Soosan SQ Series User manual

OPERATION MANUAL

PARTS LIST

Soosan Hydraulic Breaker SQ Series

OPERATION MANUAL

PARTS LIST

Head Office & Hwasung Plant

260, Jeongmunsongsan-ro, Yanggam-myeon, Hwaseong-si, Gyeonggi-do, Republic of Korea

Postal Code : 18628

TEL 1588-0499 FAX +82-31-350-5259

SQ Series

OPERATION MANUAL & PARTS LIST

Soosan Hydraulic Breaker

OPERATION MANUAL

PARTS LIST

Soosan Hydraulic Breaker SQ Series

Contents

OPERATION

MANUAL

PARTS LIST

01. Safety Precautions ··································································································1

1.1 Safety Precautions ·······························································································1

1.2 Stickers & Tags ···································································································4

02. Standard Specification ··························································································· 9

03. External Dimensions ····························································································· 11

3.1 Small range ······································································································ 11

3.2 Medium & Heavy-duty range ·············································································12

3.3 Cover Plate ·····································································································13

04. Preparation for Installation and Operation ······························································ 15

4.1 Checking before installation ··············································································· 15

4.2 Installation and Removal ···················································································16

4.3 Hydraulic pipe lines for exclusive use ·································································20

05. Precautions for safe operation ···············································································21

06. Maintenance ······································································································· 29

07. Wear Tolerance ··································································································· 38

08. Inspection and Charging of N₂ Gas at Back head ····················································44

09. Inspection and Charging of N₂ gas at Accumulator ·················································48

10. Trouble Shooting ································································································· 52

11. Hydraulic Oil and Grease ························································································ 53

12. Auto Lubrication (Option) ····················································································· 55

01. MAIN BODY ········································································································ 62

02. SEAL KIT ············································································································98

03. ROD TYPE ········································································································· 110

04. FRAME ASSEMBLY ······························································································112

05. OIL HOSE ·········································································································· 125

06. CAP BOLT ··········································································································126

07. TOOL SET(OPTION) ····························································································128

08. BACK HEAD GAS CHARGING KIT(OPTION)···························································130

09. ACCUMULATOR CHARGING TOOL SET(OPTION) ·················································· 132

Soosan Hydraulic Breaker

OPERATION MANUAL

SERIOUS INJURY OR DEATH COULD RESULT FROM THE

IMPROPER REPAIR OR SERIVICE OF THIS HYDRAULIC BREAKER.

REPAIRS AND / OR SERVICE TO THIS HYDRAULIC BREAKER

MUST ONLY BE DONE BY AN AUTHORIZED AND CERTIFIED DEALER.

DANGER

Model

Serial Number

Year of Construction

EC Declaration of Incorporation

according to EC Machinery Directive 2006/42/EC

We herewith declare, Soosan Heavy Ind. Co., Ltd.

of

260, Jeongmunsongsan-ro, Yanggam-Myeon,

Hwaseong-Si, Gyunggi-Do, Korea

that the following machine complies with the appropriate basic safety and health requirements of the

EC Directive(2006/42/EC) based on its design and type, as brought into circulation by us. In case

of alteration of the machine, not agreed upon by us, this declaration will lose its validity.

The machinery is incomplete and must not be put into service until the machinery into which it is to

be incorporated has been declared in conformity with the provisions of the Directive.

Technical documentation for the machinery is maked by :

Place : Soosan Heavy Ind. Co., Ltd

260, Jeongmunsongsan-ro, Yanggam-Myeon, Hwaseong-Si, Gyunggi-Do, Korea

Position : Manager, R&D team

Name :

The technical documentation for the machinery is available from :

Name : SOOSAN HEAVY INDUSTRIES CO., LTD EUROPE

Adress : Ohmweg 18,3208 ke, Spijkenisse, Netherlands

Description : Construction Machinery (not appendix Ⅳ)

(Hydraulic Breaker)

Machine Type :

Serial Number :

Applicable EC Directive : EC Machinery Directive ( 2006/42/EC )

Applicable Harmonized

Standards : EN ISO 12100-2010

EN474-1:2006/A4:2013

Applicable National Technical Standards And Specifications :

Weight(kg) :

Length(mm) :

Oil flow(ℓ/min) :

Operation Pressure(kg/㎠):

Blows(bpm) :

Date/ Authorized Signature :

Title of Signatory :

DANGER

DO NOT OPERATE THE HYDRAULIC BREAKER UNLESS THE FOLLOWING SAFETY

INSTRUCTIONS HAVE BEEN THOROUGHLY READ AND UNDERSTOOD!

READ THIS MANUAL BEFORE INSTALLING, OPERATING OR MAINTAINING THIS

EQUIPMENT.

•

Flying debris form the hydraulic breaker or other material may cause serious or fatal injury to the

operator. Personal protection equipment must be used.

•

Flying debris hydraulic breaker or other materials may cause serious or fatal injury to bystanders.

Never operate the grab when bystanders are in the working area.

•

On machines/carriers, the hydraulic breaker can enter the operator's compartment under specific

hydraulic breaker position. Make sure that suitable impact shields are used when operating the

hydraulic breaker with this type of equipment.

•

Do not operate the breaker unless all safety decals described in this manual are in place. The decals

must be inspected periodically to ensure that all wording is legible. The decals must be replaced if

illegible. Replacement decals can be obtained from your authorized Soosan Distributor.

•

The hydraulic breaker will become very hot during operation. Allow time for hydraulic breaker to

cool down before touching hydraulic breaker parts.

If this machine is transferred, be sure to attach this manual to the machine.

For safety, common items are described "SAFETY PRECATUIONS", and others are mentioned in the

succeeding pages.

FOREWORD

We appreciate your purchasing a Soosan Hydraulic Breaker.

The Hydraulic Breaker, designed and built to provide durable operation under any working

conditions, has been developed by Soosan's excellent engineering techniques with accumulated

experiences for many years. Without proper handling, regular inspection and maintenance,

however, the machine fails to display its full capacity, resulting in various troubles of machine parts.

This publication should be carefully read prior to installation and operation in order to prevent

any mishandling of hydraulic breaker.

We guarantee that a faithful compliance of the instruction will contribute to the best operation

condition.

Customers are, therefore, required to keep in mind that the company is not responsible for

troubles caused by not following our guidelines or not using genuine parts.

Soosan Heavy Industries Co., Ltd.

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

1

01. Safety Precautions

1.1 Safety Precautions

This manual contains safety, operation, and routine maintenance instructions. It doesn't contain service disassembly and

service assembly instructions. If needed, complete service disassembly and service assembly instructions are contained in

manual which can be ordered from your Soosan Hydraulic Breaker authorized and certified dealer.

Please read the following warning.

DANGER

Serious injury or death could result from the improper repair or service of this breaker.

Repairs or service to this breaker must only be done by an authorized and certified dealer.

