TC-K222ESG/K850ES

Standard

Output

Level

OVS)

VTVM

)

attenuator

'*®

mo

{LI

OO

1-000

set

|

esi

6008)

INE

INPUT

LINE

OUTPUT

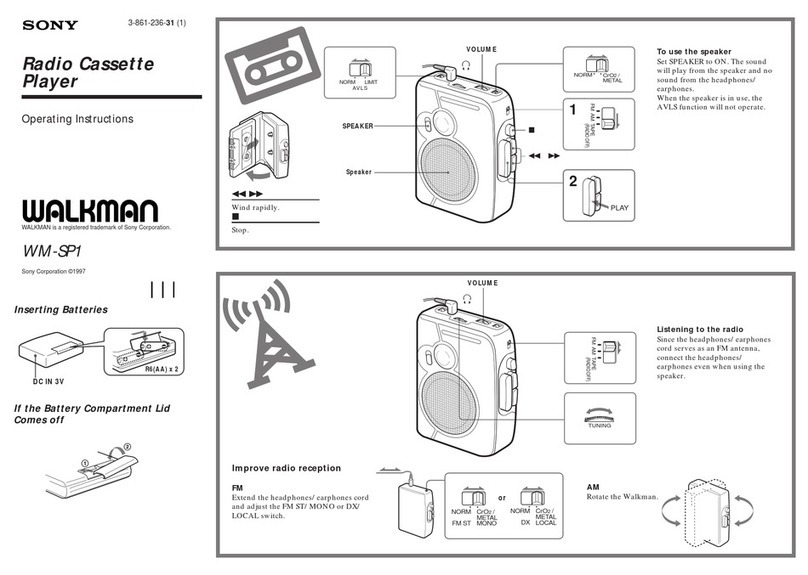

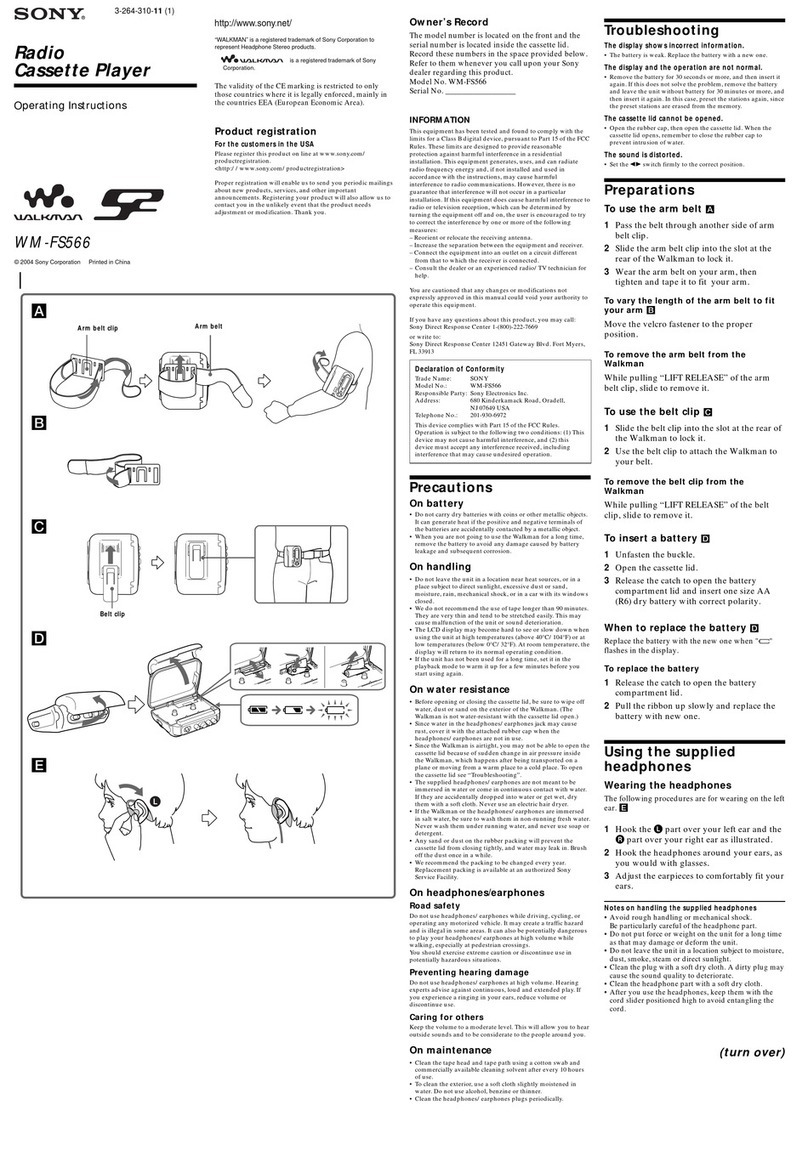

Adjustment

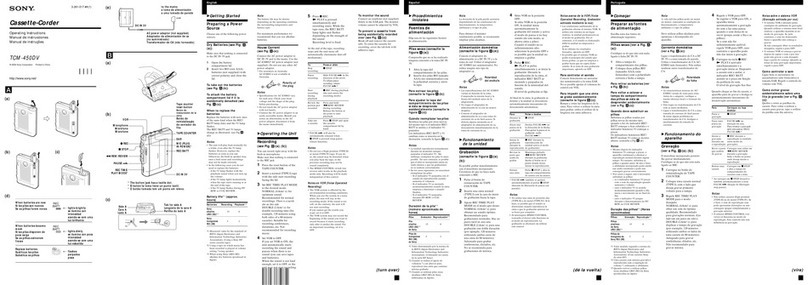

Position:

As

seen

from

the

cassette,

side

(top)

and

MD

as

seen

head

on

(bottom).

Takeup

pinch

Torque

Adjustment

and

Measurement

1.

Load

a

torque

meter

cassette

CQ-102C

and

push

Supply

pinch

roller

Erasehead

Record/playback

roller

