Sony TC-K333ESA User manual

Other Sony Cassette Player manuals

Sony

Sony Sports Walkman WM-FS497 User manual

Sony

Sony ICF-SW1000TS User manual

Sony

Sony TC-KA6ES User manual

Sony

Sony Walkman WM-FX161 User manual

Sony

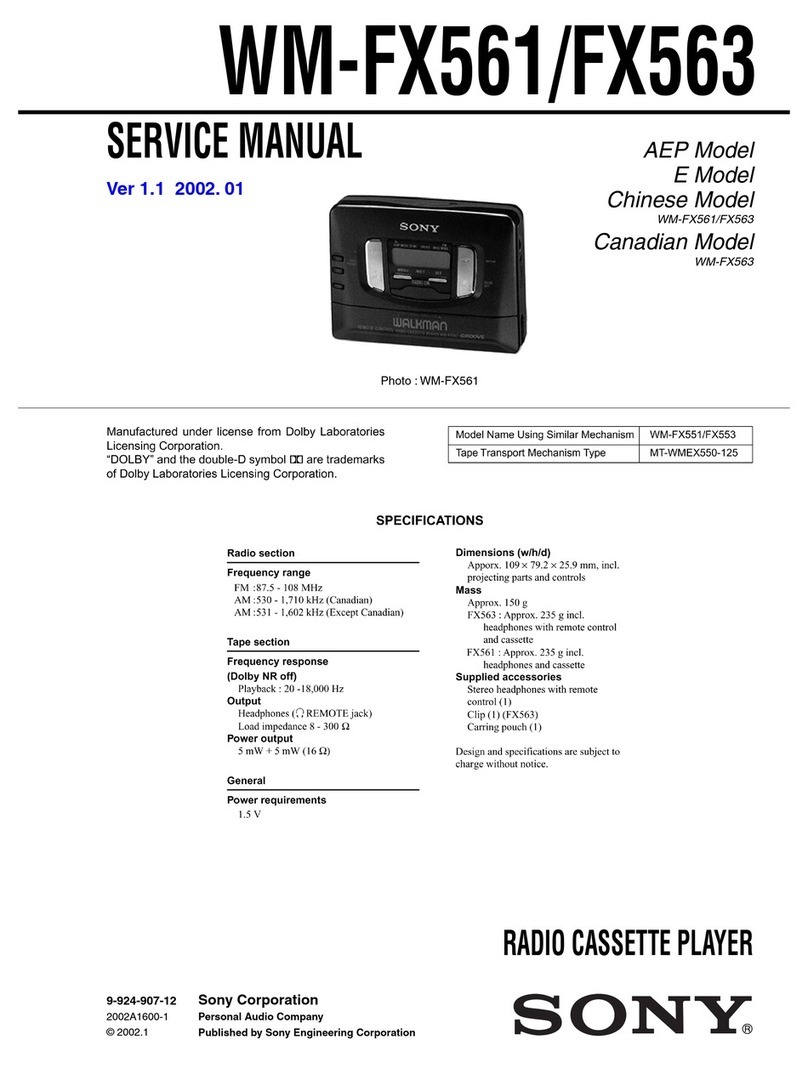

Sony Walkman WM-FX561 User manual

Sony

Sony Pressman TCM-4TR User manual

Sony

Sony WM-AF59 User manual

Sony

Sony Walkman WM-FX195 User manual

Sony

Sony Pressman TCM-465V User manual

Sony

