‘D-W20A/B/C/E/G/J/U

4,

Electrical

circuit

adjustment

procedure

Perform

the

tape

transport

checks

and

head

azimuth

adjustment

before

following

checks

and

adjustments.

Adjustment

should

be

performed

in

the

order

of

alignment

steps.

In

the

steps

marked

with

an

asterisk

(*),

adjustment

should

be

performed

after

replacing

the

heads.

Perform

this

adjustment

with

the

NR

switch

set

to

OFF.

Check

and

Adjustment

Signal

input:

LINE

IN

1

kHz,

Cal.

—40

dB

+5.7dB+1dB

DOLBY

B

(Rec)

Sel

[Cal

evel:

400

Hz,

68s

(BIAS,

CUT)

|Output

terminal:

NR.

TP

DOLBY

c

P

Adjusting

Standard

Step

Item

Adjustment

point

value

Remarks

*2

|Confirming

|

Play

back

VTT644

(or

VTT724),

then

|DeckA

When

the

head

is

replaced,

adjust

confirm

that

the

level

at

LINE

OUT

is

[L:R153,R154/Bi|-8+

1.5dB

(Al—7dBs+1.5dB,{B]—8dBs+1.5dB

alerlee

eC

|

playback

gain

playback

gain

level.

Deck

A

L:R153

cut

by

+1dB

R154

cut

by

—1dB

R:R253

cut

by

+1dB

R254

cut

by

—1dB

Deck

B

L:

R122

cut

by

+1dB

R125

cut

by

—1dB

R:R222

cut

by

+1dB

R225

cut

by

—1dB

bias

frequency

10

(No..4256)

C925,Lead

through

a

1.2

MQQ

resistor,

then

adjust

L901

so

that

the

counter

reads

95

kHz.

*3.

|

Playback

Deck

A:

Play

back

VTT739,

then

con-

B72

cut

by

—1dB

frequency

firm

that

the

level

of

1

kHz

and

IL:

B73

cut

by

—2dB

response

10

kHz

signals

is

0.5

+

2

dB.

R:VR203

|

Deck

B:

B75

cut

by

—1dB

Deck

B:

Before

adjustment,

disconnect

|DeckB

0+2dB

B76

cut

by

—2dB

B72,

B73

(L-ch)

and

B75,

B76

L:872,873

(R-ch)

so

that

the

outputs

of

1

KHz

|L:B75,B76

and

10

kHz

signals

are

flat.

a

Adjusting

Connect

the

frequency

counter

to

the

|

L901

95

kHz

METAL

Position

+

10%

=

kHz

outputs

satisfy

the

standard

values

with

respect

to

1

kHz

output.

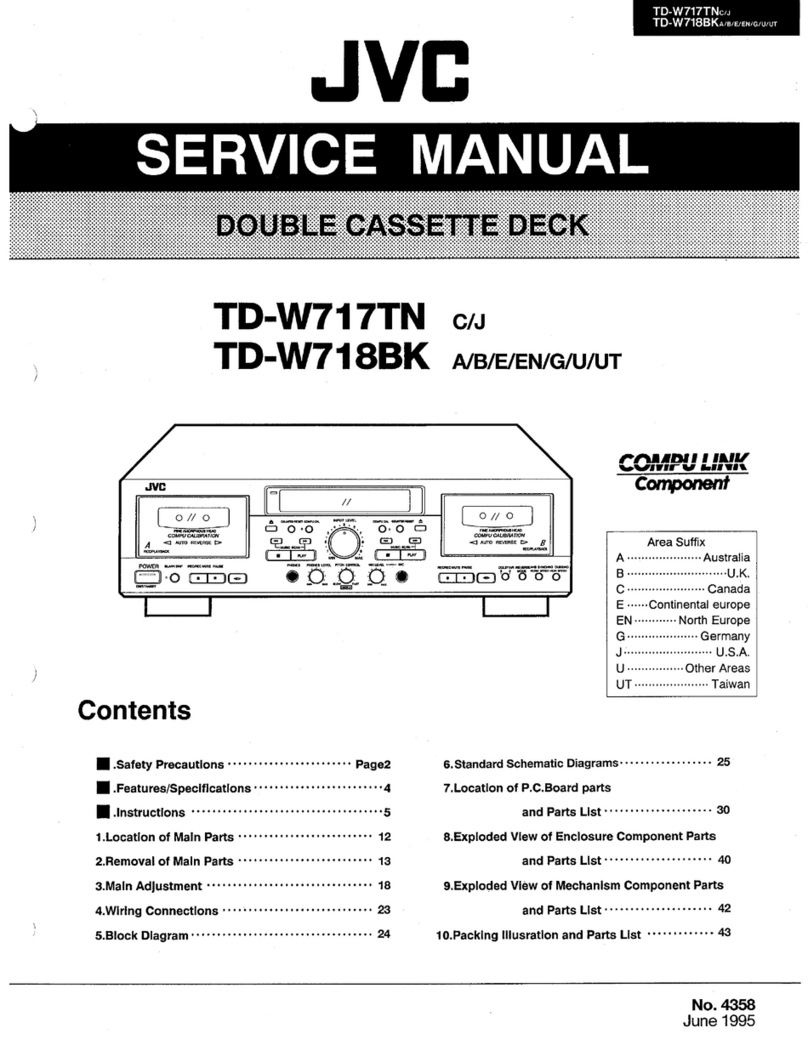

Response

(dB)

a

Decrease

in

high

frequencies

QO

50

Hz

1

kHz

ode

Increase

in

high

frequencies

Low

bias

current

Appropriate

bias

current

High

bias

current

12.5

kHz

Frequencies

*5

|Recording

|

1)

NR

switch:

OFF

For

With

respect

|

CrO2

frequency

2)

Record

a

1kHz

signal

at

an

input

;

Normal

to

1

kHz

50Hz

Q+3dB

response

reference

level

of

—20dB,

then

|

tape:

reference:

12.5kHz

O+4dB

record

50

Hz

and

12.5

kHz

signals

|}

L:

VR102;}

At

50

Hz,

Metal

and

play

them

back.

At

this

time,

|

R:VR202}

0+3

dB;

50Hz

0+3dB

adjust

VR102

and

VR202

so

that

At

12.5

kHz,

12.5kHz+1+4dB

the

deviation

of

50Hz

and

12.5

0+3dB