Soosan POSHER Series User manual

2

SOOSAN HYDRAULIC PULVERIZER

O

OP

PE

ER

RA

AT

TI

IO

ON

N

M

MA

AN

NU

UA

AL

L

SOOSAN

P

P

PO

O

OS

S

SH

H

HE

E

ER

R

RS

SE

ER

RI

IE

ES

S D511560

2

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

Before use the concrete pulverizer,

Read carefully below clauses.

1. Before use the concrete pulverizer, Operator have to read "OPERATION MANUAL"

2. Before connect the hoses, Clean the shovel's pipe-line.

3. Before use, Lubricate the frame-pin, arm-pin, and the other move parts.

4. Every time to work, Check if bolts are loosened, hoses and connection-parts are leaked,

frame and arm are cracked.

5. After work, Select a level place where there are no mud, dust, etc. and place the

pulverizer on the wood blocks.

6. Do not allow the pulverizer to drop and strike a material or strike against the side of a

material.

7. Store the pulverizer with the hydraulic cylinder retracted.

8. In order not to diffuse of dust, Use FOG-FOUNTAIN-NOZZLE which is very effective.

3

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

We appreciate your purchasing a Soosan Hydraulic Pulverizer.

The Hydraulic Pulverizer, designed and built to provide durable operation under any

working conditions, has been developed by Soosan's excellent engineering

techniques with accumulated experiences for many years. Without proper handling,

regular inspection and maintenance, however, the machine fails to display its full

capacity, resulting in various troubles of machine parts.

This publication should be carefully read prior to installation and operation in order

to prevent any mishandling of hydraulic pulverizer.

We guarantee that a faithful compliance of the instruction will contribute to the best

operation condition.

Customers are, therefore, required to keep in mind that the company is not

responsible for troubles caused by not following our guidelines or not using genuine

parts.

Soosan Heavy Industries Co., Ltd

.

