Sonic Driver FIXED-UFM User manual

Made in Britain

FIXED-UFM Ultrasonic Flowmeter

Installation Manual

Version 4.0

13th March 2023

Copyright Sonic Driver Ltd 2023

Contents

1.0 Introduction

•1.1 Transit Time Measurement

•1.2 Packing List

•1.3 General Precautions

•1.4 Cleaning

•1.5 Connecting the Flow Transducers

•1.6 Mounting the Flow Transducers

•1.7 Mounting the UFM

•1.8 Wiring the UFM

•1.9 Turning the UFM On

2.0 Using the Quick Start Sequence

•2.1 Transducer Menu

•2.1.1 Type

•2.1.2 Mounting

•2.2 Pipe Menu

•2.2.1 Outer Diameter

•2.2.2 Wall Thickness

•2.2.3 Material

•2.2.4 Sound Velocity

•2.3 Liner Menu

•2.3.1 Material

•2.3.2 Sound Velocity

•2.3.3 Thickness

•2.4 Fluid Menu

•2.4.1 Type

•2.4.2 Temperature

3.0 Sensor Positioning

•3.1 Optimising Transducer Mounting Location

•3.2 Upstream and Downstream Pipe Runs

•3.3 Transducer Mounting

•3.4 Transducer Spacing

4.0 Heat Metering

5.0 Error Codes

6.0 Icons

7.0 Specification

8.0 Product Identification

9.0 Service

10.0 Limited Warranty and Disclaimer

Appendix A Contact Details

Appendix B Table of fluid properties

Appendix C Table of pipe and lining material properties

Appendix D Table of speed of sound in water

Appendix E Table of typical pipe roughness values

1.0 Introduction

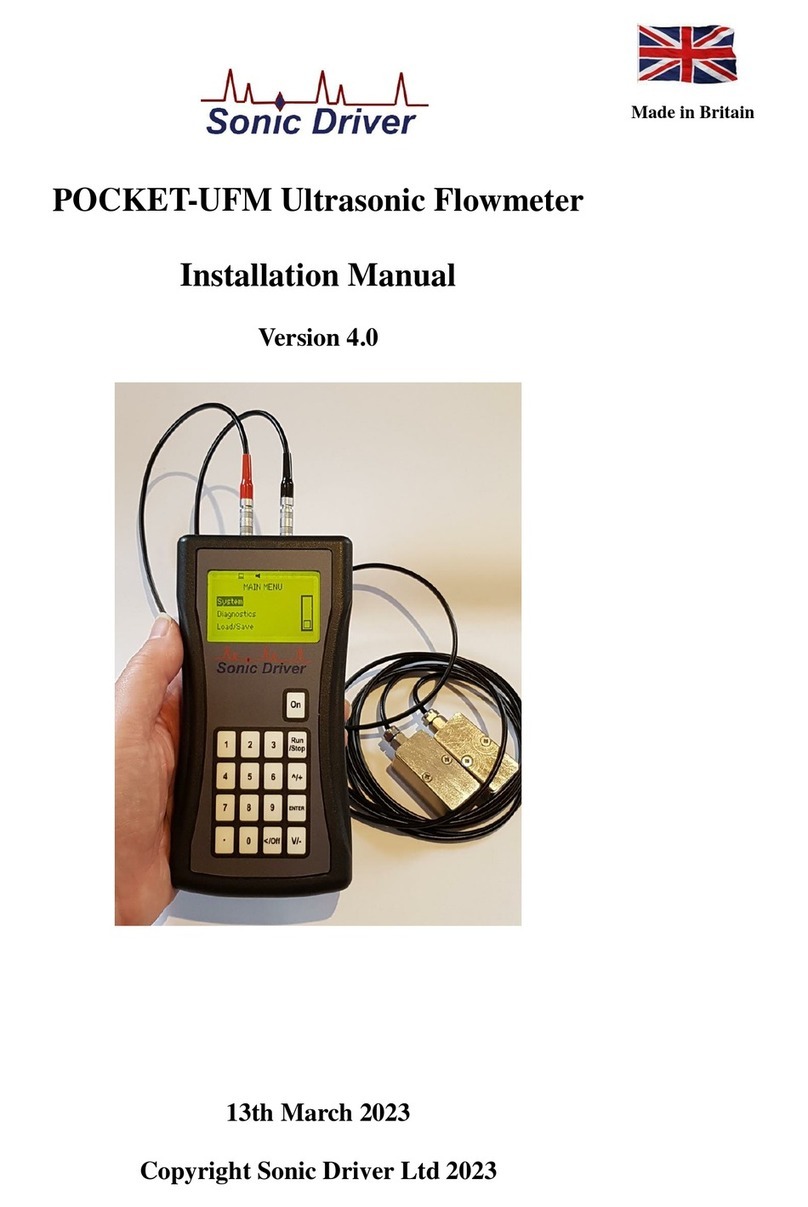

Congratulations on choosing the Sonic Driver FIXED-UFM clamp-on ultrasonic flowmeter,

figure(1).

Figure(1) The Sonic Driver FIXED-UFM.

The ultrasonic flowmeter (UFM) uses advanced Digital Signal Processing (DSP) and transit time

measurement techniques (Sonic Driver TM) to make accurate and reliable clamp-on ultrasonic flow

velocity measurements on liquids flowing in closed pipes

Using information about the installation, entered by the user, using the meters intuitive and easy to

