Semi-Automatic Priming Valve

2

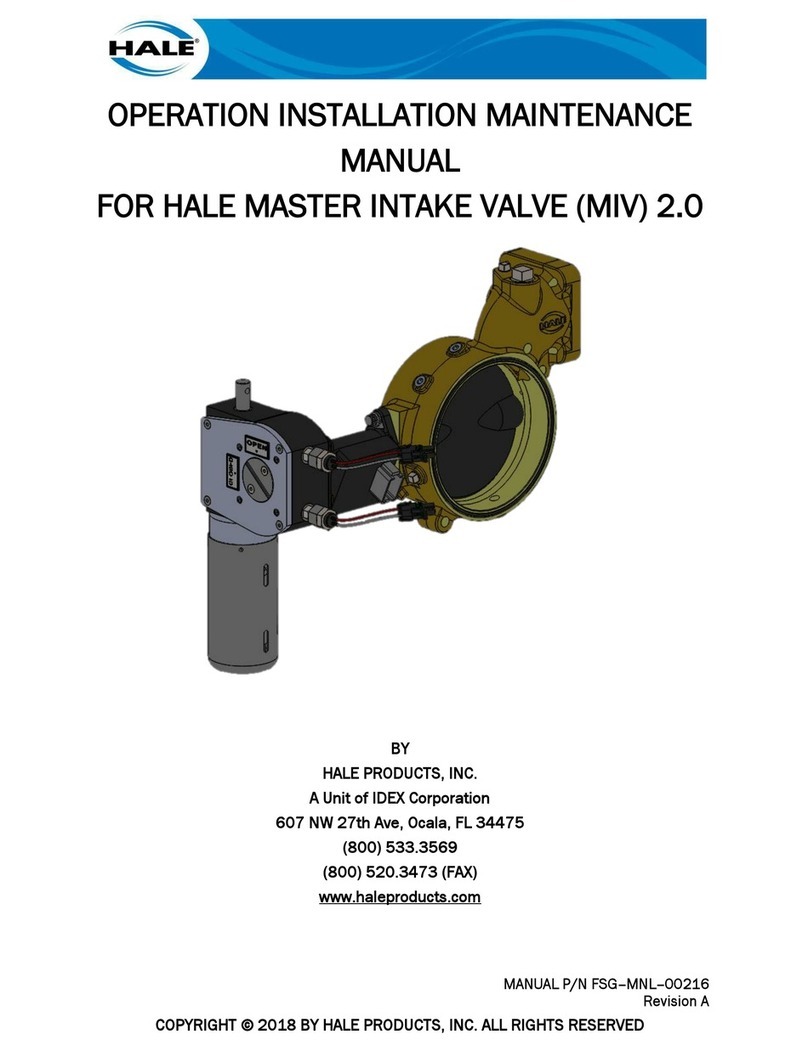

Figure 1. Hale SPV Valve and Push-Button Switch Assembly

DESCRIPTION

(19 mm) ID vacuum hose connects the Hale

SPV to the priming pump, eliminating potential

leak points in the priming hose. The short

length of hose also reduces the volume that the

priming pump must evacuate allowing faster

priming time and longer primer life. The priming

pump motor operates by a sealed momentary

contact push-button located on the pump

operator panel of the apparatus. There are NO

hose connections at the pump operator panel

thus saving valuable space.

Depressing and holding the PRIME push-button

will energize the priming pump motor creating a

vacuum in the 3/4inch (19 mm) ID hose. As

sufficient vacuum is created the diaphragm will

depress the spring allowing the priming valve to

open. Once the Hale SPV opens, the priming

pump creates a vacuum in the main pump body,

priming the main pump. Once primed, as

indicated by water discharging to the ground

from the priming pump outlet, the push-button is

released. Once push-button is released, the

priming pump stops running allowing the Hale

SPV to close for normal pump operation.

The Hale Semi-Automatic Priming Valve (Hale

SPV) (shown in figure 1) is a diaphragm

operated type valve that opens using the

vacuum generated by the priming pump. The

Hale SPV mounts directly to the priming

connection of a Hale midship pump.

Additionally, a universal adapter that bolts to an

installer supplied bracket is available to permit

use of the Hale SPV on booster and volute type

pumps. The installer must also supply hose

connections from the adapter to the pump

priming connection. The Hale SPV operates

from the vacuum generated by the priming

pump when the momentary contact push-button

located on the pump operator panel is

depressed. The Hale SPV conforms to NFPA

requirements for priming time and hydrostatic

test when bolted to Hale midship type pumps.

Each valve is factory tested to 24 in (610 mm)

hg vacuum and 600 PSIG (41 BAR).

When used on a midship fire pump, the valve

mounts to the pump body with two studs and

nuts, standard strainer and seal ring. Mounted

on the midship fire pump, in close proximity to

the priming pump, only a short length of 3/4inch