4

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

OPERATION MANUAL

1. STANDARD SPECIFICATIONS AND EXTERNAL DIMENSIONS

5

2. INSTALLING AND REMOVING FROM HYDRAULIC SHOVEL

6

3. INSPECTION BEFORE OPERATING

7

4. PRECAUTIONS FOR PULVERIZER

8

5. MAINTENANCE

13

6. REPLACEMENT OF REINFORCED CUTTER

14

5

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

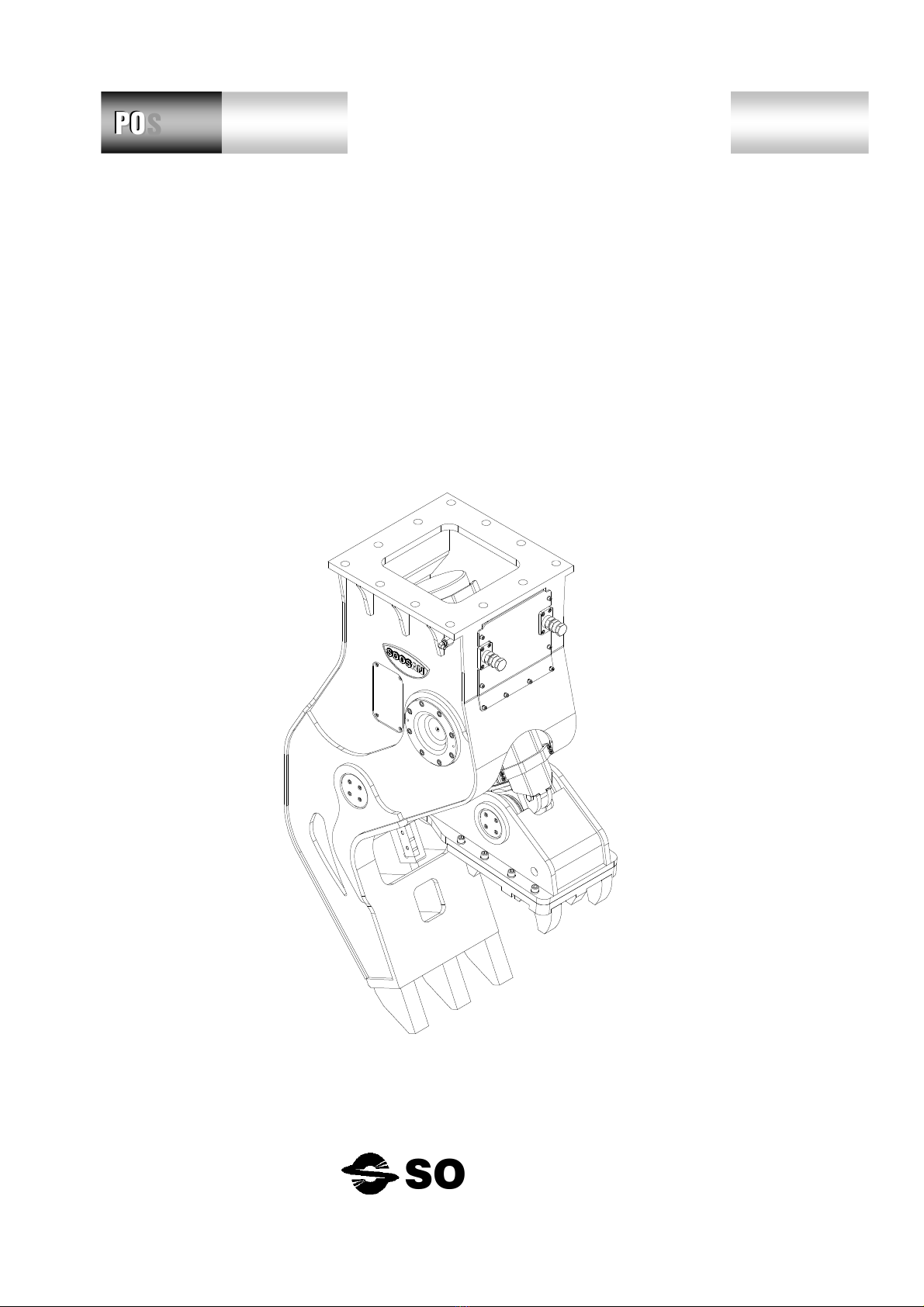

1. Standard specifications and external dimensions

1.1 Standard specifications

No.

Specifications Unit POSHER200 POSHER300

1 Operating Weight kg (lbs) 1850(4079) 2630(5798)

2 Overall Length mm(in) 1938(76.3) 2254(88.7)

3 Overall Width mm(in) 620(24.4) 710(28)

4 Max. Jaw Opening mm(in) 864(34) 1004(39.5)

5 Jaw Width mm(in) 540(21.3) 580(22.8)

6 Cutter Length mm(in) 220(8.7) 220(8.7)

7 Max. Operating Pressure kg/

㎠

(psi) 320(4551) 320(4551)

8 Oil Flow lpm(gpm) 150~ 250(33~ 55) 200 ~ 300(44 ~ 66)

9 Crushing Force ton 70 88

10 Cutting Force ton 200 267

11 Recommended Carrier Weight ton(lbs) 18 ~ 25(39683 ~ 55116) 25 ~ 36(55116 ~ 79366)

12 Recommended Hydraulic Hose Size mm(in) 25(1) 32(1 ¼)

1.2 External Dimensions

P

PO

OS

SH

HE

ER

R

2

20

00

0

P

PO

OS

SH

HE

ER

R

3

30

00

0

1

9

3

8

1249 540

480

760 620

2

2

5

4

750

1482

630

460

580

1

0

0

4

710

6

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

2. Installing and removing from hydraulic shovel

1.1 Installation

A> As shown below, Let the pulverizer place on the wood blocks, Which are used as big as possible.

B> Connect the Cylinder - Hose to the Boom pipe-line.

C> Open the stop valve at the front end of the arm.

If the Pulverizer fall down on the ground. The fittings and Hoses will be put out of shape.