us menu driven User Interface (UI) the UFM can display;

•Flow velocity

•Volumetric flow rate

•Mass flow rate

•Heat quantity flow rate

When making heat measurements the UFM uses the calculation method outlined in EN1434-1

section 8 and its appendix A.

The UFM comes in 3 different versions;

•Standard - outer pipe diameter ranged 10.0 to 115.0mm

•Medium - outer pipe diameter ranged 115.0 to 225.0mm

•Large - outer pipe diameter ranged 225.0 to 6500.0mm

1.1 Transit Time Measurement

The principle of flow measurement using ultrasonic clamp-on transit time measurement is simple,

see figure(2).

Figure(2) The principle of transit time flow measurement.

Two ultrasonic transducers are coupled or clamped to the outside of the pipe at a predetermined

distance apart.

Ultrasonic pulses travel between the transducers through the pipe wall and the fluid within the pipe.

If the fluid is flowing then it takes slightly longer for the ultrasound to travel against the flow

(upstream time T_up) than with the flow (downstream time T_down), see figure(2).

In a typical installation the individual times measured upstream and downstream are just a few

hundred microseconds, the difference between them is typically measured in tens of nanoseconds.

This very small time difference (T_up - T_down) is measured by the UFM and is directly

proportional to the flow velocity (V) of the fluid.

Knowing the pipe internal cross-sectional area the UFM can calculate volumetric flow rate in many

common engineering units. A further knowledge of the density of the fluid allows the UFM to

calculate mass flow rate.

Finally, a knowledge of inlet and outlet fluid temperature and Specific Heat Capacity of the fluid

allows the UFM to calculate heat flow rate.

All of these rates can be totalled and positive, negative and net values displayed.

