— 2 —

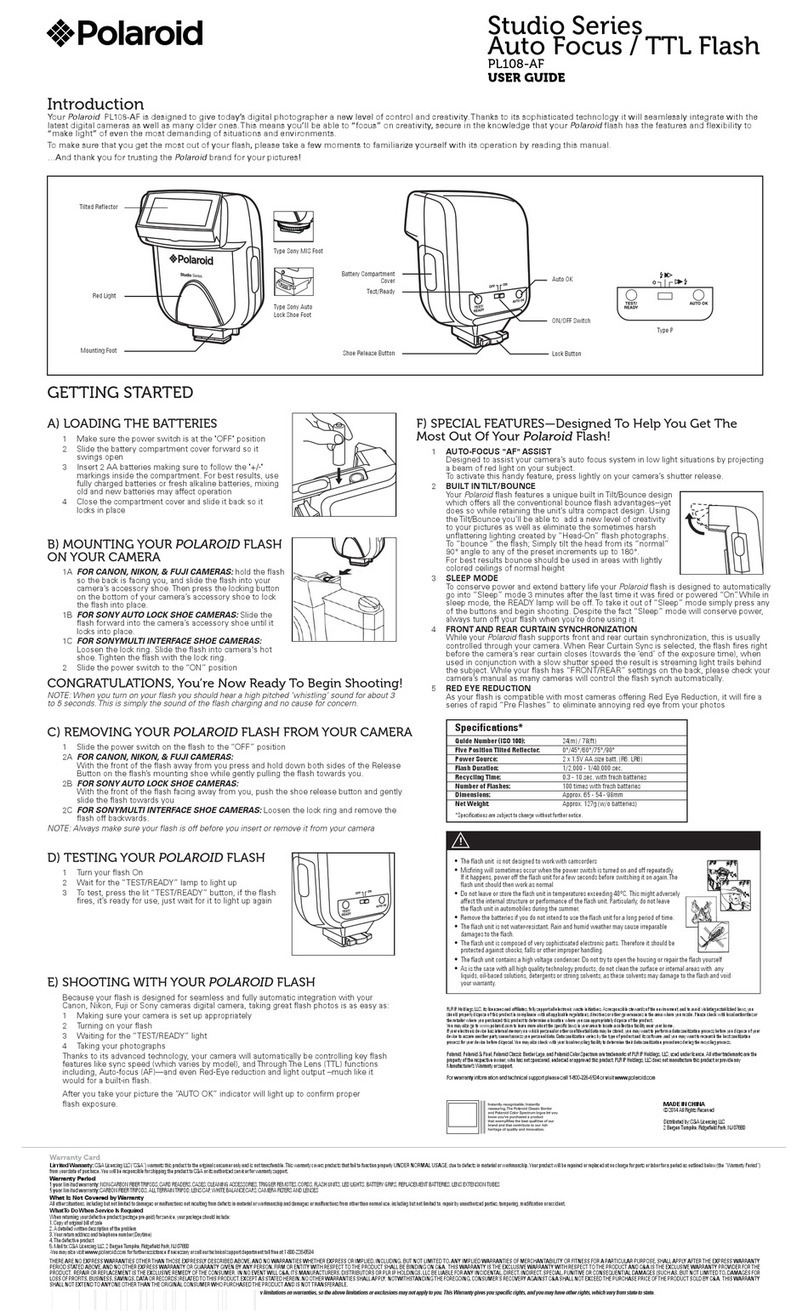

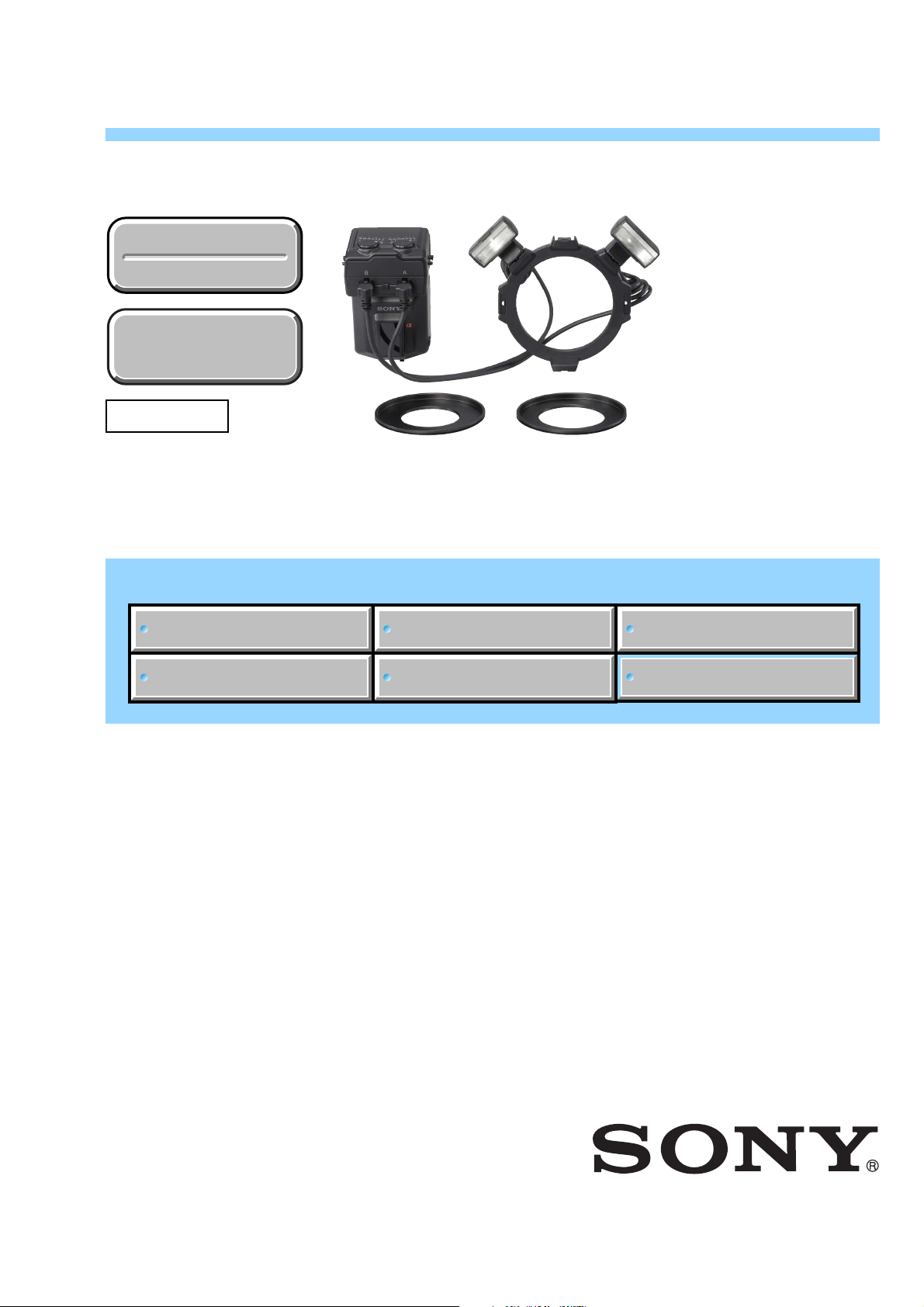

HVL-MT24AM

SPECIFICATIONS

The macro twin flash kit provides flexible lighting for macro nature photography. It is ideal for close-up photography of flowers, insects, small objects,

and so on.

• Freedom to change the attachment position and angle of the flashtube enables more expressive photography.

• Attaching two-length adjustable arms between the twin flash units and holders makes it possible to change the lighting for high magnification

close-up photography.

• Using the supplied diffuser enables softer lighting.

• The supplied wide panel expands flash coverage to a focal length of 24 mm.

• Modeling flash function can check shadows before photographing.

