4

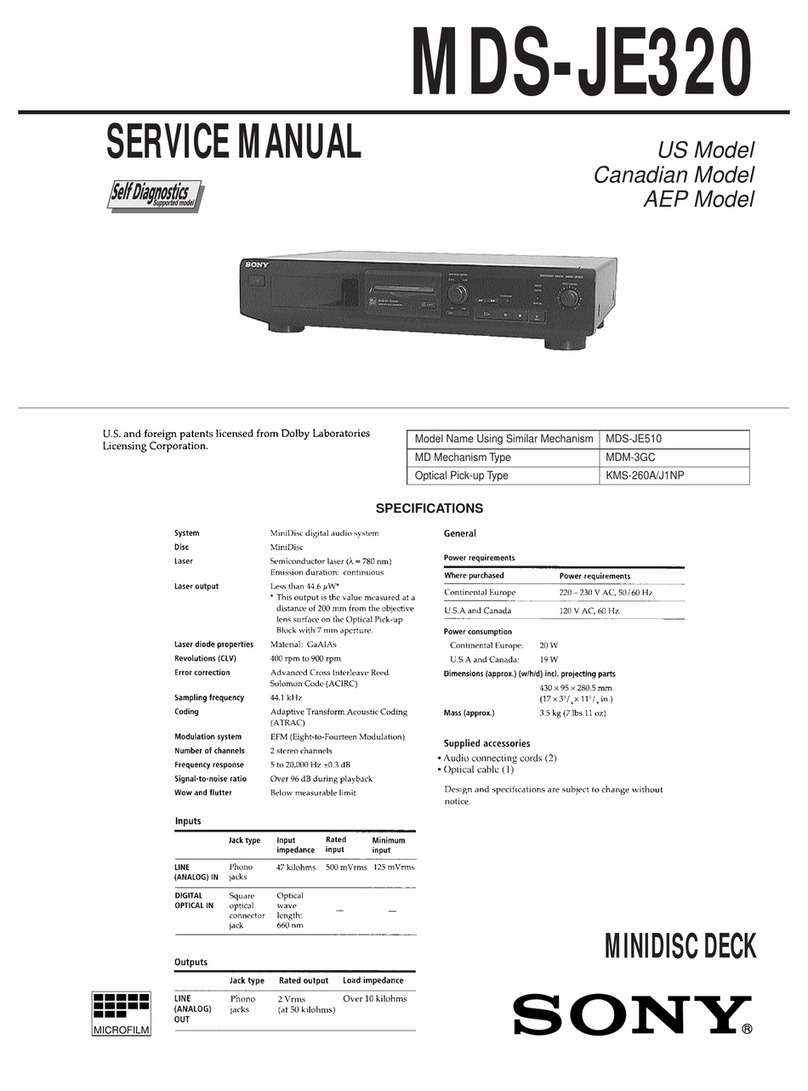

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur,and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the Self-

Diagnosis Function (Error History Display Mode)”.

The deck’s self-diagnosis function automatically checks the condition of the MD deck when an error occurs, then issues a three- or five-digit

code and an error message on the display. If the code and message alternate, find them in the following table and perform the indicated

countermeasure. Should the problem persist, consult your nearest Sony dealer.

PROCEDURE FOR USINGTHE SELF-DIAGNOSIS FUNCTION (ERROR HISTORY DISPLAY MODE)

Note: Perform the self-diagnosis function in the “error history display mode”in the test mode. The following describes the least required procedure. Be

careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button to exit the mode.

1. While pressing the lAMS Lknob and xbutton, connect the power plug to the outlet, and release the lAMS Lknob and

xbutton. When the test mode is set “[Check]”is displayed.

2. Turn the lAMS Lknob and when “[Service]”is displayed, press the YES button.

3. Turn the lAMS Lknob to display “Err Display”.

4. Press the YES button to sets the error history mode and displays “op rec tm”.

5. Select the contents to be displayed or executed using the lAMS Lknob.

6. Press the lAMS Lknob to display or execute the contents selected.

7. Press the lAMS Lknob another time to return to step 4.

8. Press the MENU/NO button to display “Err Display”and release the error history mode.

9. To release the test mode, press the REPEAT button. The unit sets into the STANDBY state and the test mode ends.

Three- or five-

digit code/

Message Cause/Remedy

C11/Protected The inserted MD is record-protected.

Take out the MD and close the record-

protect slot (page 15).

C12/Cannot Copy

You tried to record a CD with a format

that the external device connected to the

deck does not support, such as CD-ROM

or video CD.

Remove the disc and insert a music

CD.

C13/REC Error

The recording was not made properly.

Set the deck in a stable surface, and

repeat the recording procedure.

The inserted MD is dirty (with smudges,

fingerprints, etc.), scratched, or

substandard in quality.

Replace the disc and repeat the

recording procedure.

C13/Read Error The deck could not read the TOC on the

MD properly.

Take out the MD and insert it again.

C14/Toc Error

The deck could not read the TOC on the

MD properly.

Insert another disc.

If possible, erase all the tracks on the

MD (page 32).

C41/Cannot Copy

The sound source is a copy of

commercially available music software, or

you tried to record a CD-R (Recordable

CD).

The Serial Copy Management System

prevents making a digital copy

(page 52). You cannot record a CD-R.

C71/Din Unlock

The sporadic appearance of this message

is caused by the digital signal being

recorded. This will not affect the

recording.

While recording from a digital component

connected through the DIGITAL IN

connector, the digital connecting cable

was unplugged or the digital component

turned off.

Connect the cable or turn the digital

component back on.

E0001/

MEMORY NG

There is an error in the internal data that

the deck needs in order to operate.

Consult your nearest Sony dealer.

E0101/

LASER NG

There is a problem with the optical

pickup.

The optical pickup may have failed.

Consult your nearest Sony dealer.

Three- or five-

digit code/

Message Cause/Remedy