Most of the accidents are caused by disregarding the basic rules of operation inspection or repair, or by neglecting the

inspection before operation. Many accidentscan often be avoided by recognizing potentially hazardous situations before an

accident occurs. Before operating, inspecting or repairing this machine, be sure to read and fully understand the preventive

methods and warnings described on the machine or in this manual. If not, never operate, inspect or repair this machine

Safety labels and messages are classified as follows so that the users can understand the warnings on the machine or in this manual.

DANGER

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This signal word is to be limited to the most extreme situations

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury,

It may also be used to alert against unsafe practices.

NOTICE

Signs used to indicate a statement of company policy directly or

indirectly related to the safety of personal or protection of property.

The safety messages including the preventive measures to avoid danger.

For safety, common items are described in "SAFETY PRECAUTIONS", and others are mentioned in the succeeding pages.

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

2 3

Soosan cannot anticipate every possible circumstance that might involve a potential hazard on operation, inspection or repair.

Therefore the warnings in this manual are not all inclusive. If an operation, inspection or repair not described in this manual is

used, you must take measures for safety by yourself.

DANGER

Observe the cautions and take a preventive measure for safety

The Soosan Hydraulic Breaker will provide safe and dependable service if operated in accordance with the instructions given

in this manual. Read and understand this manual, any decals and tags attached to the breaker before operation. Failure to do

so could result in personal injury or equipment damage

• Operate the breaker in accordance with all laws and regulations which affect you, your equipment, and the worksite.

• Do not operate the breaker until you have read this manual and thoroughly understood all safety, operation and

maintenance instructions.

• Do not operate the breaker until you have read the carrier equipment manual and thoroughly understood backhoe or

excavator or similar equipment used to operate the breaker. The word "carrier", as used in this manual, means a backhoe

or excavator or similar equipment used to operate the breaker.

• Ensure that all maintenance procedures recommended in this manual are completed before using the equipment.

• The operator must not operate the breaker or carrier if any people are within the area where they may be injured by flying

debris or movement of the equipment.

• Know the limits of your equipment.

• Before starting a work, Check the prohibitions, cautions and working processes in a working site with the field overseer,

Observe all of them strictly.

• Wear such protective tools as a helmet, safety shoes, etc. to perform a work.

Make use of the protective glasses, earplugs, gloves and other protective tools if necessary.

• Establish a training program for all operators to ensure safe operation. Do not operate the breaker unless thoroughly trained

or under the supervision of an instructor. Become familiar with the carrier controls before operating carrier and breaker. While

learning operate the breaker and carrier, do so at a slow pace. If necessary, set the carrier to the slow position.

• Make sure all controls(levers and pedals) are in the neutral position before starting the carrier.

• Before leaving the carrier, always lower the boom and insure the carrier is stable. Never leave the machine with the engine

running. Always engage the parking brake.

• Stop the engine before attempting to make any repairs, adjustments or servicing to either the carrier or the breaker.

• Do not operate the breaker at oil temperature above 175℉/80℃. Operation at higher temperature can damage the internal

components of the breaker and carrier and will result in reduced breaker performance.

• Do not operate a damaged, leaking, improperly adjusted, or incompletely assembled breaker.

• Do not modify this breaker in any manner.

• Use only breaker parts manufactured by Soosan. Usage of breaker rod produced by another manufacturer may damage

the breaker and will void the warranty.

• To avoid personal injury or equipment damage, all breaker repair, maintenance and service must only be performed by

authorized and properly trained personnel.

• If you do not understand how to operate safely your breaker, contact an authorized Soosan Dealer for assistance.

• Keep this manual with the breaker.

• Do not operate this equipment if you are taking medication which may affect your mental judgement or physical performance.

• Do not operate this equipment if you are under the influence of drug or alcohol.

• Remove breaker form carrier during transportation.

