Sonic Driver POCKET PLUS-UFM User manual

Made in Britain

POCKET PLUS-UFM Ultrasonic Flowmeter

Operating Instructions

Version 3.0

13th March 2023

Copyright Sonic Driver Ltd 2023

Contents

1.0 Introduction

1.1 General Precautions

2.0 Keypad Functionality

3.0 FUNCTION KEY Functions

<1> Quick Start

<2> Transducer Positioning

<3>ATA/ETA %

<4> Flow Rate and Net Total

<5> Flow Velocity, Rate and Totals

<6> Flow Profile

<7> Energy Rate and Net Total

<8> Energy Rate and Totals

<9> Temperature

<.> Time Based Diagnostics

<0> Signal Based Diagnostics

4.0 Powering On

4.1 Power Off

5.0 User Interface (UI)

Quick Start Function

Installation Menu

Pipe Menu

Outer Diameter

Wall Thickness

Material

Roughness

Sound Velocity

WTG SOS

Liner Menu

Material

Sound Velocity

Thickness

Fluid Menu

Type

Temperature

Sound Velocity

Viscosity

Density

SHC

Inlet Temp

Outlet Temp

Transducer Menu

Type

Mounting

WTG Standoff

Calibration Settings Menu

Low Flow Cut

Corrected Flow

User Offset

User Scaling

Set Zero

Zero Tracking

Tup Method

Calculation Method

Display Units Menu

Flow Rate Units

Flow Rate Time Units

Totaliser Units

Energy Units

Energy Time Units

Measurement Units

Damping

Totalisers Menu

Net Flow Total

Pos Flow Total

Neg Flow Total

Flow Total Reset

Energy Total

Energy Total Reset

Load Defaults

System Settings Menu

LCD Backlit

Buzzer

Tag

Identifier

Test Display

Keypad

Memory

Clock

TOFM Scope

TOFM Values

Serial

Logger

System Info Menu

Model Code

Serial No.