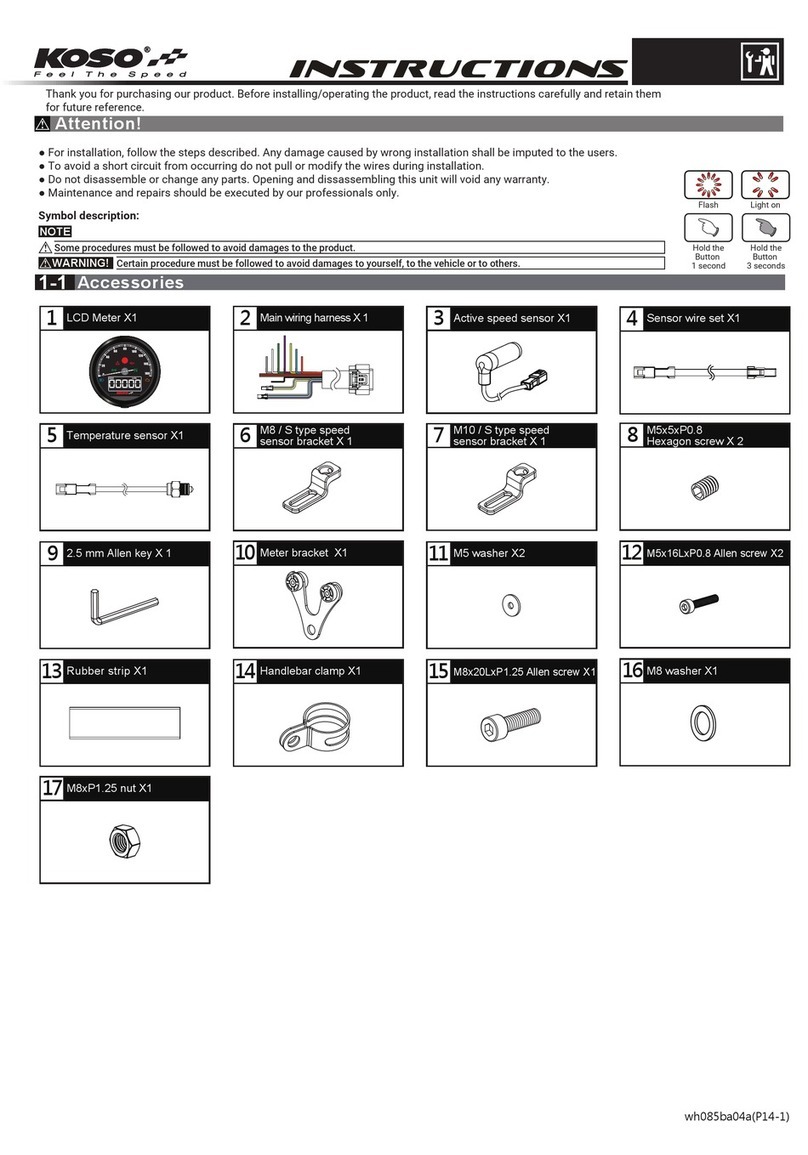

1.2 Packing List

Within the UFM packaging you should find;

Item

Quantity

FIXED-UFM

1

PEEK/Stainless Steel Flow Transducer

2

Chain Mounting Clamp

2

Tape Measure

1

Coupling Gel

1

Table(1) Packing List.

If any item on the packing list is missing or has been damaged in transit contact Service, see

Appendix A.

1.3 General Precautions

The content of this manual has been carefully checked and is believed to be accurate.

Sonic Driver Ltd assumes no responsibility for any inaccuracies that may be contained in this

manual.

In no event will Sonic Driver be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual, even if we are advised of the

possibility of such damages.

Sonic Driver Ltd reserves the right to make improvements to its manuals, instructions and products

at any time, without notice or obligation. The latest revisions may be found on the company web

site, see appendix A.

The UFM is a precision measuring instrument and should be handled and operated with care;

•Before operating the UFM for the first time read the installation manual and operating

instruction fully.

•Only use the UFM in the way and for the purpose that it is intended.

•Do not subject the UFM to bumps and shocks such as caused by dropping the UFM.

•Keep the UFM and its transducers and probes clean.

•Only use the UFM within its ambient temperature and stated level of Ingress Protection.

•Avoid excessive stress and bending of transducer cables and connectors.

•Avoid striking the clear display window and keypad with sharp objects.

1.4 Cleaning

Wipe the UFM and sensors with tissue or soft cloth after use, remove excess coupling gel.

