SonicAire COMPACT PRO Series User manual

WARNING

Installation and electrical wiring must be completed by qualified persons in accordance with all applicable codes and standards.

Before servicing or cleaning the unit, disconnect the fan from the power supply and follow proper lock-out-tag-out procedures for your

location. Any cover, guard, or safety device removed for repair must be replaced as originally installed.

Ensure installation securement does not penetrate walls or ceilings where electrical components or wiring could be potentially damaged.

Fan units are not designed or intended to be mounted to movable objects.

All overhead areas must be cleaned and free of dust buildup prior to powering on fan. If fan is not in service, any dust buildup must be

cleaned prior to restarting fan.

SonicAire fans are for the prevention of dust accumulation and are not to be used for declassifying areas with dust accumulation.

Congratulations on selecting the most powerful and

advanced SonicAire fan. Our company wants you to

be 100% satisfied with your purchase. At SonicAire,

we are focused on providing exceptional customer

service. If for any reason you are unsatisfied with your

equipment or have any other questions, we urge you

to give us a call. We have a dedicated staff eager to

assist you with any questions or concerns.

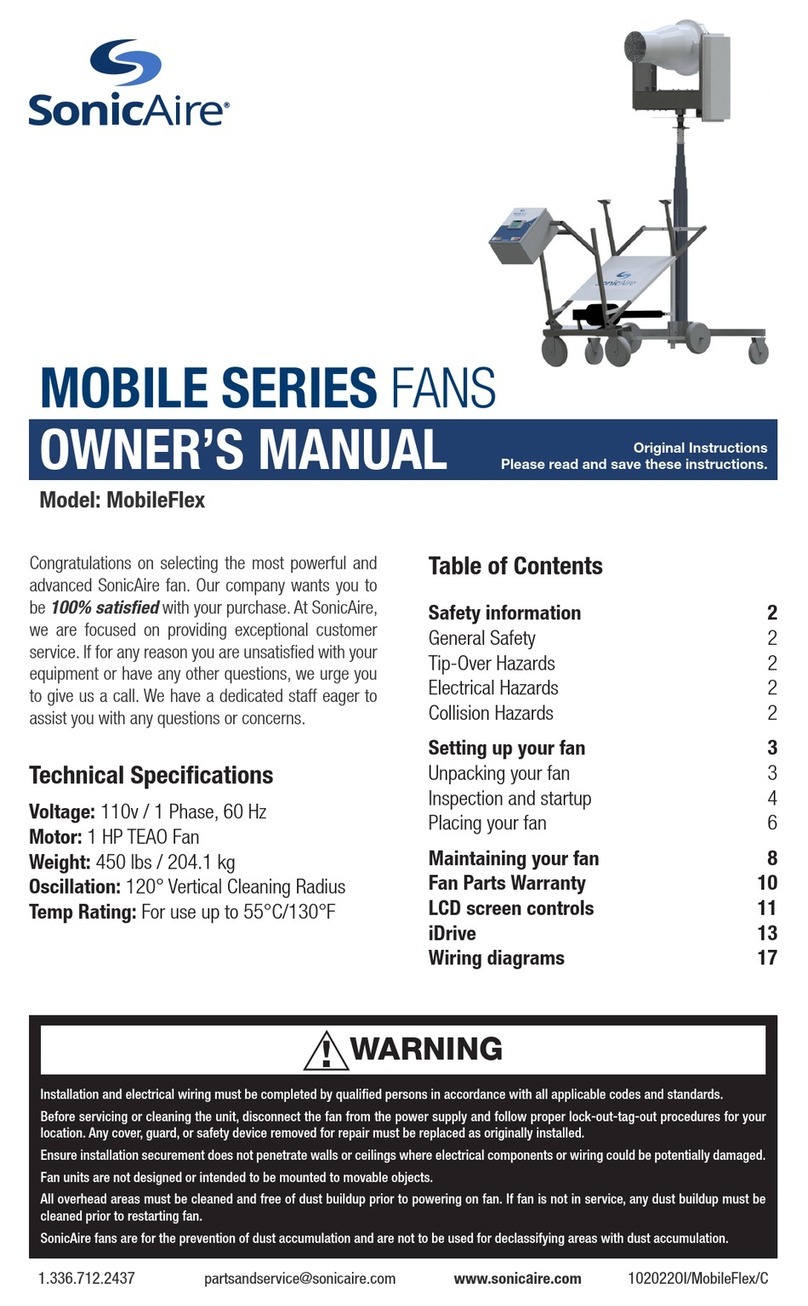

Technical Specifications

Voltage: 380v / 3 Phase, 50 Hz (Pro205

includes VFD for 60 Hz operation)

Motor:

* 1 HP TEAO Fan (Pro105)

* 2 HP TEAO Fan (Pro205)

Weight: 90.7 kg / 200 lbs

Oscillation: 75° Vertical Cleaning Radius

Temp Rating: For use up to 55°C/130°F

Model: Pro105, Pro205 (380v)

OWNER’S MANUAL

COMPACT PRO SERIES FANS

Original Instructions

Please read and save these instructions.

Table of Contents

Setting up your fan 2

Placing your fan 2

Installing your fan 3

Maintaining your fan 7

Continuous operation 7

Electrical information 8

Maintenance schedule 8

Fan Parts Warranty 9

iDrive 10

Changing the settings 11

iDrive setting options 12

Additional iDrive options 14

Variable Frequency Drive (Pro205) 16

Wiring diagrams 19

Troubleshooting 21

EC Declaration of Conformity 22

SonicAire Compact Pro Series (380v)

Owner’s Manual

2

Setting up your fan

Your SonicAire Pro Series fan comes completely assembled. The parts needed for

installation are included in your package unless otherwise noted. If you have chosen

additional accessories for your fan, please refer to the corresponding accessory manual