HW Issue

SW Issue

Diagnostics Menu

Serial Menu

Mode

Baud

Parity

Logger Menu

Interval

Date

Time

Download

Erase

Load/Save Setups Menu

Save Option

Load Option

Delete Option

Appendix A Transducer parameters

1.0 Introduction

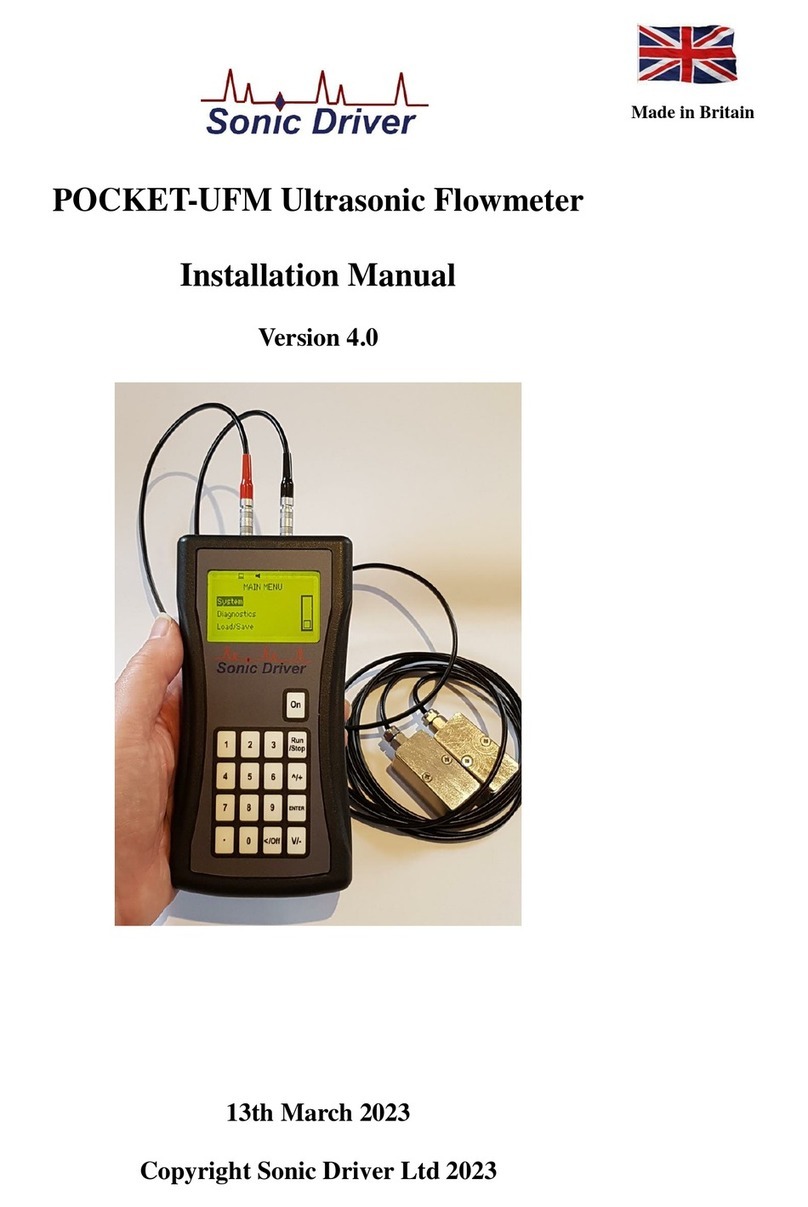

Congratulations on choosing the Sonic Driver TM POCKET PLUS-UFM TM clamp-on ultrasonic

flowmeter, figure(1).

Figure(1) The Sonic Driver POCKET PLUS-UFM.

The ultrasonic flowmeter (UFM) uses advanced Digital Signal Processing (DSP) and transit time

measurement techniques (Sonic Driver TM) to make accurate and reliable clamp-on ultrasonic flow

velocity measurements.

Using information about the installation, entered by the user, using the meters intuitive and easy to

us menu driven User Interface (UI) the UFM can display;

•Flow velocity

•Volumetric flow rate

•Mass flow rate

•Heat quantity flow rate

With the addition of a wall thickness measuring probe the UFM can also function as a pipe wall

thickness gauge (WTG).

The POCKET PLUS-UFM includes a date and time stamped 4MB datalogger and USB serial

communications functionality as standard.

When connected to a computer USB port or USB charger the UFM is powered over the USB. This

allows for extended datalogging sessions.

1.1 General Precautions

The content of this manual has been carefully checked and is believed to be accurate.

Sonic Driver Ltd assumes no responsibility for any inaccuracies that may be contained in this

manual.

In no event will Sonic Driver be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual, even if we are advised of the

possibility of such damages.

Sonic Driver Ltd reserves the right to make improvements to its manuals, instructions and products

at any time, without notice or obligation. The latest revisions may be found on the company web

site, www.sonic-driver.com

The UFM is a precision measuring instrument and should be handled and operated with care;

•Before operating the UFM for the first time read the installation manual and operating

instruction fully.

•Only use the UFM in the way and for the purpose that it is intended.

•Do not subject the UFM to bumps and shocks such as caused by dropping the UFM.

•Keep the UFM and its transducers and probes clean.

•Only use the UFM within its ambient temperature and stated level of Ingress Protection.

•Avoid excessive stress and bending of transducer cables and connectors.

•Avoid striking the clear display window and keypad with sharp objects.

2.0 Keypad Functionality

The UFM keypad offers several dual operation FUNCTION KEYS for quick setup and display.

Press any of the FUNCTION KEYS to go to the desired menu or display instantly. Note however

that depending on what the user is attempting to do the focus of certain keys will change.

On This key turns the flowmeter on.

When the user is navigating the UI and selecting a Menu screen;

1 Jump to MAIN MENU, the Quick Start option will be highlighted.

2 Jump to show Sensor Positioning screen, the user is prompted to select a

Transducer Type.

3 Jump to show ATA/ETA % diagnostic.

Run/Stop Jump to Measurement screen.

