 V~

50/60 Hz

Hot water

Hot water

Hot water

R6

S6

Hot water

S3

Hot water

MAINS

WATER

R2

R4

R5

R3

R1

MAINS

WATER

MAINS

WATER

MAINS

WATER

MAINS

WATER

MAINS

WATER

Example of Installation on different floors (up to 6 flats)

For this type, the installation is as follows:

- 1 Allegro 576 per landing. It can control up to 6 apartments per floor. The unit will be installed in the communal area of the

landing in the fuse box and probe 1 will be installed on the outgoing circuit.

- 1 Allegro 576 installed in the general meter room. In order to control collectors and additional functions such as cooling by

unit heater, calorimeter, etc.

- If the building has fewer apartments per landing, the resources can be

used for other landings, or common devices such as the unit heater,

collectors etc.

BLOCK APARTMENTS

25

1 Allegro 576 per floor

installed in the junction box of each landing

1 Allegro 576 in the machine room

EXAMPLES

RESOURCE CONTROL

Relay R1

Relay R2

Relay R3

Relay R4

Relay R5

Relay R6

Probe S2

Probe S3

Probe S4

Probe S5

Probe S6

Probe S7

Probe S1

1.1

Resources used by the Systems (probes in shared mode / relays in exclusive mode)

Function resources

INDEPENDENT THERMOSTAT 1 / 2 / 3

- 1 exclusive relay

- 1 configurable probe, shared with the system

ENVIRONMENT THERMOSTAT 1 / 2

- 1 exclusive relay

- 2 configurable probes, shared with the system

BOILER RETURN INCREASE

(preheating of the heating circuit)

- 1 exclusive, configurable relay

- 2 configurable probes, shared with the system

CALORIMETER

- 2 configurable probes, shared with the system

UNIT HEATER

- 1 exclusive relay

- 1 configurable probe, shared with the system

DOUBLE PUMP

- 1 relay, shared with the system

- 1 configurable relay in exclusive mode

ANTI-FROST

- It will use the probes and relays deemed suitable

in a shared manner (this will depend on the

system being configured)

TUBULAR SENSORS

- It will use the probes and relays deemed suitable

in a shared manner (this will depend on the

system being configured))

OR FUNCTION

- 1 relay conditioned to the status of any of the

chosen relays

AND FUNCTION

- 1 relay conditioned to the status of any of the

chosen relays

SYSTEM 1.2

X

X

X

1.3 1.4 1.5 1.6 2.1 2.2 2.3 3.1 3.2 3.3 5.1 5.2 5.3 6.1 6.2 6.34.1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

13

OPERATION

Hot water

S4

S5

R3

S3

R5

R2

S1

S7 R6

A

BC

D

EXCHANGER

PURIFIER

F

R1

R4

S6

E

S1 S2 S3 S4 S5 S6 S7

R1 R2 R3 R4 R5 R6

PROBES RELAYS

A – Diesel / gas boiler

B – Accumulator to support the heating

C – Hot-water accumulator

D – Moderato SR (remote setting adjustment)

E – Underfloor heating

F – Swimming pool

In a house, the Allegro 576 provides central control of all the devices in your installation (collectors, radiators, underfloor

heating, hot water, swimming pool heating, collector cooling, calorimeter, etc.) for up to a maximum of 6 outputs (relays) and 7

probes.

FLOW METER

MAINS WATER

S2

HOUSE

CONDOMINIUM

S6

NC C

R6

CNO

R4

CNO

R2

S2

CNO

R5 S3S2S1 S4

POWER SUPPLY S4 S5 S6

S4

S3

S5

NC CCNO

R1 R3 S7

S1

N L

230 V~

50/60 Hz

R1

R2

R3

R5

R4

S7

R6

Hot water

MAINS WATER

Hot water

MAINS WATER

Hot water

MAINS WATER

Hot water

MAINS WATER

Hot water

MAINS WATER

In a condominium the Allegro 576 provides central control of the devices. With the OR function configured as follows: Slave

relay: R6 and Main relays: R1, R2, R3, R4 and R5. When any of the main relays is activated, R6 is activated and starts the

circulation of the installation.

