3

HCD-LX10000

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL

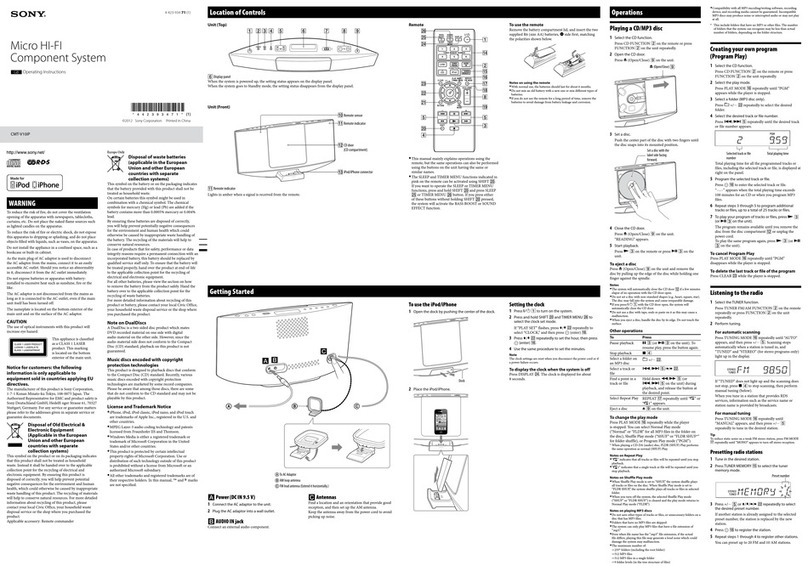

Location of Controls........................................................ 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Side Panel, Top Case ....................................................... 8

3-3. Loading Panel Assy ......................................................... 8

3-4. Front Panel Assy .............................................................. 9

3-5. Tuner Pack ....................................................................... 9

3-6. Tape Mechanism Deck, MIC Board ................................ 10

3-7. PANEL Board, CD-SW Board ........................................ 10

3-8. CD Mechanism Deck ...................................................... 11

3-9. Back Panel ....................................................................... 11

3-10. PRIMARY Board, LIGHTING Board ............................ 12

3-11. Power AMP PC Board Assy, MAIN Board ..................... 12

3-12. SURROUND Board, PA Board ....................................... 13

3-13. Power Transformer (T1200) ............................................ 13

3-14. DRIVER Board, SW Board............................................. 14

3-15. CD Board, Optical Pick-up (KSM-215DCP/C2NP) ....... 14

3-16. SENSOR Board ............................................................... 15

3-17. MOTOR (TB) Board ....................................................... 15

3-18. MOTOR (LD) Board....................................................... 16

4. TEST MODE.............................................................. 17

5. MECHANICAL ADJUSTMENTS ....................... 21

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 21

CD Section ...................................................................... 22

7. DIAGRAMS ................................................................. 25

7-1. Circuit Boards Location .................................................. 26

7-2. Block Diagram – CD Section – ...................................... 27

7-3. Block Diagram – Tape/Tuner Section – ......................... 28

7-4. Block Diagram – Main Section – ................................... 29

7-5. Block Diagram – AMP Section – ................................... 30

7-6. Block Diagram – Display/Power Section –.................... 31

7-7. Printed Wiring Board – CD Board – .............................. 32

7-8. Schematic Diagram – CD Board – ................................. 33

7-9. Printed Wiring Boards – CD Mechanism Boards – ....... 34

7-10. Schematic Diagram – CD Mechanism Boards – ............ 35

7-11. Printed Wiring Board – MAIN Board – ......................... 36

7-12. Schematic Diagram – MAIN Board (1/3) – ................... 37

7-13. Schematic Diagram – MAIN Board (2/3) – ................... 38

7-14. Schematic Diagram – MAIN Board (3/3) – ................... 39

7-15. Printed Wiring Board – PANEL Board – ....................... 40

7-16. Schematic Diagram – PANEL Board – ........................... 41

7-17. Printed Wiring Boards – CD-SW, JOG, MIC, LIGHTING

Boards –........................................................................... 42

7-18. Schematic Diagram – CD-SW, JOG, MIC, LIGHTING

Boards –........................................................................... 43

7-19. Printed Wiring Board – PA Board – ............................... 44

7-20. Schematic Diagram – PA Board – .................................. 45

7-21. Printed Wiring Boards – TRANS, PRIMARY Boards – 46

7-22. Schematic Diagram – TRANS, PRIMARY Boards – .... 47

7-23. IC Pin Function Description............................................ 50

8. EXPLODED VIEWS

8-1. Case (Top), Back Panel Section ...................................... 56

8-2. Front Panel Section ......................................................... 57

8-3. Chassis Section................................................................ 58

8-4. CD Mechanism Deck Section-1

(CDM74-F1BD81).......................................................... 59

8-5. CD Mechanism Deck Section-2

(CDM74-F1BD81).......................................................... 60

9. ELECTRICAL PARTS LIST................................ 61