4 Jump to show Flow Rate and Net Total.

5 Jump to show flow velocity, flow rate, net, positive and negative flow totaliser.

6 Jump to show Reynolds Number, flow profile correction K Factor, Raw Flow

velocity and Corrected flow velocity.

^/+ Scroll up through Menu items.

7 Jump to show Energy Rate and Net Total.

8 Jump to show energy rate, net, positive and negative energy totaliser.

9 Jump to show Compensation, Inlet and Outlet temperature.

ENTER Step forward to selected Menu.

. Jump to show time based diagnostics.

0 Jump to show signal based diagnostics.

</Off Step back to previous Menu (When at Main Menu press and hold whilst progress bar

decrements to turn meter off).

V/- Scroll down through Menu items.

When the meter is in measurement mode and measuring the keypad keys have the following

functions;

1 Jump to MAIN MENU, the Quick Start option will be highlighted.

2 Jump to show Sensor Positioning screen, the user is prompted to select a

Transducer Type.

3 Jump to show ATA/ETA % diagnostic.

Run/Stop Jump to UI, show last menu accessed.

4 Jump to show Flow Rate and Net Total.

5 Jump to show flow velocity, flow rate, net, positive and negative flow totaliser.

6 Jump to show Reynolds Number, flow profile correction K Factor, Raw Flow

velocity and Corrected flow velocity.

^/+ Display contrast up.

7 Jump to show Energy Rate and Net Total.

8 Jump to show energy rate, net, positive and negative energy totaliser.

9 Jump to show Compensation, Inlet and Outlet temperature.

ENTER Step through all available display screens.

. Jump to show time based diagnostics.

0 Jump to show signal based diagnostics.

</Off No action.

V/- Display contrast down.

When the user is editing a parameter and the parameter editing cursor starts to flash the keypad keys

change function to become alphanumeric inputs;

1 Enter "1".

2 Enter "2".

3 Enter "3".

Run/Stop No action.

4 Enter "4".

5 Enter "5".

6 Enter "6".

^/+ Enter "+" symbol or scroll up though available parameter options in a list.

7 Enter "7".

8 Enter "8".

9 Enter "9".

ENTER Accept and Save changes and return to last Menu screen.

. Enter ".".

0 Enter "0".

</Off Return to last Menu screen, discard any changes.

V/- Enter "–" symbol or scroll down though available parameter options in a list.

3.0 FUNCTION KEY Functions

The keypad has a number of FUNCTION KEYS, which allow the user to instantly access functions;

<1> Quick Start

This key jumps to the Main Menu with the Quick Start option highlighted.

Press ENTER to start the Quick Start sequence or navigate the UI in the usual way.

<2> Transducer Positioning

This key gives access to a function which calculates the recommended transducer spacing and

displays diagnostics to aid transducer mounting and allows coupling optimization.

After entering the required Quick Start parameters, the spacing between the ends of the 2

transducers is calculated and displayed. Check the value displayed and space the transducers

accordingly.

If the Set Zero calibration function is enabled a zero flow calibration will also be made. It is vitally

important to ensure that there is zero flow during this procedure. If the UFM suspects that there is

flow in the pipe then a visual warning is given.

When the process is complete the user is returned to the UI.

<3>ATA/ETA %

This key gives access to a display of transit time ratio shown as a percentage value. This is a

measure of the ratio of the measured transit time to that which is expected given the parameters

entered by the user during Quick Start. It indicates if the transducer mounting and spacing is

accurate. The normal transit time ratio should be 100 ± 3% if the installation is correct.

It is acceptable to have to move one of the transducers up to ± 5mm to achieve a figure of 100%. If

more movement is necessary then one of the pipe parameters is probably incorrect. This is most

likely to be the value entered for pipe wall thickness as this is often taken from tables or it is an

estimated value.

<4> Flow Rate and Net Total

This key gives access to a display showing;

•Flow rate

•Net flow totaliser

<5> Flow Velocity, Rate and Totals

This key gives access to a display showing;

•Flow velocity

•Flow rate

•Net flow totaliser

•Positive flow totaliser

•Negative flow totaliser

Net total is simply the sum of the positive and negative flow totals.