24

EXEMPLES

14 15

menu

SOFTWARE MAP

FUNCTIONSSTATISTICS

S

S

S

S

Press both keys

for 5 seconds

Partial statistics zones 1 to 6

Total statistics zones 1 to 6

Maximum temperature zones 1 to 7

Minimum temperature zones 1 to 7

Average temperature zones 1 to 7

Partial litre counter

Partial calorimeter

Total calorimeter

Independent thermostat 1

Independent thermostat 2

Independent thermostat 3

Ambient thermostat 1

Ambient thermostat 2

Anti-frost protection

Double pump alternation function

Activation of cooling by unit heater

Calorimeter

Specific function for tubular sensors

Increase of the return temperature from

the heating circuit

OR function

AND function

S

S

PROBE, RELAY

AND METER TEST

Press ESC for 5 seconds

OK

Temperatures S1 to S7

Relays R1 to R7

Meter L/MIN

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

ESC

S

S

S

S

S

S

OK

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

ESC

S

S

S

S

S

S

S

S

S

S

OPERATION

collector array + 2 pumps

+ 2 tanks

collector array + tank

+ swimming pool + 2 pumps

collector array + tank

+ heating + 2 pumps

collector array + 2 tanks

+ pump + 3-way valve

collector array + tank

+ swimming pool + pump

+ 3-way valve

collector array + tank

+ heating return + pump

+ 3-way valve

2 collector arrays (east and west)

+ 2 tanks + 2 pumps

+ 3-way valve

2 collector arrays (east and west)

+ tank + swimming pool

+ 2 pumps + 3-way valve

2 collector arrays (east and west)

+ tank + heating + 2 pumps

+ 3-way valve

collector array + 3 tanks

+ 3 pumps

collector array + 2 tanks

+ swimming pool + 3 pumps

collector array + 2 tanks

+ heating + 3 pumps

SYSTEMS

System 2

System 6

System 3

System 5

T2 T3

T1

R2R1 T2

T3

T1

R2

R1

T2

T3

T1

R2

R1

T2 T3

T1

R2

R1 T2

T3

T1

R2

R1

T2

T3

T1

R2

R1

T3

T4

R3

R2

R1

T3

T4

T1

R2

R1

T3

T4

T1

R2

R1

T2

R3

T2

R3

T1 T2

T2

T3

R1

T1

T4

R2 R3

T2

T3

R1

T1

T4

R2 R3

T2

T3

R1

T1

T4

R2 R3

4 probes + 3 relays

4 probes + 3 relays

3 probes + 2 relays

3 probes + 2 relays

23

MENU

SETTINGS

1.1 – collector array + 1 tank + 1 pump

1.2 – collector array + 2 tanks + 2 pumps

1.3 – collector array + 3 tanks + 3 pumps

1.4 – collector array + 4 tanks + 4 pumps

1.5 – collector array + 5 tanks + 5 pumps

1.6 – collector array + 6 tanks + 6 pumps

2.1 – collector array + 2 pumps + 2 tanks

2.2 – collector array + tank + swimming pool + 2 pumps

2.3 – collector array + tank + heating + 2 pumps

3.1 – collector array + 2 tanks + pump + 3-way valve

3.2 – collector array + tank + swimming pool + pump + 3-way valve

3.3 – collector array + tank + heating + pump + 3-way valve

4.1 – 2 collector arrays (east and west) + 1 tank + 1 pump

5.1 - 2 collector arrays (east and west) + 2 tanks + 2 pumps + 3-way valve

5.2 - 2 collector arrays (east and west) + tank + swimming pool +2 pumps+3-way valve

5.3 – 2 collector arrays (east and west) + tank + heating + 2 pumps + 3-way valve

6.1 – collector array + 3 tanks + 3 pumps

6.2 – collector array + 2 tanks + swimming pool + 3 pumps

6.3 – collector array + 2 tanks + heating + 3 pumps

Mode (winter or summer)

Activation differential

Deactivation differential

Tank temperature alarm

zones 1 to 6

Temperature differential

(general for all settings)

Minimum setting limit

Maximum setting limit

Minimum ambient limit

Maximum ambient limit

Separate calibration for each probe

(from T1 to T7)

Priority of the tanks (1 to 6)

Accumulator cooling (1 to 6)

Sequential priority

Display light

Password

(device programming protection)

S

OK

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

ESC

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

OK

S

S

S

S

S

S

S

S

ESC

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

SOFTWARE MAP

SYSTEMS

S

OPERATION

- To access the system menu press OK (with the

display on) and use the arrows to move to

SYSTEMAS.

