6

TABLE OF CONTENTS

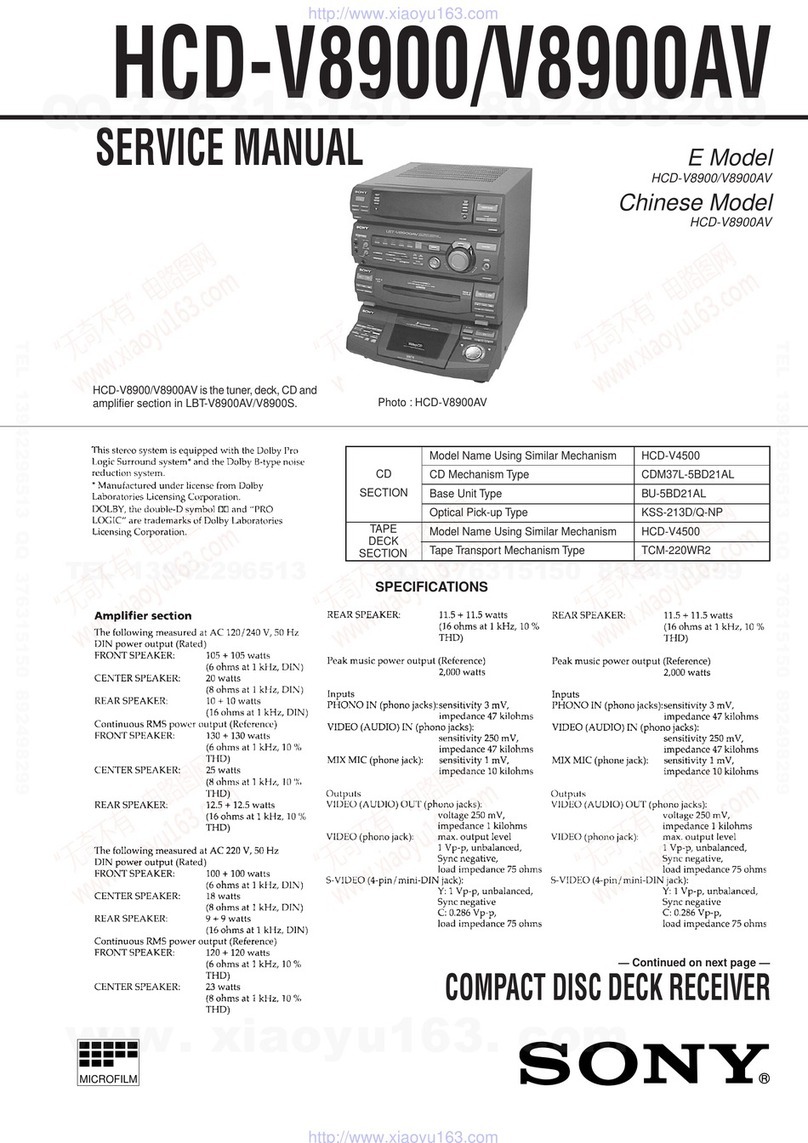

MODEL IDENTIFICATION

— BACK PANEL —

•Abbreviation

G : German model

AED : North European model

MX : Mexican model

AR : Argentine model

HK : Hong Kong model

MY : Malaysia model

SP : Singapore model

KR : Korean model

AUS : Australian model

MODEL

US model

AEP, UK, G,AED, CIS model

MY, SP model

E model

AR model

HK model

MX model

AUS model

KR model

PARTS No.

4-227-556-0s

4-227-556-2s

4-227-556-3s

4-227-556-4s

4-227-556-5s

4-227-556-6s

4-227-556-7s

4-227-556-8s

4-227-556-9s

Parts No.