<6> Flow Profile

This key gives access to a display showing;

•Reynolds Number

•Flow profile correction K factor

•Raw flow velocity

•Rolling average flow velocity

•Corrected flow velocity

The raw flow velocity is displayed without averaging and uncompensated for flow profile.

Rolling average flow velocity is raw flow velocity with average and flow profile compensation

applied.

Corrected flow velocity is rolling average flow velocity with zero flow cut off applied.

<7> Energy Rate and Net Total

This key gives access to a display showing;

•Energy rate

•Net energy totaliser

<8> Energy Rate and Totals

This key gives access to a display showing;

•Energy rate

•Net energy totaliser

•Positive energy totaliser

•Negative energy totaliser

<9> Temperature

This key gives access to a display showing;

•Fluid temperature

•Pipe inlet temperature

•Pipe outlet temperature

The fluid temperature is used for compensation of; speed of sound, density, viscosity and specific

heat capacity.

<.> Time Based Diagnostics

This display shows diagnostics relating to the timing measurements being made by the UFM.

•Delta Time

•Transit Time

•Path Time

•dT Offset

•SOS

The absolute upstream transit time through the fluid in the pipe and the absolute downstream transit

time through the fluid in the pipe are usually of the order of hundreds of microseconds. They are

very nearly identical. For this reason Transit Time is simply displaying the absolute upstream transit

time through the fluid in the pipe.

Delta Time is the difference in time between the two absolute transit times through the fluid. Delta

Time is of the order of tens of nanoseconds because the absolute upstream and downstream times

are so close together in value.

These values can help indicate the accuracy and condition of the installation. The measurement

calculations in the UFM are based upon these two values.

Therefore, when transit time difference fluctuates widely, the flow and velocities fluctuate

accordingly. This is usually accompanied by a signal strength and/or signal to noise ratio (SNR) that

is too low and varying. This may be the result of poor pipe installation conditions, inadequate

transducer installation, or incorrect parameter input. Generally, fluctuations should be less than ±

20%.

Path Time is the absolute upstream transit time through the entire ultrasonic path. This is different to

the absolute upstream transit time in the fluid as it includes time spent traversing the transducer

wedges, pipe and lining (if applicable). It is useful for fault finding with an oscilloscope as it is

referenced to a trigger signal available at a test point on the UFM PCB.

dT Offset is the offset value currently being used by the zero tracking function. This is usually in

the range ± 2.5ns.

SOS displays the expected and measured speed of sound in the fluid. It is used to calculate the value

of ATA/ETA %. Alarge difference (typically greater than ± 3%) can indicate something wrong in

the installation.

<0> Signal Based Diagnostics

This key gives access to a display showing diagnostics related to the signal strength and SNR of the

received sonic signal;

•Signal

•SNR

•Noise

•ATA/ETA

•Gain

Signal strength indicates the detected strength of the sonic signal in decibels (dB). Signal strength is

indicated by numbers from typically -25.0 to +55.0.

Normally, the stronger the signal strength detected the better and more reliable the flow

measurement is, as well as the more stable the measurement value obtained.

Adjust the transducer positioning to the best position, within limits and check to ensure that enough

sonic coupling compound is applied during installation in order to obtain the maximum signal

strength.

The UFM normally requires signal strength over 0.0dB to measure reliably. If the signal strength

detected is too low (is zero or negative), the transducer installation position and the transducer

mounting spacing should be adjusted and the pipe should be re-inspected. If necessary, change the

mounting method.

SNR indicates the quality of the sonic signal detected. SNR is indicated by numbers from typically

1.0 to 99.0, in dB.

represents the minimum SNR whilst 99.0 represents the maximum.

Normally, the transducer position should be adjusted and coupling compound application should be

checked until the SNR detected is as large as possible.

The UFM normally requires SNR over 12.0dB to measure reliably.

Noise indicates the level of extraneous sonic and electrical noise being detected in dB. Noise is

indicated by numbers from typically -25.0 to +55.0.

