Soosan SB Series User manual

OPERATION MANUAL

PARTS LIST

&

Soosan Hydraulic Breaker SB Series

C61255G 2015. 12

OPERATION

MANUAL

01. Safety Precautions ····························································································· 1

1.1 Safety Precautions ··················································································································· 1

1.2 Sticker list & Placed on the Breaker ···················································································· 4

02. Standard Specification ····················································································· 16

03. External Dimension ·························································································· 20

3.1 Side Type ····························································································································· 20

3.2 Backhoe Type ························································································································ 22

3.3 Top Type ································································································································ 24

3.3.1 Standard Top Type (Direct mounting) ····································································· 24

3.3.2 Standard Top Type (Cap mounting) ·········································································· 25

3.3.3 TRENCH FINAL TYPE ································································································ 26

3.3.4 TS-P Type ·················································································································· 27

3.4 COVER PLATE(TS-P Type) ································································································· 29

04. Preparation for Installation and Operation. ···················································· 32

4.1 Checking before installation instructions ·············································································· 32

4.2 Installation and Removal ······································································································· 33

4.3 Hydraulic pipe lines for exclusive use ················································································· 36

05. Precautions for safe operation. ······································································· 37

06. Maintenance ······································································································ 43

07. Wear Tolerance ································································································ 49

08. Inspection and Charging of N Gas at Back head

₂

····································· 53

09. Inspection and Charging of N gas in Accumulator

₂

···································· 55

10. Trouble Shooting ······························································································ 58

11. Hydraulic Oil ····································································································· 59

12. The Auto Lubrication Kit(Option) ···································································· 61

13. Underwater Operation of the Breaker(Option) ······· ······································· 64

PART LIST

01. Main Body ········································································································· 70

02. Seal kit ·············································································································· 92

03. Cylinder Set ······································································································ 94

04. Front Head Set ································································································ 98

05. Rod type ··········································································································· 99

06. Side type ········································································································· 102

07. Backhoe type ·································································································· 108

08. Top type ·········································································································· 116

8.1 Standard top type(Direct mounting) ··················································································· 116

8.2 Standard top type(Cap mounting) ······················································································ 118

8.3 Standard top type (TRENCH FINAL TYPE) ····································································· 120

8.4 TS-P type ····························································································································· 124

09. Oil Hose ·········································································································· 134

10. Tool set (Option) ···························································································· 135

11. Back head gas charging kit (Option) ··························································· 140

11.1 Back head gas charging kit 1(SB10 ~ SB50)

Ⅱ

···························································· 140

11.2 Back head gas charging kit 2(SB60 ~ SB151) ····························································· 140

12. Accumulator charging tool set (Option) ······················································· 141

OPERATION MANUAL

Soosan Hydraulic Breaker

!

DANGER

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER

REPAIR OR SERIVICE OF THIS HYDRAULIC BREAKER.

REPAIRS AND / OR SERVICE TO THIS HYDRAULIC BREAKER MUST ONLY

BE DONE BY AN AUTHORIZED AND CERTIFIED DEALER.

M odel

S e r ia l N u m b e r

Y e a r o f C o n s t r u c t io n

EC Declaration of Incorporation

according to EC Machinery Directive 2006/42/EC

We herewith declare, Soosan Heavy Ind. Co., Ltd.

of

109-2, Songsan-Ri, Yanggam-Myeon,

Hwaseong-Si, Gyeonggi-Do, 445-933,

REPUBLIC OF Korea

that the following machine complies with the appropriate basic safety and health requirements of

the EC Directive(2006/42/EC) based on its design and type, as brought into circulation by us. In case

of alteration of the machine, not agreed upon by us, this declaration will lose its validity.

The machinery is incomplete and must not be put into service until the machinery into which it is to

be incorporated has been declared in conformity with the provisions of the Directive.