Sony TC-WR10ES User manual

Sony

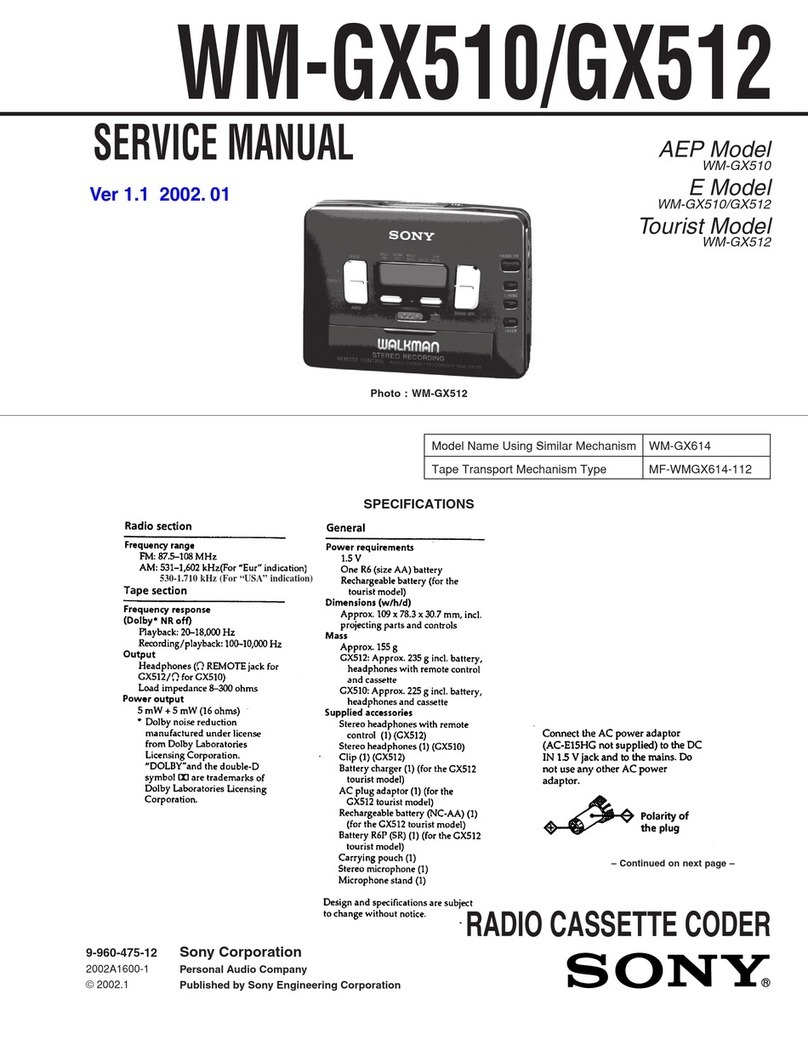

Sony WM-GX510 User manual

Sony

Sony Walkman WM-FX479 User manual

Sony

Sony CFD-151 User manual

Sony

Sony Walkman WM-GX322 User manual

Sony

Sony TCS-580V User manual

Sony

Sony TC-K81 User manual

Sony

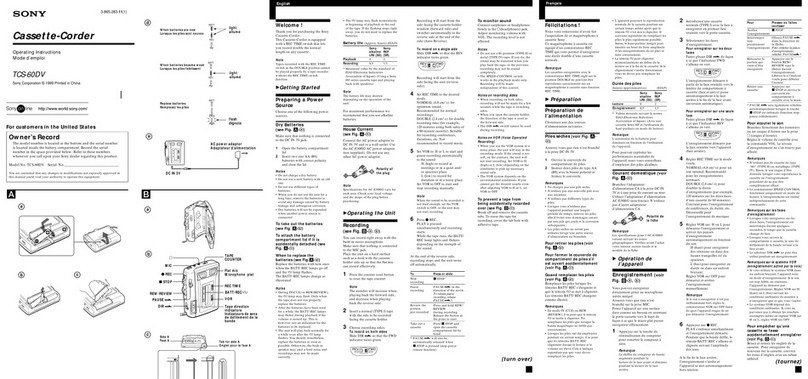

Sony Pressman TCS-60DV User manual

Sony

Sony WALKMAN WM-GX822 User manual

Sony

Sony WALKMAN WM-FS420RS User manual

Sony

Sony Walkman WM-FX522 Setup guide