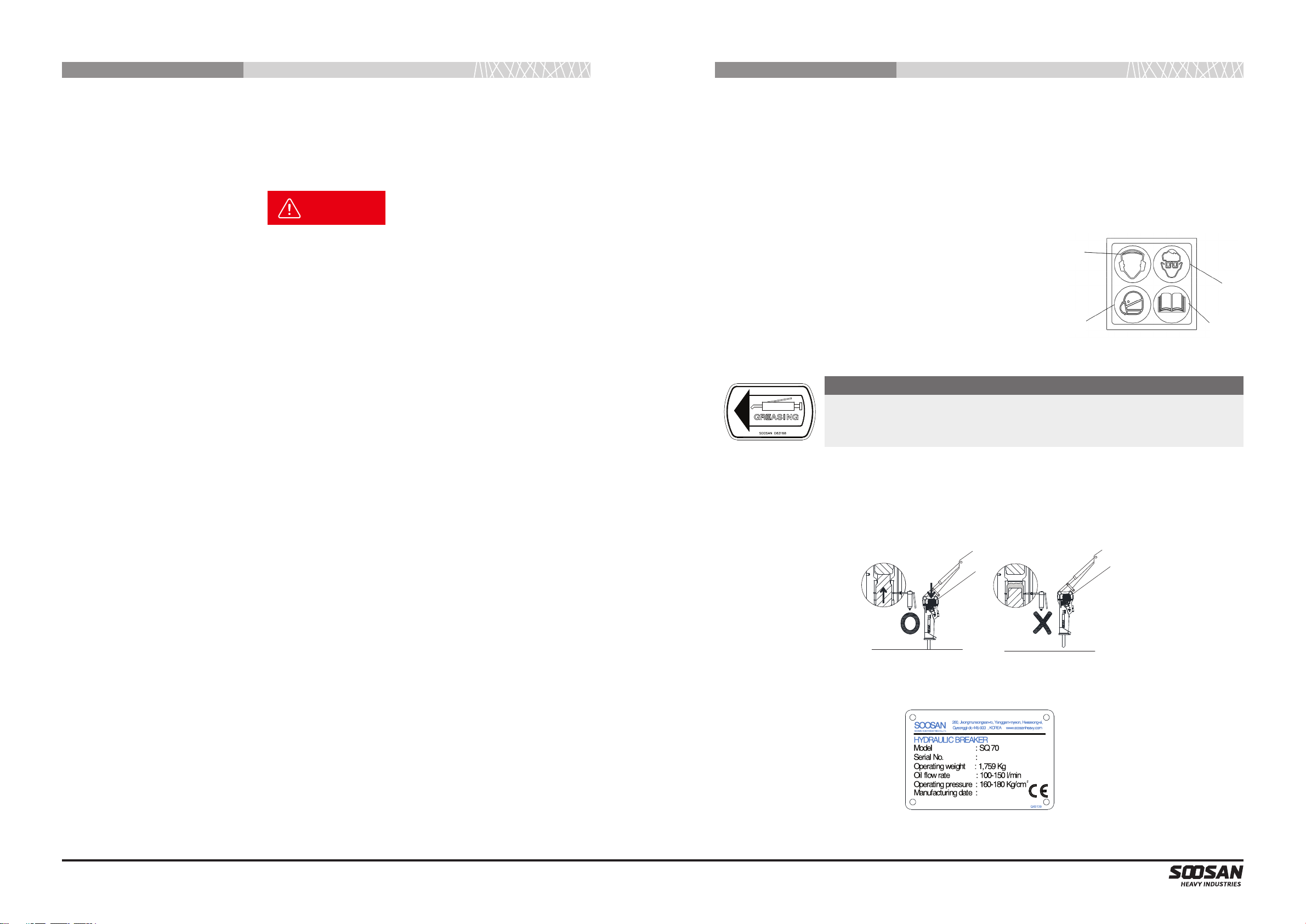

1.2 Stickers & Tags

• Warning sticker

1) Use ear protection 2) Use eye protection

3) Use breathing protection 4) Read the manual before use

• Greasing Sticker

Correct Greasing

1) Position the Breaker standing upright resting on the rod on firm surface.

2) Stop carrier engine and wait 10 minutes for oil pressure to drop inside Breaker.

3) Apply Rod grease from grease gun to greasing points marked with the following sticker.

Note : The Breaker must stand upright resting on the tool to ensure that the grease will penetrate

downwards between the tool and the bushing.

Do not fill the space between the piston and the rod with grease. A lower piston seal

failure can result and the Breaker will subsequently leak oil.

• Specification plate (For Example SQ70)

①

③

②

④

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

4 5

• SQ10 ~ SQ50AutoLube

NO.

MODEL

Sticker

Ass’y

1 2 3 4 5 6 7 8 9 10

BI

STICKER

AUTOLUBE

STICKER

NAME

PLATE EMBLEM LIFTING

STICKER

GREASE

STICKER

BACK

HEAD

STICKER

WARNING

STICKER

DANGER

STICKER

NOISE

STICKER

SQ10 B0003557 B0003627 -B0003635 B0003440 C23344 D83168 E83144 E83211 E83210 B0003643

SQ20 B0003558 B0003628 -B0003636 B0003440 C23344 D83168 E83144 E83211 E83210 B0003644

SQ30 B0003559 B0003629 -B0003637 B0003440 C23344 D83168 C02135 E83211 E83210 B0003645

SQ35

AutoLube B0009854 B0003630 B0009645 B0003638 B0005617 C23344 D83168 C02135 E83211 E83210 B0003646

SQ40

AutoLube B0009855 B0003631 B0009645 B0003639 B0005617 C23344 D83168 C02135 E83211 E83210 B0003647

SQ43

AutoLube B0003562 B0003632 B0009646 B0003640 B0005617 C23344 D83168 C02135 E83211 E83210 B0003648

SQ45

AutoLube B0003563 B0003633 B0009646 B0003641 B0005617 C23344 D83168 C02135 E83211 E83210 B0003649

SQ50

AutoLube B0003564 B0003634 B0009646 B0003642 B0005617 C23344 D83168 C02135 E83211 E83210 B0003650

383

5

8

9

1

7

SQ10 ~ SQ30 SQ35 ~ SQ50 AutoLube

10 4

4

6

10

2

7

4

1

5

6

9

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

6 7

• SQ60 ~ SQ181

NO.

MODEL

Sticker

Ass’y

1 2 3 5 6 8 9 10 11 12 13 14 15 16

BI

STICKER

(L)

BI

STICKER

(R)

SOOSAN

LOGO

NAME

STICKER

BACK

HEAD

STICKER

LOGO

STICKER

ACC

STICKER

(A)

ACC

STICKER

(B)

LIFTING

STICKER

NOISE

STICKER

WARNING

STICKER

DANGER

STICKER

BI

STICKER

BI

STICKER

SQ60 Q53145

B0009287 B0009288

Q53148 Q53149 C02135 Q53150 C62212 C62213 C23344 Q53139 D83166 Q53134 Q53131 Q53132

SQ70 Q63146

B0009287 B0009289

Q53148 Q63148 C02135 Q53150 C62212 C62213 C23344 Q63140 D83166 Q53134 Q53131 Q63138

SQ80 Q23148

B0009287 B0009290

Q53148 Q23150 C02135 Q53150 C62212 C62213 C23344 Q23144 D83166 Q53134 Q53131 Q23142

SQ100 Q73148

B0009291 B0009292

Q53148 Q73151 C02135 Q53150 C62212 C62213 C23344 Q73143 D83166 Q53134 Q53131 Q73141

SQ120 Q83143

B0009291 B0009293

Q53148 Q83145 C02135 Q53150 C62212 C62213 C23344 Q83139 D83166 Q53134 Q53131 Q83137

SQ130 Q43150

B0009294 B0009295

Q43153 Q43154 C02135 Q53150 C62212 C62213 C23344 Q43147 D83166 Q53134 Q43143 Q43144

SQ140 Q03179

B0009294 B0009296

Q43153 Q03181 C02135 Q53150 C62212 C62213 C23344 Q03135 D83166 Q53134 Q43143 Q03133

SQ150 Q33150

B0009298

Q33151 Q43153 Q33153 C02135 Q53150 C62212 C62213 C23344 Q33146 D83166 Q53134 Q43143 Q33144

SQ181 Q13222

B0009299 B0009300

Q43153 Q13225 C02135 Q53150 C62212 C62213 C23344 Q13174 D83166 Q53134 Q43143 Q13172

5

3

14

1

15

2

16 11

812

6

13

10

9

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

8 9

02. Standard Specification(1/2)

DESCRIPTION UNIT

MODEL

SQ10 SQ20 SQ30 SQ35

AutoLube

SQ40

AutoLube

SQ43

AutoLube

SQ45

AutoLube

SQ50

AutoLube

Body Weight

(Including rod)

