Dhatec V-Sup User guide

Elskensakker 8, NL-5571 SK

Bergeijk, The Netherlands

Tel +31 497 542 527

Fax +31 497 555 399

Web www.dhatec.nl

Rev.

Date

Status

Prepared By

Approved By

00

03-04-2018

Released

Daan Neutkens

Martijn Bayens

01

10-08-2018

Released

Daan Neutkens

Clovis Kouamé

02

23-01-2018

Released

Bas Coenen

Martijn Bayens

03

12-02-2018

Released

Bas Coenen

Martijn Bayens

04

02-04-2019

Released

Bas Coenen

Martijn Bayens

©Dhatec B.V. The following document shall be considered as copyright and the design right reserved. Copying and/or disclosure of the information

contained within the following document to any third-party, other than specifically for the purpose of the project is forbidden without prior written

permission of the proprietor.

Application Procedure Specification Dhatec V-Sup

Dhatec Document No.: DHA415-APS-VS

2

Change Record

Rev.

Description of Revision

00

First Issue

01

Amount of stackable beams per stack (page 7)

02

Adaptation of minimum usage temperature

03

Adaptation of maximum usage temperature

General Information

Equipment

V-Sup

Supplier Name

Dhatec B.V.

Telephone No.

+31 497 542 527

Fax No.

+31 497 555 399

Contact e-mail address

Disclaimer of liability: Every effort has been made to ensure that the information in this document is accurate and

correct to the best of our knowledge, correct at the date of publication. However, Dhatec B.V. cannot be held

responsible for consequences that follow from the claims that were made in this document.

Do not carry out any repairs or modifications on the equipment without consulting Dhatec B.V., doing so will invalidate

the guarantee. The guarantee is also invalidated if accidents and damage of anyform are caused as a result of improper

use and/or not obeying the warnings in general as explained in this user guide. Dhatec B.V. accepts no responsibility

for any personal accidents as a consequence of not following the safety instructions and warnings. This is also the case

for consequential loss in any form.