1.2 Remove

A> Select a level place where there are no mud, dust, etc. and place the pulverizer on wood blocks.

B> Stop the engine and turn OFF the main switch to prime the oil tank.

C> Close the stop valve to prevent the hydraulic oil from flowing out.

D> After disconnecting the oil hoses, install the hose plugs to the oil hoses to prevent the hydraulic oil

from flowing out of the pulverizer and mud, dust, etc. from getting into the pulverizer

CAUTION

7

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

3. Inspection before operating

1.1 Before starting the operation, place this pulverizer the concrete floor or

hard ground, make sure that the engine is stopped and then check the

following points.

A> Check if the bolts locking the pulverizer and hydraulic shovel connection pins are proper.

B> Check each part of the pulverizer for cracks and other damages.

C> Be sure to lubricate the pins, bushes and the other move parts.

The lubrication points are shown below.

Before install on the shovel, Lubricate at

①

. After install on the shovel, protrude the CYL's

Rod and Lubricate at

②

. Retract the CYL's Rod and Lubricate at

③

.

D> Recommended Lubricants

Maker Lubricant

Cosmo Grease Dynamax No. 2

Mobil Mobil Mobilux 2

Shell Alvania Grease 2

Esso Esso Beacon 2

1.2 Start the engine and check the following points.

A> Move the control pedal to the UP or DOWN position form the neutral position to extend or retract

the hydraulic cylinder for checking of the external operation is proper and no oil leaks form the

joint of each hose.

B> Operate the pedal to move the pulverizer arm several times for checking if each movable part

moves smoothly.