kg 54 68 90 130 155 215 292 469

lbs 119 150 199 287 342 474 644 1035

Operating Weight

kg 104 130 156 231 299 379 566 845

lbs 229 287 344 510 660 836 1249 1864

Length

mm 1135 1237 1317 1472 1620 1899 2161 2348

in 45 49 52 58 64 75 85 92

Width

mm 264 264 264 324 324 324 420 420

in 10 10 10 13 13 13 17 17

Required

Oil Flow

ℓ/min 15~35 20~45 25~55 30~65 40~75 50~90 60~110 80~120

gal/min 4~9 5.3~11.9 6.6~14.5 7.9~17.2 13.2~23.8 13.2~23.8 15.9~29.1 21.1~31.7

Operating Pressure

㎏/㎠

(≒bar) 90~120 90~120 90~120 100~130 110~140 120~150 130~160 150~170

psi 1280

~1707

1280

~1707

1280

~1707

1422

~1849

1565

~1991

1707

~2134

1849

~2276

2134

~2418

Impact

Rate

Low BPM ---960

~1690

900

~1650

800

~1330

740

~1195

650

~1020

Middle BPM ---800

~1290

790

~1220

700

~1130

670

~1030 590~880

High BPM 800

~1530

700

~1320

600

~1250

620

~1040

570

~1020 540~800 525~850 455~730

Hose Diameter in 3/8, 1/2 3/8, 1/2 1/2 1/2 1/2 1/2 3/4 3/4

Rod Diameter

mm 40 45 53 60 68 75 85 100

in 1.6 1.8 2.1 2.4 2.7 3.0 3.3 3.9

Applicable Carrier

㎥~0.07 0.03~0.1 0.06~0.2 0.1~0.25 0.15~0.3 0.2~0.35 0.25~0.5 0.4~0.6

ton 0.8~2.5 1.2~3.0 2.0~4.5 3.0~6.0 4.0~9.0 5~12 7~15 9~16

lbs 1760

~5510

2645

~6615

4410

~9920

6615

~13220

8820

~19840

11020

~26455

15430

~33070

19840

~35275

Noise Level dB(A) 105.5 106.8 108.5 116.9 108.7 114.5 112.0 113.5

* Operating weight include Cap, Rod weight by AEM regulation.

(Except for pin, hose, fitting and tubing)

* The above specifications are subject to change without prior notice for the quality enhancement..

* Rod is long type standard.

Local safety regulations.

Enter any local safety regulation here, keep these instructions in an area accessible to the operator and maintenance

personnel.

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

10 11

03. External Dimensions

3.1 Small range (1/2)

MODEL UNIT A B C D E F G H I

SQ10 mm 307 272 264 152 724 267 40 1135 144

in 12.1 10.7 10.4 6.0 28.5 10.5 1.6 44.7 5.7

SQ20 mm 314 272 264 162 797 286 45 1237 154

in 12.4 10.7 10.4 6.4 31.4 11.3 1.8 48.7 6.1

SQ30 mm 327 272 264 162 868 295 53 1317 154

in 12.8 10.7 10.3 6.3 34.1 11.6 2.0 51.8 6.0

SQ35

AutoLube

mm 418 404 324 165 933 339 60 1472 200

in 16.5 15.9 12.7 6.4 36.7 13.3 2.3 57.9 7.8

SQ40

AutoLube

mm 417 404 324 220 1016 385 68 1620 219

in 16.4 15.9 12.7 8.6 40.0 15.1 2.6 63.7 8.6

SQ43

AutoLube

mm 412 404 324 220 1203 467 75 1899 229

in 16.2 10.7 10.3 6.3 34.1 11.6 2.0 51.8 6.0

SQ45

AutoLube

mm 570 570 420 267 1336 556 85 2161 269

in 22.4 22.4 16.5 10.5 52.5 21.8 3.3 85.0 10.5

SQ50

AutoLube

mm 570 570 420 330 1476 540 100 2348 332

in 22.4 22.4 16.5 12.9 58.1 21.2 3.9 92.4 13.0

** D, I, H : The dimension is for reference only and may vary depending on the required mounting bracket (Top Cap).

02. Standard Specification(2/2)

DESCRIPTION UNIT MODEL

SQ60 SQ70 SQ80 SQ100 SQ120 SQ130 SQ140 SQ150 SQ181

Body Weight

(Including rod)

kg 737 862 1084 1116 1425 1605 1806 1945 3096

lbs 1625 1900 2389 2460 3142 3538 3982 4288 6825

Operating Weight

kg 1607 1759 2053 2185 2671 3033 3169 3950 5889

lbs 3543 3878 4526 4817 5889 6687 6986 8708 12983

Length

mm 2561 2666 2806 2924 3168 3360 3441 3677 4112

in 101 105 110 115 125 132 135 145 162

Width

mm 620 620 669 694 760 756 761 793 891

in 24 24 26 27 30 30 30 31 35

Required

Oil Flow

ℓ/min 90~120 100~150 120~180 150~210 180~240 200~260 200~260 210~290 350~450

gal/min 23.8

~31.7

26.4

~39.6

31.7

~47.6

39.6

~55.5

47.6

~63.4

52.8

~68.7

52.8

~68.7

55.5

~76.6

93~

119

Operating Pressure

㎏/㎠

(≒ bar) 160~180 160~180 160~180 160~180 160~180 160~180 160~180 160~180 180~200

psi 2276

~2560

2276

~2560

2276

~2560

2276

~2560

2276

~2560

2276

~2560

2276

~2560

2276

~2560

2560

~2845

Impact

Rate

Low BPM 350~650 350~600 350~500 300~450 300~450 250~400 200~350 200~350 200~300

High BPM 600~850 500~850 500~700 430~580 430~580 380~550 300~500 320~470 300~400

Hose Diameter in 1 1 1 1 1⅟⁴1⅟⁴1⅟⁴1⅟⁴1⅟⁴

Rod Diameter

mm 125 135 140 150 155 165 165 175 200

in 4.9 5.3 5.5 5.9 6.1 6.5 6.5 6.9 7.9

Applicable Carrier

㎥0.5~0.7 0.6~0.8 0.7~0.9 0.9~1.2 1.1~1.4 1.2~1.7 1.2~1.7 1.4~2.0 2.0~5.0

ton 15~18 16~21 18~26 25~30 28~35 30~45 30~45 40~55 50~90

lbs 33000~

40000

40000~

46000

40000~

58000

55000~

66000

62000~

77000

66000~

100000

71000~

110000

88000~

121000

110000~

200000

Noise Level dB(A) 115 120 118 120 123 124 124 125 125

* Operating weight include Cap, Rod weight by AEM regulation.

(Except for pin, hose, fitting and tubing)

* The above specifications are subject to change without prior notice for the quality enhancement..

* Rod is long type standard.