1.5 Connecting the Flow Transducers

Connect the flow transducers to the screw terminal connectors in the screw terminal compartment

of the UFM, see figure(3).

Figure(3) Flow transducer connection.

The left-hand screw terminals connect the flow transducer which is mounted on the pipe

downstream, the right-hand screw terminals connect the flow transducer which is mounted

upstream.

1.6 Mounting the Flow Transducers

Mount the flow transducers on the pipe using the chain clamps supplied, see figure(4). Ensure that

the arrow on the labels (arrowhead and flights) on the flow transducers is pointing in the direction

of flow.

Use coupling gel between the transducers and the pipe to give good ultrasonic contact.

Measure the spacing of the transducers using the tape measure provided, note that spacing is

measured between the front faces of the transducers. Ensure the transducers are facing each other

and aligned axially along the pipe.

Figure(4) Flow transducer mounting, spacing is 25mm between front faces.

In figure(5) and figure(6) the transducers are misaligned and twisted, as a result the UFM will make

poor flow measurements.

Figure(5) Misaligned transducers. Figure(6) Twisted transducers.

1.7 Mounting the UFM

When wall mounting the UFM refer to Figure(7),

Figure(7) Wall mounting the UFM.

1.8 Wiring the UFM

To power on the UFM simply apply AC or DC power as appropriate to the model.

Always disconnect the mains supply before removing any covers and connecting any external

wiring to the UFM. Only qualified Electricians should install the UFM and IET BS7671:2008

wiring regulations must be adhered to.

Always install a ground fault interrupt circuit (GFIC)/residual current circuit breaker (RCCB) with

a maximum trigger current of 30 mA.

If installed outside, provide over voltage protection through an MCB rated not greater than 5 Amps.

With fixed wiring, a disconnecting device (local interruption) must be integrated into the power

supply line. The disconnecting device must meet BS7671:2008 standards and regulations. It must

be installed near the device, be able to be reached easily by the operator and labelled as a

disconnecting device.

1.9 Turning the UFM On

To power on the UFM simply apply AC or DC power as appropriate to the model.

As soon as the UFM is switched on a self-diagnostic program will start. If an error is detected an

error message will be displayed prompting user action. If the error persists, contact customer

support.

See relevant sections on Input/Output and Datalogger below for more detail of what tests are carried

out.

Error codes and their meanings can be found in the Diagnostics Menu.

2.0 Using the Quick Start Sequence

Once powered on the UFM will be in UI mode displaying the Main Menu.

The Main Menu allows the user to select a group of parameters to edit or a meter function;

•Quick Start

•Installation

•System Settings

•Diagnostics

•Input/Output

•RS232/USB

•Datalogger

•Batching

•Manual Totaliser

•Phase Detection

•Heat Metering

The Quick Start function takes the user through the minimum sequence of parameters needed to get

the UFM measuring reliably and accurately;

•Pipe Outer Diameter

•Pipe Wall Thickness

•Pipe Material

•Liner Material

•Fluid Type

•Fluid Temperature

•Transducer Type

•Transducer Mounting

Each parameter is described below in the relevant section.

2.1 Transducer Menu

This menu allows the user to change transducer settings.

2.1.1 Type

The user is prompted to select the type of sensors mounted on the pipe from a list;

•DS05

•DS10

•DS20

•DS40

•DM10(Default)

•DM20

•DN40

•Flow Other

DM sensors are Sonic Driver standard PEEK/stainless steel design. DN sensors are Sonic Driver

small pipe design. DS sensors are Sonic Driver large pipe design.

If Flow Other is selected, then the user will be prompted to enter detailed transducer specific

information.

The ability to select Flow Other is intended for use when using the UFM with special sensors

supplied by Sonic Driver.

2.1.2 Mounting

The user is prompted to select the sound path in the pipe from a list;

•Auto (Default)

•Z

•V

•N

•W

•5

•6

•7

•8

•9

•10

•11

•12

•13

•14

Selecting Auto means that the UFM determines for itself which sound path to use.