3

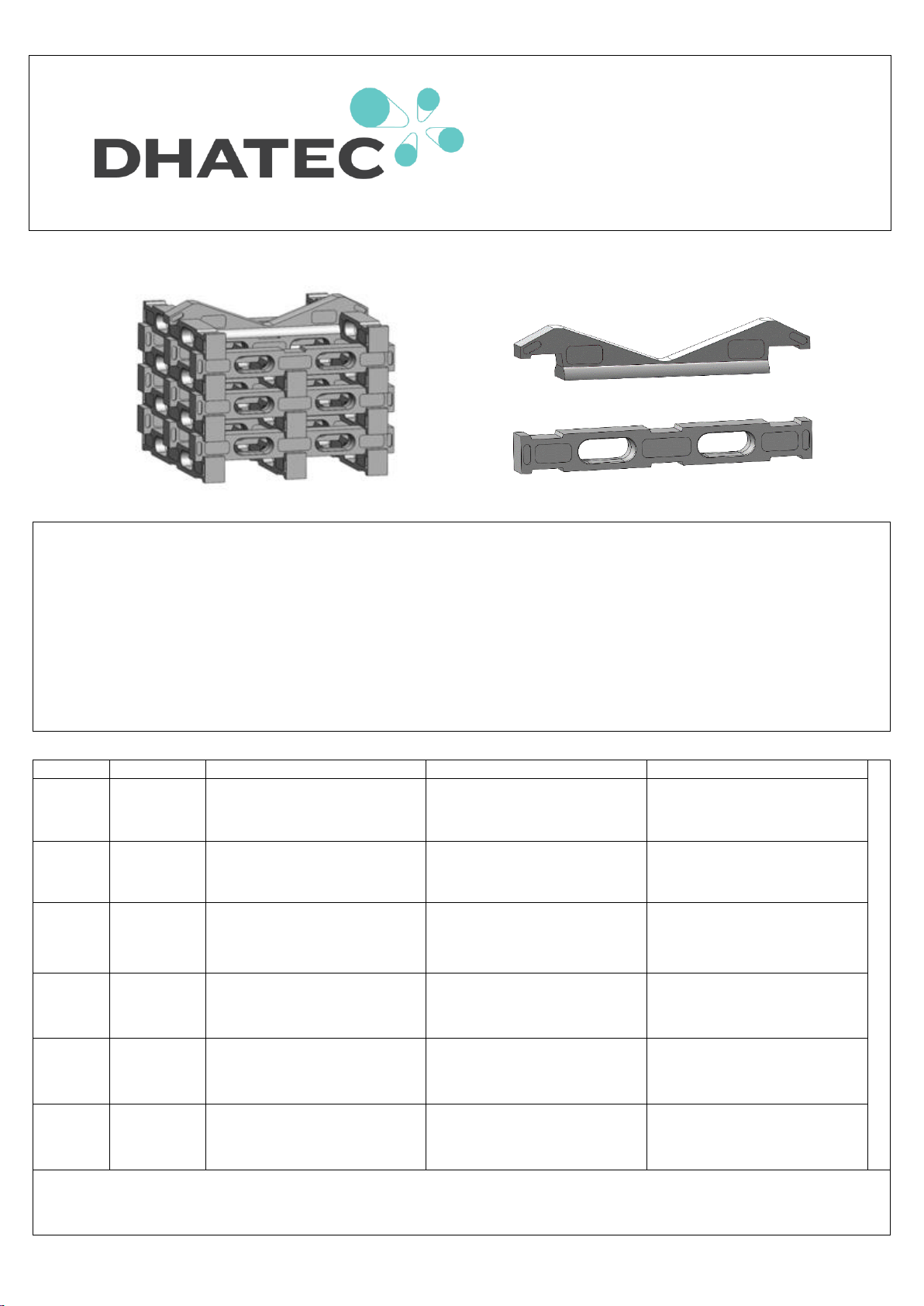

Safety Requirements

These are general guidelines, all personnel involved should adhere to the safety requirements of the particular location

at which they are performing their operations.

Dhatec recommends wearing of suitable PPE while handling their products. This includes gloves, safety shoes, safety

glasses, safety helmet and suitable work clothing.

The working areas should be kept tidy at all times in order to minimize the risk of trips and slips.

All personnel involved should use suitable manual handling techniques and follow industry recommended guidelines for

lifting and moving, such as those described in “Ergonomic Guidelines for Manual Material Handling” published by the

National Institute for Occupational Safety and Health (Publication 2007-131), or those otherwise prescribed by the client.

Introduction

The V-Sup is a system designed to support pipes during construction activities. Supporting these pipes is not without

risks. If the pipes are not handled and supported carefully, serious damages or injuries can occur.

The purpose of this installation manual is to make the users of the V-Sup aware of the risks and dangers resulting from

the installation, use and maintenance of the system. This manual provides basic safety guidelines to cope with the risks

and hazards and to guarantee a safe way of supporting pipes. In spite of these basis guidelines, one should always

respect the local safety regulations.

Everybody who will use the V-Sup system should be familiar with the essence of this manual. Therefore, it is obligatory

to carefully read this manual thoroughly, before installing and using the V-Sup system. The installation of the V-Sup

may only be realized by trained employees, who are completely known with the guidelines and procedures specified in

this manual.

Always contact Dhatec in case of doubts or uncertainties during installation, operation and maintenance of the V-Sup.

4

SAFETY FIRST (user values and actions)

User values

- One V-Sup stack may be loaded up to 12.000 kg (26.455 lbs) in a dynamic situation (work in progress).

- One V-Sup stack may be loaded up to 16.000 kg (35.274 lbs) in a static situation (no work in progress).