Technical documentation for the machinery is maked by :

Place : Soosan Heavy Ind. Co., Ltd

109-2, Songsan-Ri, Yanggam-Myeon, Hwaseong-Si, Gyeonggi-Do, 445-933,

REPUBLIC OF Korea

Position : Manager, R&D team

Name : Lee, Young-dong

The technical documentation for the machinery is available from :

Name : SOOSAN HEAVY INDUSTRIES CO., LTD EUROPE

Adress : Ohmweg 18,3208 ke, Spijkenisse, Netherlands

Machine Description : Construction Machinery (not appendix )

Ⅳ

(Hydraulic Breaker)

Machine Type :

Serial Number :

Applicable EC Directive : EC Machinery Directive ( 2006/42/EC )

Applicable Harmonized Standards : EN ISO 12100-1:2003 EN ISO 12100-2:2003

EN 982/A1:2008 EN ISO 14121-1:2007

CEN/TS 13778:2004

Applicable National Technical Standards And Specifications :

Weight(kg) :

Length(mm) :

Oil flow( /min) :ℓ

Operation Pressure(kg/ ):

㎠

Blows(bpm) :

Date / Authorized Signature : Title of Signatory :

Title of Signatory :

!

DANGER

DO NOT OPERATE THE HYDRAULIC BREAKER UNLESS THE

FOLLOWING SAFETY INSTRUCTIONS HAVE BEEN THOROUGHLY

READ AND UNDERSTOOD!

READ THIS MANUAL BEFORE INSTALLING, OPERATING OR

MAINTAINING THIS EQUIPMENT.

ANY OTHER LANGUAGE WILL BE SERVICED ON REQUEST.

> Flying debris form the hydraulic breaker or other material may cause serious or fatal

injury to the operator. Personal protection equipment must be used.

> Flying debris hydraulic breaker or other materials may cause serious or fatal injury to

bystand- ers. Never operate the grab when bystanders are in the working area.

> On machines/carriers, the hydraulic breaker can enter the operator's compartment

under spe- cific hydraulic breaker position. Make sure that suitable impact shields are

used when operat-ing the hydraulic breaker with this type of equipment.

> Do not operate the breaker unless all safety decals described in this manual are in

place. The decals must be inspected periodically to ensure that all wording is legible.

The decals must

be replaced if illegible. Replacement decals can be obtained from your authorized

Soosan Distributor.

> The hydraulic breaker will become very hot during operation. Allow time for hydraulic

breaker to cool down before touching hydraulic breaker parts.

If this machine is transferred, be sure to attach this manual to the machine.

For safety, common items are described "SAFETY PRECATUIONS", and others are

mentioned in the succeeding pages.

P

R

E

F

A

C

E

We appreciate your purchasing a Soosan Hydraulic Breaker.

The Hydraulic Breaker, designed and built to provide durable

operation under any working conditions, has been developed

by Soosan's excellent engineering techniques with accumulated

experiences for many years. Without proper handling, regu-

lar inspection and maintenance, however, the machine fails to

display its full capacity, resulting in various troubles of

machine parts.

This publication should be carefully read prior to installation

and operation in order to prevent any mishandling of hydraulic

breaker.

We guarantee that a faithful compliance of the instruction will

contribute to the best operation condition.

Customers are, therefore, required to keep in mind that the

company is not responsible for troubles caused by not

following our guidelines or not using genuine parts.

S

o

o

s

a

n

H

e

a

v

y

I

n

d

u

s

t

r

i

e

s

C

o

.

,

L

t

d

.

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

1

0

1

.

S

a

f

e

t

y

P

r

e

c

a

u

t

i

o

n

s

1.1 Safety Precautions

This manual contains safety, operation, and routine maintenance instructions. It doesn't contain service

disassembly and service assembly instructions. If needed, complete service disassembly and service assembly

instructions are contained in manual which can be ordered from your Soosan Hydraulic Breaker authorized and

certified dealer.

Please read the following warning.

!

DANGER

Serious injury or death could result from the improper repair or service of this breaker.

Repairs or service to this breaker must only be done by an authorized and certified dealer.

Most of the accidents are caused by disregarding the basic rules of operation inspection or repair, or by

neglecting the inspection before operation. Many accidentscan often be avoided by recognizing potentially

hazardous situations before an accident occurs. Before operating, inspecting or repairing this machine, be sure

to read and fully understand the preventive methods and warnings described on the machine or in this

manual. If not, never operate, inspect or repair this machine

Safety labels and messages are classified as follows so that the users can understand the warnings on the

machine or in this manual.

!

DANGER

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This signal word is to be limited to the most extreme situations

!

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

!

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury,

It may also be used to alert against unsafe practices.

NOTICE

Signs used to indicate a statement of company policy directly or

indirectly related to the safety of personal or protection of property.