CAUTION

GREASING

POSHER

GREASING

GREASING

8

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

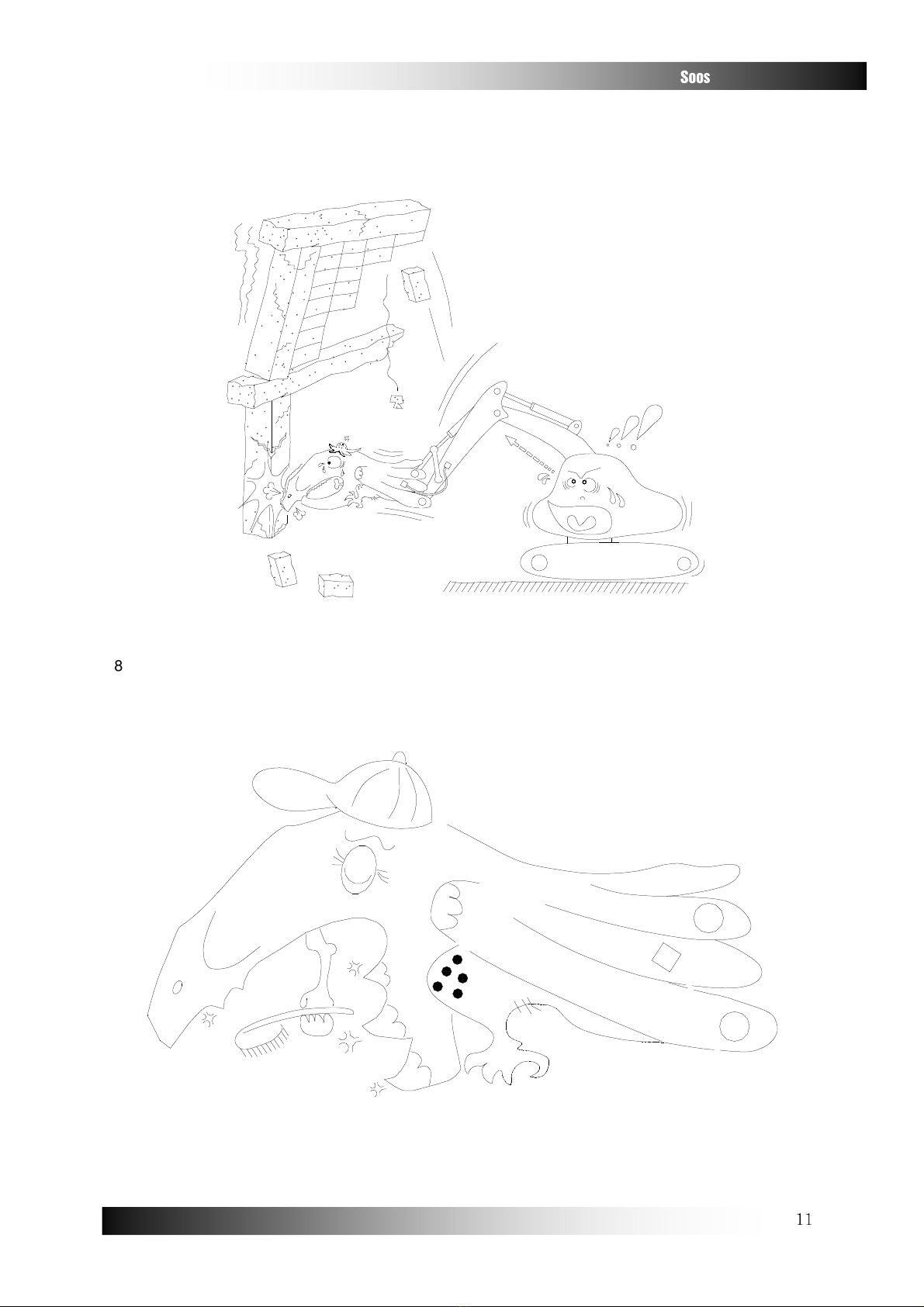

4. Precautions for pulverizer

[1] Before every time to work, Lubricate the frame-pin arm-pin, Cylinder-pin.

Recommended Lubricants and the lubrication points are illustrated(P5)..

[2] Don't lift or rotate the hydraulic shovel manipulating the boom.

Since the entire concrete pulverizer is longer than the bucket (see above the picture: A<B) so, the

force of about 1.5~2 times is directly applied to the bucket cylinder, or bucket link, swivel bearing.

Keep in mind above, otherwise, the bucket,, cylinder bucket link, swivel bearing will be broken.

B

9

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

[3] Do not allow the pulverizer body to drop and strike a material or strike against the side of a material

because not only the pulverizer body but also the hydraulic shovel may be damaged or become

defective.

[4] Perform the pulverizing operation by utilizing the pulverizing force.

Do not move the pulverizer body in all directions with a material gripped with pulverizer arm

because an unreasonable force may be applied to each part of body.

