– 2 –

TABLE OF CONTENTS

Servicing Notes ............................................................... 2

1. GENERAL

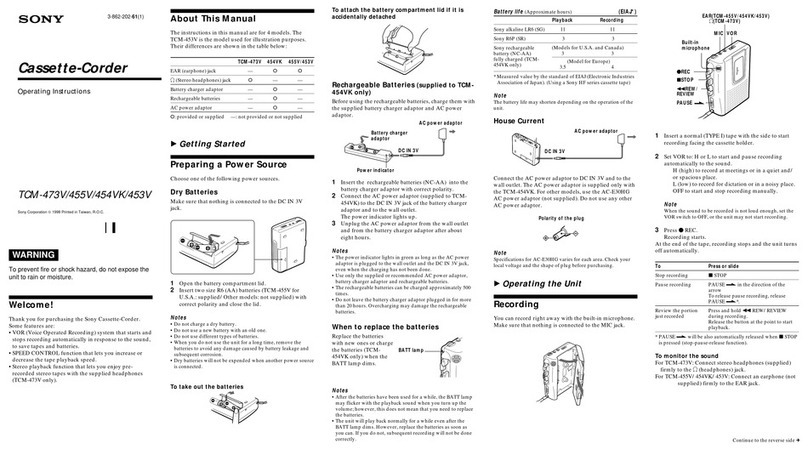

Playing a Tape ................................................................ 3