Ideally choose a number of passes that results in a path length in the fluid of 100mm or greater.

•Z or 1 pass, most common on large diameter pipes, typically 100mm or more in diameter. If

the UFM suggests a negative spacing, then this is measured as in figure(8).

Figure(8) Z or 1 pass, demonstrating a negative transducer spacing.

•V or 2 passes, the most commonly used method, this is the simplest to install as both sensors

are on the same side of the pipe, see figure(9).

Figure(9) V or 2 passes.

•N or 3 passes, used on small diameter pipes.

•W or 4 passes, used on the smallest diameter pipes, see figure(10).

Figure(10) W or 4 passes.

•5 to 13 and 14, etc.

It may be that on the smallest diameter pipes then the recommended transducer spacing at 14 passes

is not sufficient to allow the transducers to be coupled on the same side of the pipe, using an even

number of passes as they still touch. In this case it is unavoidable to couple the transducers on

opposite sides of the pipe using an odd number of passes, for example 11 or 13 passes.

2.2 Pipe Menu

The following parameters allow the user to specify the pipe.

2.2.1 Outer Diameter

The user is prompted to enter a value for the pipe outer diameter. The UFM comes in 3 different

versions;

•Standard - Allowed values are ranged 10.0 to 115.0mm

•Medium - Allowed values are ranged 115.0 to 225.0mm

•Large - Allowed values are ranged 225.0 to 6500.0mm

For each size the default is 60.6mm.

2.2.2 Wall Thickness

The user is prompted to enter a value for the pipe wall thickness.Allowed values are ranged 0.5 to

100.0mm, default 3.2mm.

2.2.3 Material

The user can select the pipe material from a list;

•Carbon Steel (Default)

•Stainless 304

•Stainless 316

•Cast Iron

•Ductile Iron

•Copper

•PVC

•Lead

•Nylon

•PE

•Aluminium

•Asbestos

•Fibre Glass

•Other

If Other is selected then the user is prompted to enter the transverse (shear) speed of sound in the

pipe material, see below. Otherwise the transverse speed of sound in the pipe material is read from a

database held in the UFM.

2.2.4 Sound Velocity

Appearance of this parameter is context driven. If the user selected Other from the list of pipe

materials, then the user is prompted to enter the transverse speed of sound in the pipe material.

Otherwise the speed of sound in the pipe material is read from a database held in the UFM.

Allowed values are ranged 500 to 7000m/s, default 3206m/s (Carbon Steel).

2.3 Liner Menu

This menu allows the user to change pipe lining settings.

2.3.1 Material

The user can select a pipe liner material from a list;

•None (Default)

•Cement

•Epoxy

•Glass

•PP

•Teflon

•Rubber

•Other

The list allows no liner (None) to be selected.

2.3.2 Sound Velocity

Appearance of this parameter is context driven. If the user selected Other from the list of liner

materials, then the user is prompted to enter the transverse speed of sound in the liner material.

Otherwise the speed of sound in the liner material is read from a database held in the UFM.

Allowed values are ranged 500 to 7000m/s, default 0m/s (None).

2.3.3 Thickness

Appearance of this parameter is context driven. If the user selected a liner, then the user is prompted

for the thickness of the liner. Allowed values are ranged 0.5 to 100.0mm, default 0.0mm (None).

2.4 Fluid Menu

This menu allows the user to change fluid settings.

2.4.1 Type

The user can select the fluid in the pipe from a list;

•Water (Default)

•Sea Water

•Kerosene

•Petrol

•Fuel Oil

•Crude Oil

•Freon R134a

•Freon R22

•Diesel Oil

•Castor Oil

•F776 Fuel Oil

•Novec 1230

•Glycol/Water

•Alcohol

•Other

If the user selected Other from the list of fluid types then the user is prompted to enter various other

context driven parameters including; Fluid Sound Velocity, Fluid Kinematic Viscosity and Fluid

Density.