The safety messages including the preventive measures to avoid danger.

For safety, common items are described in “SAFETY PRECAUTIONS", and others are mentioned in the

succeeding pages.

2

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

www.soosanheavy.com

Soosan cannot anticipate every possible circumstance that might involve a potential hazard on operation,

inspection or repair. Therefore the warnings in this manual are not all inclusive. If an operation, inspection or

repair not described in this manual is used, you must take measures for safety by yourself.

!

DANGER

Observe the cautions and take a preventive measure for safety

The Soosan Hydraulic Breaker will provide safe and dependable service if operated in accordance with the

instructions given in this manual. Read and understand this manual, any decals and tags attached to the

breaker before operation. Failure to do so could result in personal injury or equipment damage

n

Operate the breakerin accordance with all laws and regulations which affect you, your equipment, and the

worksite.

n

Do not operate the breakeruntil you have read this manual and thoroughly understood all safety, operation

and maintenance instructions.

n

Do not operate the breakeruntil you have read the carrier equipment manual and thoroughly understood

backhoe or excavator or similar equipment used to operate the breaker. The word "carrier", as used in this

manual, means a backhoe or excavator or similar equipment used to operate the breaker.

n

Ensure that all maintenance procedures recommended in this manual are completed before using the

equipment.

n

The operator must not operate the breaker or carrier if any people are within the area where theymay be

injured by flying debris or movement of the equipment.

n

Know the limits of your equipment.

n

Before starting a work, Check the prohibitions, cautions and working processes in a working site with the

field overseer, Observe all of them strictly.

n

Wear such protective tools as a helmet, safety shoes, etc. to perform a work.

Make use of the protective glasses, earplugs, gloves and other protective tools if necessary.

n

Establish a training program for all operators to ensure safe operation. Do not operate the breakerunless

thoroughly trained or under the supervision of an instructor. Become familiar with the carrier controls before

operating carrier and breaker. While learning operate the breaker and carrier, do so at a slow pace. If

necessary, set the carrier to the slow position.

n

Make sure all controls(levers and pedals) are in the neutral position before starting the carrier.

n

Before leaving the carrier, always lower the boom and insure the carrier is stable. Never leave the

machine with the engine running. Always engage the parking brake.

n

Stop the engine before attempting to make any repairs, adjustments or servicing to either the carrier or the

breaker.

n

Do not operate the breaker at oil temperature above 175 /80 . Operation at higher temperature can

℉ ℃

damage the internal components of the breaker and carrier and will result in reduced breaker performance.

n

Do not operate a damaged, leaking, improperly adjusted, or incompletely assembled breaker.

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

3

n

Do not modify this breaker in any manner.

n

Use only breaker parts manufactured by Soosan. Usage of breaker rod produced by another manufacturer

may damage the breakerand will void the warranty.

n

To avoid personal injury or equipment damage, all breakerrepair, maintenance and service must only be

performed by authorized and properly trained personnel.

n

If you do not understand how to operate safely your breaker, contact an authorized Soosan Dealer for

assistance.

n

Keep this manual with the breaker.

n

Do not operate this equipment if you are taking medication which may affect your mental judgement or

physical performance.

n

Do not operate this equipment if you are under the influence of drug or alcohol.

n

Remove breaker form carrier during transportation.

4

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

www.soosanheavy.com

1.2 Sticker list & Placed on the Breaker

n

Warning sticker (C03 192)

1) Use hearing protection 2) Use eye protection

3) Use breathing protection 4) Use the manual before use

n

Greasing Sticker (SOOSAN D83 168)

GREASING

1. Use the recommended grease.

2. Grease whenever the Rod looks dry.

3. Failure to comply with these instructions, can result in damage to

Rod and rod bushes and will void the warranty.

n

Specification Plate (For Example SB130)

Model : SB130 TR-F

Serial No. :

Operating Weight : 2996 Kg

Oil flow rate : 200-260 l/min

HYDRAULIC BREAKER

SOOSAN

SOOSAN HEAVY INDUSTRIES CO.,LTD.