A

A

E

E

I

I

F

F

SQ10 ~ SQ30 SQ35 ~ SQ50 AutoLube

H

H

CC

B

B

DD

ØGØG

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

12 13

3.3 Cover Plate

• SQ10∼30, SQ35 AutoLube ~ SQ43 AutoLube

MODEL HOLE

(EA) UNIT A B C D E F G H K

SQ10

~SQ30 8

mm 272 264 74 74 74 25 20 224 19

in 10.70 10.39 2.91 2.91 2.91 0.98 0.78 8.81 0.74

SQ35 AutoLube

~SQ43 AutoLube 8

mm 404 324 115 124 115 25 25 274 21

in 15.90 12.75 4.52 4.88 4.52 0.98 0.98 10.78 0.82

• SQ45 AutoLube ∼SQ50 AutoLube

MODEL HOLE

(EA) UNIT A B C D E F G H I J K

SQ45 AutoLube

~SQ50 AutoLube 12

mm 570 420 170 180 170 25 25 120 130 120 21

in 22.44 16.53 6.69 7.08 6.69 0.98 0.98 4.72 5.11 4.72 0.82

3.2 Medium & Heavy-duty range (2/2)

MODEL UNIT

A’

Upper

Plate

A B C D E F G H I

SQ60 mm 620 620 360 766 700 1615 589 125 2561 357

in 24.4 24.4 14.1 30.1 27.5 63.5 23.1 4.9 100.8 14.0

SQ70 mm 620 620 360 765 700 1659 650 135 2666 357

in 24.4 24.4 14.1 30.1 27.5 65.3 25.5 5.3 104.9 14.0

SQ80 mm 620 669 360 833 760 1744 705 140 2806 357

in 24.4 26.3 14.1 32.7 29.9 68.6 27.7 5.5 110.4 14.0

SQ100 mm 620 694 430 904 760 1849 692 150 2924 383

in 24.4 27.3 16.9 35.5 29.9 72.7 27.2 5.9 115.1 15.0

SQ120 mm 720 760 450 948 856 1920 846 155 3168 402

in 28.3 29.9 17.7 37.3 33.7 75.5 33.3 6.1 124.7 15.8

SQ130 mm 720 756 450 951 856 2086 872 165 3360 402

in 28.3 29.7 17.7 37.4 33.7 82.1 34.3 6.4 132.2 15.8

SQ140 mm 720 761 450 965 856 2167 872 165 3441 402

in 28.3 29.9 17.7 37.9 33.7 85.3 34.3 6.4 135.4 15.8

SQ150 mm 720 793 495 992 856 2343 839 175 3677 495

in 28.3 31.2 19.4 39.0 33.7 92.2 33.0 6.8 144.7 19.4

SQ181 mm 850 891 675 1081 950 2671 912 200 4112 529

in 33.4 35.0 26.5 42.5 37.4 105.1 35.9 7.8 161.8 20.8

** B, I, H : The dimension is for reference only and may vary depending on the required mounting plate (Top Cap).

AC

8‖ØK

12‖ØK

C

C

D

D

E

E

F

F

A

A

H

HIJ B

B

G

G

ØG

E I

A' D

H

F

B

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

14 15

04. Preparation for Installation and Operation

4.1 Checking before installation

CAUTION

CHECK THE "SPECIFICATIONS" SECTION OF THIS MANUAL TO DETERMINE CORRECT EXCAVATOR SIZES AND

HYDRAULIC PRESSURE, AND HYDRAULIC FLOW IF HYDRAULIC PRESSURE, HYDRAULIC FLOW IS EXCEEDED, THE

HYDRAULIC BREAKER WARRANTY IS VOID

BE SURE THE FLUID IN THE HYDRAULIC SYSTEM IS CLEAN.

CHECK THE HYDRAULIC FILTER, REPLACE THE FILTER IF DIRTY OR DETERIORATED.

CHECK THE GAS PRESSURE IN ACCUMULATOR AND BACK HEAD.

SEE INSPECTION AND CHARGING OF NITROGEN GAS AT BACK HEAD, ACCUMULATOR, HOSE AND FLUSHING.

CONTAMINATED PARTS MUST BE CLEANED WITH NO DELAY.

HYDRAULIC OIL OR LIGHT OIL IS HIGHLY RECOMMENDABLE.

THE CIRCUIT RELIEF SETTING PRESSURE IS NOT FIXED

BUT IT WILL BE ADJUSTED BY PUMP CAPACITY.

• Recommended circuit relief setting pressure and back pressure

MODEL UNIT SQ10 SQ20 SQ30 SQ35

AutoLube

SQ40

AutoLube

SQ43

AutoLube

SQ45

AutoLube

SQ50

AutoLube

Relief Setting Pressure

kg/㎠ 150 150 160 160 170 180 190 200

psi 2134 2134 2276 2276 2418 2560 2702 2845

Back Pressure

kg/㎠ 10 10 10 10 10 10 10 10

psi 142 142 142 142 142 142 142 142

MODEL UNIT SQ60 SQ70 SQ80 SQ100 SQ120 SQ130 SQ140 SQ150 SQ181

Relief Setting Pressure

kg/㎠ 200 210 210 210 210 210 210 210 230

psi 2845 2987 2987 2987 2987 2987 2987 2987 3271

Back Pressure

kg/㎠ 10 10 10 10 10 10 10 10 10

psi 142 142 142 142 142 142 142 142 142

• SQ60∼181

MODEL HOLE

(EA) UNIT A B C D E F G H I I’ J K

SQ60 12

mm 760 620 225 240 225 35 35 175 200 -175 26

in 29.92 24.40 8.85 9.44 8.85 1.37 1.37 6.88 7.87 -6.88 1.02

SQ70 12

mm 760 620 225 240 225 35 35 175 200 -175 26

in 29.92 24.40 8.85 9.44 8.85 1.37 1.37 6.88 7.87 -6.88 1.02

SQ80 12

mm 760 620 225 240 225 35 35 175 200 -175 26

in 29.92 24.40 8.85 9.44 8.85 1.37 1.37 6.88 7.87 -6.88 1.02

SQ100 12

mm 760 620 225 240 225 35 35 175 200 -175 26

in 29.92 24.40 8.85 9.44 8.85 1.37 1.37 6.88 7.87 -6.88 1.02

SQ120 12

mm 856 720 258 260 258 40 40 220 200 -220 38

in 33.70 28.34 10.15 10.23 10.15 1.57 1.57 8.66 7.87 -8.66 1.49

SQ130 12

mm 856 720 258 260 258 40 40 220 200 -220 38

in 33.70 28.34 10.15 10.23 10.15 1.57 1.57 8.66 7.87 -8.66 1.49

SQ140 12

mm 856 720 258 260 258 40 40 220 200 -220 38

in 33.70 28.34 10.15 10.23 10.15 1.57 1.57 8.66 7.87 -8.66 1.49

SQ150 12

mm 856 720 258 260 258 40 40 220 200 -220 38

in 33.70 28.34 10.15 10.23 10.15 1.57 1.57 8.66 7.87 -8.66 1.49

SQ181 14

mm 950 850 220 430 220 40 40 195 380 190 195 38

in 37.40 33.46 8.66 16.92 8.66 1.57 1.57 7.67 14.96 7.48 7.67 1.49

ØK HOLE

C D E F

A

HI

I'

J

B

G

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

16 17

• Removal of the Hydraulic Breaker

When the bucket and breaker operate alternately, the bucket and breaker can be easily exchanged by the

hydraulic hoses and two mounting pins. However, there is a risk of hydraulic contamination accordingly.

Do installation and removal as follows.

(1) Move the carrier to stable ground, free from mud, dust and dirt.

(2) Place the hydraulic breaker on timber.

(3) Stop the engine, turn off the main switch and deflate air from oil tank if it is

(4) Turn 90° the shut off valve installed to the end of arm to prevent hydraulic from flowing out.