10

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

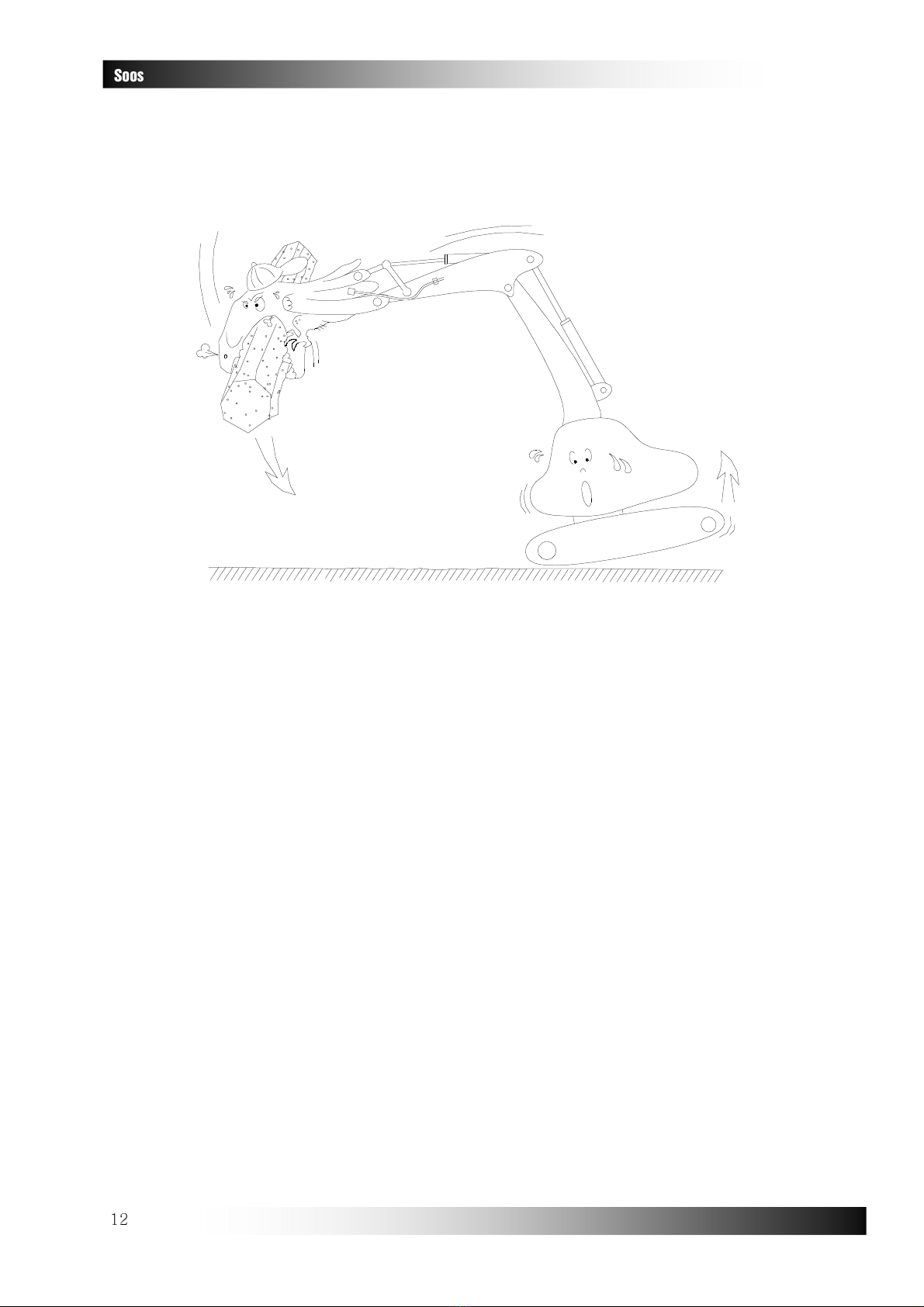

[5] Operating the pulverizer beyond equipment's power causes shorten pulverizer's life also shovel's

[6] Beware of electric contact!!

Keep away from the Pulverizer when working in energized area.

11

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

[7] Because works always have danger of collapse, Demolish the building from the upstairs.

Consult Soosan for modifications if you have an underwater requirement.

[8] Pulverizer mainly works under Hard working condition, therefore the Teeth are worn out very fast,

so if the pulverizing parts are worn out, Built it up by welding.(see the table of 11page)

12

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

[9] Don't lift, move, or load an overweighted material with pulverizer.

Otherwise, Not only the pulverizer but also the shovel will be damaged.

13

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

5 Maintenance

1) After using the pulverizer in water, wash thoroughly and lubricate properly with grease.

2) Repair when the pulverizer arm's pulverizing parts(tooth) and the lower central part of the main

Use below table.

☞

Standards Under laid-welding Rod

AWS E-308 L-16

BS 23.12R

DI ETI 221 226

ISO E 23. 12R 26

JIS D 309 L-16

When the pulverizing parts are built up by welding rod, The welder has to observe a property,

use, precaution of welding rod.

Moreover, in order not to crack, Observe a preheating and post heating of base metal.

3) Store the pulverizer with the hydraulic cylinder retracted, Also retract the cylinder when the

operation has been finished.

Replace if hydraulic cylinder's

☞

seals worn out, or the seals are used over one year.

4) Check the following points before user the pulverizer.

A> Check the arm and main frame and bracket for damage, wear and deformation.

B> Check the piping connections for oil leakage and damage.

C> Check the pins and bushes for wear and damage.

