GDM-90W01T5

–3 –

TABLE OF CONTENTS

Section Title Page

1. GENERAL................................................................... 4

2. DISASSEMBLY

2-1. Cabinet Removal ................................................. 11

2-2. D Board Removal ................................................ 11

2-3. G Board Removal ................................................. 12

2-4. A Board Removal ................................................. 12

2-5. M Board Removal ................................................ 13

2-6. L Board Removal ................................................. 13

2-7. Service Position .................................................... 14

2-8. Harness Location

(1) D Block Side ....................................................... 14

(2) G Block Side ....................................................... 15

2-9. H1, H2 and J Boards Removal............................. 15

2-10. Picture Tube Removal ......................................... 16

3. SAFETY RELATED ADJUSTMENT............. 17

4. ADJUSTMENTS ...................................................... 18

Section Title Page

5. DIAGRAMS

5-1. Block Diagrams ................................................... 21

5-2. Frame Schematic Diagram .................................. 27

5-3. Circuit Boards Location ...................................... 29

5-4. Schematic Diagrams and Printed Wiring Boards ... 29

(1) Schematic Diagram of D Board .......................... 33

(2) Schematic Diagrams of G, GA, GB and

J Boards ........................................................... 37

(3) Schematic Diagrams of H1, H2, L and

M Boards ......................................................... 41

(4) Schematic Diagram of A Board .......................... 45

5-5. Semiconductors ................................................... 52

6. EXPLODED VIEWS

6-1. Chassis ................................................................. 54

6-2. Picture Tube ........................................................ 55

6-3. Packing Materials ................................................ 56

7. ELECTRICAL PARTS LIST ............................ 57

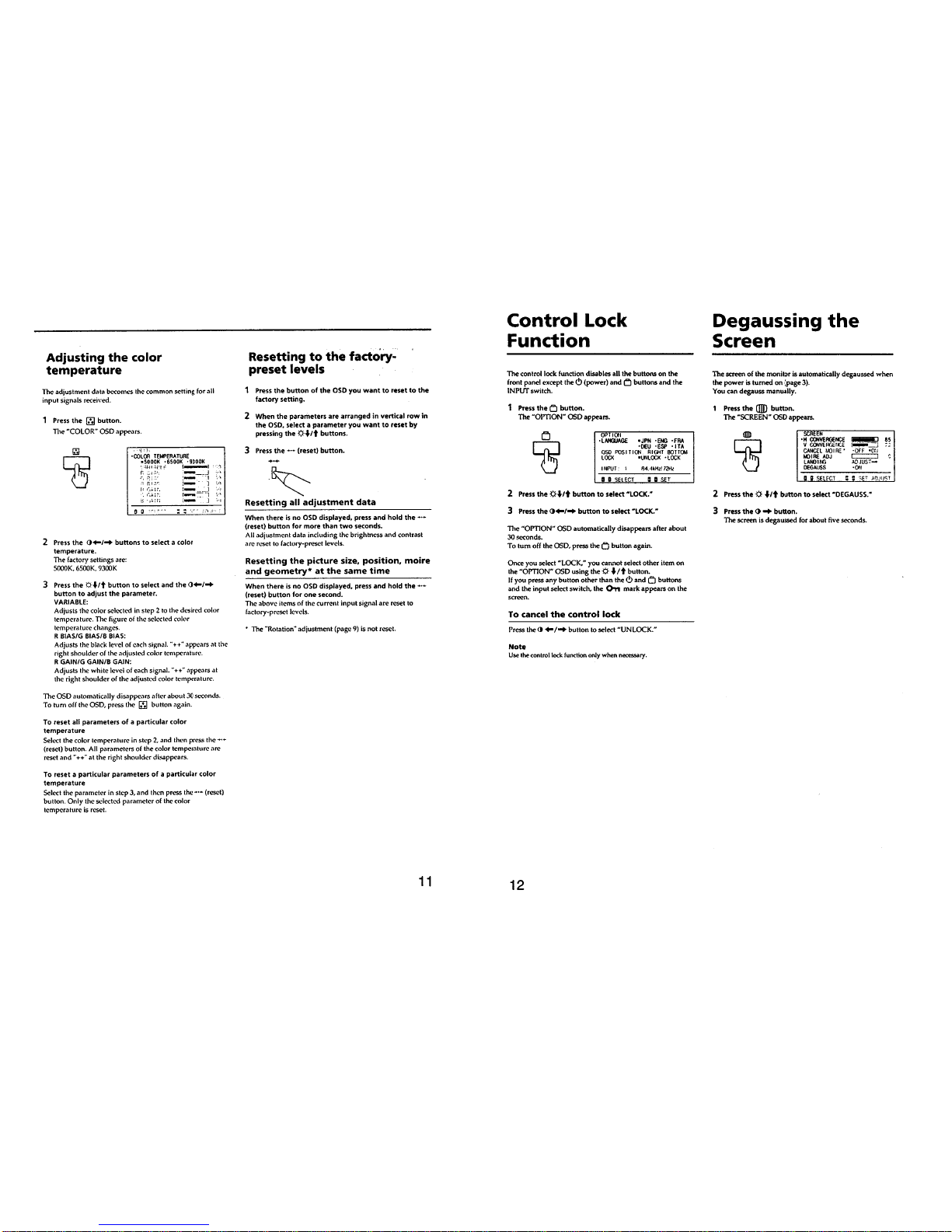

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ¡

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERATION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

Note: Hand degauss must be used on stand-by or power-off condition.

This model has an automatic earth magnetism correction function by using an earth

magnetism sensor and a LCC coil. When using a hand degauss while monitor (LCC

coil) is being operated, it sometimes gets magnetized, and the system may not work

properly as a result.