(5) Loosen the hose plug on the breaker arm. Collect a small amount of oil flowing out at this time and put into a container.

(6) Be careful to prevent mud or dust from entering oil hoses and pipe lines. Plug oil hoses with hose plug and pipe lines

with union caps. Bind high and low-pressure hoses with a wire to prevent them from getting on the ground.

4.2 Installation and Removal

• Basic set up

CAP

Shut off valve

Breaker pipe lines

Hydraulic oil tank

Oil filter

Hydraulic pump

Timber

Stop Valve

Oil Hose Close

Open

Low-pressure line

High-pressure line

Breaker

Foot pedal

Rod

Control Valve

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

18 19

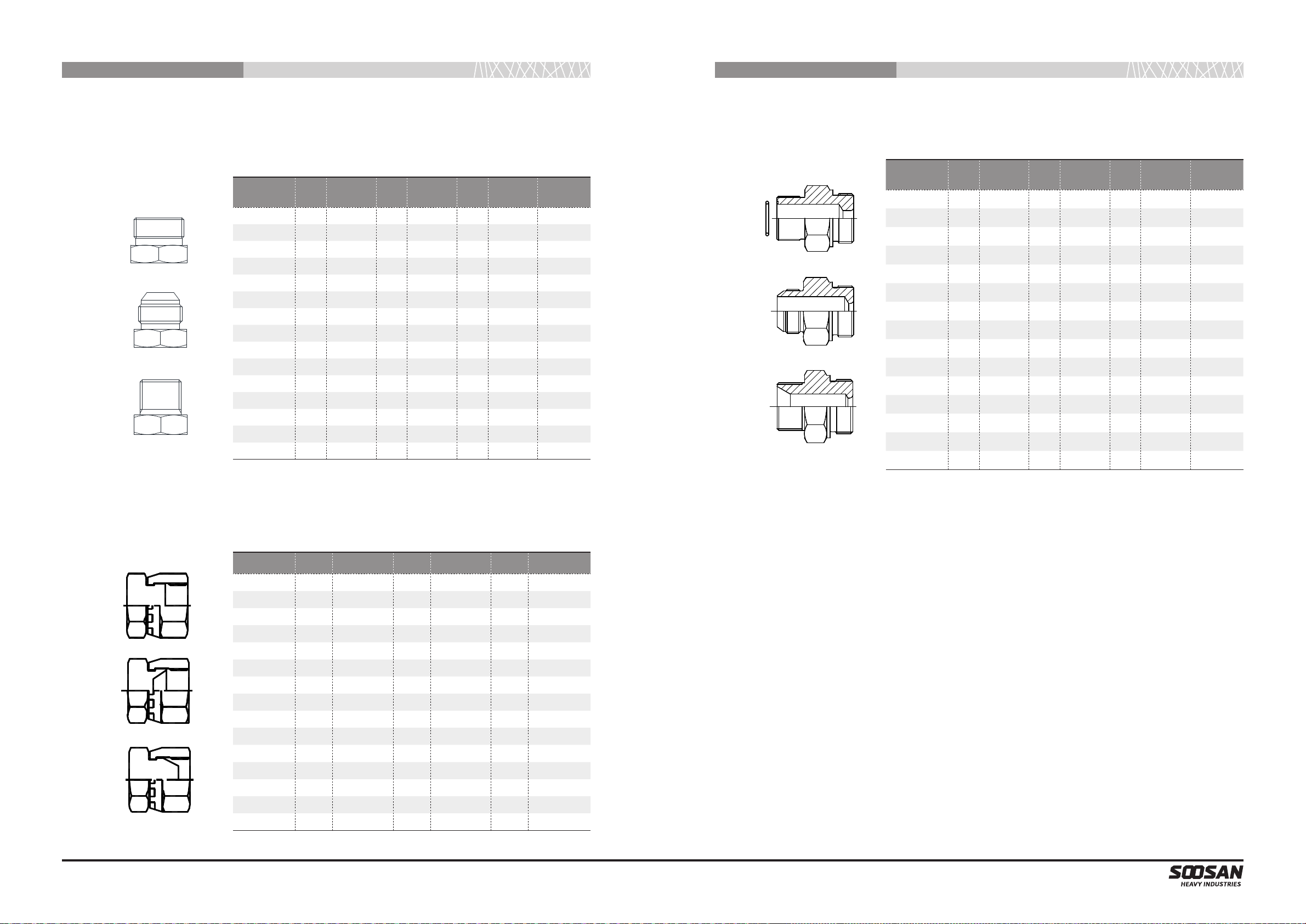

• Adapter

This parts connect to BREAKER IN/OUT port with hydraulic hose.

MODEL TYPE P / N TYPE P / N TYPE P / N O-RING

(#3)

SQ10 ~ SQ30 # 3 -# 4 C01201 # 5 C91120 -

SQ35 AutoLube # 3 -# 4 C01201 # 5 C91120 -

SQ40 AutoLube # 3 -# 4 C01201 # 5 C91120 -

SQ43 AutoLube # 3 -# 4 C01201 # 5 C91120 -

SQ45 AutoLube # 3 -# 4 C11121 # 5 2710311 -

SQ50 AutoLube # 3 -# 4 C11121 # 5 2710311 -

SQ60 # 3 C21124 # 4 C21131 # 5 2710315 2856004

SQ70 # 3 C21124 # 4 C21131 # 5 2710315 2856004

SQ80 # 3 C21124 # 4 C21131 # 5 2710315 2856004

SQ100 # 3 C31115 # 4 C31201 # 5 C31193 2856004

SQ120 # 3 B0003996 # 4 C31117 # 5 2710318 2856005

SQ130 # 3 B0003996 # 4 C31117 # 5 2710318 2856005

SQ140 # 3 B0003996 # 4 C31117 # 5 2710318 2856005

SQ150 # 3 B0003996 # 4 C31117 # 5 2710318 2856005

SQ181 # 3 C61150 # 4 C61152 # 5 2710319 2856005

• Oil hose plug

The oil hose plug is used to plug the hose attached to the hydraulic breaker. It prevents contamination of the hose when

the hydraulic breaker is removed from the carrier for bucket operation.