- Press OK.

- The menu contains 19 installation systems you can

choose from.

- Each one of the systems has a diagram to identify its

operation.

- Use the keys to move on to the next system. To

confirm the chosen system press OK and press the ESC

key to return the previous menu.

- Once the system has been configured, the unit saves the

changes and returns to normal operation.

SYSTEMS

The representation of the units on these diagrams is symbolic.

One solar panel means there is one array of solar collectors, but when there are 2 it means that there is one array of solar

collectors facing east and another facing west.

The accumulator symbols can refer, according to the type of installation, to one accumulator, several accumulators, a

swimming pool, an underfloor heating system, panel exchangers, etc.

The probe symbol indicates which device the probe belongs to.

The resources of the systems are pre-assigned and fixed, which means that each system has a probe and a specific relay

assigned for each element of the selected system. The probes can be shared with the functions, but the relays only operate

exclusively; if a relay is being used by a system it cannot be assigned to a function (except for functions that only need a relay as

a reference: double pump, OR, AND, etc.)

If you configure the functions before the systems, you will see that some of the systems cannot be selected and will not be

shown on the menu. If the system you want is not shown on the menu, it is because a function is activated that needs exclusive

relays and there are not enough relays free. You will have to deactivate a function in order to be able to configure the system.

When the password is activated, the Allegro 576 allows you to consult the types of systems and when you select another

system you will be asked to enter the password to configure the change.

ESC

OK

576

ESC

OK

576

Sonder

1 collector array + 1 tank (configurable for up to 6 tanks)

+ 1 pump

2 collector arrays (east and west)

+ 1 tank + 1 pump

System 1 Required resources: 2 probes + 1 relay System 4.1

T1

T2

R1

T1

T3

R1

R2

T2

3 probes + 2 relays

22

S

S

MENU

15

Partial operation hours zone 1 to 6

Total operation hours zone 1 to 6

Maximum temperature zones 1 to 7

Minimum temperature zones 1 to 7

MENU

STATISTICS

16

In this menu you will find all the data that the Allegro 576 has compiled

since it has been in operation. You can use it to optimise your

installation as it provides information about operation times, maximum

and minimum temperatures, in addition to the water meters and

calorimeters.

All this data allows you to assess the performance of the installation

according to the weather conditions and your configuration.

To access the statistics menu, press for 5 seconds (with the screen lit), use the arrows to select the statistics

menu and then press OK. In the menu you will find:

S

S

Partial operation hours (R1 to R6)

ESC

OK

576

Sonder

Total operation hours (R1 to R6)

ESC

OK

576

Sonder

Maximum temperatures (T1 to T7)

ESC

OK

576

Sonder

Average temperature zones 1 to 7

Partial litre counter

Partial calorimeter

Total calorimeter

OK

576

Sonder

This indicates how long each tank has been in operation since the last reset.

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

This indicates how long each tank has been operating since the Allegro 576

was installed. The value of this statistic cannot be reset to zero.

Pressing OK does effect any change.

Press to move on to the next value.

Press ESC to go back.

S

S

This indicates the maximum temperature reading of each one of the probes.

No readings are registered for probes that are not connected and as such

they produce an error.

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

FUNCTIONS

Summary of functions

FUNCTION DESCRIPTION RESOURCES

21

Tip: First of all configure the solar system you need for your installation and then

the functions, since you may not be able to configure the rest of the functions

according to relays the systems leaves frees.

MENU

Thermostat 1, 2, 3

independent

Thermostat 1, 2

ambient

Anti-frost

Double pump

(alternation)

Cooling by unit

heater

Calorimeter

Tubular sensor

Return increase

OR

AND

Regulates the temperature of a probe (heating,

underfloor heating, etc.) regardless of the chosen solar

system.

Controls a remote adjustment probe. This probe

regulates the temperature of a room and modifies the

temperature setting without having to configure it in the

Allegro 576.