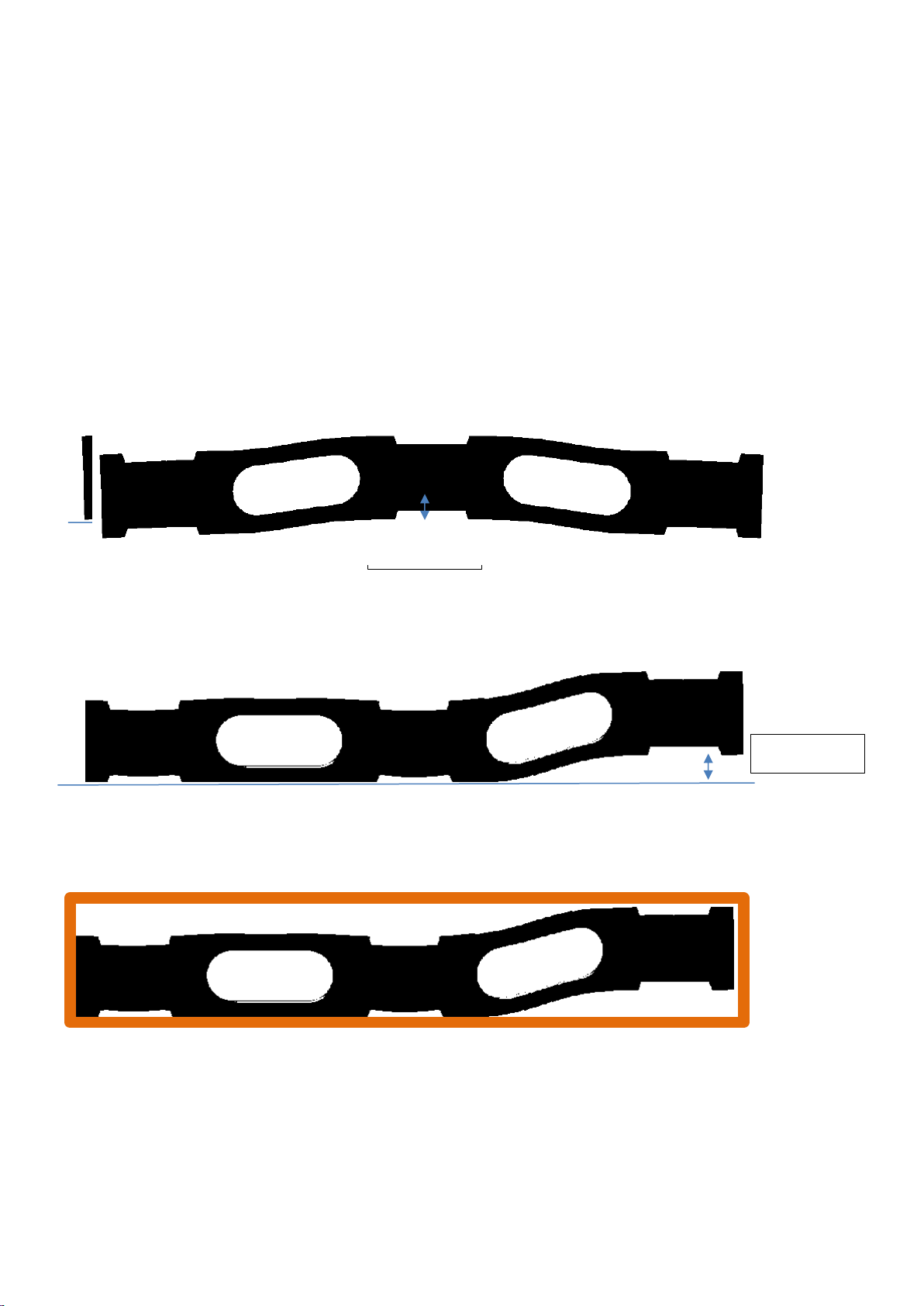

- Always keep in mind on what angles the V-Sup system is used. The pictures below show the maximum angle

in a certain situation:

8° 8° 25°15°

- The V-Sup may be used on terrains with unevenness up to 50 mm (2’) (Figure 13).

- The V-Sup may be used in a maximum operating temperature of 45°C (118°F).

- The V-Sup may be used in a minimum operating temperature of -30°C (-22°F).

- The V-Sup may be in contact with objects that have a maximum temperature 90°C (194°F).

User actions

- Before installing a V-Sup stack, subject the parts to an extensive visual inspection and discard the parts that

show product failures (chapter A.2.).

- The V-Sup beams must be free from substances that have a negative influence on the friction (chapter B.1.).

- Always position the V-Sup beams as explained (chapter B and C). Make sure the recessed lock into each

other to prevent the beams from sliding. Always use the beams in the way than what they are designed for.

- Before loading the pipe, check the stability of the V-Sup (chapter D.1.).

- Never allow anybody underneath or near the lifted pipe during loading and unloading of the pipe (chapter

D.2.).

- This instruction manual is put together with great care. When safety risks and issues are noticed which are not

covered by this instruction, please contact Dhatec to share this remark.

Figure 1. Slopes in the terrain

5

Installation manual

When using the V-Sup, the procedures listed below should always be regarded. The following list is only a brief

overview of the procedures that should be respected, a complete elaboration can be found in the following paragraphs

of this chapter.