for instructions regarding installation and operation.

Placing your fan

We recommend that you manually clean your facility’s overhead area before

turning on your fan(s). The dust build up must be reduced to below the minimum

explosive concentration (MEC) level. Disconnect power from ALL OTHER equipment

during start-up to prevent a hazardous condition.

Ensure the chosen structure is suitable to support a 250lb (115kg) load (SonicAire

recommends consulting with a structural engineer prior to installing the fan or penetrating

structural elements).

DO NOT locate the fan near humidifiers or adiabatic coolers that produce free moisture

(water) that may accumulate on the fan.

If you need assistance with a layout or system design to make sure the effective cleaning

distance is not exceeded, please contact SonicAire.

DO NOT use this fan with any solid state speed device.

1 Determine where you will mount your fan. Use the dimensions in Figure 1.1 to

ensure:

a The fan should have clearance to rotate 360° without colliding with any

overhead objects. Please allow 6 inches of clearance in all directions.

b The bottom of the fan should be at least 8.5ft (2.7m) above the floor or other

nearby walking surfaces. If the fan will be mounted less than 8.5 ft (2.7m)

above the ground, please contact SonicAire for a Fan Guard Kit (FGK).

Tip: For large overhead obstructions, locate fans on each side of the objects to achieve

maximum cleaning capacity.

SonicAire Compact Pro Series (380v)

Owner’s Manual

3

Top View Front View

Side View

Figure 1.1

Pro100/200 Dimensions

Installing your fan

Please refer to the mount manual for specific instructions on attaching your fan to

the building structure. This fan product manual assumes all mount installation

instructions have been completed properly.

I. Install the safety cables and sway braces

One end of each safety cable is attached to your fan from the factory as shown in Figure

1.3.

SonicAire Compact Pro Series (380v)

Owner’s Manual

4

Figure 1.2

Complete hanging fan assembly

Figure 1.3

Figure 1.4

1 Attach the free end of each safety cable to a secure building structure by using the

included beam clamps and eye bolt Figure 1.4 or loop the cable around a secure

beam.

2 If you are using the included beam clamps, install clamps on opposite sides of

adjacent beams so that they would potentially be pulled into the beam, not away

from it.

3 Adjust the cable so that there is no slack in the cable and so there is at least 4

inches (100mm) of cable turn back.