2.4.2 Temperature

The user is prompted to enter the temperature of the fluid in the pipe.Allowed values are ranged -20

to +150 degC, default 18 degC.

Changing Fluid Temperature causes Fluid Sound Velocity, Fluid Kinematic Viscosity, Fluid Density

and Fluid Specific Heat Capacity to be recalculated.

3.0 Sensor Positioning

After completing entry of all parameters in the Quick Start function sequence the user is prompted

to confirm Transducer Type and is then taken to the Sensor Positioning screen.

Using the entered parameters the UFM calculates and gives the required transducer spacing on the

pipe. The screen also displays the number of passes selected by the user or calculated by the UFM if

in Auto Passes mode.

The user is then presented with a sensor positioning screen showing,

•Graph of received ultrasonic signal

•Calculated sensor spacing

•Number of sound passes in the pipe

•Signal to Noise Ratio

•ATA/ETA

If the parameters entered are all correct, then the graph should appear as in figure(11).

Figure(11) Ideal Sensor Positioning.

However, if the user has an incomplete knowledge of the pipe then the screen may look like

figure(12) or figure(13).

Figure(12) Non-ideal Sensor Positioning, transducers too far apart.

Figure(13) Non-ideal Sensor Positioning, transducers too close together.

In figure(12) the received signal is too far to the right, the user should slide the transducers closer

together.

In figure(13) the received signal is too far to the left, the user should slide the transducers further

apart.

The most common cause of an incomplete or incorrect spacing is a lack of knowledge about the

pipe wall thickness.

As long as the vertical line acting as arrival marker is between the 2 guide marks, resulting in an

ATE/ETA value between 97 and 103% then the UFM will measure accurately. It is acceptable to

reposition the transducers to adjust their spacing by +/- 5 mm to optimise the positioning screen, the

arrival marker will move on the screen accordingly.

SNR should peak and be above 24 dB.

3.1 Optimising Transducer Mounting Location

For the best results ensure that,

•Ideally the transducers are mounted on bare pipe material, for metal pipes this should be

metal free from dust, rust and paint.

•Consider a location away from internal corrosion, sediment and streams of entrained air, do

not mount the transducers top to bottom on the pipe, mount at 2 or 10 o'clock.

•Avoid mounting the transducers either on or opposite axial welds along the pipe.

•Ensure the transducers are aligned axially along the pipe.

•Mount the transducers away from bends, valves and other inserted instrumentation.

•Observe were practical the advised upstream and downstream straight sections, see below,

figure(14).

•Ensure the pipe will always be full at the point of installation, ideally mount the transducers

at a low point in the system.

•If mounting the transducers on a vertical pipe section ensure the flow direction is upwards in

the section.

•Composite pipes can have de-laminations in their wall thickness, this type of pipe is

notoriously bad when installing a UFM.

•Ensure the temperature at the transducer location is within the transducers rated range.

•Ideally the fluid should be free of particulates and bubbles, in the limit then an alternative

method such as Doppler flow measurement may be required.

•Pipe linings that are not bonded properly or are not conductive of ultrasound (rubber) will

cause measurement problems.

•Porous pipes, such as concrete can cause measurement problems.

•Using information from Standard Pipe Tables can be inaccurate, it is always best to measure

the pipe outer diameter and wall thickness.

•No matter how accurate the meter is at making a velocity measurement, an inaccurate

knowledge of the internal cross-sectional area of the pipe will lead to inaccuracy in the

conversion to volumetric flow rate.

3.2 Upstream and Downstream Pipe Runs

Ideally the UFM transducers should be installed on as long a section of straight pipe as is possible,

see figure(14).

Figure(14) Upstream and downstream pipe lengths.

Considering a pipe with an outer diameter of D then if possible ensure at least 10D upstream

distance between the transducers and a bend in the pipework.