In installations that use water without coolant as a heat-

transfer liquid, the heat of the installation is used to

prevent the circuit from freezing.

Allows you to double a pump in your installation so that

the two pumps work in alternation.

Allows you to cool a part of the circuit by means of an

independent device or recirculation

It measures the energy supplied by the solar collector to

your installation by means of reading two probes and the

pulse input.

Reduces the reading delay for probes installed outside

the collector by means of brief recirculation.

Controls a valve to increase the temperature of the

heating return circuit to use the solar heat from the

accumulator for heating.

The status of one relay is conditioned by the status of

ANY of the chosen relays. This function is executed after

the AND function.

The status of one relay is conditioned by the status of

ALL the chosen relays.

1 shared and configurable

probe

1 configurable exclusive relay

2 shared and configurable

probes

1 configurable exclusive relay

1 or 2 shared probes

1 or 2 shared relays

2 configurable relays

1 exclusive and 1 shared

1 shared and configurable

probe

1 configurable exclusive relay

2 shared and configurable

probes

No resources required

2 shared and configurable

probes

1 configurable exclusive relay

No resources required

No resources required.

17

STATISTICS

Minimum temperatures (T1 to T7)

ESC

OK

576

Sonder

Average temperatures (T1 to T7)

ESC

OK

576

Sonder

Water meter

ESC

OK

576

Sonder

PARTIAL Energymeter

The KWh meter shows how much energy the panels have supplied the

installation.

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

ESC

OK

576

Sonder

TOTAL Energymeter

ESC

OK

576

Sonder

This indicates the amount of heat provided to the installation by the solar

collectors and the performance of the installation.

This sub-menu shows the amount of heat-transfer liquid that has passed

through the meter (in litres).

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

The MWh meter shows how much energy the panels have supplied to the

installation since commissioning. The value of this statistic cannot be

reset to zero.

PPress OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

This indicates the total amount of heat provided to the installation by the solar

collectors and the performance of the installation.

This indicates the average temperature (reading for the last 2 hours) of each

one of the probes. No readings are registered for probes that are not

connected and as such they produce an error.

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

This indicates the minimum temperature reading of each one of the probes.

No readings are registered for probes that are not connected and as such

they produce an error.

Press OK to reset the values to zero.

Press to move on to the next value.

Press ESC to go back.

S

S

MENU

- Press OK to enter the function settings, where you can activate/deactivate the

function, choose the slave relay and the main relays that will condition the status

of the slave relay. Press to change the flashing value and press OK to

confirm the selection.

- Press ESC to return to the FUNCIONES menu.

This function conditions the status of a relay based on the status of all the selected relays. For example: if you choose R1 as the

slave relay and R2, R4 and R6 as the main relays, R1 will be activated when R2 AND R4 AND R6 are activated. When any one

of the main relays is off, the slave relay switches off.

AND

ESC

OK

576

FUNCTIONS

20

- Press OK to enter the function settings, where you can activate/deactivate

the function and set the temperature differential (0.3 to 9 ºC) between the

accumulator of the solar circuit and the return from the heating circuit so that

it is activated. It will select which probe is shared with the accumulator and

the relay that activates the circuit return valve. Press to change the

flashing value and press OK to confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

The return increase function allows you to control a valve by diverting the course of the hot-water circuit to increase the

temperature of the heating return circuit. This allows us to use solar heat from the accumulator for heating. It uses solar energy

to preheat the water from the heating installation before adding the rest of the hot water from a backup source, either a boiler or a

heating element.

Increase of the circuit return temperature

ESC

OK

576

Sonder

- Press OK to enter the function settings, where you can activate/deactivate the

function, choose the slave relay and the main relays that will condition the status

of the slave relay. Press to change the flashing value and press OK to

confirm the selection.

- Press ESC to return to the FUNCIONES menu.

This function conditions the status of a relay based on the status of any of the selected relays. For example: if you choose R1 as

the slave relay and R2, R4 and R6 as the main relays, R1 will be activated when R2 OR R4 OR R6 are activated. When they are

all off, the slave relay switches off. The function is executed after AND (example of this function on page 24).

