3

MDS-S9

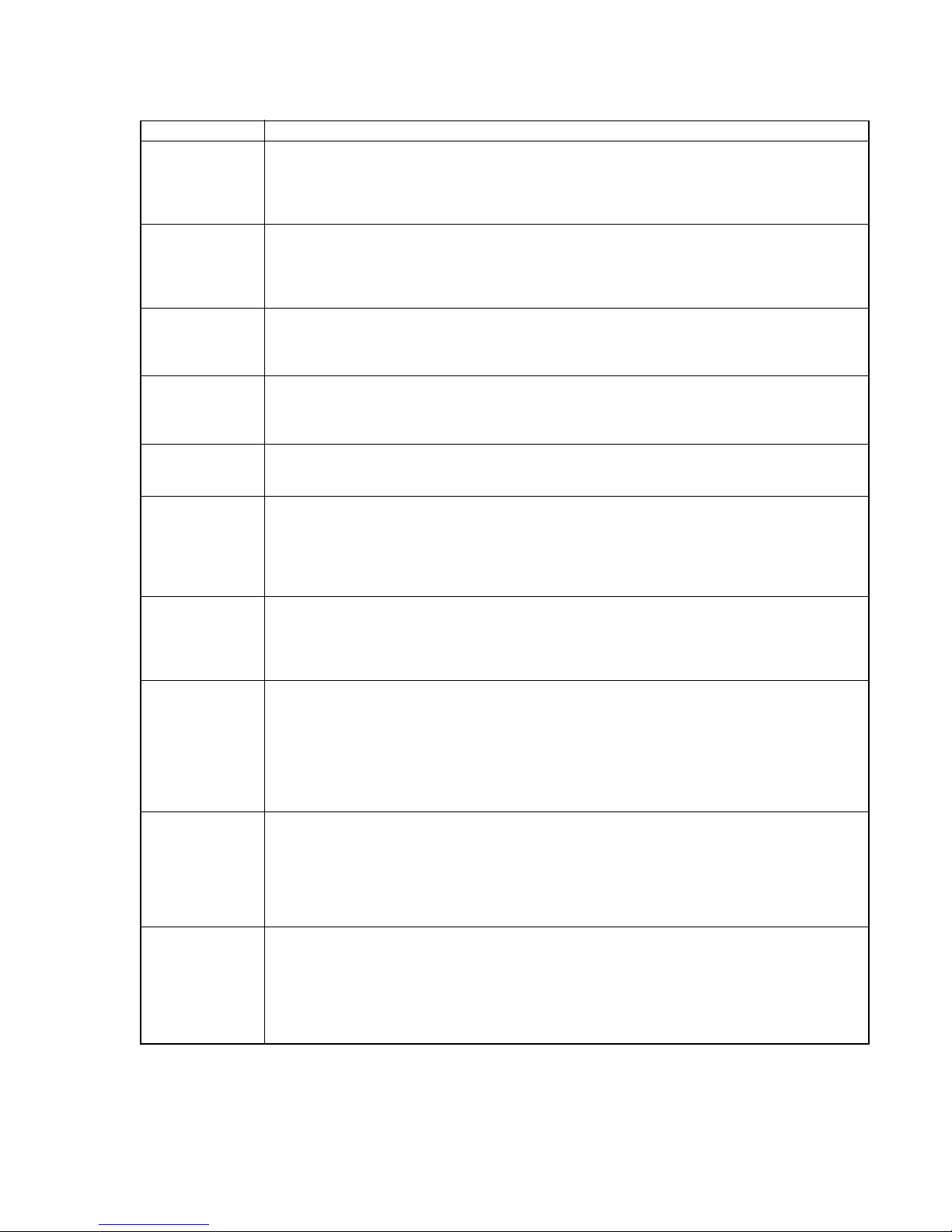

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Display Details of History

op rec tm Cumulative recording time is displayed.

When cumulative recording time is over 1 minute, the hour and minute are displayed as they are.

When it is under 1 minute, “Under 1 min”is displayed.

The displayed time is the total time the laser is set to the high power state.

This is about 1/4 of the actual recording time. The time is displayed in decimal digits.

op play tm Cumulative playing time is displayed.

When cumulative playing time is over 1 minute, the hour and minute are displayed as they are.

When it is under 1 minute, “Under 1 min”is displayed.

The displayed time is the total of the actual play time. Pauses are not counted.

The time is displayed in decimal digits.

spdl rp tm Cumulative spindle motor running time is displayed.

When cumulative spindle motor run time is over 1 minute, the hour and minute are displayed as they are.

When it is under 1 minute, “Under 1 min”is displayed.

The time is displayed in decimal digits.

retry err Displays the total number of retries during recording and number of retry errors during playback.

Displayed as “r ss p ss”.

“r”indicates the retries during recording while “p”indicates the retry errors during playback.

The number of retries and retry errors are displayed in hexadecimal digits from 00 to FF.

total err Displays the total number of errors.

Displayed as “total ss”.

The number of errors is displayed in hexadecimal digits from 00 to FF.