1. SERVICING NOTES ............................................. 7

2. GENERAL ........................................................................ 15

3. DISASSEMBLY

3-1. Case .................................................................................. 18

3-2. Front Panel Section .......................................................... 18

3-3. MD Mechanism Section

Tape Mechanism Deck Section (TCM-230AWR12)........ 19

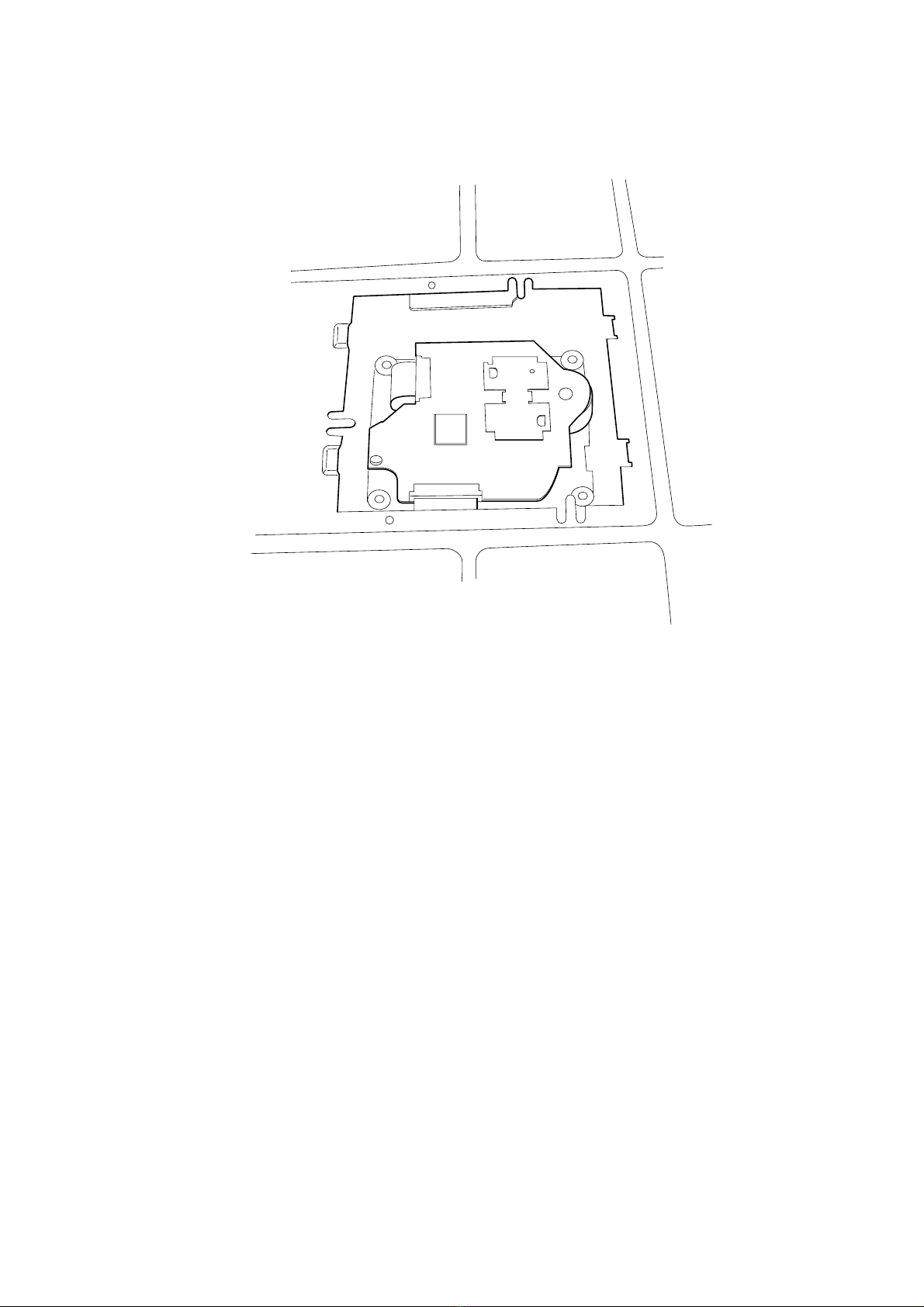

3-4. Back Panel Section ........................................................... 19

3-5. MD Mechanism Deck Section (MDM-7B)...................... 20

3-6. Main Board, Front AMP Board ........................................ 20

3-7. CD Base Unit (BU-K4BD40)........................................... 21

3-8. CD Mechanism Deck Section (CDM53F-K4BD40)........ 21

3-9. Fitting Base (Guide) Assy, Bracket (Chassis) and

Fitting Base (Magnet) Assy ..............................................22

3-10. Tray (Sub) ......................................................................... 22

3-11. Chassis (Mold B) Section, Stocker Section and

Slider (Selection) ............................................................. 23

3-12. Gears Installation.............................................................. 23

