SERVICE MANUAL

Sony Corporation

Audio&Video Business Group

Published by Sony Techno Create Corporation

HBD-E770W

BLU-RAY DISC/DVD RECEIVER

9-889-767-01

2010B05-1

© 2010.02

US Model

Ver. 1.0 2010.02

• HBD-E770W is the amplifier, video, BD/DVD/Super Audio

CD/CD system, USB, LAN and tuner section in BDV-E770W.

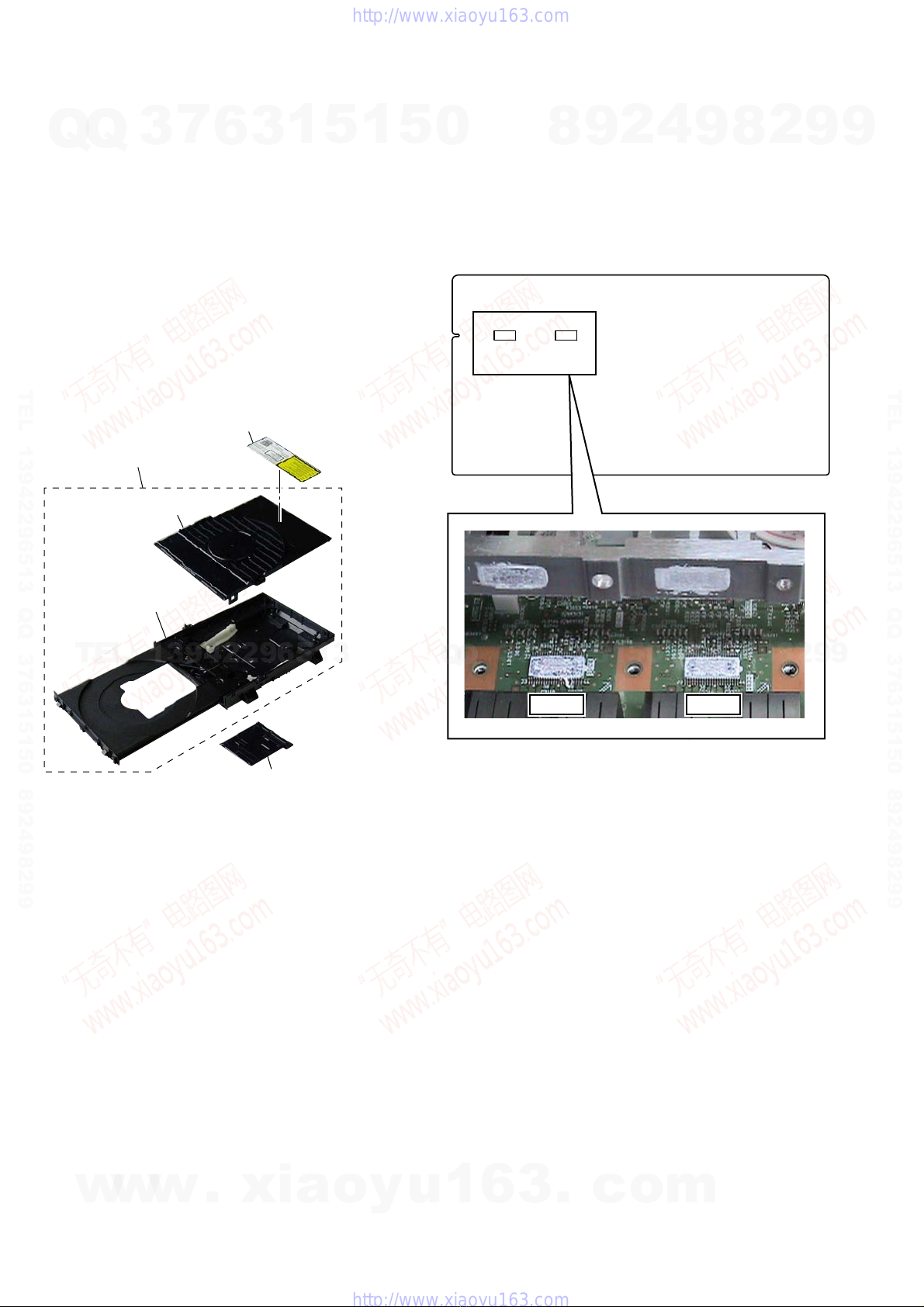

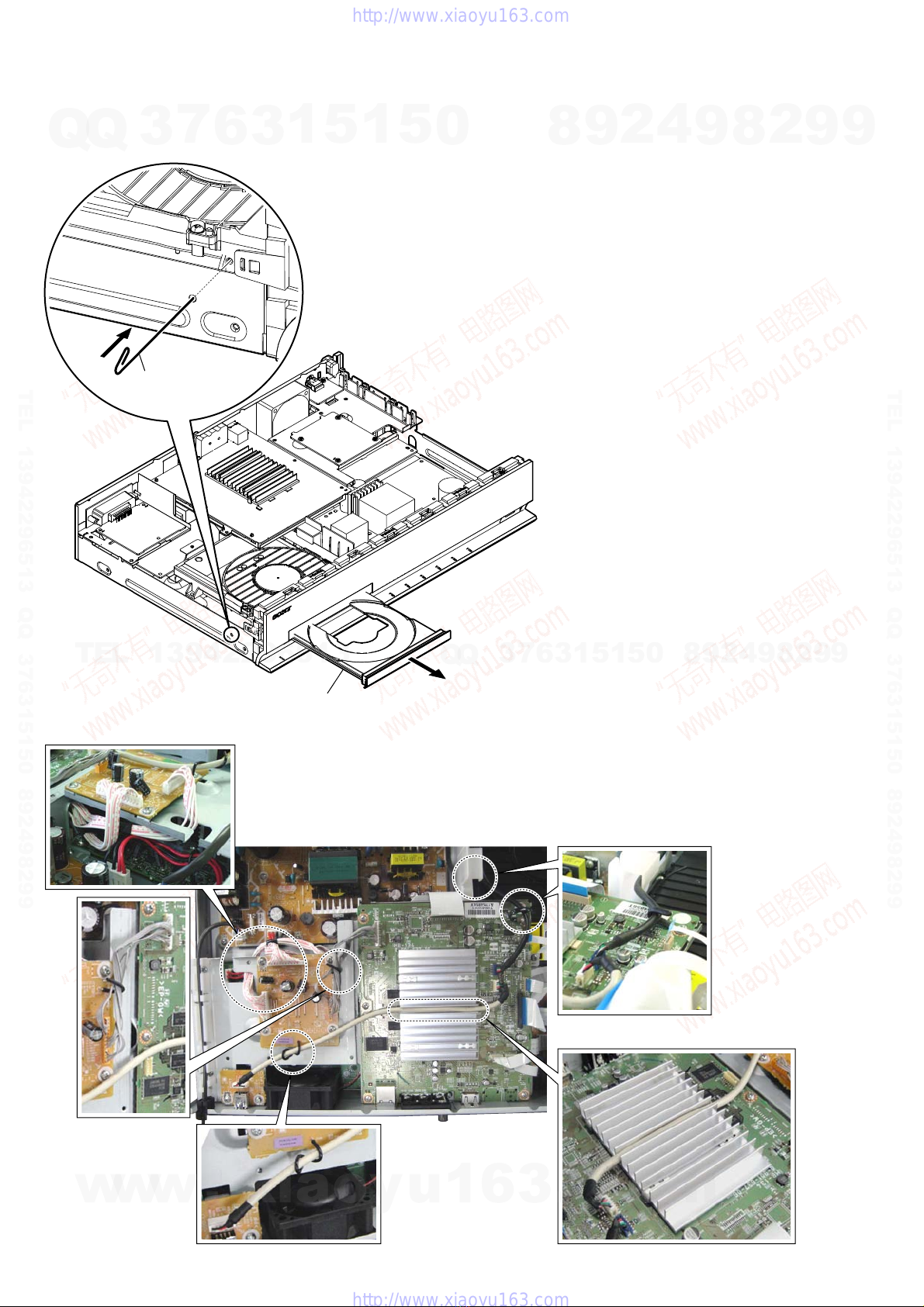

Model Name Using Similar Mechanism BDP-S370

Mechanism Type

BPX-5

Optical Pick-up Block Name KEM-460AAA

SPECIFICATIONS

Amplifier Section

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

(FTC)

Front L + Front R: With 3 ohms loads, both

channels driven, from 180

- 20,000 Hz; rated 60 watts

per channel minimum

RMS power, with no more

than 1% total harmonic

distortion from 250 milli

watts to rated output.