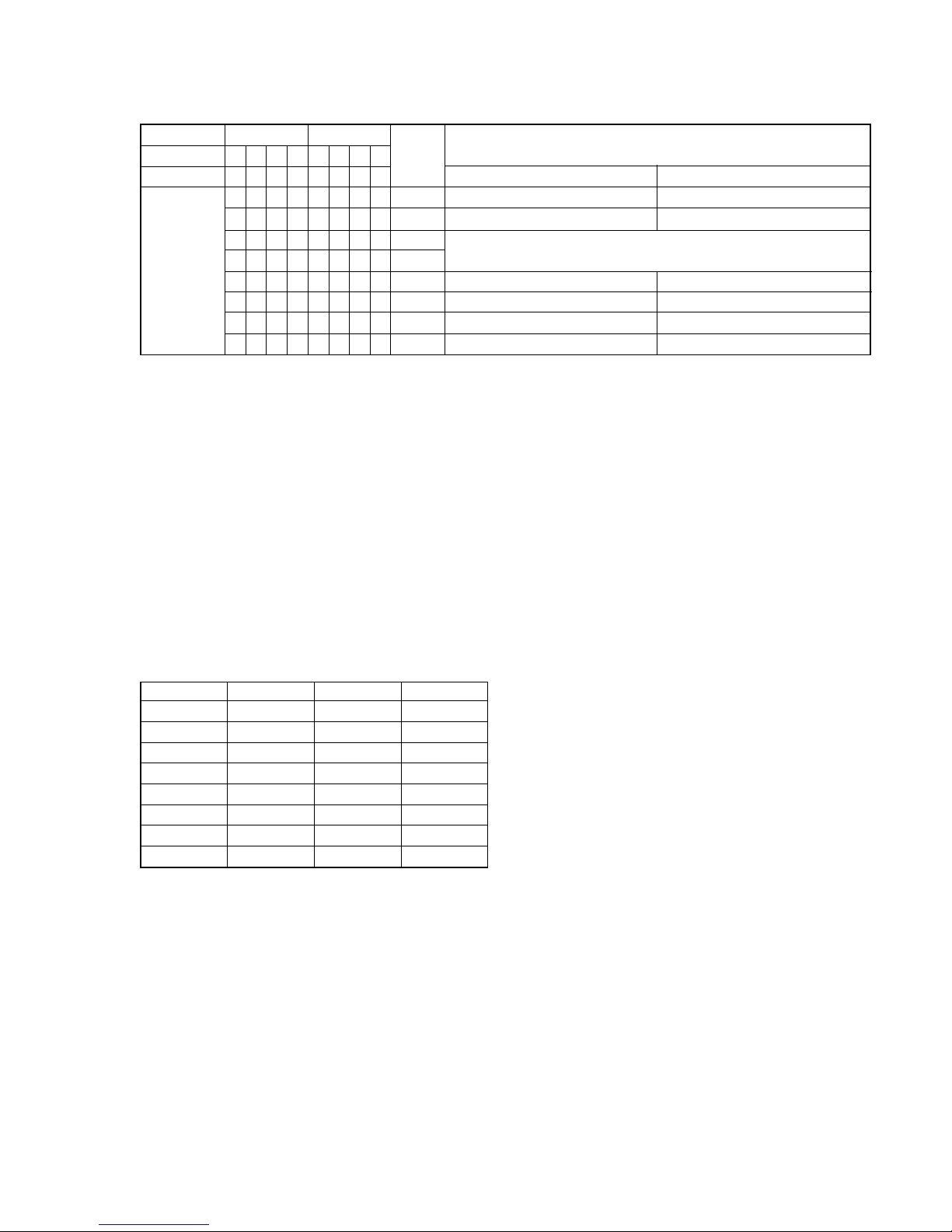

err history Displays the 10 latest errors.

Displayed as “0sErrCd @@”.

sindicates the history number. The smaller the number, the more recent is the error. (00 is the latest)

@@ indicates the error code.

Refer to the following table for the details. The error history can be switched by turning the [ AMS ]

knob.

retry adrs Display the 5 latest retry address.

Display as “ss ADRS@@@@”.

ss indicates the history number. The smaller the number, the more recent is the error. (00 is the latest)

@@@@ indicates the cluster of retry address.

The number of retry address can be switched by turning the [ AMS ] knob.

er refresh Mode to clear the error history and retry address history.

Procedure:

1) Press the [ AMS ] button.

2) The display will change to “er refresh?”, and then press the [YES] button.

The operation is over if “Complete!”is displayed.

After this mode was executed, check the following:

•The data have been cleared.

•Perform the recording and playing to check that the mechanism operates normally.

op change Mode to clear cumulative time of “op rec tm”and “op play tm”.

These historical data are used to determine the timing when the optical pick-up is to be replaced. When the

optical pick-up was replaced, perform this operation to clear historical data.

Procedure:

1) Press the [ AMS ] button.

2) The display will change to “op chang?”, and then press the [YES] button.

The operation is over if “Complete!”is displayed.

spdl change Mode to clear cumulative time of “spdl rp tm”.

This historical data is used to determine the timing when the spindle motor is to be replaced. When the spindle

motor was replaced, perform this operation to clear historical data.

Procedure:

1) Press the [ AMS ] button.

2) The display will change to “spdl chang?”, and then press the [YES] button.

The operation is over if “Complete!”is displayed.

. >

. >

. >

. >

. >