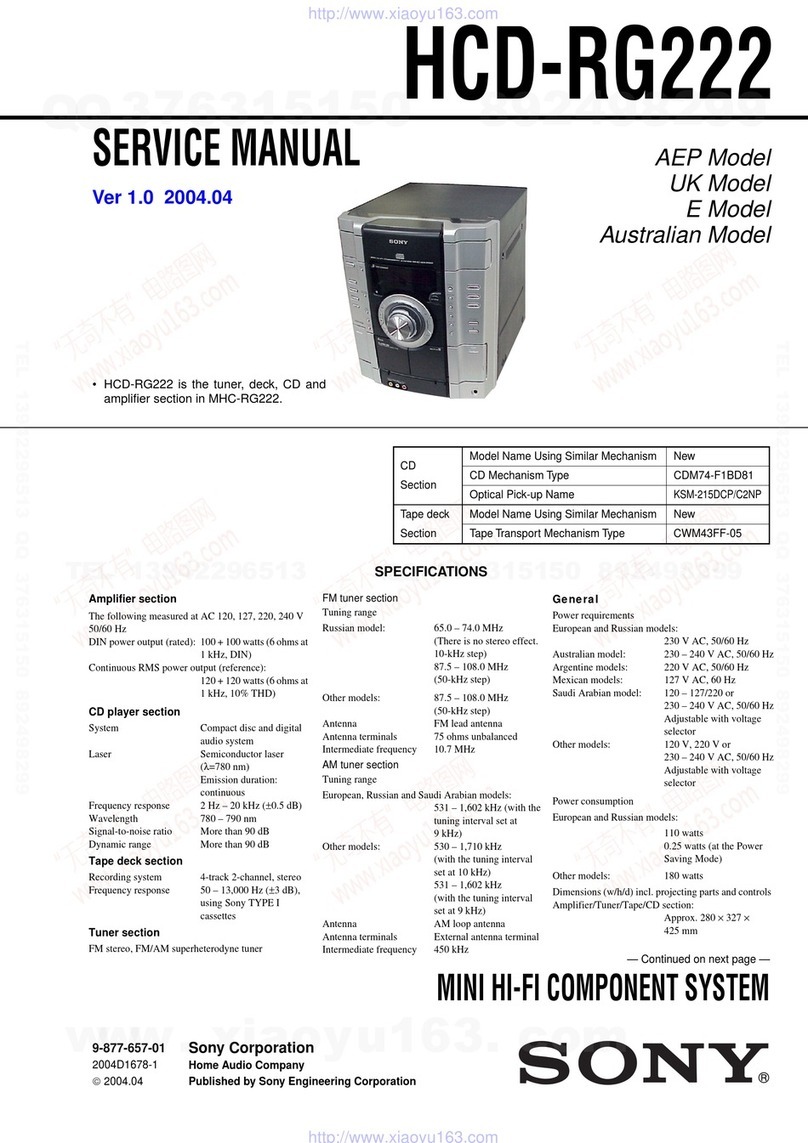

— 4 —

MC Cold Reset

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press three buttons NEXT , ENTER/NEXT , and DISC 1

simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

CD Delivery Mode

• This mode moves the pick-up to the position durable to vibration.

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press POWER button to turn the set ON.

2. Press PLAY MODE buttonand POWER button simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

MC Hot Reset

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power cord

is plugged in and out.

Procedure:

1. Press three buttons NEXT , ENTER/NEXT , and DISC 2

simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

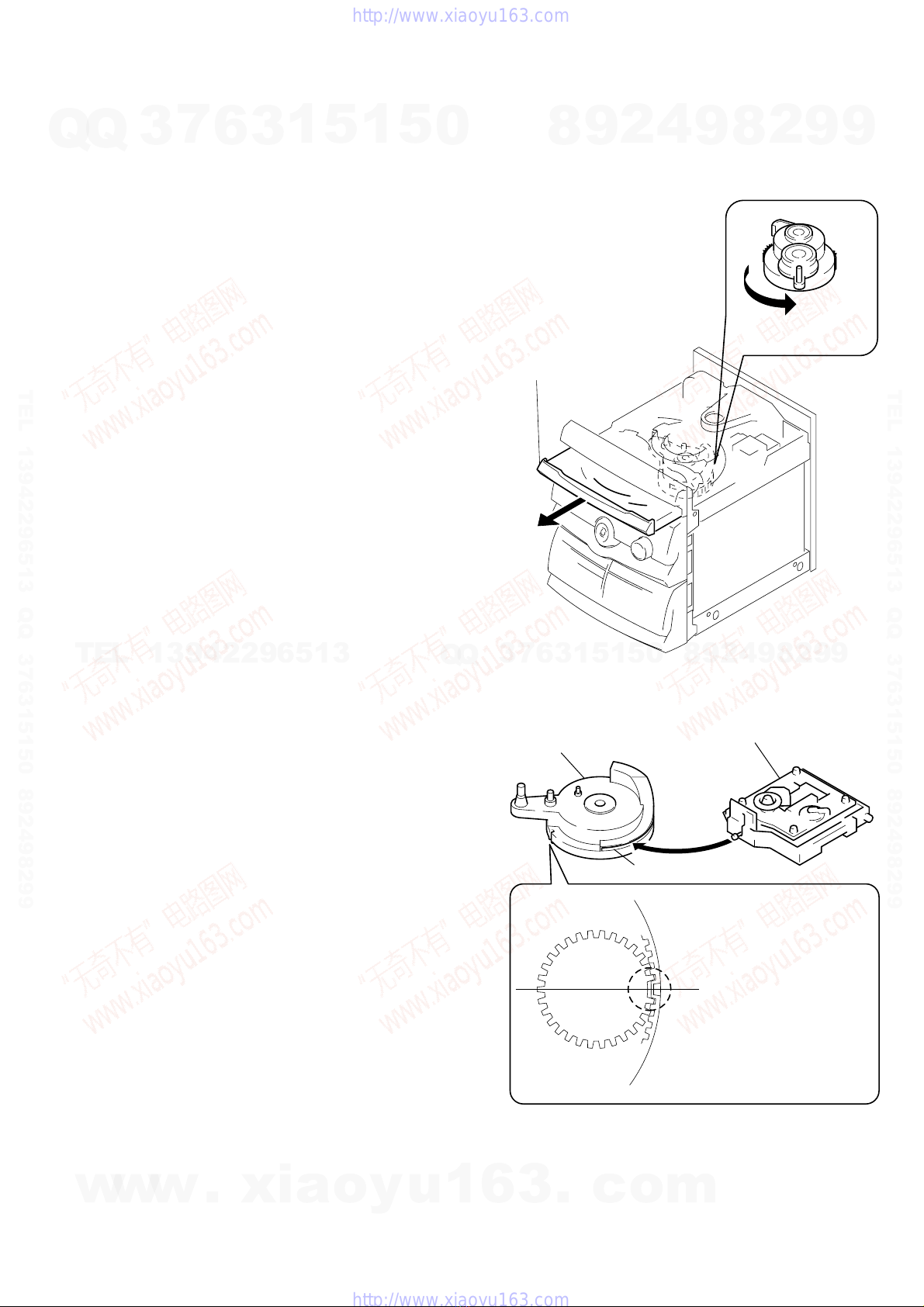

Sled Servo Mode

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pick-up.

Procedure:

1. Select the function “CD”.

2. Press three buttons NEXT , ENTER/NEXT , and FUNC-

TION simultaneously.

3. The Sled Servo mode is selected, if “CD” is blanking on the

fluorescent indicator tube.

4. With the CD in stop status, press )button in CD section to

move the pick-up to outside track, or 0button to inside track.

5. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press three buttons in the same manner as step 2.

Note:

• Always move the pick-up to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be

chipped.

Change-over of FUNCTION Name

• The FUNCTION name of external input terminal can be changed

over toVIDEO or MD. With the FUNCTION selected to “MD”,

about 5dB mute is applied to the input gain.

Procedure:

1. Press POWER button to turn the set OFF.

2. Press POWER button together with FUNCTION button, and

the power is turned on, the display of fluorescent indicator tube

changes to “MD” or “VIDEO” instantaneously, and thus the

FUNCTION is changed over.

Change-over of AMTuner Step between 9kHz and 10kHz

• A step of AM channels can be changed over between 9kHz and

10kHz.

Procedure:

1. Press POWER button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND but-

ton to select the BAND “AM” or “MW”.

3. Press POWER button to turn the set OFF.

4. Press ENTER/NEXT and POWER buttons simultaneously,

and the display of fluorescent indicator tube changes to “9k

STEP” or “10k STEP”, and thus the channel step is changed

over.

LED and Fluorescent Indicator Tube All Lit, Key Check

Mode

Procedure:

1. Press three buttons NEXT , ENTER/NEXT , and DISC 3

simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays

“K 1V0 J0”. Each time a button is pressed, “K”value increases.

However, once a button is pressed, it is no longer taken into

account.

“J” Value increases like 1, 2, 3 ... if rotating JOG knob in “+”

direction, or it decreases like 0, 9, 8 ... if rotating in “–” direc-

tion.

“V”Value increases like 1, 2, 3 ... if rotating VOLUME knob in

“+” direction, or it decreases like 0, 9, 8 ... if rotating in “–”

direction.

4. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

Aging Mode

This mode can be used for operation check of CD section and tape

deck section.

• If an error occurred:

The aging operation stops.

• If no error occurs:

The aging operation continues repeatedly.

1. Aging Mode in CD Section

1-1. Operating procedure of Aging Mode

1. Set discs in DISC 1 and DISC 2 trays.

2. Select the function “CD”.

3. Press three buttons NEXT , ENTER/NEXT , and

KARAOKE PON/MPX simultaneously.

4. The aging mode is activated, if a roulette mark on the fluo-

rescent indicator tube is blinking.

5. In the aging mode, the aging is executed in a sequence given

in “1-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

6. To exit from the aging mode, press POWER button to turn

the set OFF.

•If a button other than buttons In CD section is pressed during

aging, the aging in the CD section is finished.

•To execute aging to the tape deck section successively, press ·

button in the deck A.

“AGING” is displayed on the fluorescent indicator tube. (For

the aging in tape deck, see “2. Aging Mode in Tape Deck Sec-

tion”.

1-2. Operation during aging Mode

In the aging mode, the program is executed in the following se-

quence.

1. The disc table is ejected.

2. The disc tray turns to select a disc. (For a disc selection se-

quence, see Section 1-3.)

3. TOC of disc is read.

4. The pick-up accesses to the last track.

5. Disc table is ejected.

6. Steps 2 through 5 are repeated.

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com