SonicAire Compact Pro Series (380v)

Owner’s Manual

5

4 Tighten the two cable clips on each cable securely and torque each nut evenly to

10 ft-lbs.

5 Ensure that the saddle (not the U-bolt) of the cable clip is resting against the load

bearing side of the cable.

Caution: Secure power cable/conduit and safety cables above the indicated red line in

Figure 1.2 to prevent interference with moving parts.

II. Connect the iDrive

The iDrive is disconnected for shipping purposes. For step by step instructions on the

initial setup of the iDrive follow the directions below.

1 Identify the iDrive door on the side of the fan by locating the tag in Figure 1.6.

Figure 1.5

Correct order of

connecting link shoulder

bolt and hardware

2 To access the iDrive, open the door by releasing

the 1/4 turn fasteners.

3 Locate the Connecting Link.

The top most end of the Connecting Link (Drive Disc)

should be attached from the factory to the appropriate

position on the Drive Disc.

4 Locate the bottom most end of the Connecting

Link. The hardware necessary for attachment (Figure

1.5) is already installed, in the correct order, on the end

of the Connecting Link.

Figure 1.6 Figure 1.7

5 Locate the NOTICE tag in Figure 1.7. This tag indicates the Driven Disc hole in which

you need to attach the Connecting Link.

6 Remove the locknut from the back side of the Connecting Link.

7 Remove the NOTICE tag from the hole in the Driven Disc and thread the end of the

SonicAire Compact Pro Series (380v)

Owner’s Manual

6

shoulder bolt through the Driven Disc.

8 Reinstall the locknut on the end of shoulder bolt and torque to 15 ft-lbs.

Note: All fans are set to Standard Oscillation (See Figure 1.8 and Figure 2.1) from the

factory. For information regarding custom oscillation settings refer to Additional iDrive

Options on page 14.

Figure 1.8

Standard oscillation setting for HANGING Fan

WARNING: INSTALLING THE CONNECTING LINK IN THE INCORRECT HOLES

WILL CAUSE THE KEYS TO SHEAR AND CAN CAUSE POTENTIAL GEAR MOTOR

FAILURE. WARRANTY DOES NOT COVER FAILURES ASSOCIATED WITH INCORRECT

CONNECTING LINK PLACEMENT. PLEASE CONTACT SONICAIRE IF YOU HAVE ANY

QUESTIONS REGARDING THE PROPER PLACEMENT OF THE CONNECTING LINK.

III. Connect the TBE (Terminal Block Enclosure)

CAUTION: All electrical wiring (by owner) must be designed and installed in

accordance with local/national electrical codes (NEC NFPA 70).

Figure 1.9

SonicAire Compact Pro Series (380v)

Owner’s Manual

7

1 Secure the enclosure to the building structure using the mounting holes on the

outside of the enclosure.

2 Use correct fittings for field wiring type and connect field wiring fittings or conduit

to the TBE.

3 Install conductors as indicated in Figure 1.9.

IV. Start up your fans

1 Turn ON the power to each fan one at a time.

2 Check for proper rotation of the fan blades.

3 If the air is not blowing out of the fan discharge, change two of the electrical leads

at the local disconnect switch to change the direction of the fan rotation.

4 Observe the fan as it oscillates through one complete cycle to ensure the fan has

proper clearance and there is no apparent binding of the iDrive system.

Your SonicAire®fan is now ready for operation.

Maintaining your fan

Continuous operation

SonicAire fans are designed so that they can operate continuously. In order for the fan

to create an effective overhead barrier to prevent dust accumulation, the fan MUST be

running during production.

CAUTION: It is the customer’s responsibility to ensure that the fans are operated

frequently enough that a “dust cloud” is not produced by the fan(s). SonicAire fans are

not designed or intended to be used as a “blow down” tool, and should not be used as

such. Dust concentrations must remain below Minimum Explosive Concentration (MEC)

levels.