3-13. Slider (Selection) Installation ........................................... 24

3-14. Stocker Section Installation .............................................. 24

3-15. Chassis (Mold B) Section Installation.............................. 25

3-16. BD Board.......................................................................... 25

4.TEST MODE...................................................................... 26

5. MECHANICAL ADJUSTMENTS............................... 35

6. ELECTRICAL ADJUSTMENTS................................. 35

7. DIAGRAMS

7-1. Circuit Boards Location ...................................................... 51

7-2. Block Diagrams

•CD Section ....................................................................... 54

•MD Section ...................................................................... 55

•SYSCON/SERVO Section ............................................... 56

•MAIN Section.................................................................. 57

7-3. Printed Wiring Board –Deck Section –.............................. 58

7-4. Schematic Diagram –Deck Section –................................ 59

7-5. Printed Wiring Board –CD Section –................................. 60

7-6. Schematic Diagram –CD Section –................................... 61

7-7. Printed Wiring Board –MD Section –................................ 62

7-8. Schematic Diagram –MD (1/2) Section –.......................... 63

7-9. Schematic Diagram –MD (2/2) Section –.......................... 64

7-10. Printed Wiring Board –Main Section –........................... 65

7-11. Schematic Diagram –Main (1/4) Section –..................... 66

7-12. Schematic Diagram –Main (2/4) Section –..................... 67

7-13. Schematic Diagram –Main (3/4) Section –..................... 68

7-14. Schematic Diagram –Main (4/4) Section –..................... 69

7-15. Printed Wiring Board –Digital (Side A) Section –.......... 70

7-16. Printed Wiring Board –Digital (Side B) Section –.......... 71

7-17. Schematic Diagram –Digital (1/2) Section –.................. 72

7-18. Schematic Diagram –Digital (2/2) Section –.................. 73

7-19. Printed Wiring Board

–AMP (US, AEP, UK, G, AED, CIS model) Section –.. 74

7-20. Schematic Diagram

–AMP (US, AEP, UK, G, AED, CIS model) Section –.. 75

7-21. Printed Wiring Board –AMP (E, MX,AR, HK,

MY, SP, KR, AUS model) Section –................................ 76

7-22. Schematic Diagram –AMP (E, MX,AR, HK,

MY, SP, KR, AUS model) Section –................................ 77

7-23. Printed Wiring Board –Panel Section –........................... 78

7-24. Schematic Diagram –Panel Section –............................. 79

7-25. Printed Wiring Board –Switch Section –........................ 80

7-26. Schematic Diagram –Switch Section –........................... 81

7-27. Printed Wiring Board –CD Mechanism Section –.......... 82

7-28. Schematic Diagram –CD Mechanism Section –............. 83

7-29. Printed Wiring Board –Leaf SW Section –..................... 84

7-30. Schematic Diagram –Leaf SW Section –........................ 84

7-31. Printed Wiring Board –MIC Section –............................ 85

7-32. Schematic Diagram –MIC Section –............................... 85

7-33. Printed Wiring Board –Power Supply (US, AEP, UK,

G, AED, CIS model) Section –........................................ 86

7-34. Schematic Diagram –Power Supply (US, AEP, UK,

G, AED, CIS model) Section –........................................ 87

7-35. Printed Wiring Board –Power Supply (E, MX, AR, HK,

MY, SP, KR, AUS model) Section –................................ 88

7-36. Schematic Diagram –Power Supply (E, MX, AR, HK,

MY, SP, KR, AUS model) Section –................................ 89

7-37. IC Block Diagrams........................................................... 90

7-38. IC Pin Functions............................................................... 94

8. EXPLODEDVIEWS

8-1. Back Panel Section ......................................................... 106

8-2. Front Panel Section ........................................................ 107

8-3. Chassis Section ............................................................... 108

8-4. CD Mechanism Deck Section-1 ..................................... 109

8-5. CD Mechanism Deck Section-2 ..................................... 110

8-6. Base Unit Section ........................................................... 111

8-7. Tape Mechanism Deck Section-1 ................................... 112

8-8. Tape Mechanism Deck Section-2 ................................... 113

8-9. MD Mechanism Section-1.............................................. 114

8-10. MD Mechanism Section-2.............................................. 115

9. ELECTRICAL PARTS LIST ...................................... 117