D> Check the bolts and nuts for looseness, coming off the damage.

5) When replacing a part, use a genuine SOOSAN PART.

CAUTION

14

S

oosan

Hydrau ic Pu verizer

S

o

osan Heavy Industries Co.,Ltd

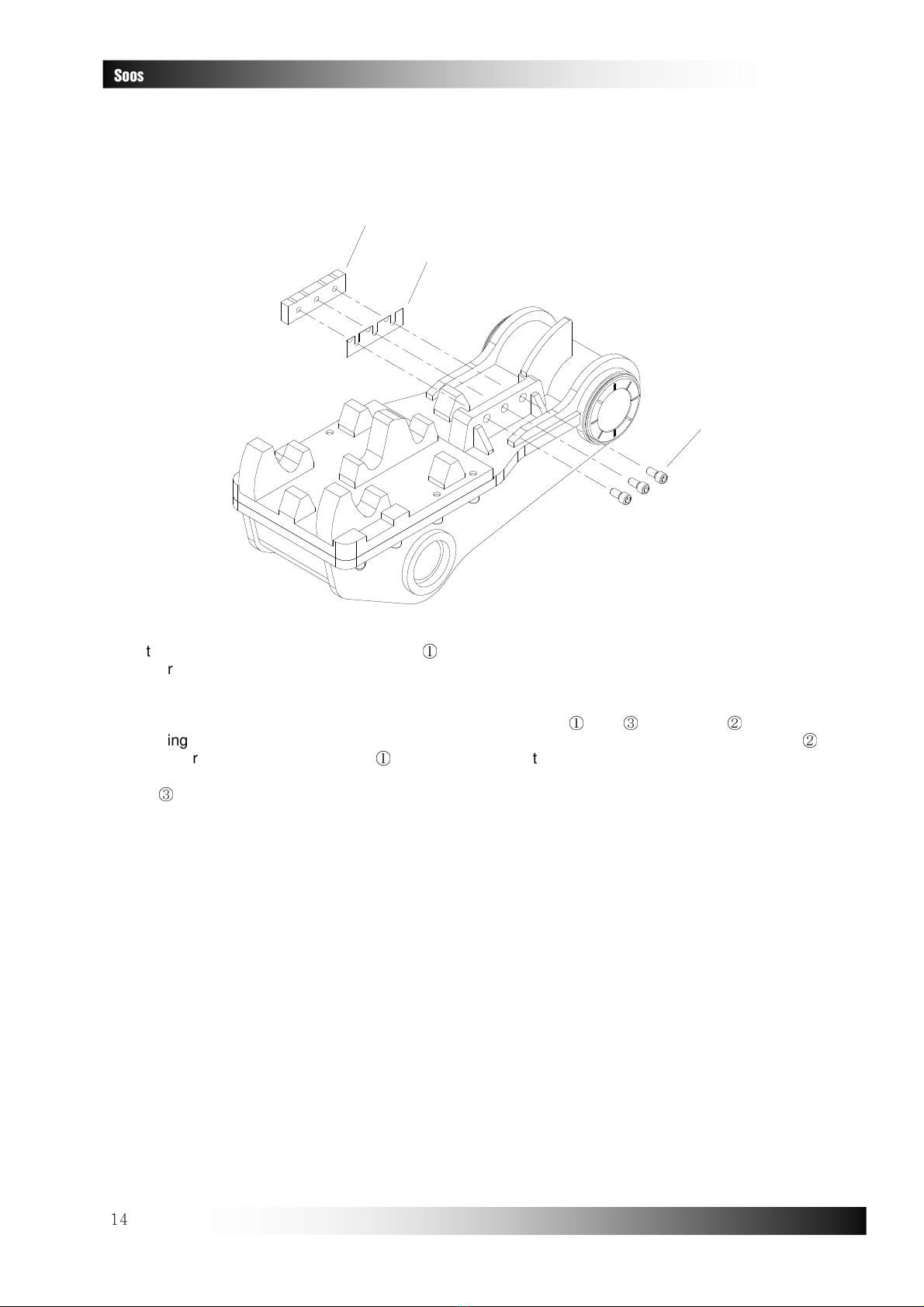

6. Replacement of reinforced cutter

1.1 Procedure

1

3

2

If the cutter is rotated 180

o

, then the cutter can be used two times.