The UFM normally requires noise strength below +10.0dB to measure reliably.

Gain indicates the amount of electronic gain being used by the UFM receiver amplifier. Gain is

indicated by numbers from typically 0.0 to 81.0, in dB.

0.0 represents the minimum gain whilst 81.0 represents the maximum.

Old pipes, attenuating pipes, corrosion, attenuating fluids, etc. can require the UFM to automatically

turn up its gain.

The UFM normally operates with a gain typically around 30.0 to 60.0dB.

ATA/ETA% or transit time ratio indicates if the transducer mounting spacing is accurate. The

normal transit time ratio should be 100 ±3% if the installation is correct.

The Installation Manual that accompanies these Operating Instructions gives more details regarding

mounting, coupling and spacing the transducers correctly.

4.0 Powering On

To power on a POCKET-UFM press and hold the On key.

As soon as the UFM is switched on a self diagnostic program will start.

If an error is detected an error message will be displayed prompting user action. If the error persists

contact customer support.

Error codes and their meanings can be found in the Diagnostics Menu.

Alternatively, when connected to a computer USB port or USB charger the UFM is powered over

the USB and will power on automatically. This allows for extended datalogging sessions.

4.1 Power Off

From the Main Menu press and hold the “</Off” key.

A progress bar decrements to turn the meter off.

If the “</Off” key is released before the progress bar fully decrements the meter returns to the

Measurement screen.

If there is no keypad activity in UI mode for 60 seconds then the UFM will automatically power off.

Automatic power off does not apply in Measure mode.

To fully power down the UFM it is also necessary to disconnect the USB if it is connected.

5.0 User Interface (UI)

The Main Menu allows the user to select a group of parameters to edit or a meter function;

•Quick Start

•Installation

•System

•Diagnostics

•Serial

•Logger

•Load/Save

Quick Start Function

The Quick Start function takes the user through the minimum sequence of parameters needed to get

the UFM measuring reliably and accurately;

•Transducer Type

•Transducer Mounting

•Pipe Diameter

•Pipe Wall Thickness

•Pipe Material

•Liner Material

•Fluid

•Fluid Temperature

Each parameter is described below in the relevant section.

After selecting Transducer Type and Transducer Mounting it is also possible to jump to the end of

the sequence by pressing the Run/Stop key.

If Transducer Type WTG (Wall Thickness Gauge) is selected then the sequence of parameters

changes to;

•Transducer Type

•Pipe Material

and the UFM enters a wall thickness measuring mode. To make use of this feature the user must

purchase an additional WTG probe as well as a pair of flow measurement transducers. Contact

Sales for details.

When operating as a wall thickness gauge the user can scroll between 3 display modes by

repeatedly pressing the “Enter” key, the modes are;

•Full display of wall thickness measurement and all measurement diagnostics.

•A-Scan showing the raw received ultrasonic signal.

•Processed signal showing the measured signal corresponding to the wall thickness.

Installation Menu

The Installation Menu allows the user to edit parameters specific to the physical installation of the

UFM on a pipe;

•Pipe

•Liner

•Fluid

•Transducer

•Calibration

•Display Units

•Totaliser

•Load Defaults

These parameters represent an extended set of parameters needed to get the UFM measuring and

displaying values, above and beyond the very basic parameter set used by the Quick Start sequence.

Pipe Menu

This menu allows the user to change pipe settings. A test is made to check that the parameters that

are entered do not result in a Closed Pipe.

Outer Diameter

The user is prompted to enter a value for the pipe outer diameter. Allowed values are ranged 10.0 to

6500.0mm, default 60.6mm.

Wall Thickness

The user is prompted to enter a value for the pipe wall thickness.Allowed values are ranged 0.5 to

100.0mm, default 3.2mm.