Recording on a Tape Manually....................................... 4

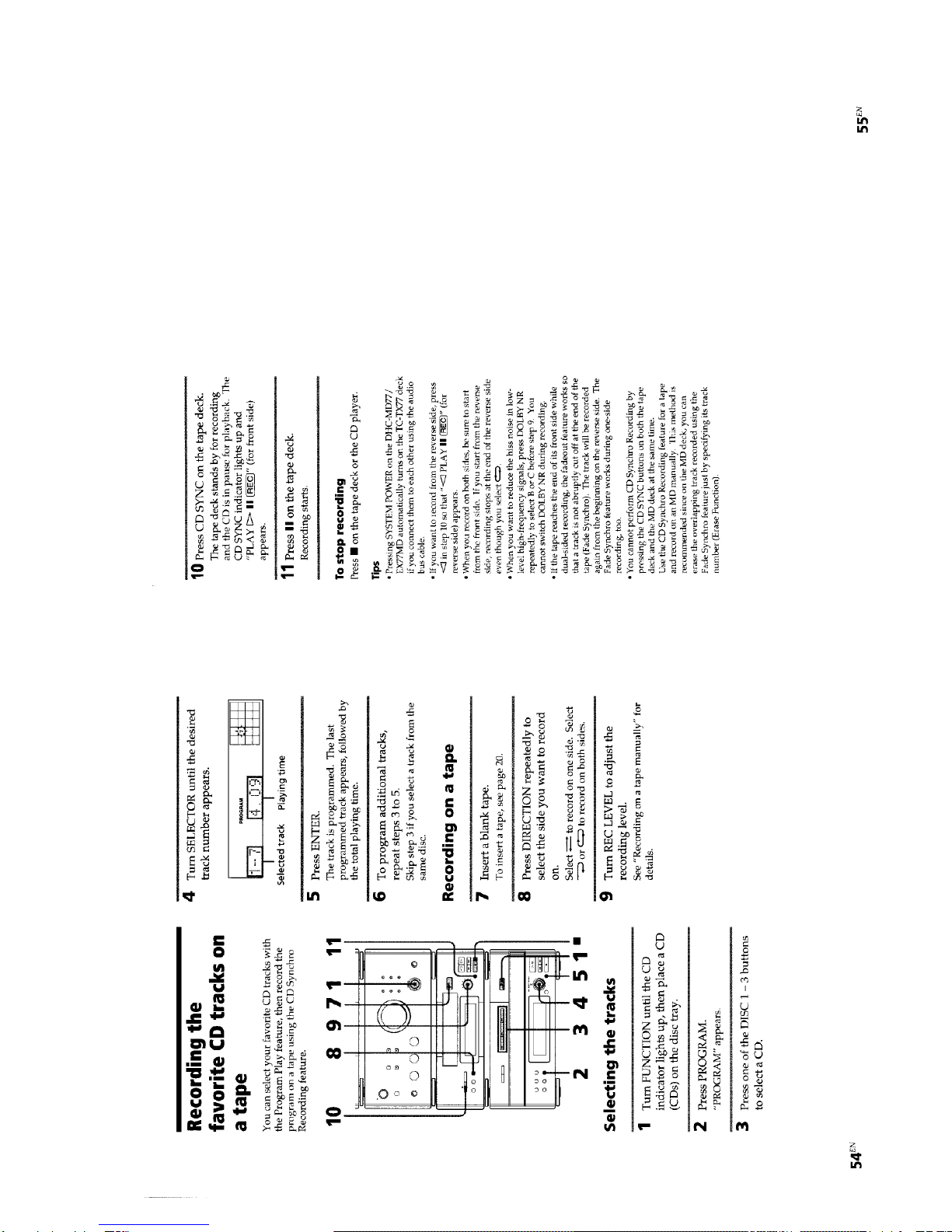

Recording the favorite CD Tracks on a Tape.................. 5

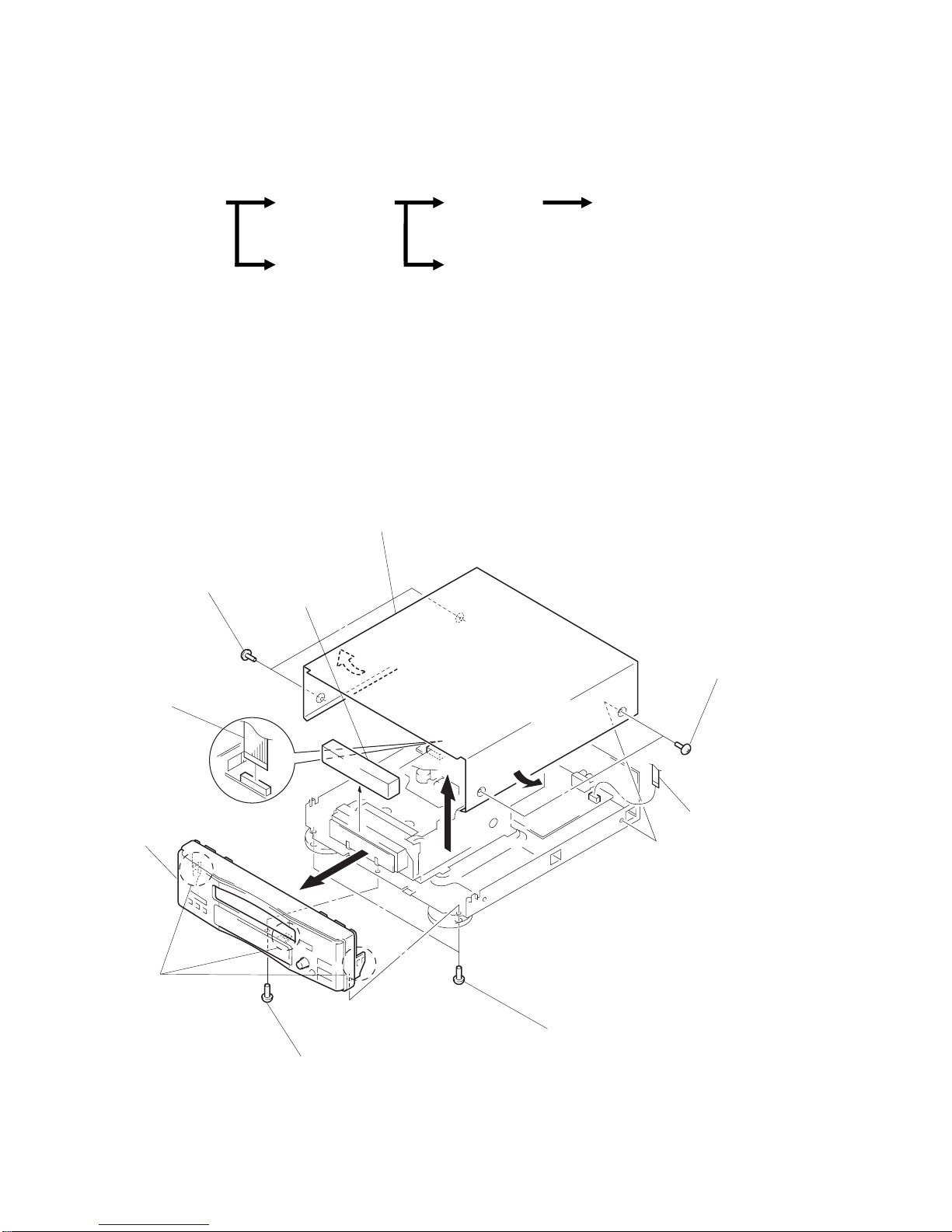