A. General instructions for V-Sup

A.1. Equipment

A.2. Product check

B. Installation of the V-Sup

B.1. Preparation of construction location

B.2. Installation of Stackable Beams

B.3. Installation of V-beam

C. V-beam for pipe stringing

C.1. Preparation of location

C.2. Installation of the V-beams

D. Placing of pipes

D.1. Safety check 1

D.2. Placing pipe

D.3. Safety check 2

6

A. General instructions for V-Sup

A.1. Equipment

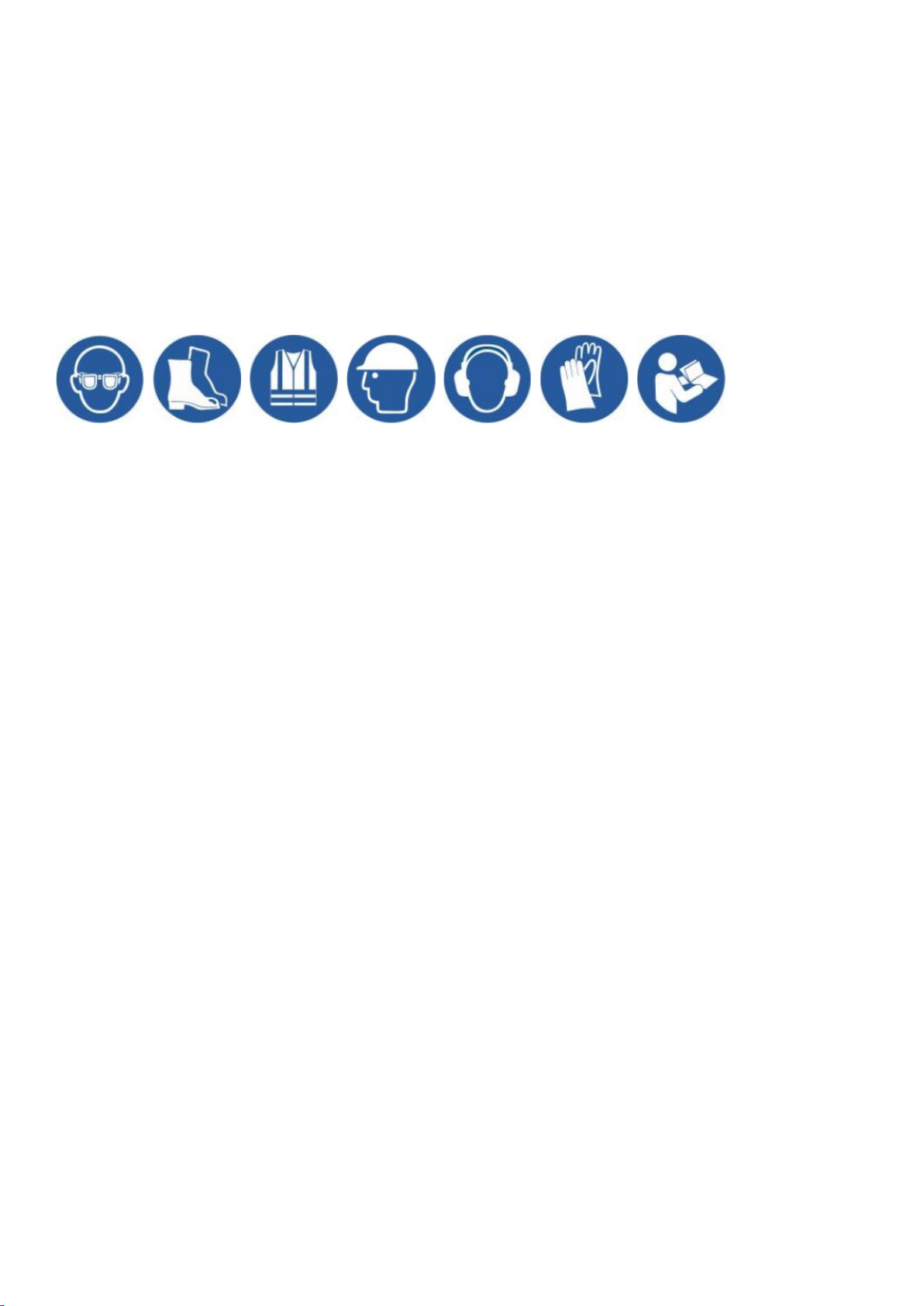

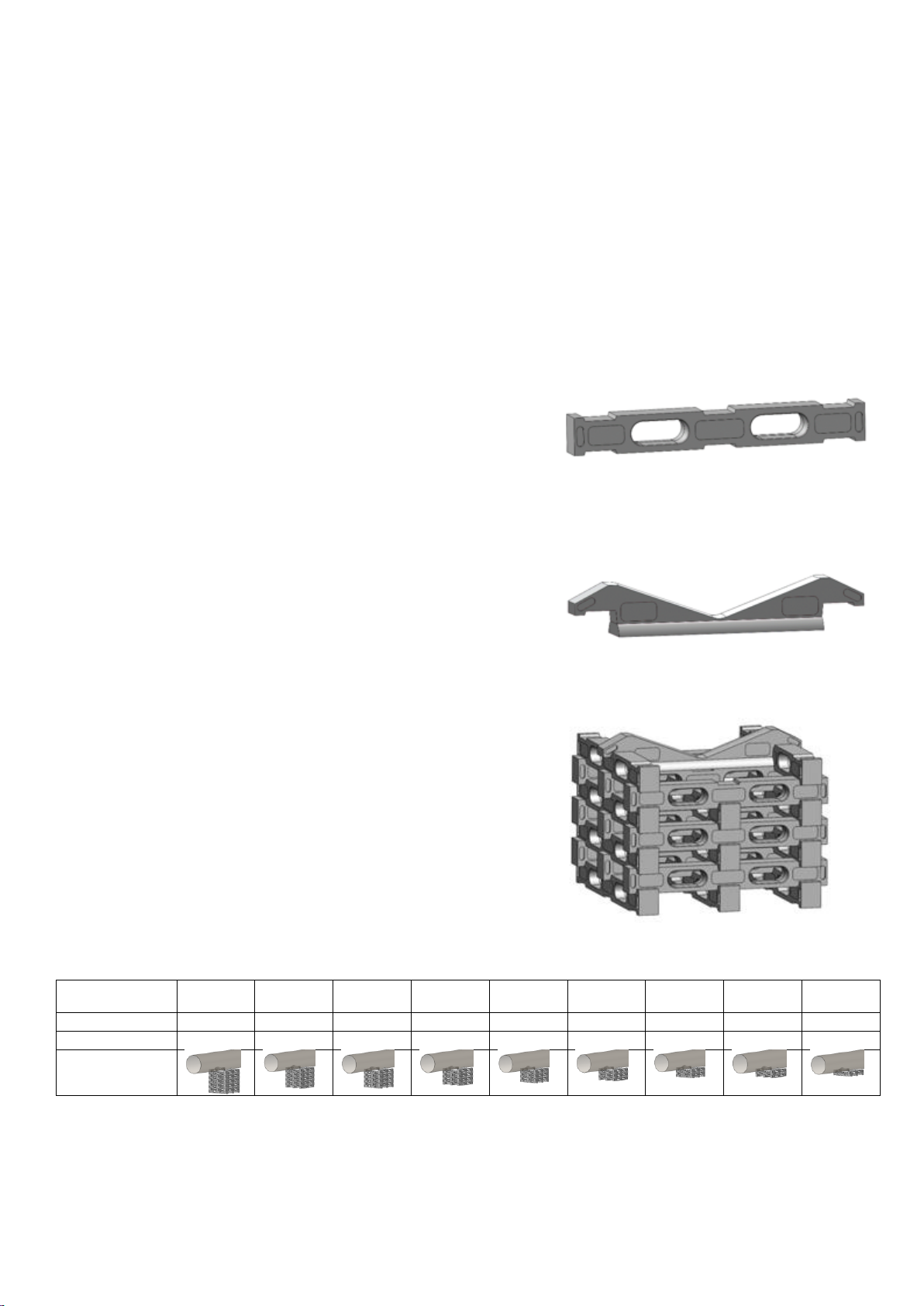

V-Sup is a system of beams to build a stack (Figure 4). The stack can be used to support pipes during pipeline

construction activities. A V-Sup stack consists of several Stackable Beams (Figure 2) and one V-Beam (Figure 3). The

Stackable Beams are increasing the height of the stack with 120 mm per layer (3 beams per layer). The V-Sup stack

can also be used for other temporary support applications (e.g. in a factory or storage area).

On top of the stack of Stackable Beams a V-beam will be placed to make sure the pipe won’t roll of the support. This V-

beam can also be used for pipe stringing. This means two beams will be placed directly on the ground after which a

pipe can be placed on top of them.

The V-Sup is capable of supporting pipes up to Ø2032 mm / 80’’. A pipe has to be supported by at least 2 V-Sup Stacks.

Stackable Beam (Figure 2)

Length: 1200 mm

Height: 150 mm

Depth: 120 mm

Stacking height: 120 mm