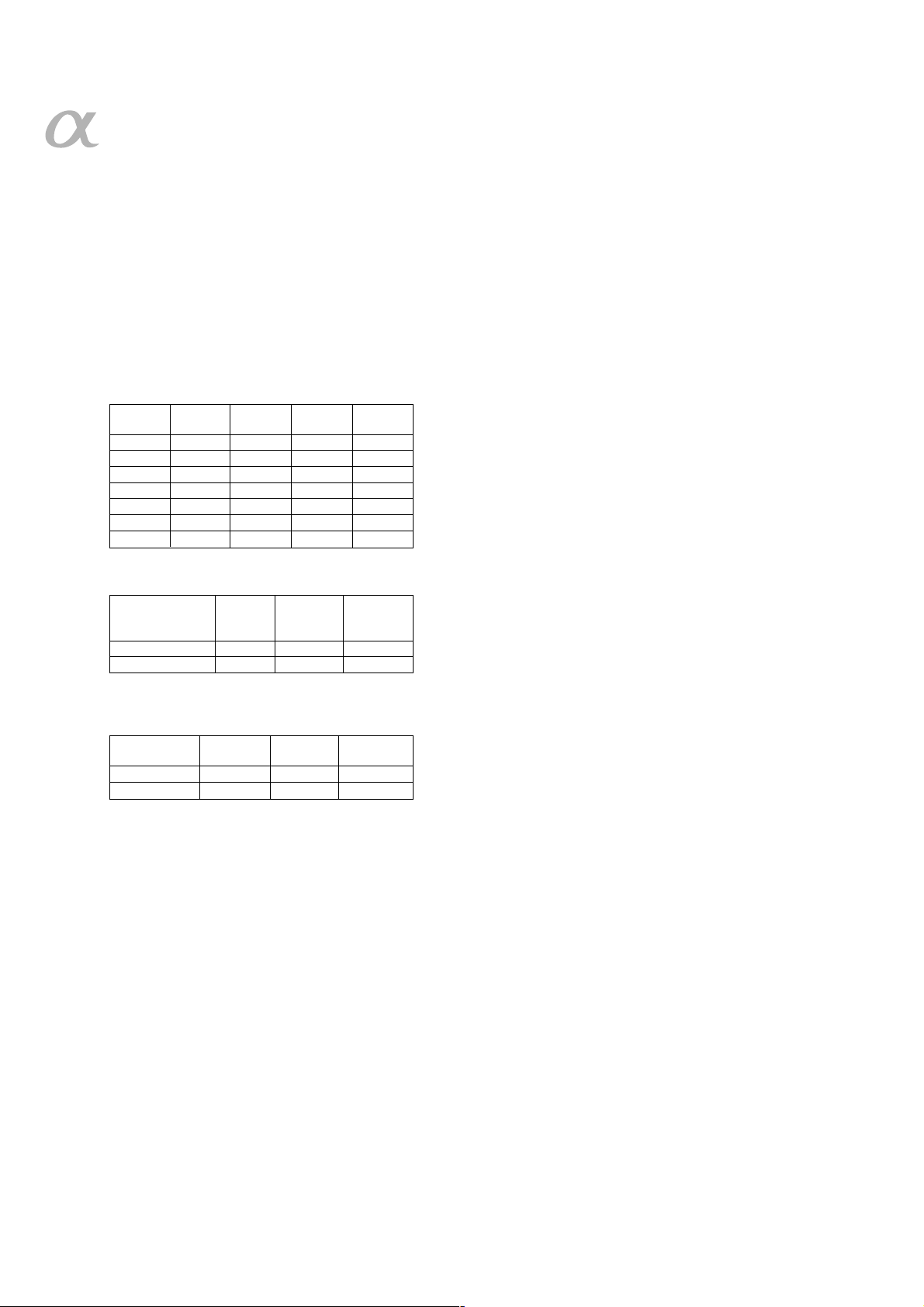

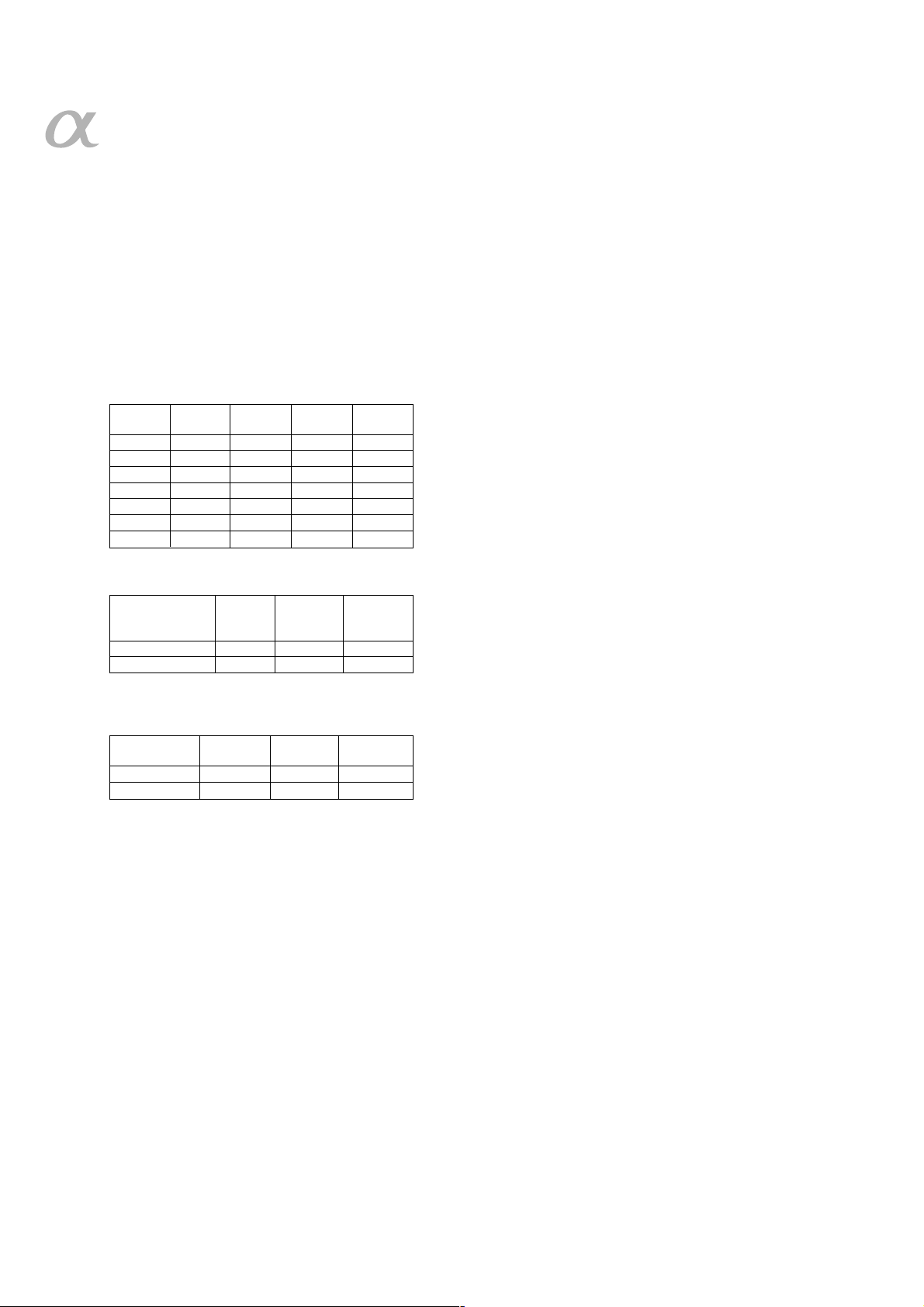

Guide number

Normal flash (ISO 100)

Power 1 tube 2 tubes Wide Diffuser

level panel

1/1 17 24 11 7

1/2 12 17 8 5

1/4 8.5 12 5.6 3.5

1/8 6 8.5 4 2.5

1/16 4.2 6 2.8 1.8

1/32 3 4.2 2 1.3

1/64 2.1 3 1.4 0.9

Wide panel and diffuser is for one tube.

Frequency/Repetition

Nickel-

Alkaline Lithium hydride

(1550 mAh)

Frequency (sec) 0.2~6 0.2~6 0.2~5

Repetition (times) 200~4000 500~10000 150~3000

• Repetition is the approximate number of times that are

possible before a new battery is completely dead.

Flash coverage

Flash Twin Wide Diffuser

coverage flash panel

Vertical 45 °60 °90 °

Horizontal 60 °78 °90 °

Continuous flash performance

40 flashes at 5 flashes per second

(Power level 1/32, nickel-metal hydride battery)

Flash control

Flash control using pre-flash, TTL direct metering,

Manual flash

Dimension (Approx.)