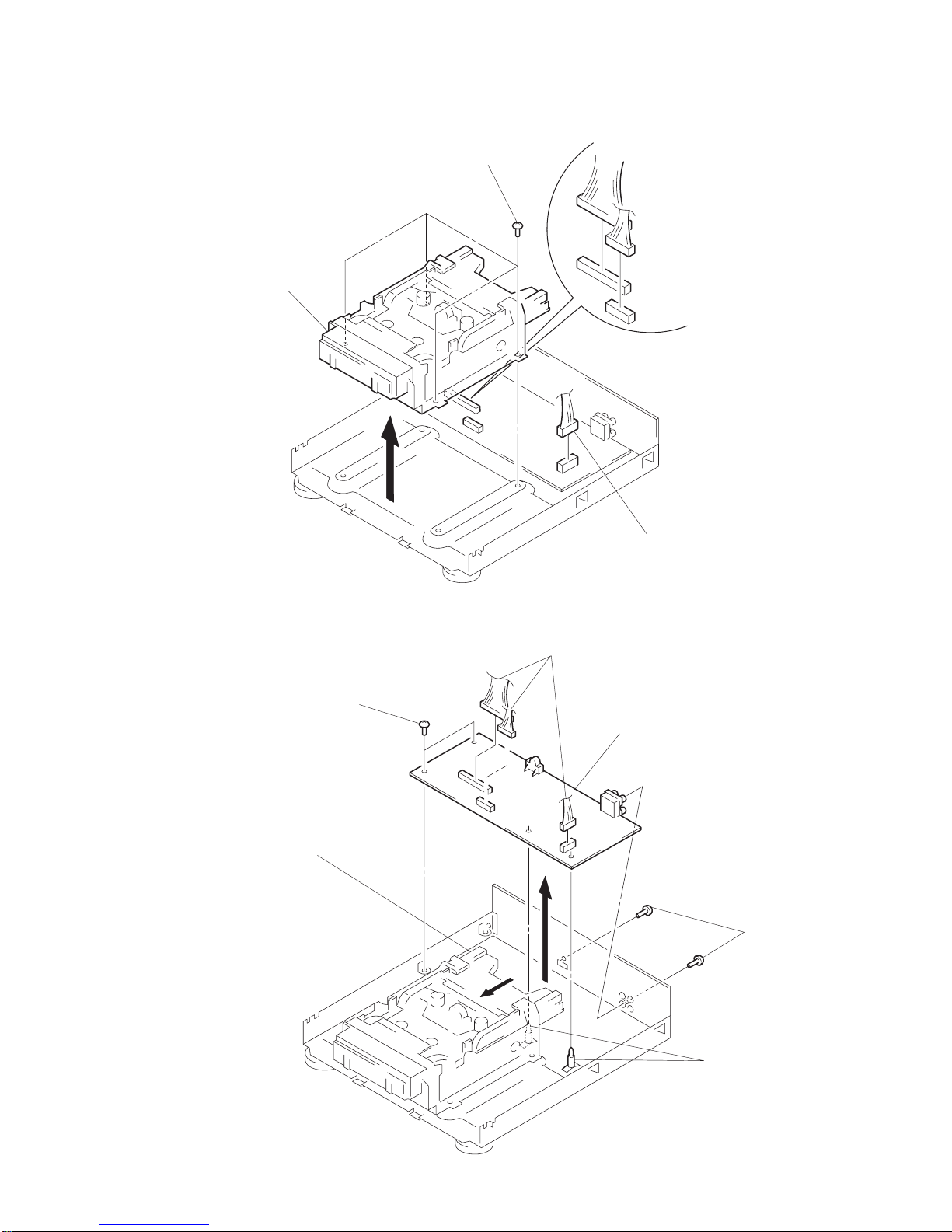

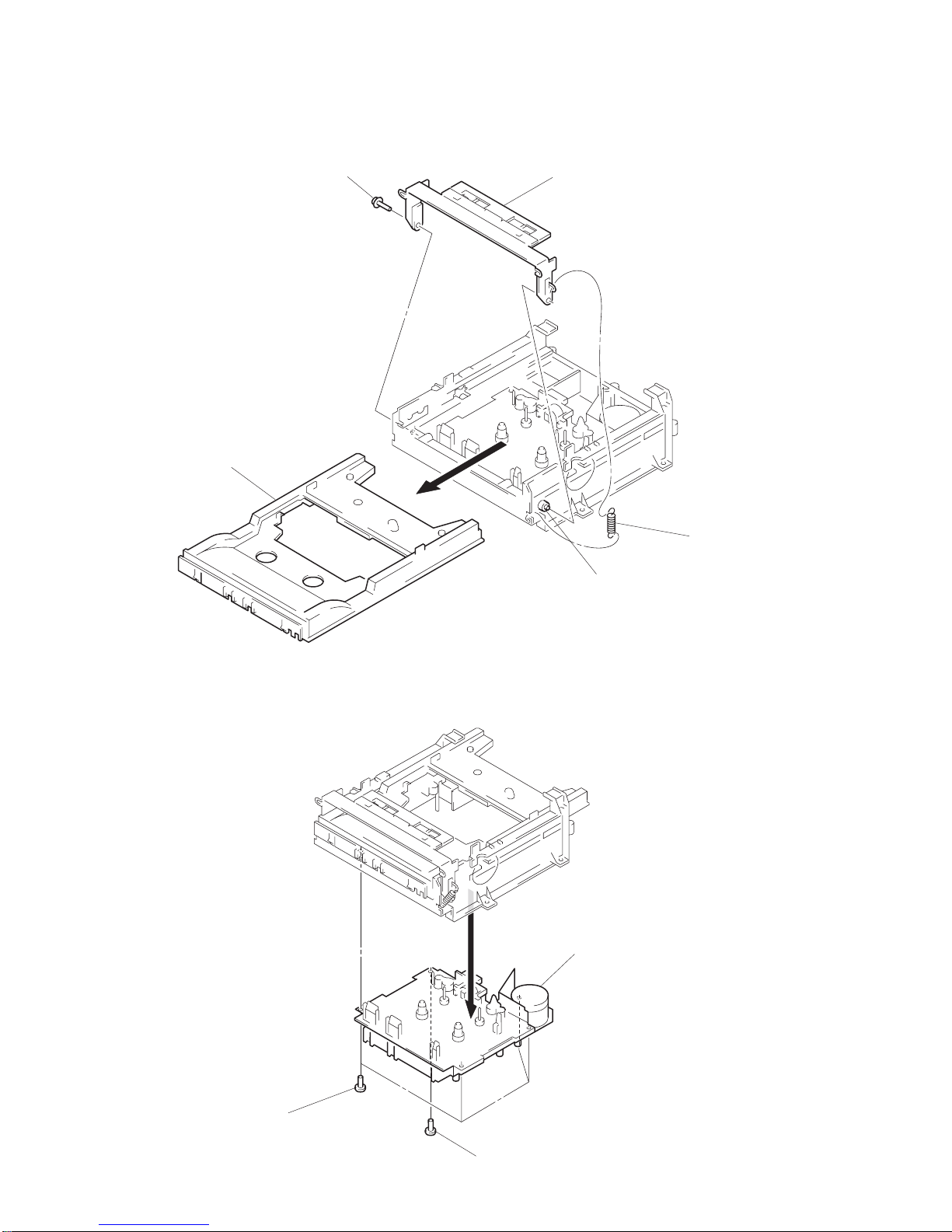

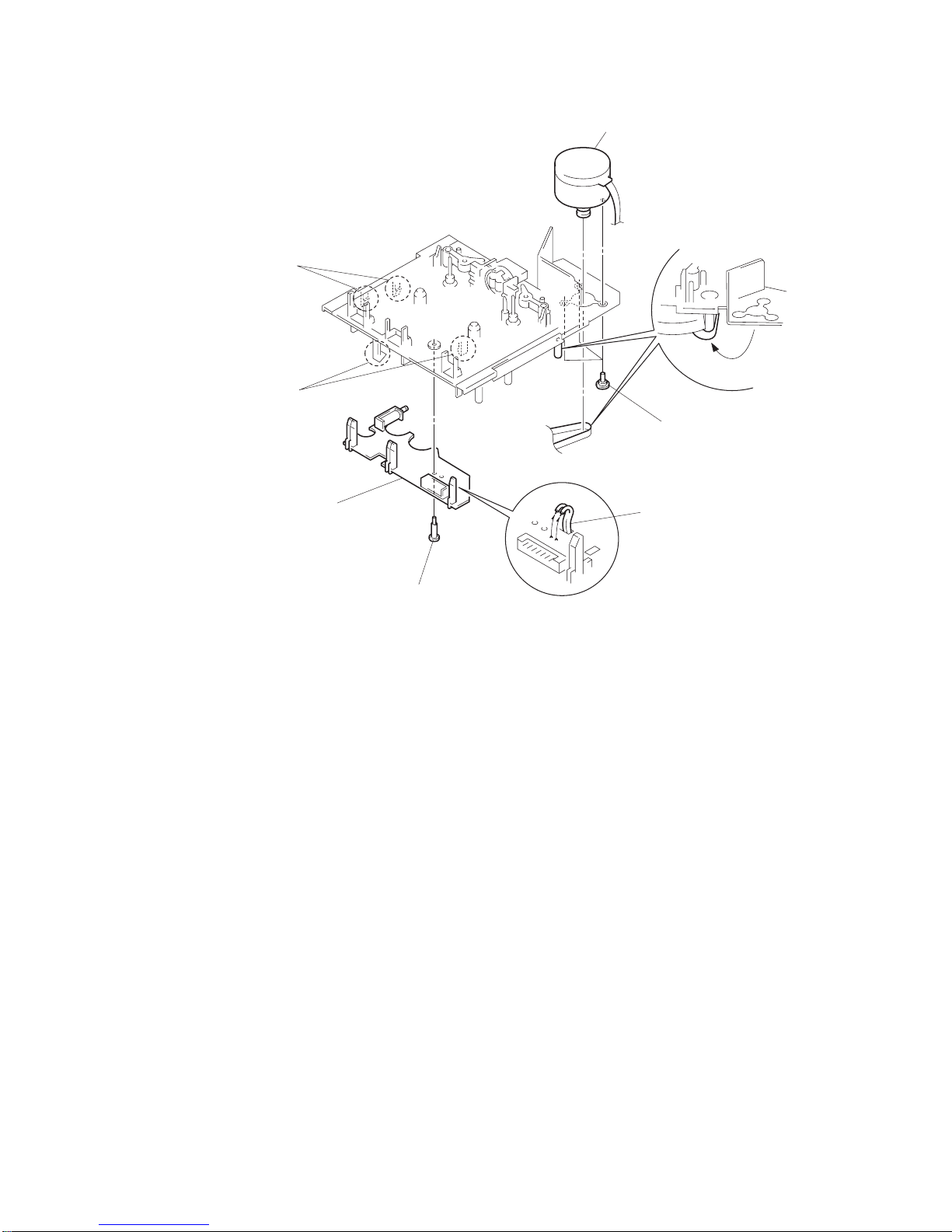

2. DISASSEMBLY ........................................................ 6

3. MECHANICAL ADJUSTMENTS ...................... 10

4. ELECTRICAL ADJUSTMENTS ........................ 10

5. DIAGRAMS

5-1. Printed Wiring Boards .................................................... 15

5-2. Schematic Diagram ........................................................ 19

5-3. IC Pin Function .............................................................. 25