①

Accordingly, when the cutter is worn properly, it can be reversed and the reused.

The cutter retaining socket bolts are coated with thread lock cement.

When loosening each bolt, heat it with a burner or the like.

When installing the socket bolts, remove stains from the cutter , shim , socket bolts and cutter

① ① ①

attaching part, remove oil with cleaning fluid and then apply thread lock cement on the socket bolts .

①

The clearance between the cutters are factory

①

-adjusted to 1mm or below.

When replacing a reinforced cutter, check the two cutters for engagement and adjust with the

shim if necessary.(Two Shims <0.5mm> are supplied)

①

15

S

oosan

Hydrau ic

Pu verizer

S

o

osan Heavy Industries Co.,Ltd

1.2 Proper clearance between Frame and Arm cutters.

Cutter

Shim

Cutter

Proper Cleranc 0.5 ~ 1 mm

Shim

1.3 Type of shim

o. Part o. Part ame Q'ty REMARK

1 L41 159 shim-1 1 t=1.0

2 L41 160 shim-0.5 1 T=0.5

This manual suits for next models

2

Table of contents

Other Soosan Construction Equipment manuals

Popular Construction Equipment manuals by other brands

DOSKO

DOSKO 337-13H operating instructions

Manitowoc

Manitowoc 91501 Series Operator's manual

Dynapac

Dynapac BV21 Instructions and spare parts catalogue

Ammann

Ammann ATR 60 P operating instructions

bergmann

bergmann BCT20 operating instructions

Ranger Products

Ranger Products RSC-2TF Installation and operation manual

Labounty

Labounty MHP 350 Operating and maintenance manual

FOUNTAINLINE

FOUNTAINLINE PROLINE V4 instruction manual

HIAB

HIAB K-HiPro 505 X4 Operator's manual

jcb

jcb 3TS-8W Quick reference guide

Chicago Pneumatic

Chicago Pneumatic CP 0112 Safety and operating instructions

RaycoWylie

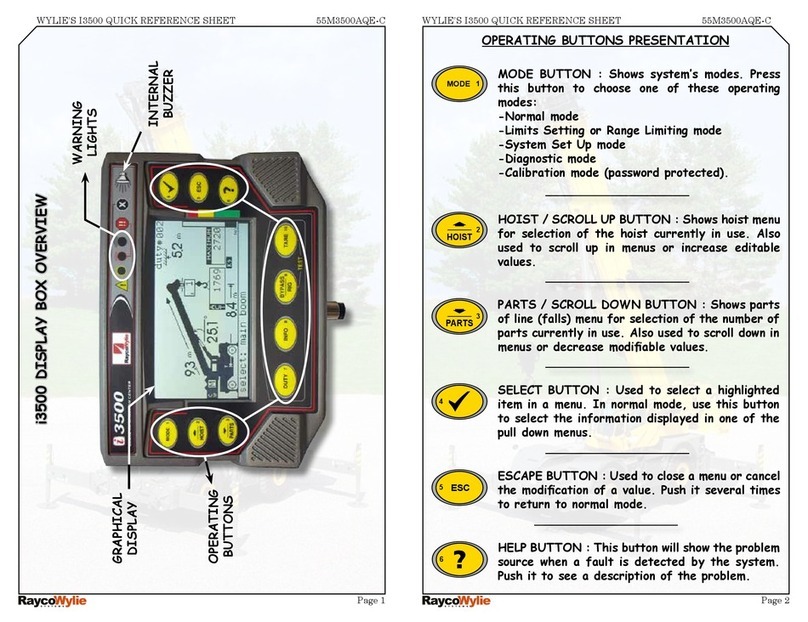

RaycoWylie i3500 quick start guide