MODEL TYPE P/ N TYPE P/ N TYPE P/ N O-RING

(#3)

SQ10~SQ30 - - # 4 2715302 # 5 2715306 -

SQ35 AutoLube - - # 4 2715302 # 5 2715306 -

SQ40 AutoLube - - # 4 2715302 # 5 2715306 -

SQ43 AutoLube - - # 4 2715302 # 5 2715306 -

SQ45 AutoLube - - #4 2715303 #5 2715307 -

SQ50 AutoLube - - #4 2715303 #5 2715307 -

SQ60 # 3 2715300 # 4 2715304 # 5 2715308 2856004

SQ70 # 3 2715300 # 4 2715304 # 5 2715308 2715308

SQ80 # 3 2715300 # 4 2715304 # 5 2715308 2715308

SQ100 # 3 2715300 # 4 2715304 # 5 2715308 2715308

SQ120 # 3 2715301 # 4 2715305 # 5 2715309 2715309

SQ130 # 3 2715301 # 4 2715305 # 5 2715309 2715309

SQ140 # 3 2715301 # 4 2715305 # 5 2715309 2715309

SQ150 # 3 2715301 # 4 2715305 # 5 2715309 2715309

SQ181 # 3 2715301 # 4 2715305 # 5 2715309 2715309

* O-Ring(#3) use only TYPE #3

• Union cap

The union cap is used to cap the piping bracket attached to the carrier for prevention of the piping bracket from

contamination during bucket operation.

MODEL TYPE P/ N TYPE P/ N TYPE P/ N

SQ10~SQ30 # 3 -# 4 C01202 # 5 2715002

SQ35 AutoLube # 3 -# 4 C01202 # 5 2715002

SQ40 AutoLube # 3 -# 4 C01202 # 5 2715002

SQ43 AutoLube # 3 -# 4 C01202 # 5 2715002

SQ45 AutoLube # 3 -# 4 C11149 # 5 2715003

SQ50 AutoLube # 3 # 4 C11149 # 5 2715003

SQ60 # 3 2715063 # 4 C21132 # 5 2715004

SQ70 # 3 2715063 # 4 C21132 # 5 2715004

SQ80 # 3 2715063 # 4 C21132 # 5 2715004

SQ100 # 3 2715063 # 4 C21132 # 5 2715004

SQ120 # 3 2715064 # 4 C31175 # 5 2715005

SQ130 # 3 2715064 # 4 C31175 # 5 2715005

SQ140 # 3 2715064 # 4 C31175 # 5 2715005

SQ150 # 3 2715064 # 4 C31175 # 5 2715005

SQ181 # 3 2715064 # 4 C31175 # 5 2715005

#3

#3

#3

#4 #4

#4

#5 #5

#5

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

20 21

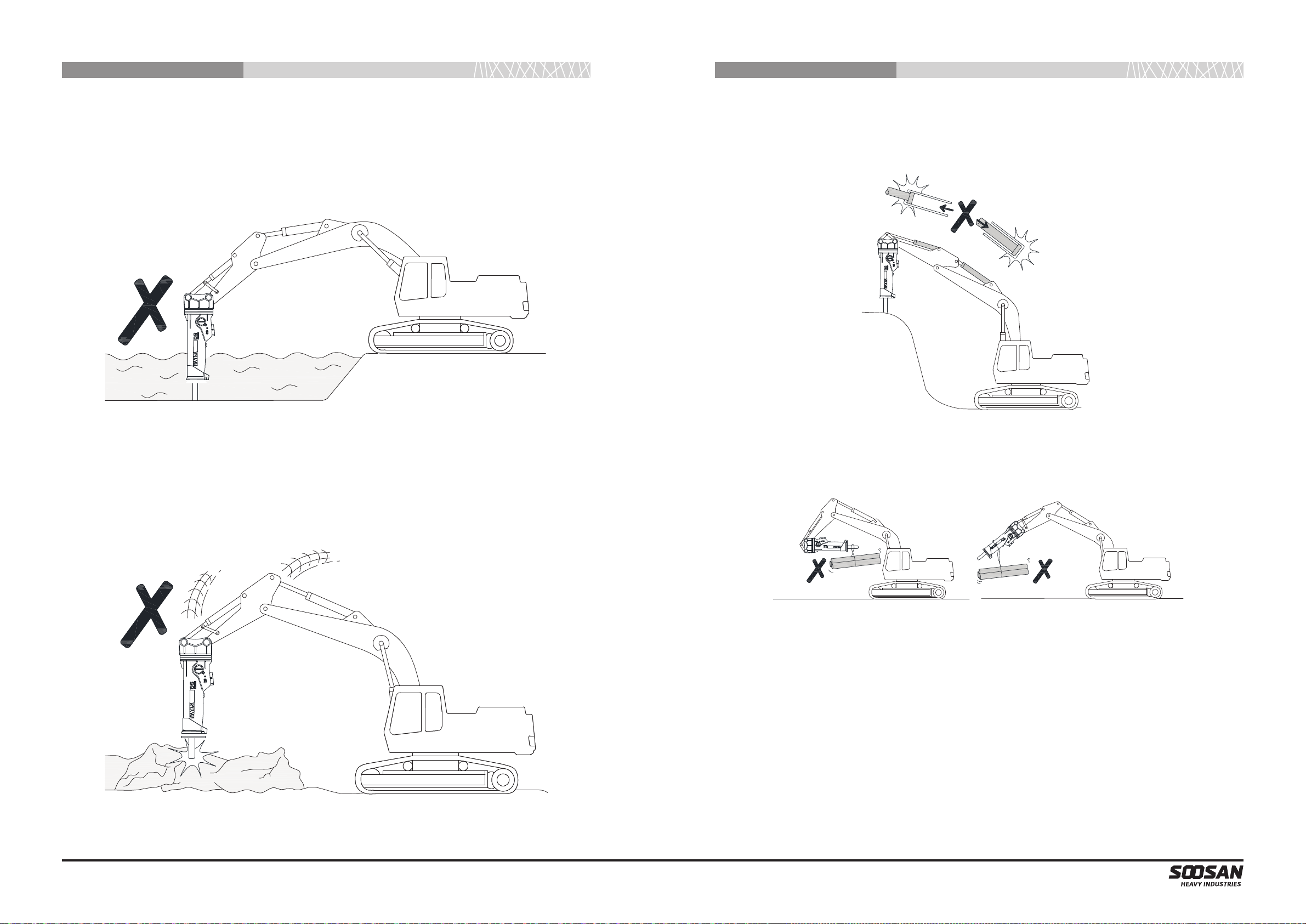

05. Precautions for safe operation.

[1] Proper position must be applied for an effective usage of breaking force.

When position is incorrect, hammering energy of the piston is too weak to break rocks,

[2] On the contrary, when position is excessive enough to break rocks with front of the base machine raised, the machine

may suddenly tilt forward the moment rocks are broken. Then, the breaker body or the end of bracket may violently hit

against rocks and result in damage.