Weigh: ± 12,7 kg

V-Beam (Figure 3)

Length: 1200 mm

Height: 210 mm

Depth: 120 mm

Weight: ± 15,3 kg

V-Sup Stack (Figure 4)

Length: 1200 mm

Width: 1200 mm

Height: Variable (increasing by 120 mm per layer)

Every stack contains one V-Beam on top in the middle recess. No more than one V-Beam is allowed per stack.

Ground distance

120 cm

47 ¼ ‘’

108 cm

43 ½ ‘’

96 cm

37 ¾ ‘’

84 cm

33 ‘’

72 cm

28 ⅜ ‘’

60 cm

23 ⅝ ‘’

48 cm

19 ‘’

36 cm

14 ⅛ ‘’

24 cm

9 ½ ‘’

Layers

10

9

8

7

6

5

4

3

2

# beams

29

26

23

20

17

14

11

8

5

Figure 2. Stackable Beam

Figure 3. V-Beam

Figure 4. V-Sup Stack 7 layers

7

Max. 19 mm

A.2. Product check

Before using the Dhatec V-Sup, all parts should be subjected to an extensive visual inspection. If any below listed defect

is observed, discard the relevant part.

For safe use of the V-Sup, check the beams on the following aspects:

To make sure that the beams are not deformed too much to use them in a safe way, check all products before using

them. Do that by looking at the next points:

−The beams should always be able to lock into each other without any problems.

−The beams should not show signs of extensive wear of (pipe) imprints. (+ 5 mm)

−The beams should not show carves of more than 5 mm deep or wide.

−The beams should not show signs of extensive bending or deflection (Figure 5 and Figure 6).

If there are doubts of the functionality of a used item, please contact Dhatec.