In the case of an upstream Valve then if possible ensure at least 20D upstream.

In the case of an upstream Pump then if possible ensure at least 30D upstream.

In all cases ideally ensure 5D downstream exists before a bend or obstruction in the pipework.

3.3 Transducer Mounting

Locate an optimum position on the pipe following the advice above.

Use Coupling gel. Apply adequate couplant and ensure no gap exists between the transducer and the

pipe surfaces.

Banding or clamping is required to keep the transducers in place. It is recommended to use chain

Other manuals for FIXED-UFM

1

Table of contents

Other Sonic Driver Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

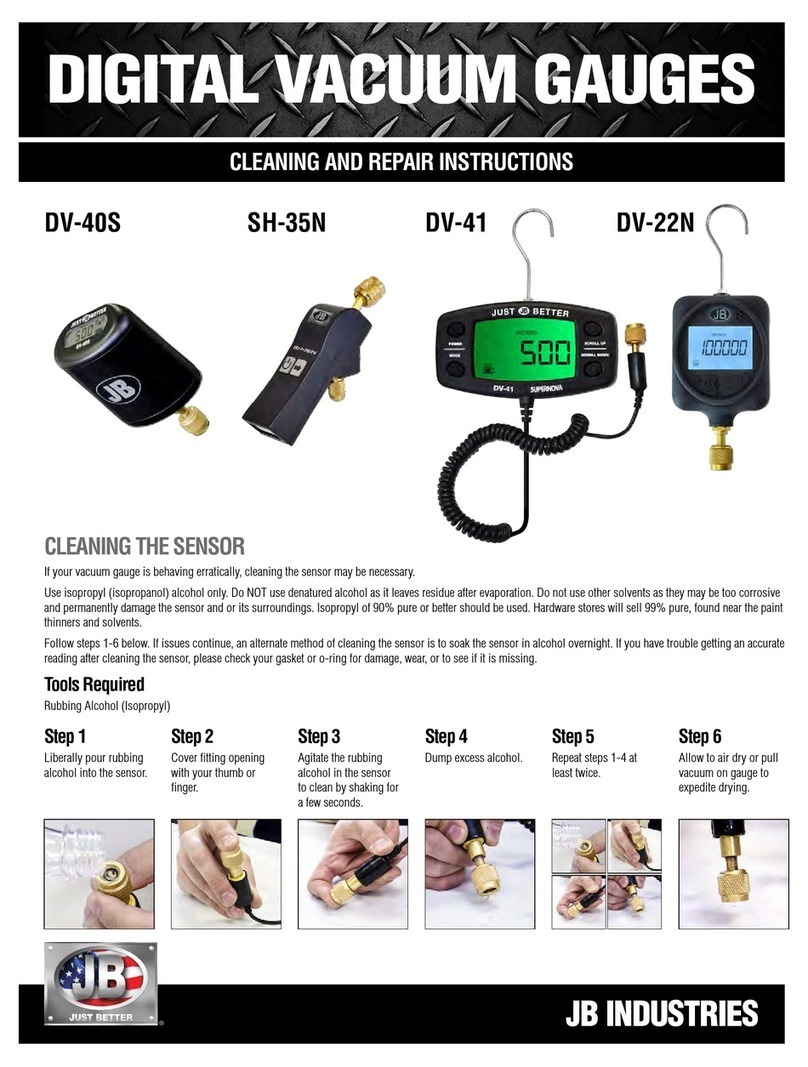

JB INDUSTRIES

JB INDUSTRIES DV-40S Cleaning & Repair Instructions

Telestream

Telestream PRISM MPI-UP PHY-12G Field Upgrade Instructions

Campbell

Campbell CMP6 product manual

PST

PST Michell Instruments Pura Advanced Online 2 user manual

audioscan

audioscan Verifit VF-1 user guide

Chino

Chino IM Series instructions