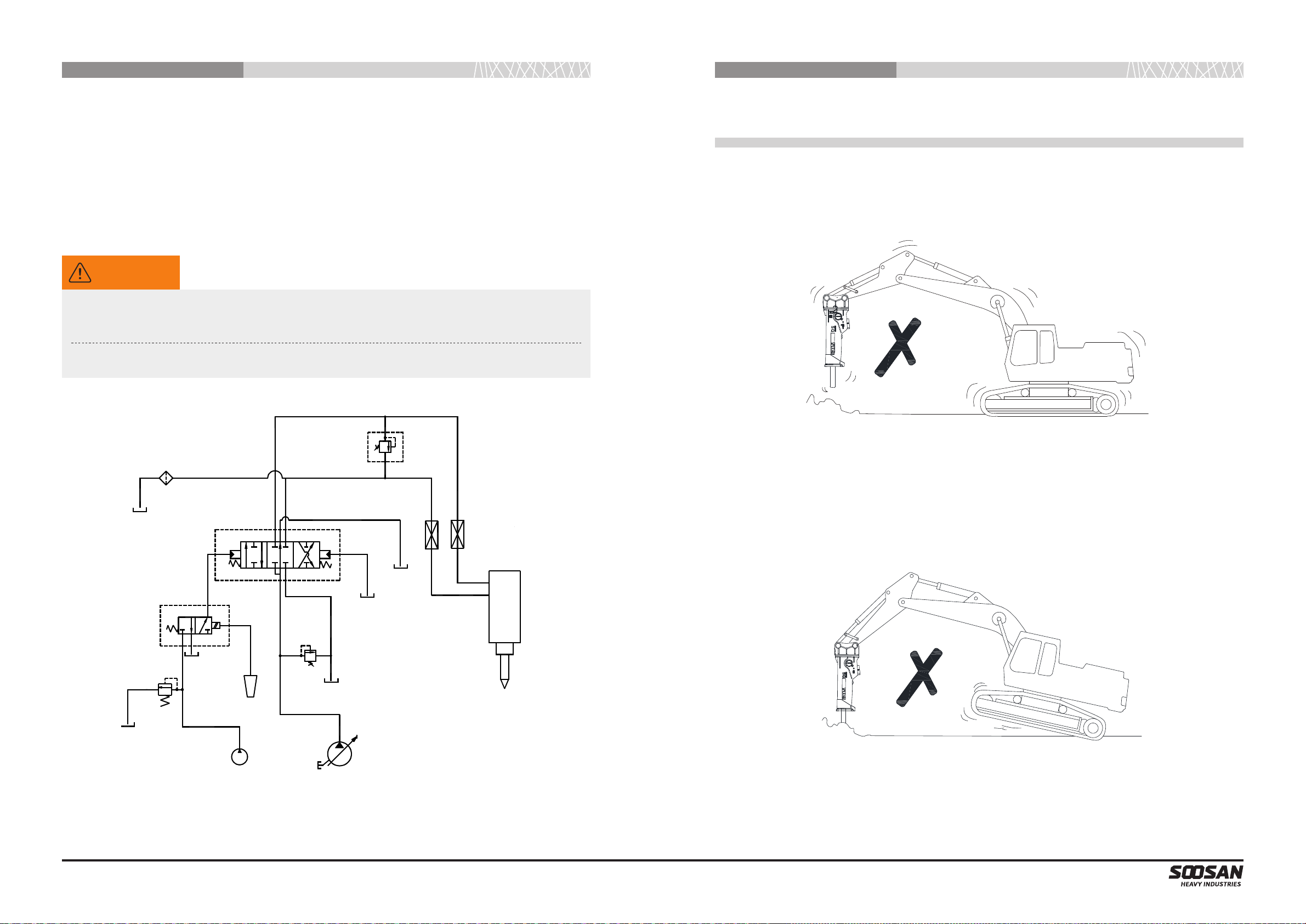

4.3 Hydraulic pipe lines for exclusive use

Operation of the hydraulic breaker requires installation of hydraulic pipe lines for exclusive use of the hydraulic breaker. As

hydraulic pipe lines vary depending on base machines, our service engineer must first check hydraulic pressure, oil capacity,

pressure loss and other conditions of the base machine before installing hydraulic pipe lines. Use only genuine parts in case of

replacement because hydraulic pipe lines (hoses, pipes and fittings) are made of materials carefully selected in consideration

of durability.

WARNING

THE HYDRAULIC SYSTEM TO THE BASE MACHINE MUST BE CHECKED BY AN AUTHORIZED SOOSAN SERVICE

ENGINEER BEFORE FIRST USE AND AFTER ANY MODIFICATIONS.

MAKE SURE THAT THE HYDRAULIC BREAKER VALVE OF HYDRAULIC SYSTEM IS PROPERLY SET.

RELIEF V/V

M.C.V

STOP V/V

IN

OUT

BREAKER

MAIN PUMP

GEAR PUMP

O/SWITCH

PILOT V/V

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

22 23

[5] Do not use the breaker rod to move rocks. The stone claws are designed for this purposes.

[6] Do not use the breaker to sweep the ground of debris.

This may damage the breaker and the housing will wear out more quickly

[3] It is undesirable to carry out hammering under the below condition, because vibrations during hammering

may be transmitted to tracks of the base machine.

During hammering, however, proper position must be always applied to the breaker.

Special care must be taken not to hammer under abnormal condition.

[4] Apply same direction of boom force in line with the rod and place the rod in the rock with hammering surface as vertical

as possible. If hammering surface is oblique, the rod may slip during hammering. This causes the rod to seize and to be

broken and piston to be damaged. When breaking, fully stabilize the rod first and then select the point of a rock on which

hammering can be performed in a stable condition.

90˚

③ ② ①

90˚

SOOSAN HYDRAULIC BREAKERS SOOSAN HYDRAULIC BREAKERS

OPERATION MANUAL OPERATION MANUAL

www.soosanheavy.com

24 25

[9] Do not operate the breaker with the carrier's boom, stick or bucket cylinders at the end of

their stroke (either fully extended or fully retracted). Damage to the carrier may result

[10] Do not use the breaker or breaker rods for lifting.

Lifting eyes on the breaker are for storage and maintenance purposes only.

[11] Warm-up of machine prior to operation

- Do not operate the machine right after starting the engine. Idle the machine for warm-up. Warm the hydraulic oil

sufficiently especially in winter or in the cold place.

- Especially in winter, the carrier's engine should be warmed up for 5 to 10 minutes 30~40℃(86∼105℉) before breaker

operation.

- When operating the hydraulic breaker, idle the engine and operate the hydraulic breaker with a light load.

[12] Stop operation when hoses are vibrating abnormally.

Check the hoses on the high pressure and low pressure sides of the breaker for abnormal vibration. If they are vibrating

abnormally, contact the nearest Soosan dealer.

[7] Do not operate breaker when all components except rod are immersed in water and mud.

Underwater usage of the breaker will cause internal damage to the breaker.

Consult Soosan for modifications if you have an underwater requirement.

[8] Do not allow the breaker to fall to a rock.

Falling down the breaker will apply excessive force to the breaker or the carrier, causing damage to the parts of the

breaker and carrier.

Other manuals for SQ Series

2

This manual suits for next models

17

Table of contents

Other Soosan Construction Equipment manuals