head

>

button.

2.

Adjust

RV803

so

that

the

reading

on

the

torque

meter

is

40+3g*cm

(0.56

+

0.0420z

inch).

3.

After

the

adjustment,

apply

suitable

locking

compound

to

RV803.

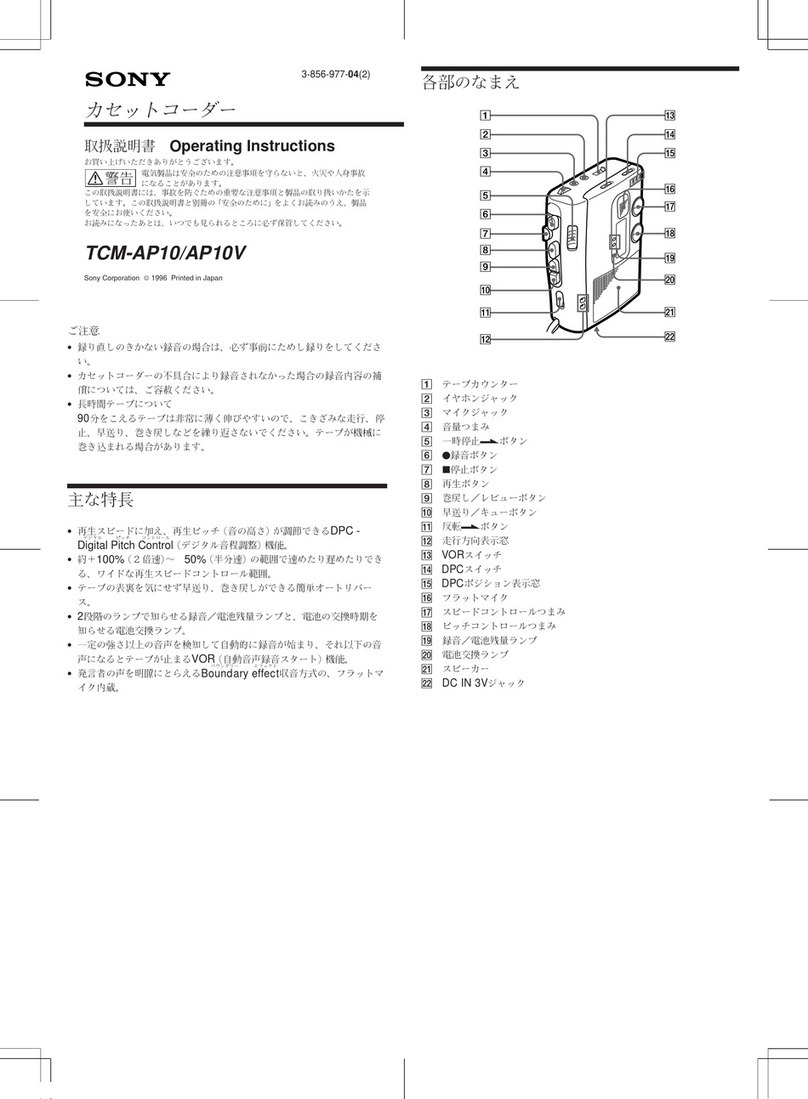

3-2.

ELECTRICAL

ADJUSTMENTS

Note:

The

adjustment

should

be

performed

in

the

order

given

in

this

service

manual.

The

adjustments

should

be

performed

for

both

L-CH

and

R-CH.

@

Simultaneous

REC/PB

Mode:

Input

the

signals

to

LINE

IN

terminal

and

set

to

REC

mode.

