3

HCD-X1

•Theinstructions in this manual describe the

controls on the remote. You can also use the

controls on the system if theyhave the same or

similar names as those on the remote.

•The Control Menu items may be different

depending on the area.

•“DVD” may be used as a general term for

DVD VIDEOs, DVD+RWs/DVD+Rs, and

DVD-RWs/DVD-Rs.

•Measurements are expressed in feet (ft) for

North American models.

•Thefollowing symbols are used in this

manual.

*MP3 (MPEG1 Audio Layer 3) is a standard format

defined by ISO/MPEG which compresses audio

data.

The “DVD VIDEO” logo and “DVD-RW” logo are

trademarks.

*1Except for multi-channel playback area.

*2CD text data can be displayed (album title only).

Note about CDs/DVDs

The system can play CD-ROMs/CD-Rs/CD-

RWs recorded in the following formats:

–audioCDformat

–videoCDformat

About This Manual

Symbol Meaning

Functions available for DVD

VIDEOs, DVD-Rs/DVD-RWs in

video mode, and DVD+Rs/

DVD+RWs

Functions available for DVD-RWs

in VR (Video Recording) mode

Functions available for VIDEO

CDs (including Super VCDs or CD-

Rs/CD-RWs in video CD format or

Super VCD format)

FunctionsavailableforSuperAudio

CDs

Functions available for music CDs

or CD-Rs/CD-RWs in music CD

format

Functions available for DATA CDs

(CD-ROMs/CD-Rs/CD-RWs

containing MP3* audio tracks and

JPEG image files)

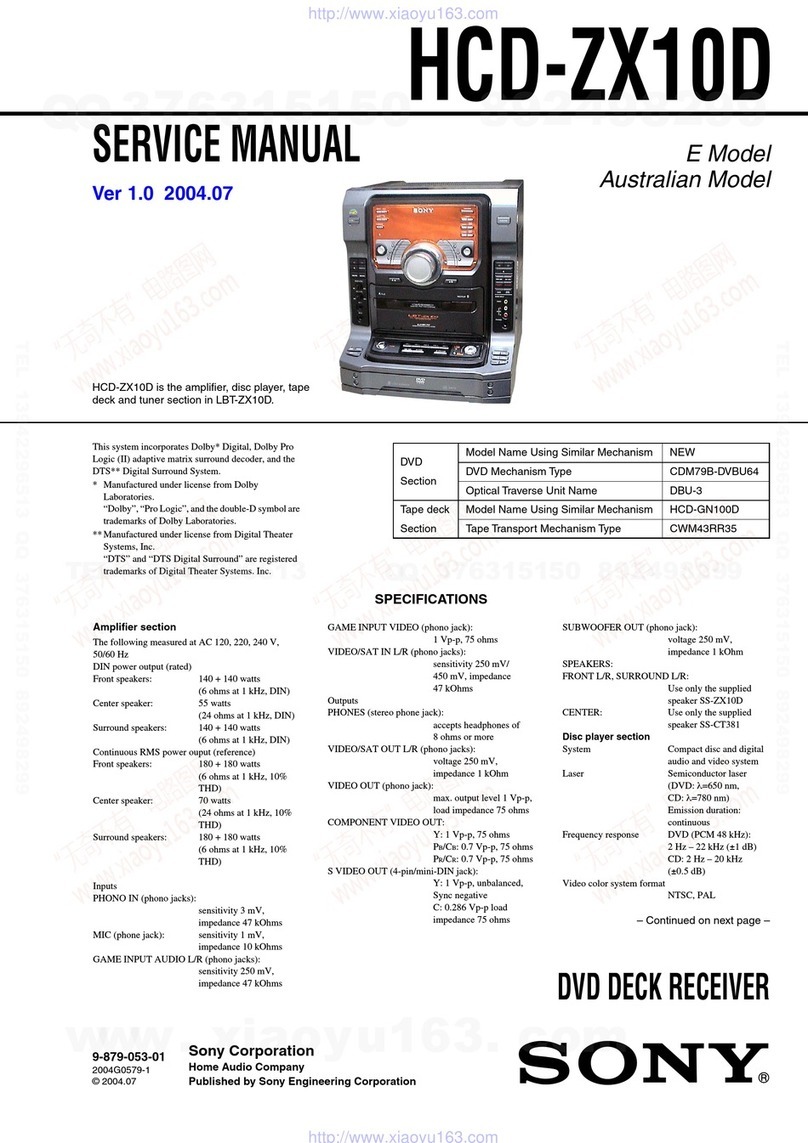

This System Can Play the

Following Discs

Format of

discs Disc logo

DVD VIDEO

DVD-RW

VIDEO CD

Super Audio

CD*1

Audio CD*2

CD-R/CD-RW

(audio data)

(MP3 files)

(JPEG files)

–MP3audiotracks, JPEG image files, and

DivXvideo files of format conforming to ISO

9660 Level 1/Level 2, or its extended format,

Joliet

The system can play DVD-ROMs/DVD+RWs/

DVD-RWs/DVD+Rs/DVD-Rs recorded in the

following formats:

–DivXvideofiles of format conforming to

UDF.

Example of discs that the

system cannot play

The system cannot play the following discs:

•CD-ROMs recorded in PHOTO CD format

•Datapart of CD-Extras

•DVD Audios

•DVD-RAMs

•ADVD VIDEO with a different region code.

•Adiscthat has a non-standard shape (e.g., card

shaped, heart shaped).

•Adiscthathas a commercially available

accessory attached, such as a label or ring.

•Anadaptertoconvert an 8 cm disc to standard

size.

•Adisc with paper or stickers on it.

•Adiscthathas the adhesive of cellophane tape

or a sticker still left on it.

Notes about CD-R/CD-RW/DVD-R/

DVD-RW/DVD+R/DVD+RW

In some cases, CD-R/CD-RW/DVD-R/DVD-RW/

DVD+R/DVD+RW cannot be played on this system

due to the recording quality or physical condition of the

disc, or the characteristics of the recording device and

authoring software.

The disc will not play if it has not been correctly

finalized. For more information, see the operating

instructions for the recording device.

Note that discs created in the Packet Write format

cannot be played.

Music discs encoded with

copyright protection

technologies

This product is designed to play back discs that

conform to the Compact Disc (CD) standard.

Recently, various music discs encoded with copyright

protection technologies are marketed by some record

companies. Please be aware that among those discs,

there aresome thatdo not conform to the CD standard

and may not be playable by this product.

Note on DualDisc

A DualDisc is a two sided disc product which mates

DVD recorded material on one side with digital audio

material on the other side. However, since the audio

material side does not conform to the Compact Disc

(CD) standard, playback on this product is not

guaranteed.

Note about DVD-RW (Except for

U.S./Canadian/European models)

Images in DVD-RWs with CPRM

*protection may not

be played if they contain a copy protection signal.

“Copyright lock” appears on the screen.

*CPRM (Content Protection for Recordable Media) is

a coding technology that protects the copyright of

images.

Label

Ring

Adapter