Figure 5. Deflection type 1

Figure 6. Deflection type 2

Max. 23 mm

8

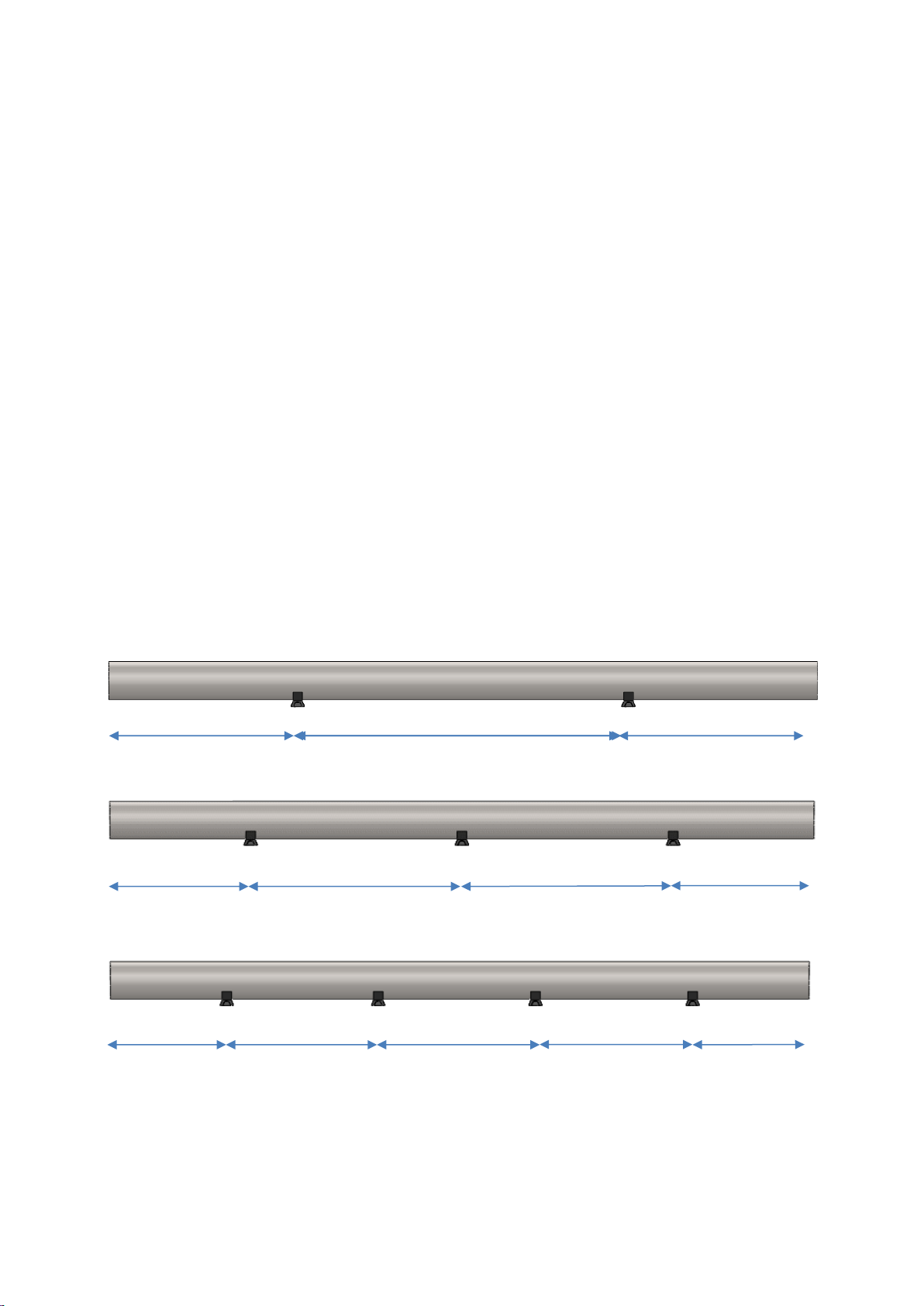

22%

22%

56%

14%

14%

36%

36%

10%

10%

27%

26%

27%

4 Supports

3 Supports

2 Supports

Figure 7. Ideal placement of supports

B. Installation of the V-Sup

Step B.1. Preparation of construction location:

−Make sure the construction area is visibly marked and the transport and emergency routes are clearly indicated.

−Make sure the surface on which the V-Sup will be installed is levelled, the maximum slopes should be accepted.

Check the right-of-way (pipeline route) for any slopes.

−Make sure the surface on which the V-Sup will be installed is flat, unevenness in the terrain of maximum 50 mm

are acceptable. Unevenness larger than 50 mm should be levelled out properly.

−Make sure the surface on which the V-Sup will be installed is free of ice, snow, oil, mud, algae, or any other

substances that have a negative influence on the friction.

−Make sure the surface on which the V-Sup will be installed is free of obstacles (such as wood, stones, gravel

or any other obstacles).

−To ensure a safety envelop large enough, the use of the V-sup is recommended within a temperature window

of -30°C up to +45°C. (-22°F to 113°F)

Step B.2. Installation of Stackable Beams

−Each V-Sup Stack will be assembled from stackable beams, placed on top of each other. For every pipe, at

least two V-Sup stacks are necessary.

−Make sure all beams are free of ice, snow, oil, mud, algae, or any other substances that have a negative

influence on the friction.

−Make sure the V-Sup segments are not damaged, deformed or worn down.

−Make sure the recesses in the beams lock precisely into each other.

−The alignment of the V-Sup stacks is of vital importance for the safe functioning of the system. The V-sup stacks

needed for one pipe should be aligned parallel.

−To give the best support for the pipes, the V-Sup stacks have to be placed at a set distance according to the

pipe length and the amount of V-sup stacks needed. The distance is prescribed as a percentage of the pipe

length. Figure 7 will show the prescribed distances with 2, 3 and 4 supports.