If the fans will not be operated continuously, they should be operated frequently enough

that when turned on, no visible quantities of dust can be seen in the atmosphere. If dust

is visible when the fan started from a “cold” state, the fan should be operated more

frequently.

The SonicAire fan is designed to rotate continuously through a full 360° circle. While

rotating, the fan discharge will oscillate through the chosen angle as determined by the

SonicAire Compact Pro Series (380v)

Owner’s Manual

8

iDrive settings. Since the oscillation of the fan discharge and the rotation of the fan are

not synchronized, the fan is directing air at a different angle each time it passes through

a complete 360° of rotation (approximately every 20 minutes). This design assures that

all of the overhead structures, and plant equipment, if desired, is thoroughly cleaned.

Electrical information

All owner furnished electrical service and components must meet

the requirements of local/national codes. All SonicAire fans must

have individual circuit protection. Failure to use individual circuit

protection will void the equipment warranty.

CAUTION

The SonicAire Pro205 fan motor is a three-phase 1.5kw/2 hp motor which operates

through a VFD at 1725 rpm when supplied with 50 Hz power (or a 0.75kW/1 hp motor for

the Pro105 Series. The Pro105 motor operates at 1450 rpm at 50 Hz). The indexing gear

motor is a sealed three phase, 12W, 1/56 HP motor running at 0.7 RPM (at 60Hz) for the

Pro205 and 0.59 rpm (at 50 Hz) in the case of the Pro105. Power is transmitted to the

fan motor and gear motor through a 30 amp slip ring mounted in the unified electrical

enclosure (See Wiring Diagrams, p. 16-17).

Maintenance schedule

Recommended Preventive Maintenance Schedule

Industry Schedule Exceptions

Textile 12 months

Wood 9 months 6 months in damp environments

Gypsum 9 months

Paper 12 months 6 months in damp environments

Plastics 12 months

Chemical 9 months

Agricultural 12 months

Pharmaceutical 9 months

Recycling 12 months

SonicAire Compact Pro Series (380v)

Owner’s Manual

9

WARNING: Lock out the fan prior to accessing the fan or opening any electrical or

mechanical enclosures.

SonicAire recommends that you complete the following steps every six months:

• Clean and visually inspect your fan for any abnormal conditions or wear.

• Verify that all fasteners (bolts, nuts, etc.) are tight and tighten as required.

• Inspect the gear motor for oil leakage.

Once per year we recommend that you:

• Check all electrical connections for proper tightness.

All bearings are sealed or self-lubricated and require no additional lubrication. Although

they require no maintenance they may wear out over time.

Fan Parts Warranty

SonicAire equipment comes with a 1-year parts and factory service only warranty. The

warranty begins after the product is shipped from the factory. This should allow sufficient

time for transportation and installation of the fan unit. This warranty is provided to the

original purchaser of the product and is non-transferable.

When the fan unit is installed, operated and maintained in conjunction with other

SonicAire mounting equipment, controls, and accessories according to instructions

included or provided by SonicAire, SonicAire will provide replacement parts and factory

labor to correct defects in materials or workmanship that existed when the fan unit was

purchased, or at its sole discretion replace the unit.

Should you experience any issues with your SonicAire fan unit, please contact SonicAire

guided through some troubleshooting steps and offered the option to receive replacement

parts or return the unit to the factory for repairs. SonicAire replacement parts carry a 1

year warranty.

WHAT IS NOT COVERED

1 Use in a manner that is inconsistent with SonicAire’s user, operator, or installation

instructions.

2 Service or parts to correct improper installation, maintenance, or installation not in

SonicAire Compact Pro Series (380v)

Owner’s Manual

10

accordance with electrical codes or safety standards.

3 Parts for conversion of fan unit to different operational voltage than was originally

ordered.

4 Damage from unapproved environmental conditions, accident, misuse, abuse, fire,

floods, or acts of God.

5 Damage from use in conjunction with products not approved by SonicAire.

6 Repairs to parts or fan unit to correct product damage or defects caused by improper

service, alteration or modification of the fan unit.