Operating pressure : 160-180 Kg/cm

Manufacturing Date :

2

260, Jeongmunsongsan-ro, Yanggam-myeon, Hwaseong-si,

Gyeonggi-do 445-933 , KOREA www.soosan.co.kr

D83445

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

5

n

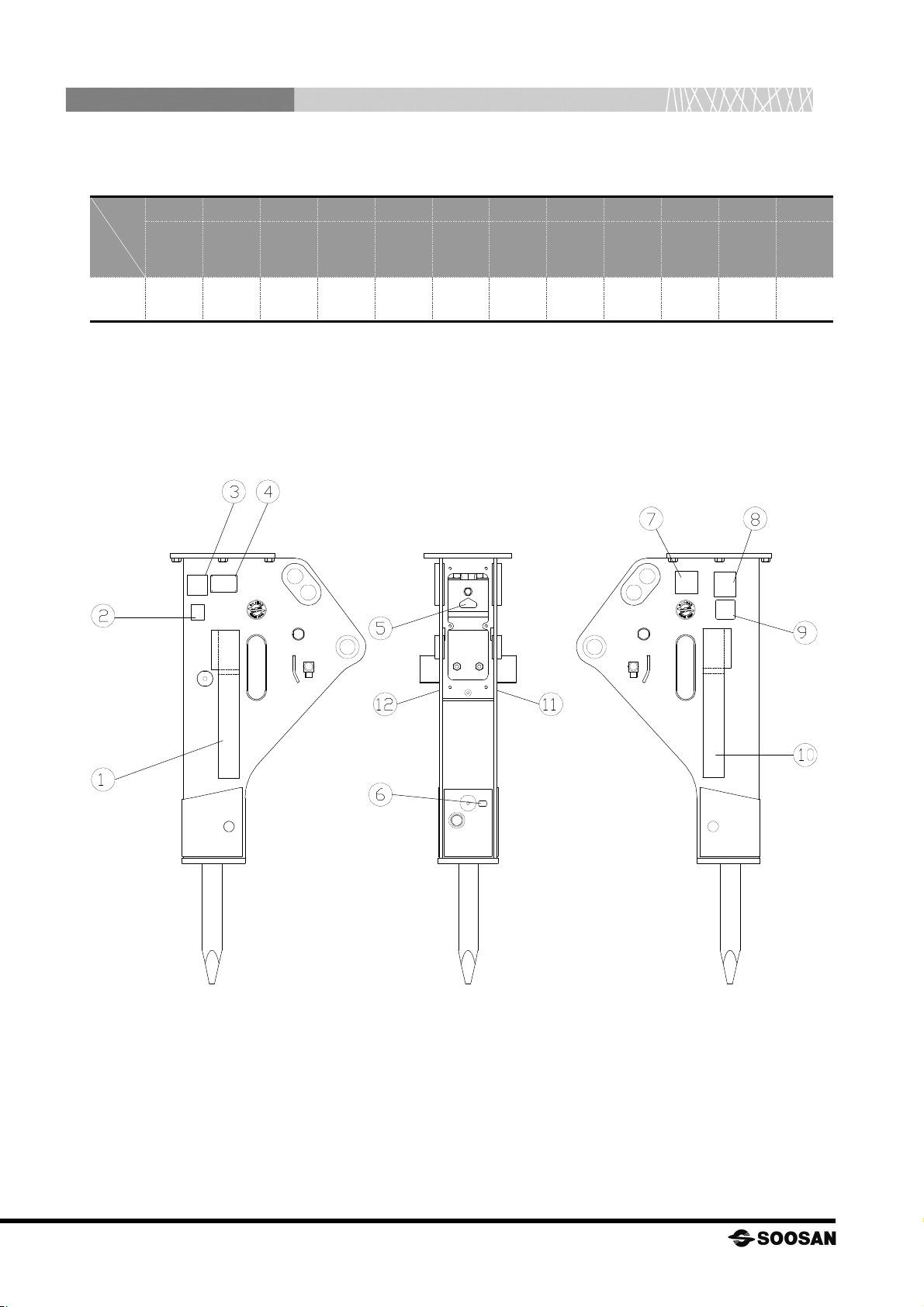

SB43B SIDE SILENCED BACKHOE - ( #~) is applied Serial Number)

NO.