9

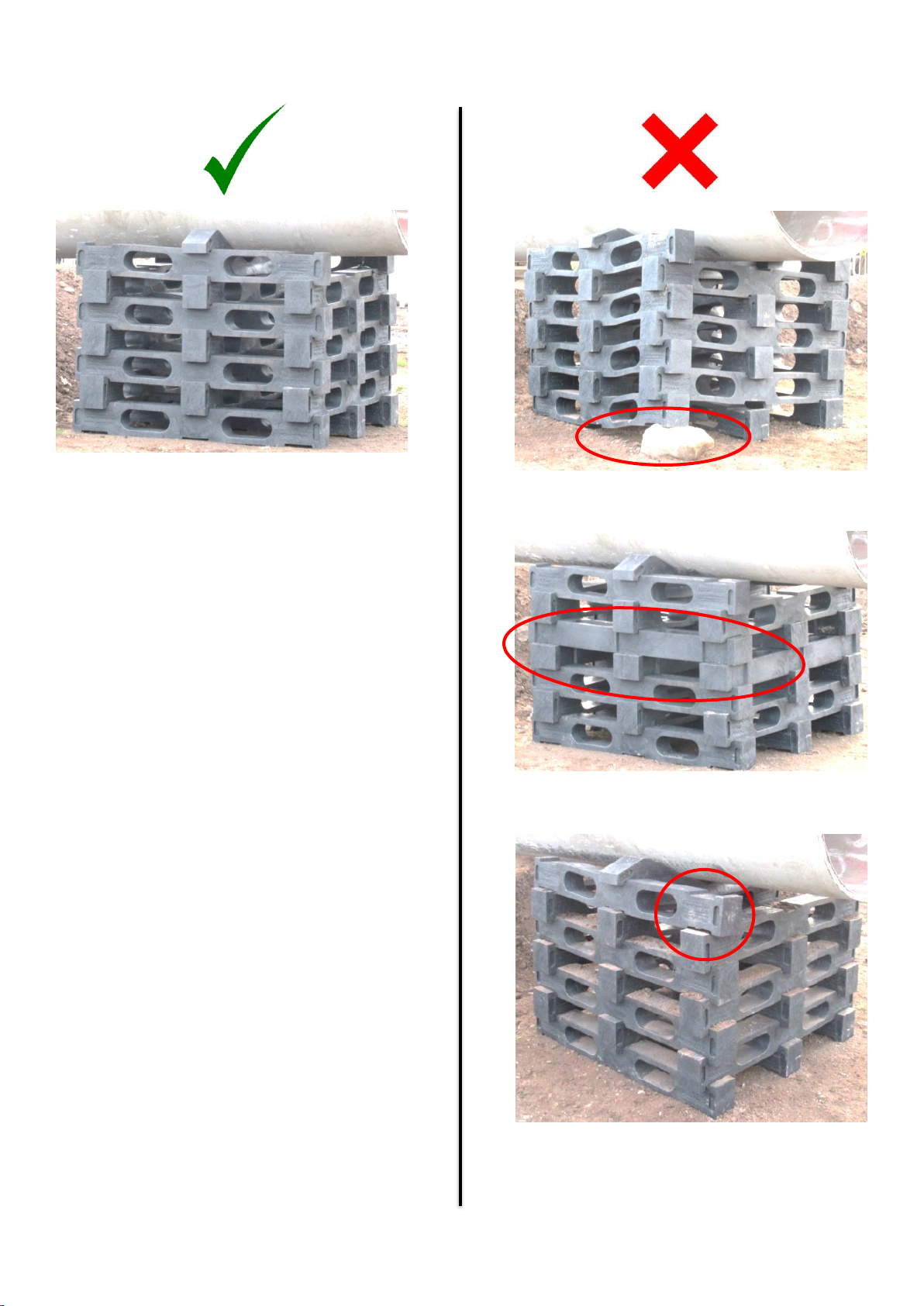

−When the distances between the supports is decided, stacking of the stackable beams can start. Always start

−with 3 beams next to each other on the ground followed by 3 beam crosswise to that. Repeat this to the

desired height. When the stack has to contain an even number of layers stackable beam, place the bottom

row at right angles to the longitudinal direction of the pipe. When an odd number of layers stackable beams

have to be used, the bottom row has to be placed in the longitudinal direction of the pipe. The V-Sup may not

be build up higher than 10 layers of stackable beams.

Figure 8. Building up stackable beams

Step B.3. Installation of V-beams

−Make sure the Stackable Beams on top of the V-Sup stack are free of ice, snow, oil, mud, algae, or any other

substances that have a negative influence on the friction.

−Make sure the V-beam is free of ice, snow, oil, mud, algae, or any other substances that have a negative

influence on the friction.

−Make sure that neither the Stackable Beams on top are damaged, nor the V-Beam.

−Place the V-Beam on top of the Stackable Beams. Make sure that all recesses in the different beams precisely

lock into each other. This has to be checked properly in order to make sure the pipe can be placed on top of

the V-Sup in a safe way.