7 Cosmetic damage including scratches, dents, chips,and other damage to the fan unit

finishes, unless such damage results from defects in materials and workmanship

and is reported to SonicAire within 45 days of shipment from factory.

8 Discoloration, rust, or oxidation of surfaces resulting from caustic or corrosive

environments including but not limited to high salt concentrations, high moisture or

humidity, exposure to chemicals, or elevated ambient temperatures. Standard Pro

Series fans are warrantied to 130°F/55°C. Extreme Temperature Fans and Parts are

available for warrantied parts to 170°F/75°C. Contact SonicAire Parts and Service

at 1-336-712-2437 for more information.

9 Housekeeping expenses due to inoperative condition of a fan unit.

10 On-site field labor, removal, re-installation, or shipping costs of returning fan unit

back to factory for repairs.

The cost of the repair or replacement under any of these excluded circumstances shall

be borne by the customer.

iDrive

The iDrive system allows you to adjust the preferred cleaning area by changing the

vertical oscillation angle. The iDrive system (Figure 2.1) allows the user to make simple

adjustments to achieve a custom cleaning angle.

Connecting Link

The Connecting Link connects the Drive and Driven Discs. Figure 1.6 shows the proper

assembly order of the Connecting Link.

Drive Disc

The Drive Disc is located at the top of the iDrive assembly. This disc determines the

SonicAire Compact Pro Series (380v)

Owner’s Manual

11

magnitude of oscillation.

Driven Disc

The Driven Disc is located at the bottom of the iDrive assembly. This disc determines

where the fan nozzle angle will be directed.

Each setting consists of an alphanumeric combination that indicates where to install the

Connecting Link as shown in Figure 2.1 (see Page 13 for additional settings).

1

1

-

-

Z

Z

G

G

StandardOscillation

Figure 2.1

Standard oscillation setting for hanging fan

Changing the settings

1 After reviewing the angle illustrations to decide which setting would be ideal for

your facility, choose a setting from the list on page 13.

Note: For additional oscillation settings, see the Additional iDrive Options section

or contact SonicAire Parts and Service at 1-336-712-2437 or at partsandservice@

sonicaire.com.

SonicAire Compact Pro Series (380v)

Owner’s Manual

12

2 The fan nozzle must be positioned to the right of the fan when viewing the iDrive for

all hanging mounts (to the left for standing mounts).

3 While supporting the fan nozzle, disconnect the Connecting link from the Drive Disc

by loosening the locknut on the end of the shoulder bolt.

4 Review your Oscillation Setting for the Drive Disc position. This will be the first

character in the setting and will be a numerical digit.

5 Install the shoulder bolt into the specified opening by threading the bolt through the

disc.

6 Secure the bolt with the locknut removed in step #3 and torque bolt to 15 ft-lbs.

7 Proceed to the Driven Disc end of the Connecting Link and remove the locknut from

the end of the shoulder bolt.

8 Review your setting to determine the proper attachment position on the Driven

Disc. The second and third digits in the setting combination defines the Driven Disc

connection.

9 Determine which side of the Driven Disc you will be attaching the Connecting Link.

Review the decal and ascertain the appropriate side for your mount option.

10 Find the indicated row on the Driven Disc from your chosen setting. This will be the

second digit in the setting (Y or Z).

11 Find the hole within the selected row that corresponds with the third digit in your

setting selection (A-N).

12 Thread the shoulder bolt into the designated hole while ensuring the correct

assembly order of parts (Figure 1.6).

13 Install the locknut removed in Step #8 and torque bolt to 15 ft-lbs.

iDrive setting options

Each of these illustrations depicts a different setting and a color coded diagram indicating

the relationship between the setting character and the Connecting Link attachment

position on each the Drive and Driven Discs.

Important: Contact SonicAire for assistance if you are not certain of your selection or

simply want to confirm your selection process. Warning: Improper attachment of the

Connecting Link may result in equipment damage!