6. EXPLODED VIEWS ............................................... 27

7. ELECTRICAL PARTS LIST............................... 32

SERVICING NOTES

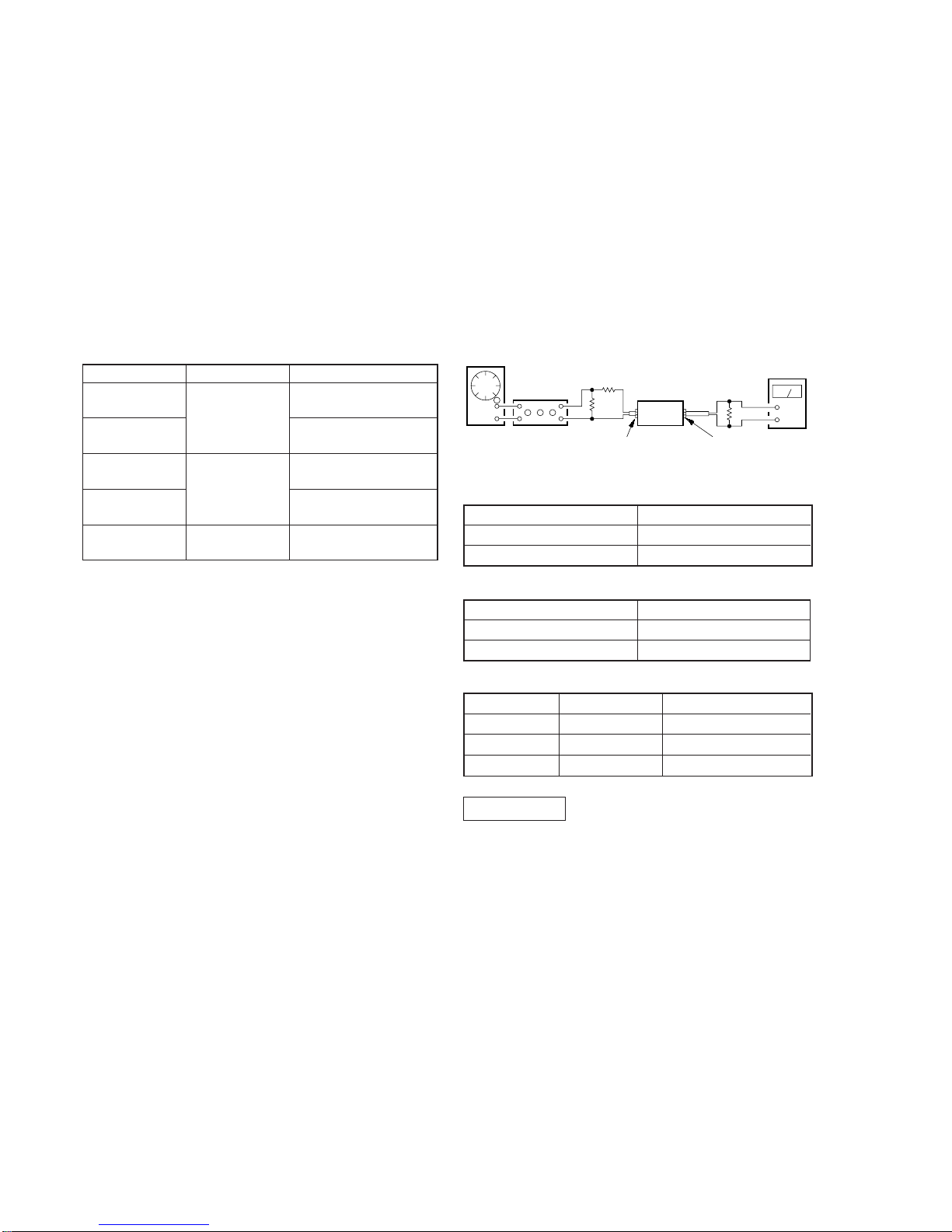

How to operate with a single unit.

Normally, this set is not operated with its own.

The exclusive jig (J-2501-078-A) and service box (PFJ-1) are nec-

essary to operate the set with a single unit.

Turn the power set of the service box ON. Then press the

ENTER/NEXT button and SLEEP button at the same time to

turn the power on.

Connection:

• KEY/FL tube/LED check mode.

To enter KEY/FL tube/LED check mode, press the ENTER/NEXT

and REC buttons at the same time.

Under mode, every time when press any key or turn

MULTI CONTROLLER knob, change to next situation.

1All LED indicators light on

2All FL tube indicators light on

3A part of FL tube light on mode 1. (Indicated ST-SEG)

4A part of FL tube light on mode 2. (Indicated RDS-SEG)

5KEY check mode

Note:

1) All LED light on mode is kept, when buttons which is pressed

to enter all LED light on mode, release same time.

When release them separate timing, it is moved to next All

LED light on mode.