POWER OUTPUT (reference)

Front L/Front R/Center: 167 W (per channel at 3

ohms, 1 kHz)

Subwoofer: 165 W (at 3 ohms, 80 Hz)

Inputs (Analog)

AUDIO (AUDIO IN) Sensitivity: 450/250 mV

Inputs (Digital)

SAT/CABLE (COAXIAL), TV (OPTICAL)

Supported formats: LPCM

2CH (up to 48 kHz), Dolby

Digital, DTS

Video Section

Outputs VIDEO: 1 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

HDMI OUT: Type A (19

pin)

BD/DVD/Super Audio CD/CD System

Signal format system NTSC

USB Section

(USB) port: Type A (For connecting

USB memory, memory

card reader, digital still

camera, and digital video

camera)

Maximum current: 500 mA

LAN Section

LAN (100) terminal 100BASE-TX Terminal

Tuner Section

System PLL quartz-locked digital

synthesizer

FM tuner section

Tuning range 87.5 MHz - 108.0 MHz

(100 kHz step)

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

Design and specifications are subject to change

without notice.

General

Power requirements 120 V AC, 60 Hz

Power consumption On: 130 W

Standby: 0.3 W (at the

Power Saving mode)

Dimensions (approx.) 430 mm × 85 mm × 335

mm (17 in × 3 3/8in ×

13 1/4in) (w/h/d) incl.

projecting parts

430 mm × 85 mm × 365

mm (17 in × 3 3/8in ×

14 3/8in) (w/h/d) (incl.

wireless transceiver)

Mass (approx.) 4.7 kg (10 lb 6 oz)

• This product incorporates copyright

protection technology that is protected by

U.S. patents and other intellectual property

rights.

Use of this copyright protection technology

must be authorized by Macrovision, and is

intended for home and other limited view-

ing uses only unless otherwise authorized

by Macrovision.

Reverse engineering or disassembly is

prohibited.

• This system incorporates with Dolby*

Digital and Dolby Pro Logic (II) adaptive

matrix surround decoder and the DTS**

Digital Surround System.

* Manufactured under license from

Dolby Laboratories.

Dolby, Pro Logic, and the double-D

symbol are trademarks of Dolby

Laboratories.

** Manufactured under license under

U.S. Patent #’s:

5,451,942; 5,956,674; 5,974,380;

5,978,762; 6,226,616; 6,487,535;

7,212,872; 7,333,929; 7,392,195;

7,272,567 & other U.S. and worldwide

patents issued & pending. DTS is a

registered trademark and the DTS

logos, Symbol, DTS-HD and DTS-

HD Master Audio are trademarks of

DTS, Inc. © 1996-2008 DTS, Inc. All

Rights Reserved.

• This system incorporates High-Definition

Multimedia Interface (HDMI™) technol-

ogy.

HDMI, the HDMI logo and High-Defini-

tion Multimedia Interface are trademarks

or registered trademarks of HDMI Licens-

ing LLC.

• Java and all Java-based trademarks and

logos are trademarks or registered trade-

marks of Sun Microsystems, Inc.

• “BD-LIVE” and “BONUSVIEW” are

trademarks of Blu-ray Disc Association.

• “Blu-ray Disc” is a trademark.

• “Blu-ray Disc,” “DVD+RW,” “DVD-RW,”

“DVD+R,” “DVD-R,” “DVD VIDEO,”

and “CD” logos are trademarks.

• “BRAVIA” is a trademark of Sony Corpo-

ration.

• “AVCHD” and the “AVCHD” logo are

trademarks of Matsushita Electric Indus-

trial Co., Ltd. and Sony Corporation.

• “S-AIR” and its logo are trademarks of

Sony Corporation.

• , “XMB,” and “xross media bar” are

trademarks of Sony Corporation and Sony

Computer Entertainment Inc.

• “PLAYSTATION” is a trademark of Sony

Computer Entertainment Inc.

• Music and video recognition technology

and related data are provided by Grace-

note®.

Gracenote is the industry standard in music

recognition technology and related content

delivery. For more information, please visit

www.gracenote.com.

CD, DVD, Blu-ray Disc, and music and

video-related data from Gracenote, Inc.,

copyright © 2000-present Gracenote.

Gracenote Software, copyright ©

2000-present Gracenote. One or more

patents owned by Gracenote apply to this

product and service. See the Gracenote

website for a nonexhaustive list of ap-

plicable Gracenote patents. Gracenote,

CDDB, MusicID, MediaVOCS, the Grace-

note logo and logotype, and the “Powered

by Gracenote” logo are either registered

trademarks or trademarks of Gracenote in

the United States and/or other countries.

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com