SonicAire Compact Pro Series (380v)

Owner’s Manual

13

Hanging fans

StandardOscillation

1

1

-

-

Z

Z

G

G

MaximumOscillation

3

3

-

-

Y

Y

E

E

Standing fans

Y

Y

K

K

StandardOscillation

3

3

-

-

MaximumOscillation

Y

Y

J

J

3

3

-

-

SonicAire Compact Pro Series (380v)

Owner’s Manual

14

Additional iDrive options

Each of the following fan diagrams illustrates a range of oscillation settings for a

particular Drive Disc number (1-6) and Driven Disc axis (Y or Z) combination. This

combination determines how wide the vertical oscillation radius will be. The final iDrive

setting selection - the Driven Disc letter (A-N)(A-N) - determines the extent angles of the

oscillation range.

Hanging fans

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

10

20

30

40

50

60

70

80

90

100

110

70°

Coverage

70°

Coverage

--

3Y_

D

D

E

E

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

10

20

30

40

50

60

70

80

90

100

110

60°

Coverage

60°

Coverage

--

3Z_

A

A

B

B

C

C

D

D

E

E

F

F

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

10

20

30

40

50

60

70

80

90

100

110

43°

Coverage

43°

Coverage

--

1Z_

A

A

B

B

C

C

D

D

E

E

F

F

G

G

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

10

20

30

40

50

60

70

80

90

100

110

42°

Coverage

42°

Coverage

--

1Y_

D

D

E

E

F

F

G

G

SonicAire Compact Pro Series (380v)

Owner’s Manual

15

Standing fans

0

10

20

30

40

50

60

70

80

90

100

110

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

70°

Coverage

70°

Coverage

--

3Y_

J

J

K

K

0

10

20

30

40

50

60

70

80

90

100

110

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

56°

Coverage

56°

Coverage

--

3Z_

I

I

J

J

K

K

L

L

M

M

0

10

20

30

40

50

60

70

80

90

100

110

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

42°

Coverage

42°

Coverage

--

1Y_

H

H

I

I

J

J

K

K

0

10

20

30

40

50

60

70

80

90

100

110

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

35°

Coverage

35°

Coverage

--

1Z_

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

SonicAire Compact Pro Series (380v)

Owner’s Manual

16

Variable Frequency Drive

(Pro205)

ODE-3-140041-3F1A

1.5 kW (2 HP), 4.1 A, 380-480 V, 3PH

IP66 Outdoor Non-switched Variable Frequency Drive with EMC Filter

Input Ratings

Supply Voltage 380-480 V

Input Phases 3

Supply Current Continuous 5.6 A

Supply Fuse or MCB (Type B) 10 A

Output Ratings

Motor Output Rating 1.5 kW (2 HP)

Output Voltage 0 — Supply Voltage

Output Current 4.1 A

Cable Information

Max Supply Cable Size 8 mm2(0.01 sq in)

Max Motor Cable Size 8 mm2(0.01 sq in)

Max Motor Cable Length 100 m (328 ft)

Factory Build Options

EMC Filter Internal EMC Filter

Brake Transistor No Internal Brake Transistor

Enclosure IP66 Outdoor Non-switched

SonicAire Pro200, 205, and XT (380v) fans are equipped with an Invertek Optidrive

E3 Variable Frequency Drive (VFD) with EMC filter. This drive has already been pre-

programmed by SonicAire as shown below. If the VFD should need to be reprogrammed

to SonicAire factory settings the following instructions should be used.This programming

method allows the fan to be operated with the on/off knob.

In addition to the keypad programming below, to run the SonicAire fan through the on/off

knob control it is CRITICAL to wire the 1 and 2 control terminals with a standard gauge

wire. When the drive is being programmed, disconnect the 1 and 2 control terminals

(Figure 1.2).

SonicAire Compact Pro Series (380v)

Owner’s Manual

17

Wiring the Pro205 (380v)

L1 L3 EMCL2/N UV W

1 2 3 4 5 6 7 8 9

10

11

I0I0I I0I0I

AB

C

3-phase

AC Input

Fan

power out

The Pro205 Fan Manual includes a

wiring diagram that configures your

SonicAire fan to run with 50Hz, 380

source voltage. In addition to the

terminal 1 and 2 connection mentioned above, use Figure 1.2 to correctly configure your

VFD for power-in from source and power-out to fan.

