IMPORTANTINFORMATION

TOAVOIDSERIOUSPERSONALINJURY,ALLUSERSAND

EMPLOYERS/OWNERSMUSTREADAND UNDERSTAND

ALL INSTRUCTIONSINTHISMANUALBEFOREOPERATING

ORMAINTAINING THISTOOL.

1

EXPLANATION OF

THENAILING ACTION

SINGLE ACTUATION MECHANISM:

CONTACTACTUATIONMECHANISM:

FULLSEQUENTIAL ACTUATIONMECHANISM:

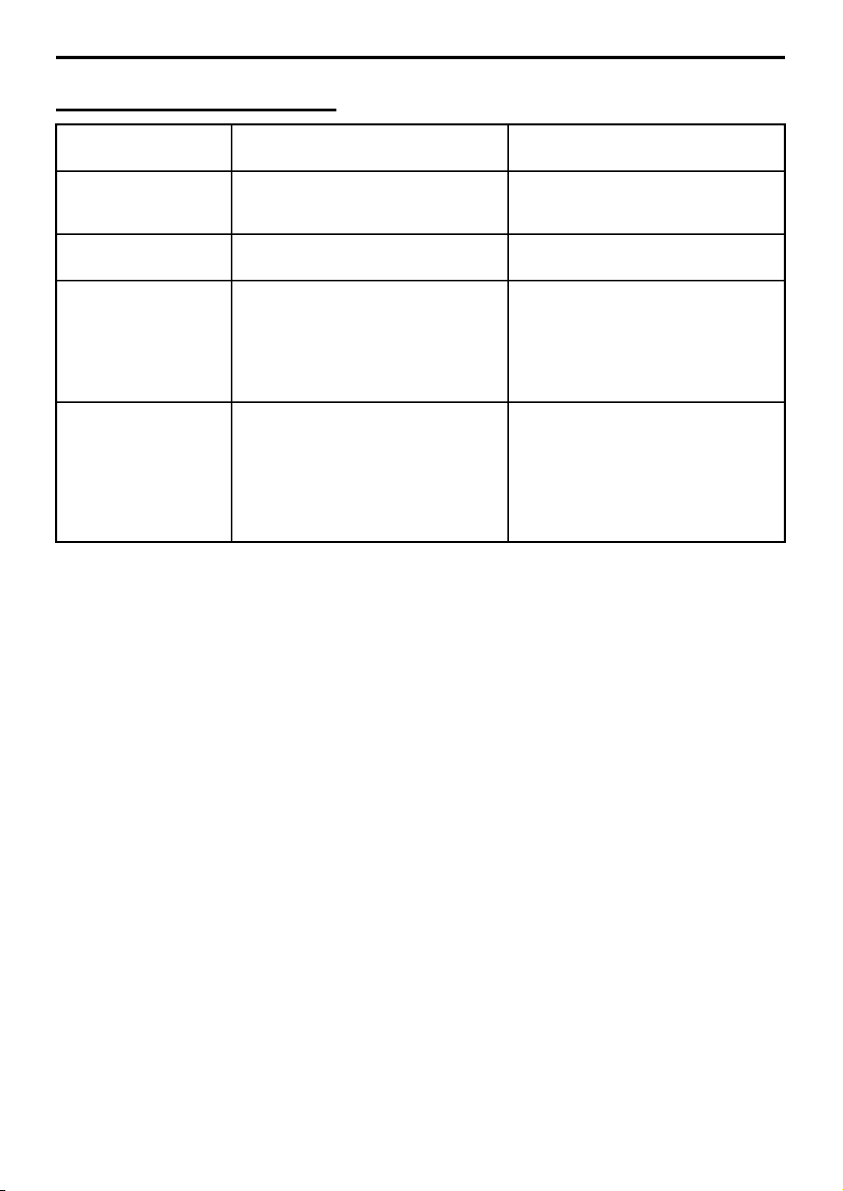

First,press thesafetyagainstthe wood;next,pullthe

triggertodrivethe fastener.Afterfasteningonce,

fastening willnotbe possibleagainuntil thetriggeris

releasedandpressedagain.

First,press thesafetyagainstthe wood;next,pullthe

triggertodrivethefastener.First.Pullthe trigger;next,

pressthesafetyagainstthewood todrivethefastener.If

thetriggerisheldback,afastenerwillbe driveneach

timewhenthesafetyispressedagainstthe wood.

First,press thesafetyagainstthe wood;next,pullthe

triggertodrive thefastener.Followthe samesequence

tocontinuedrivingfasteners.

Anactuating

systeminwhich thedrivingoperationsarecarriedout

foraslongas thetriggerremainsactuated.Nosafety

yoko ispresent.

CONTINUOUSACTUATIONMECHANISM:

GENERALSAFETY RULES

PERSONALSAFETY

Safetyglassesmustconformtothe requirementsof

AmericanNationalStandardsInstitute,ANSIZ87.1and

provideprotectionagainstflyingparticlesbothfromthe

frontandside.Theemployermustenforce theuse of

safetyglassesby thetooloperatorandothersinwork

area.

Always

wearearprotectiontoprotectyourearsfromloudnoise,

Alwayswearhead protectiontoprotectyourheadfrom

flyingobjects.

Adustmask,non-skidsafety

shoesandahardhatmustbe usedforthe applicable

conditions.Wearafullface shieldifyou areproducing

metalfilings orwood chips.