OR

T1 T4

T2

R2

R1

EXEMPLE

Boiler

R3

Exchanger

Solar

collector Heating

system

Hot water

T3

T

Ambient

thermostat

ESC

OK

576

RETURN INCREASE

MENU

S

S

S

S

Independent thermostat 1

Independent thermostat 2

Independent thermostat 3

Ambient thermostat 1

Ambient thermostat 2

Anti-frost protection

Double pump alternation function

FUNCTIONS

The functions use the probes shared by the systems and the relays left free by

the systems and other functions.

If you try to configure more functions than supported by the unit, the VOID

message will appear on the screen and it will exit the function.

Activation of cooling by unit heater

Calorimeter

Specific function for tubular sensors

Increase of the return temperature from the heating

circuit

OR function

AND function

18

Independent thermostat

ESC

OK

576

Sonder

- Press OK to enter the function settings where you can activate/deactivate the

function, set the temperature to be regulated (10 to 90 ºC), the reading probe

and the relay activated. Press to change the flashing value and press

OK to confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This function allows you to install one or two remote adjustment probes (MODERATOR SR) in your installation. This allows you

to regulate the temperature of the room without having to change the temperature setting using the Allegro 576.

Ambient thermostat

Thermostat 2

Thermostat 1 Thermostat 3

- Press OK to enter the function settings to activate/deactivate the function, set the

setting probe (to select the temperature at which the room must be kept), the

regulation probe (it will take the reading of the room temperature) and the relay

to be activated. Press to change the flashing value and press OK to

confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This function allows you to regulate the temperature of a probe (underfloor heating, central heating, thermostat, etc.) regardless

of the chosen solar system.

It has three independent thermostat functions, each one of which has a

different icon so that you can easily tell which one the data on the screen

relates to in normal mode.

Although the icons are different, they operate in the same way.

To access the functions menu, press for 5 seconds (with the screen lit), use the arrows to select the functions

menu and then press OK. In the menu you will find:

Thermostat 2

Thermostat 1

ESC

OK

576

Sonder

2

Once you have configured and installed the remote probe you have to calibrate

the reading on the button of the remote terminal with the value of the Allegro 576

reading. To do this:

- Set the button of the remote probe to 20 ºC.

- Enter menú, parámetros and calibrado de sondas.

- Change the value of the setting probe to 20 ºC

Example setting probe S4: on screen the reading from this probe is 19.5 ºC, go

to probe calibration and change the value of S4 from 0.0 to 0.5.

S

S

ESC

OK

576

Sonder

MENU

19

- Press OK to enter the function settings, where you can activate/deactivate the

function and set the total time that each pump will operate before changing (4 to

120 hours). Press to change the flashing value and press OK to confirm

the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This function allows you to double a pump in your installation so that the two pumps work in alternation.

Double pump alternation

ESC

OK

576

Sonder

FUNCTIONS

- Press OK to enter the function settings, where you can activate/deactivate the

function, set the temperature (40 to 140 ºC), the reading probe and the

recirculation or unit heater activation relay. Press to change the flashing

value and press OK to confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This function allows you to reduce the temperature of a device by recirculating the circuit or a cooling device. The configured

relay is activated when it detects that the temperature of the device is higher than the temperature of the circuit

Cooling by unit heater

ESC

OK

576

- Press OK to enter the function settings, where you can activate/deactivate the

function, adjust the configuration of the pulse input (1 to 200 litres per pulse), the

composition of the heat-transfer liquid (0 to 100% glycol) the input probe and the

meter probe (at the input and output of the accumulator to calculate the amount

of heat transferred). Press the keys to change the flashing value and

press OK to confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This function measures the amount of energy supplied to your installation by the solar collector by reading two probes (one

at the input and the other at the output of the part of the installation you want to control) and the pulse input (it measures

the flow rate of the installation).

Calorimeter

ESC

OK

576

Sonder

- Press OK to enter the function settings, where you can activate/deactivate the

function, set the temperature at which the pump is to be activated (-20 to 20 ºC)

and the relay that will circulate the water from the accumulator through the circuit

of the installation to the solar collector. Press to change the flashing

value and press OK to confirm the selection.

- Press ESC to return to the FUNCIONES menu.

S

S

The anti-frost function has been designed for installations that use water as a heat-transfer liquid. Since it does not contain any

anti-freeze, the heat of the installation is used to prevent the circuit from freezing.