−The V-beam always has to be positioned in the centre of the V-Sup (Figure 9). Only one V-Beam has to be

used. Never place a V-Beam on the outside of a V-Sup. The risk of the whole V-Sup stack tipping over with a

pipe on it increases a lot when a V-Beam is placed on the outside (Figure 16).

Figure 9. Placing V-beam (V-Sup Stack 7 layers)

10

Figure 10. Pipe on V-beam

C. V-beam for pipe stringing

Step C.1. Preparation of location

−Make sure the construction area is visibly marked and the transport and emergency routes are clearly indicated.

−Make sure the surface on which the V-Sup will be installed is levelled, make sure that the maximum slopes

named on page 5 are respected. Check the right-of-way (pipeline route) for any slopes.

−Make sure the surface on which the V-Sup will be installed is flat, unevenness in the terrain of maximum 20 mm

are acceptable. Unevenness larger than 20 mm should be levelled out properly.

−Make sure the surface on which the V-Sup will be installed is free of ice, snow, oil, mud, algae, or any other

substances that have a negative influence on the friction.

−Make sure the surface on which the V-Sup will be installed is free of obstacles (such as wood, stones, gravel

or any other obstacles).

−Make sure the minimum and maximum operating temperatures of respectively -30 and +45 °C are respected.

Step C.2. Installation of the V-beams

−For pipe stringing, at least two V-beams per pipe are necessary.

−Make sure all V-beams are free of ice, snow, oil, mud, algae, or any other substances that have a negative

influence on the friction.

−Make sure the V-beams segments are not damaged, deformed or worn down.

−The alignment of the V-beams is of vital importance for the safe functioning of the system. The V-beams needed

for one pipe should be aligned parallel.

−To give the best support for the pipes, the V-beams have to be placed at a set distance according to the pipe

length and the amount of V-beams needed. The distance is prescribed as a percentage of the pipe length.

Figure 7 shows the prescribed distances with 2, 3 and 4 supports.

11

D. Placing of pipes

Step D.1. Safety check 1

−Make sure the V-Sup stack is free of ice, snow, oil, mud, algae, or any other substances that have a negative

influence on the friction. Especially check the contact areas between the beams, the bottom surface, and the

contact surface of the V-Beam with the pipe.

−Make sure the contact surface of the V-Beams are free of substances that can cause damages to pipe coatings.

−Check if the V-Sup is build up properly. Give it a visible check but also push against it to feel any unevenness

in the V-Sup stack. Also check the contact areas of the V-Sup with the bottom surface. Check for any

unevenness which previously may have been overlooked.

−Check if the V-Sup beams make full contact with each other. When some recesses don’t lock together in a

proper way, the whole stack can become skew and unstable. This can cause dangerous situations when a pipe

is placed on top of it. Again, make sure all beams lock into each other in a proper way.

Step D.2. Placing pipe

−Before placing the pipe, follow step D.1. of this manual completely. Then position the pipe on the V-Sup stacks.

Do this with caution and make sure the V-Sup stacks are loaded carefully.

−The V-Sup can be loaded with all different lifting equipment (hooks, reach stacker, vacuum lifter, slings, etc.)

−Make sure that during the lifting and loading procedures of the pipes, nobody is standing underneath or near

the lifted pipe.

−The dynamic loads/forces to the V-Sup should be kept to a minimum. Pipes need to be positioned with minimum

impact. Avoid horizontal movement of the pipe when this is in contact with the V-Sup, always lift it first.

Step D.3. Safety check 2

−Make sure there is no contact between the pipe and the stackable beams. In case there is contact, the angle of

the surface is probably too big. Remove the pipe from the V-sup stacks and correct this (consult Figure 1).

−Check if all stackable beams still lock into each other with the recesses. This is important in order to prevent the

beams from sliding relative to each other.

−Check if the V-Sup and separate beams are not tilted and they make full contact with the bottom surface or the

beams below. In case a beam is tilted or there is no full contact, remove the overlying pipe and reposition the

beam (check the recesses) to restore full contact.

−Generally check the overall V-Sup. Check if it stands solid with the pipe on it. A worker has to feel safe when

working underneath a pipe on V-Sup.

Figure 11. Pipe on two V-Sup Stacks

12

Guidelines to check if V-Sup is used properly

Figure 15. Contamination in recesses

Figure 13. Unevenness in terrain

Figure 12. Correct V-Sup stack

Figure 14. Beams on their sides

13

Figure 16. V-Beam in outer recesses

Figure 16. Correct V-Sup Stack

Figure 17. Beams placed next to recesses

Figure 18. Stackable Beam left out of the stack

Table of contents

Popular Construction Equipment manuals by other brands

GP

GP HBM-NOBAS BG 160TA-4 Maintenance instructions

Brugg Pipesystems

Brugg Pipesystems CALPEX-Big-T-I-L instruction manual

Auto Crane

Auto Crane 6006H owner's manual

Denzel

Denzel DCM-125 user manual

Wacker Neuson

Wacker Neuson RD24 instruction manual

Furukawa Unic

Furukawa Unic URW376C4U -T Series Operation & maintenance manual