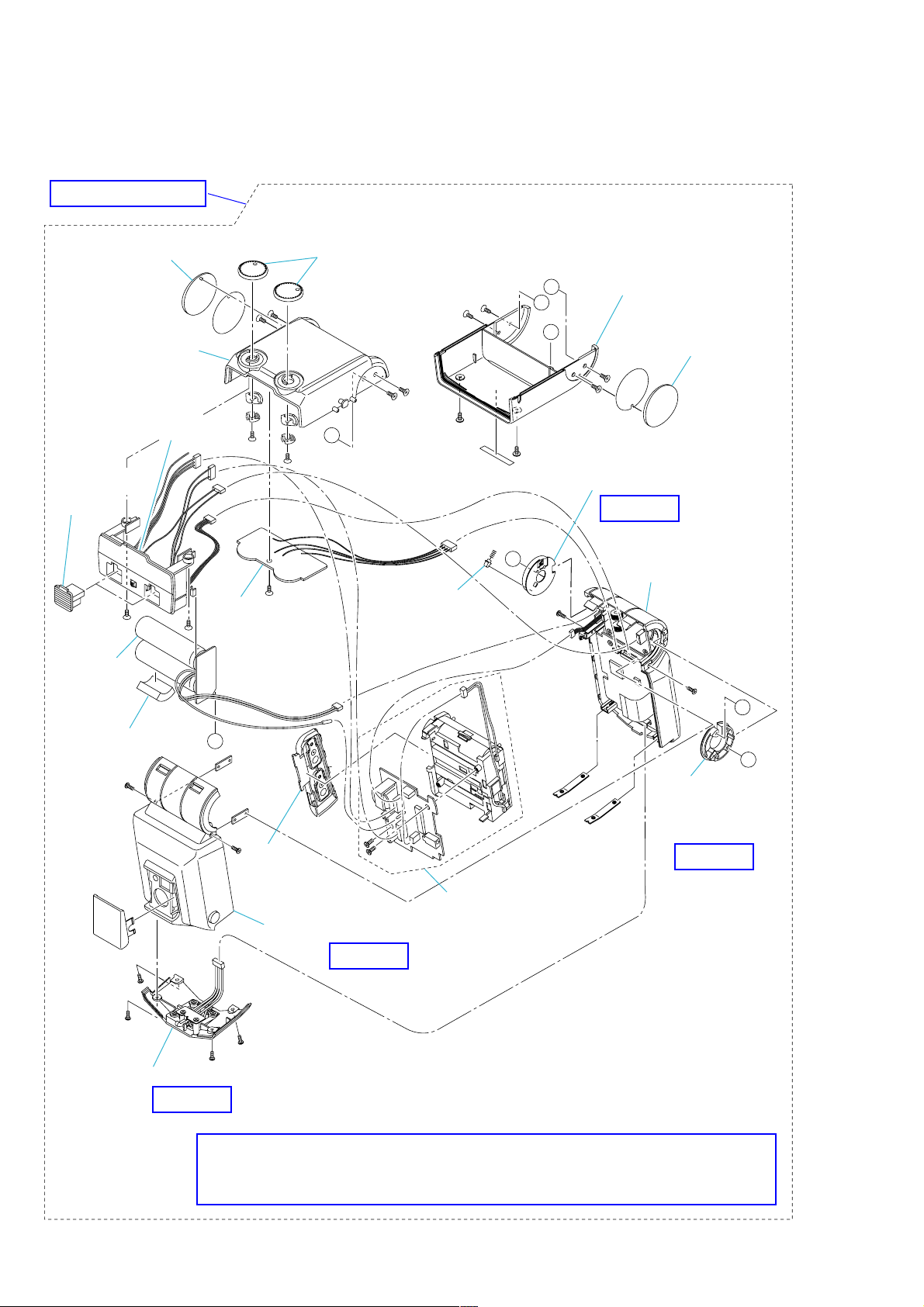

Macro flash controller

68 ×123 ×91 mm (2 3/4 ×4 7/8 ×3 5/8 in.) (w ×h ×d)

Twin flash unit

43 ×41 ×37 mm (1 3/4 ×1 5/8 ×1 1/2 in.) (w ×h ×d)

Mass (Approx.)

Macro flash controller 235 g (8.3 oz.) (without batteries)

Twin flash unit 33 g (1.2 oz.) (per twin flash unit)

Operating temperature

0 °C to 40 °C (32 °F to 104 °F)

Included items

Macro flash controller (1), Twin flash unit (2), Holder (1),

Arm (2), Adaptor ring ø 49mm (1),

Adaptor ring ø 55mm (1), Wide panel (2), Diffuser (2),

Cord reel (2), Controller case (1), Flash case (1),

Set of printed documentation

Functions in these operating instructions depend on testing conditions

at our firm.

Design and specifications are subject to change without notice.