NAVIGATE

Used to display real-time information, to access

and exit parameter edit mode and to store

parameter changes.

UP

Used to increase speed in real-time mode or

to increase parameter values in parameter edit

mode.

DOWN Used to decrease speed in real-time mode or to decrease parameter

values in parameter edit mode.

RESET/

STOP

Used to reset a tripped drive.

When in Keypad mode is used to Stop a running drive.

START When in Keypad mode, used to Start a stopped drive or to reverse the

direction of rotation if bi-directional keypad mode is enabled.

Figure 1.3 - VFD keypad controls

VFD factory reset

With the device powered on, ensure the VFD has been reset to factory defaults by doing

the following:

A Incoming power connections

B Motor connections

C Control terminal connections

(1 and 2 control terminals

highlighted)

Figure 1.2

Wiring the VFD

SonicAire Compact Pro Series (380v)

Owner’s Manual

18

1 Press and hold Up, Down, and Stop buttons for > 2 seconds. The display will show

“P-dEF.”

2 Press the Stop key. The display will show “StoP.” The drive is now reset to Invertek

factory settings.

VFD programming for use with SonicAire fans

1 Now program the drive keypad (Figure 1.3) for SonicAire’s basic European settings:

2 Press and hold the Navigate key for > 2 seconds. The display will show “P-01.”

3 Press the Up arrow key to cycle through numbers until the display shows “P-14.”

4 Press the Navigate key. The display will show “0.”

5 Press and hold the Up arrow key to cycle through numbers until the display shows

“101.”

6 Press the Navigate key. The display will show “P-14.”

7 Press the Up arrow key. The display will show “P-15.”

8 Press the Navigate key. The display will show “0.”

9 Press the Up arrow key to cycle through numbers until the display shows “2.”

10 Press the Navigate key. The display will show “P-15.”

11 Press the Up arrow key to cycle through numbers until the display shows “P-20.”

12 Press the Navigate key. The display will show “H 5.0.”

13 Press and hold the Up arrow key to cycle through numbers until the display shows

“H 60.0”

14 Press the Navigate key. The display will show “P-20”

15 Press the Up arrow key to cycle through numbers until the display shows “P-30.”

16 Press the Navigate key. The display will show “Ed9E-r.”

17 Press the Up arrow key until the display shows “Auto-0.”

18 Press the Navigate key 3 times. The display will show “P-30”

19 Hold square button for 2 seconds. The fan is now completely programmed to run

with its basic settings.

Now that the drive has been reprogrammed to SonicAire defaults, reconnect the 1 and 2

control terminals as designated in Figure 1.2.

SonicAire Compact Pro Series (380v)

Owner’s Manual

19

Wiring diagrams

SonicAire fan wiring diagram

Slip Ring

MSP

Fan Motor

Cable

Gnd

TBE

FAN MOTOR

GEAR MOTOR

TB

TB

TB

TB

TB

TB

TB

TB

TB

BL R

R

BL

BK

BK BL R

BK

Fan Enclosure

Primary Motor

Overload

Protection

and LOTO

Disconnect

Provided by

Others

Pro105 (380v) Pro205 (380v)

Motor (hp) 1 2

Gearmotor (W) 10 10

MSP (380v) 0.14 0.14

SonicAire Compact Pro Series (380v)

Owner’s Manual

20

Multiple fan wiring diagram

B

R

Bk

Fan Motor

Fan #1

Fan Motor

Fan #2

Fan Motor

Fan #3

Overload Heaters

Motor Starter/

Local Protection

Provided by

Others

Power Contacts

Properly Sized

Conductors

Properly

Sized

Conductors

380v, 3 phase, 50Hz

power from circuit

breaker or control panel

Additional fans

on same circuit

Multiple SonicAire Fans on the same circuit

TBE TBE TBE

Amperage

Voltage Pro105 (380v) Pro205 (380v)

380 1.8 3.3

This manual suits for next models

7

Table of contents

Other SonicAire Fan manuals