MODEL

1 2 3 4 5 6 7 8 9 10 11 12

BI

Sticker

(L)

AEM TUV Name

Plate

Back

Head Greasing Warning Danger Noise

BI

Sticker

(R)

Acc'

Sticker

(A)

Acc'

Sticker

(B)

SB43B F93256 D83164 D83174 F93261 F93264 D83168 D83166 E83210 F93262 F93257 C62212 F93263

6

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

www.soosanheavy.com

n

SB10II~SB50 TOP (Cap mounting)

NO.

MODEL

1 2 3 4 5 6 7 8 9 10

BI

Sticker

(L)

Name

Plate TUV AEM Back

Head Greasing DANGER Warning

BI

Sticker

(R)

Emblem

SB10II E83252 E83212 E73190 D83164 E83144 D83168 E83210 E83211 E83255 E83213

SB20II F03248 F03219 ↑ ↑ ↑ ↑ ↑ ↑ F83251 ↑

SB30II E73315 E73257 ↑ ↑ ↑ ↑ ↑ ↑ E73316 ↑

SB35II F83257 F83216 ↑ ↑ ↑ ↑ ↑ ↑ F83260 ↑

SB40II C03603 C03463 ↑ ↑ ↑ ↑ ↑ ↑ C03606 -

SB43II F93306 F93235 ↑ ↑ ↑ ↑ ↑ ↑ F93309 -

SB45 D43403 D43334 ↑ ↑ ↑ ↑ ↑ ↑ D43406 -

SB50 C13602 C13452 ↑ ↑ ↑ ↑ ↑ ↑ C13603 -

LEFT MAINBODY RIGHT

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

7

n

SB10II~SB50 TOP (Direct mounting)

NO.

MODEL

1 2 3 4 5 6 7 8 9 10

BI

Sticker

(L)

Name

Plate TUV AEM Back

Head Greasing DANGER Warning

BI

Sticker

(R)