Set

the

monitor

switch

to

TAPE,

and

monitor

the

recorded

signal

from

LINE

OUT

terminal,

@

Switch

Position:

DOLBY

NRevecccrsscecersscesecensscnensersssceuneeseeens

OFF

MPX

FILTER

coccccecssceeeecceesscceeccseeseseeensseues

OFF

TIME

Recccccesscctssceeeneccetseceessceescsenssceusessenees

OFF

MONITOR

crosceesccssceceecectsouecescesceerseenscenens

TAPE

HX

PRO

corccsecrascentscessccescencsesconsceescererscenees

OFF

CALIBRATION

«cccesecctteceerececcescssatsnsesassceonee

OFF

CD

DIRECT

rreccrsseeccecseeecteenesseeseecanesseenanees

OFF

BY

AS

cessaevedwcsnlvereatzccnanonsidyereya

CENTER

CLICK

REC

LEVEL

«oresssssressseesceeseeees

CENTER

CLICK

BALANCEeersrcccresceceectescsesecenes

CENTER

CLICK

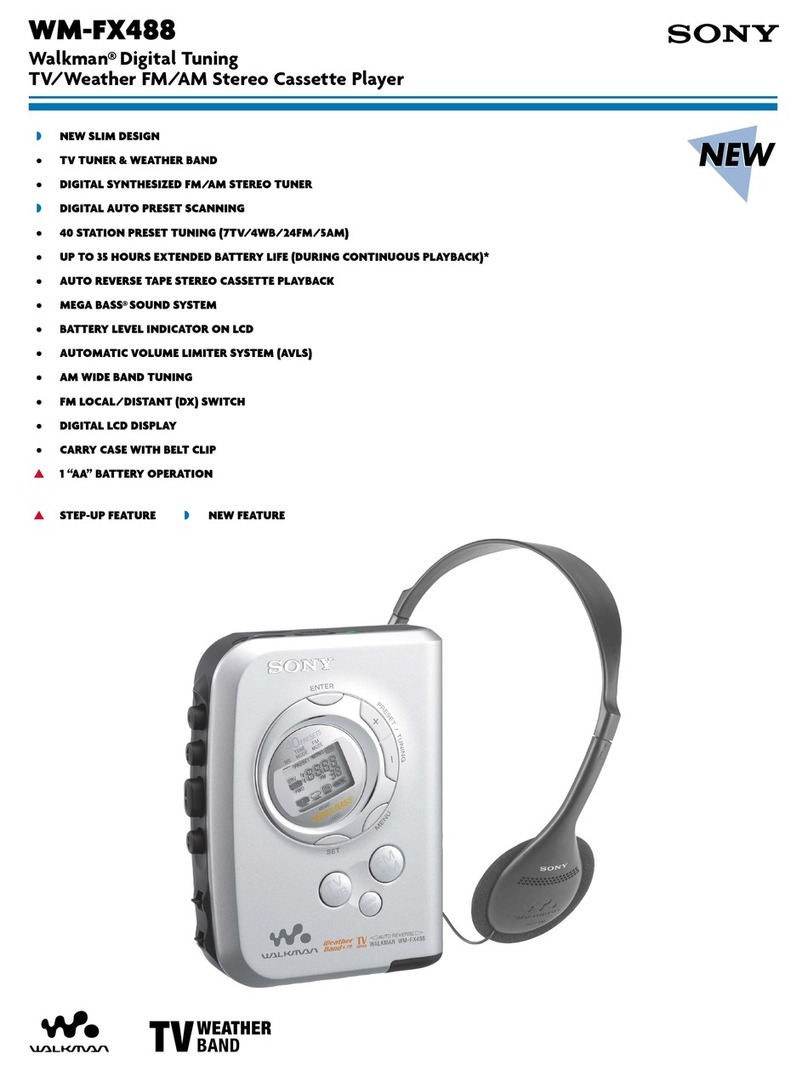

@

Standard

Record:

Deliver

the

standard

input

signal

level

to

the

input

jack

and

set

the

REC

LEVEL

control

to

obtain

the

standard

output

signal

level.

Standard

Input

Level

025

v

(1008

FWD

Back

tension

FF/REW

CQ-201B

70

—

120g*cm

(0.97

—

1.670z*inch)

Playback

Head

Azimuth

Adjustment

Procedure:

1.

Mode:

playback

test

tape

P-4-A100

(10

kHz

~10d8)

LINE

OUT

2.

Turn

the

adjustment

screw

for

the

maximum

output

levels.

If

these

levels

do

not

match,

turn

the

adjustment

screw

until

both

of

output

levels

match

together

within

1dB.

L-CH

output

peak

level

within

within

1

dB

R-CH

peak

screw

ition

—©

lock-nut

positio

Beak

R-CH

ae

peak

—10—

FWD

CQ-102C

|37—43g+*cm

(0.51

—

0.600z*

inch)

CQ-102C

|8-

10.5g*cm

(0.11

—0.150z*inch)