2) After all LED light on mode, light on point remove one by one,

when any button pressed or MULTI CONTROLLER knob

turned.

3) Under KEY check mode, every time buttons pressed numeri-

cal value of “KEY” in FL tube increase.

And that time, numerical value of “ECDR” increase when

MULTI CONTROLLER button turn to + direction, and it

decrease turn to – direction.

When you want to finish this mode, unplug the power of amplifier

or turn off PFJ-1 of POWER switch.

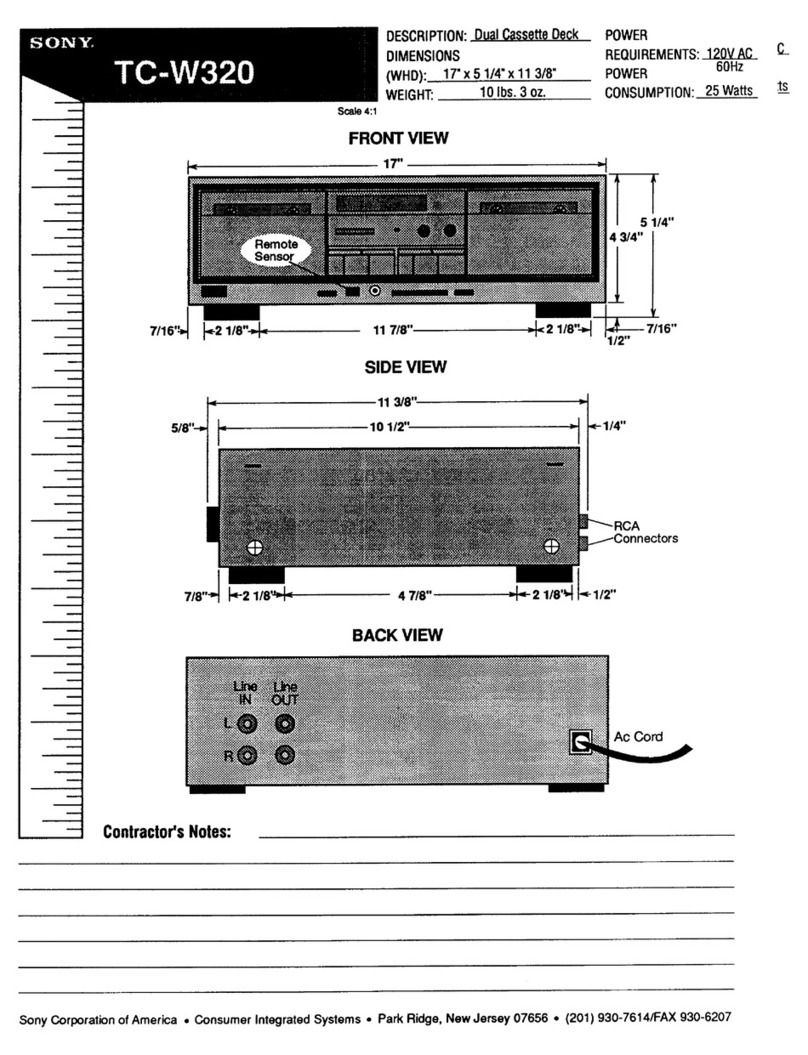

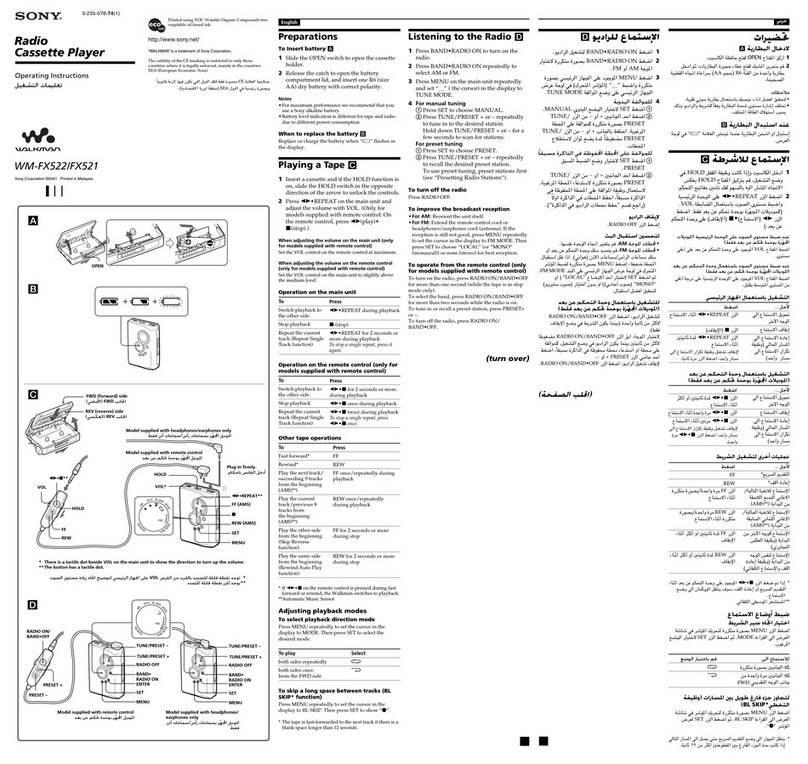

POWER SW

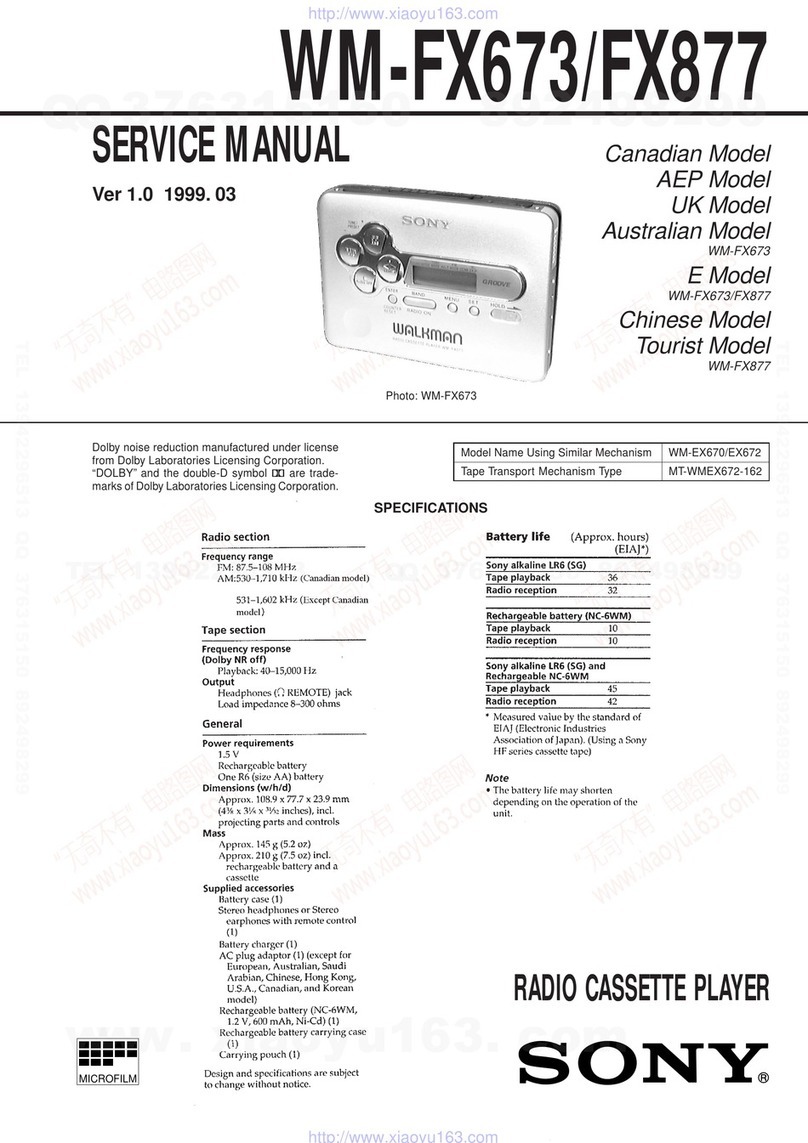

FH-E939, 838,937

CDP/TC CN904

17P CN902

7P CN101 7P

JIG

(J-2501-078-A)

SERVICE BOX (PFJ-1)

SET

SYSTEM CONTROL

CORD WITH CONNECTOR 7P