Anti-frost

ESC

OK

576

Sonder

- Press OK to enter the function settings, where you can activate/deactivate the

function. Press to change the flashing value and press OK to confirm the

selection.

- Press ESC to return to the FUNCIONES menu.

S

S

This updates the reading of the probes installed outside the collectors by recirculation for 30 seconds when it detects that the

temperature has increased 2K with regard to the last memorised reading.

Tubular sensors

ESC

OK

576

Sonder

MENU

This manual suits for next models

2

Table of contents

Other Sonder Control Unit manuals

Popular Control Unit manuals by other brands

Tekmar

Tekmar 325 Wiring Brochure

Schell

Schell EDITION E Assembly and installation instructions

Cameron

Cameron WKM 370D6 Installation, operation and maintenance manual

Woodward

Woodward easYlite-200 manual

Paxton

Paxton ins-30219 manual

Lucent Technologies

Lucent Technologies PacketStar PSAX 8-Port Voice 2-Wire Station... user guide

Idex

Idex HALE SPV Installation and maintenance manual

Tektronix

Tektronix KEITHLEY 7703 Instructions for use

National Instruments

National Instruments NI 9402 Getting started guide

ICP DAS USA

ICP DAS USA XP-8000-Atom-CE6 quick start guide

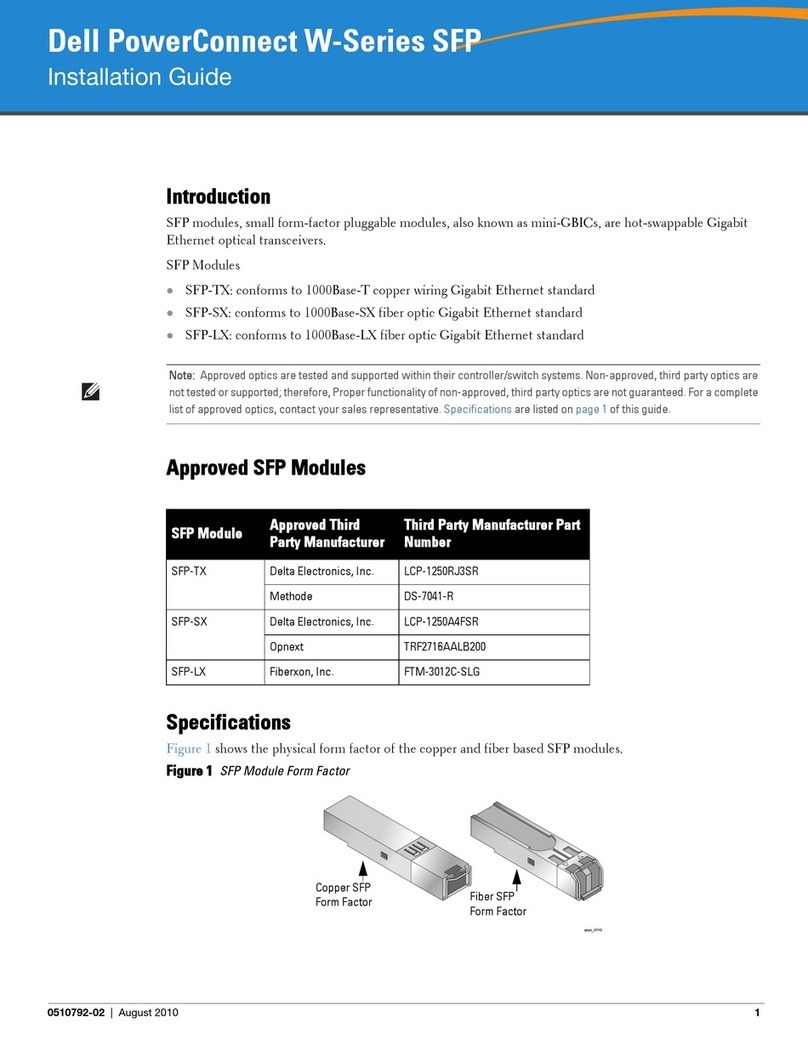

Dell

Dell PowerConnect W Series Installation guides

TMT

TMT TM-8258 instruction manual