Emblem

SB10II E83252 E83214 E73190 D83164 E83144 D83168 E83210 E83211 E83255 E83213

SB20II F03248 F03222 ↑ ↑ ↑ ↑ ↑ ↑ F83251 ↑

SB30II E73315 E73261 ↑ ↑ ↑ ↑ ↑ ↑ E73316 ↑

SB35II F83257 F83217 ↑ ↑ ↑ ↑ ↑ ↑ F83260 ↑

SB40II C03603 C03466 ↑ ↑ ↑ ↑ ↑ ↑ C03606 -

SB43II F93306 F93238 ↑ ↑ ↑ ↑ ↑ ↑ F93309 -

SB45 D43403 D43335 ↑ ↑ ↑ ↑ ↑ ↑ D43406 -

SB50 C13602 C13453 ↑ ↑ ↑ ↑ ↑ ↑ C13603 -

LEFT MAINBODY RIGHT

8

SOOSAN HYDRAULIC BREAKERS OPERATION MANUAL

www.soosanheavy.com

n

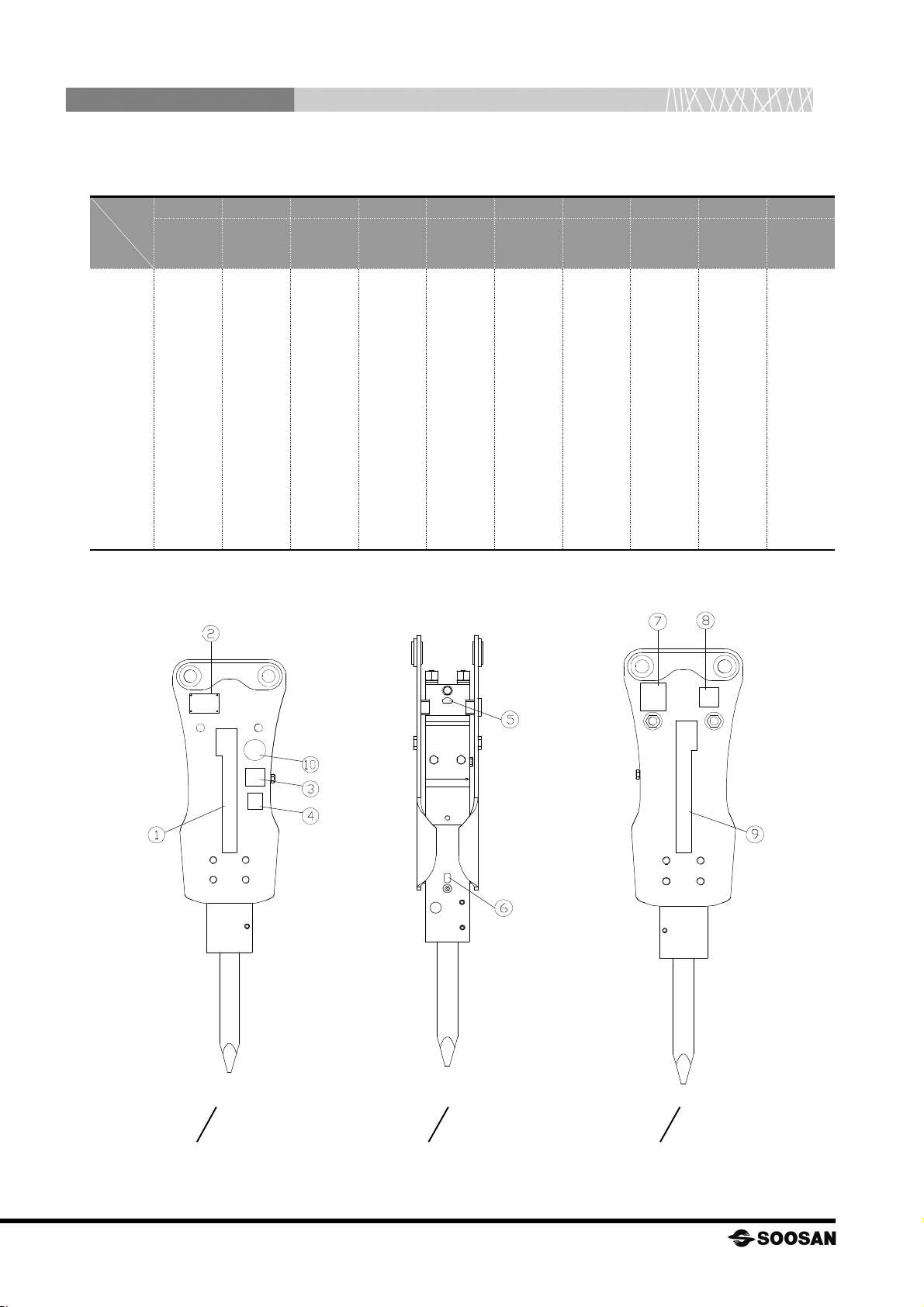

SB50~SB151 TR-F - ( #~) is applied Serial Number )

NO.

MODEL

1 2 3 4 5 6 7 8 9 10 11 12

BI

Sticker

(L)

Model

Sticker AEM TUV Name

Plate

Back

Head Greasing

Acc'

Sticker

(A)

Acc'

Sticker

(B)

Danger Warning

BI

Sticker

(R)

SB50

(#11393~) C23564 C13469 D83164 E73190 C13468 E83144 C01167 - - C03193 E83211 C23565

SB60

(#2294~) ↑ C23559 ↑ D83174 C23560 C02135 ↑ - - Q53134 D83166 ↑

SB70

(#4374~) L03314 L03309 ↑ ↑ L03310 ↑ ↑ - - ↑ ↑ L03315

SB81

(#8563~) C23564 C33879 ↑ ↑ C33880 ↑ ↑ - - ↑ ↑ C23565

SB81A

(#5314~) ↑ C33881 ↑ ↑ C33882 ↑ ↑ C62212 C62213 ↑ ↑ ↑

SB100

(#1786~) ↑ E93417 ↑ ↑ E93418 ↑ ↑ ↑ ↑ ↑ ↑ ↑

SB121

(#4875~) C63558 C63547 ↑ ↑ C63548 ↑ ↑ ↑ ↑ ↑ ↑ C63559

SB130

(#3172~) D83442 D83444 ↑ ↑ E83445 ↑ ↑ ↑ ↑ ↑ ↑ C83443

SB140

(#1151~) ↑ L23278 ↑ ↑ L23279 ↑ ↑ ↑ ↑ ↑ ↑ ↑

SB151

(#950~) ↑ C73561 ↑ ↑ C73562 ↑ ↑ ↑ ↑ ↑ ↑ ↑

1

2

3

4

5

7

8

6

9

10

12

2

11

LEFT MAINBODY RIGHT

Other manuals for SB Series

2

Table of contents

Other Soosan Power Tools manuals