Material

The user can select the pipe material from a list;

•Carbon Steel (Default)

•Stainless 304

•Stainless 316

•Cast Iron

•Ductile Iron

•Copper

•PVC

•Lead

•Nylon

•PE

•Aluminium

•Asbestos

•Fibre Glass

•Other

If Other is selected then the user is prompted to enter the transverse (shear) speed of sound in the

pipe material, see below. Otherwise the transverse speed of sound in the pipe material is read from a

database held in the UFM.

Roughness

The user is prompted to enter a value for the peak/trough height of the roughness on the inside

surface of the pipe. Allowed values are ranged 0.001 to 10.000mm, default 0.010mm.

If a liner material is selected then this roughness is automatically transposed and applied to the inner

surface of the lining.

This value is used in flow profile correction calculations.

Sound Velocity

Appearance of this parameter is context driven. If the Pipe Material is entered as Other then the user

is prompted to enter a pipe transverse sound velocity.

The user is prompted to enter the transverse speed of sound in the pipe.Allowed values are ranged

500 to 7000m/s, default 3206m/s (Carbon Steel default).

WTG SOS

This value is used to make wall thickness measurements using the UFM when fitted with a wall

thickness probe rather than flow transducers, see the Transducer Type parameter below.

Appearance of this parameter is context driven. If the Material is entered as Other then the user is

prompted to enter a pipe longitudinal sound velocity.

The user is prompted to enter the longitudinal speed of sound in the pipe. Allowed values are ranged

500 to 7000m/s, default 6412m/s (Carbon Steel default).

Liner Menu

This menu allows the user to change pipe lining settings.

Material

The user can select a pipe liner material from a list;

•None (Default)

•Cement

•Epoxy

•Glass

•PP

•Teflon

•Rubber

•Other

The list allows no liner (None) to be selected.

Sound Velocity

Appearance of this parameter is context driven. If the user selected Other from the list of liner

materials then the user is prompted to enter the transverse speed of sound in the liner material.

Otherwise the speed of sound in the liner material is read from a database held in the UFM.

Allowed values are ranged 500 to 7000m/s, default 0m/s (None).

Thickness

Appearance of this parameter is context driven. If the user selected a liner then the user is prompted

for the thickness of the liner. Allowed values are ranged 0.5 to 100.0mm, default 0.0mm (None).

Fluid Menu

This menu allows the user to change fluid settings.

Type

The user can select the fluid in the pipe from a list;

•Water (Default)

•Sea Water

•Kerosene

•Petrol

•Fuel Oil

•Crude Oil

•Freon R134a

•Freon R22

•Diesel Oil

•Castor Oil

•F-76 Fuel Oil

•Novec 1230

•Glycol/Water

•Alcohol

•Other

If the user selected Other from the list of fluid types then the user is prompted to enter various

context driven parameters, see below.

Temperature

The user is prompted to enter the temperature of the fluid in the pipe.Allowed values are ranged -20

to +150 degC, default 18 degC.

Changing Fluid Temperature causes Fluid Sound Velocity, Fluid Kinematic Viscosity, Fluid Density

and Fluid Specific Heat Capacity to be recalculated.

Sound Velocity

Appearance of this parameter is context driven. If the user selected Other from the list of fluid types

then the user is prompted to enter the longitudinal speed of sound in the fluid (NOTE not transverse

as this type of wave is not supported in fluids). Otherwise the longitudinal speed of sound in the

fluid is read from a database held in the UFM.

The user is prompted to enter the longitudinal speed of sound in the fluid. Allowed values are

ranged 50 to 4000m/s, default 1475m/s (Water at 18degC).

Viscosity

Appearance of this parameter is context driven. If the user selected Other from the list of fluid types

then the user is prompted to enter the kinematic viscosity of the fluid. Otherwise the kinematic

Table of contents

Other Sonic Driver Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

GREISINGER

GREISINGER GMH 3610 operating manual

BRUEL & KJAER

BRUEL & KJAER HBK Z6AM Mounting instructions

Coster

Coster IET 7143 C1 Wiring diagram

DEVA Broadcast

DEVA Broadcast Band Scanner PRO Quick user guide

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS CyberScan IR TB100 instruction manual

Edmunds Gages

Edmunds Gages Trendsetter II user manual