Donotwearlooseclothingor

jewelry. Containlonghair. Keepyourhair, clothing,and

glovesawayfrommovingparts.Loose clothes, jewelry,

orlong haircan becaughtinmovingpartsandincreases

theriskofinjury.

Donotuse toolwhiletired orundertheinfluenceof

drugs,alcohol,ormedication.Amomentofinattention

whileoperating thetoolmay causeseriousinjury.

Keep fingersawayfrom

triggerwhennotdrivingfasteners,especiallywhen

connecting thetooltothe airsupply.

keepproperfootingandbalance

atalltimes.Properfooting andbalanceenablebetter

controlofthetoolinunexpectedsituations.

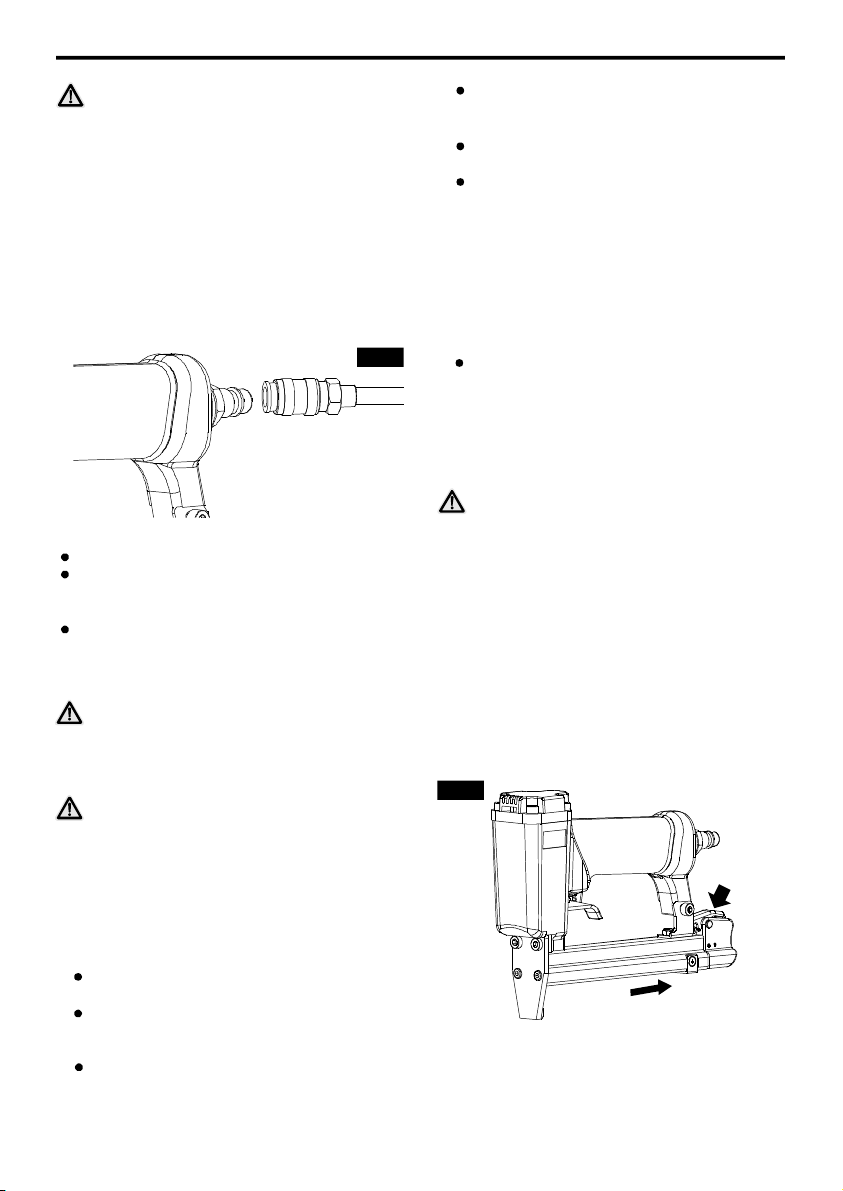

Entangledorsnarledhoses can

causealoss ofbalance orfootinginadditionto

unintentionaltooloperation.Attachthehose tothe

structuretoreduce theriskofloss ofbalance ofthehose

shifts.

ALWAYS WEAREARANDHEADPROTECTION.

USESAFETY EQUIPMENT.

DRESSPROPERLY.

STAYALERT,WATCH WHATYOUAREDOINGANDUSE

COMMON SENSEWHENOPERATING APOWERTOOL.

AVOIDUNINTENTIONALFIRING.

DONOTOVERREACH.

MAKESUREAIRHOSEISFREEOFSNAGSAND

OBSTRUCTIONS.DONOTATTACHANAIRHOSEOR

TOOLTOYOUR BODY.

WORK AREA

KEEPTHEWORK AREACLEANANDWELLLIGHTED.

Cluttered benchesand darkareas increasetherisksof

accidents.

suchas inthepresenceofflammable

liquids,gases,ordust.The toolcreatesasparkwhich

mayigniteflammableliquids,gasesordust.

Donotletvisitorshandlethe

tool. All visitorsshouldbekeptsafetyawayfromwork

area.

Respectthetoolasaworkingimplement.

DONOTOPERATETHETOOLINEXPLOSIVE

ATMOSPHERES,

KEEPVISITORSAWAY.

NEVERENGAGEINHORSEPLAY WITHTHETOOL.

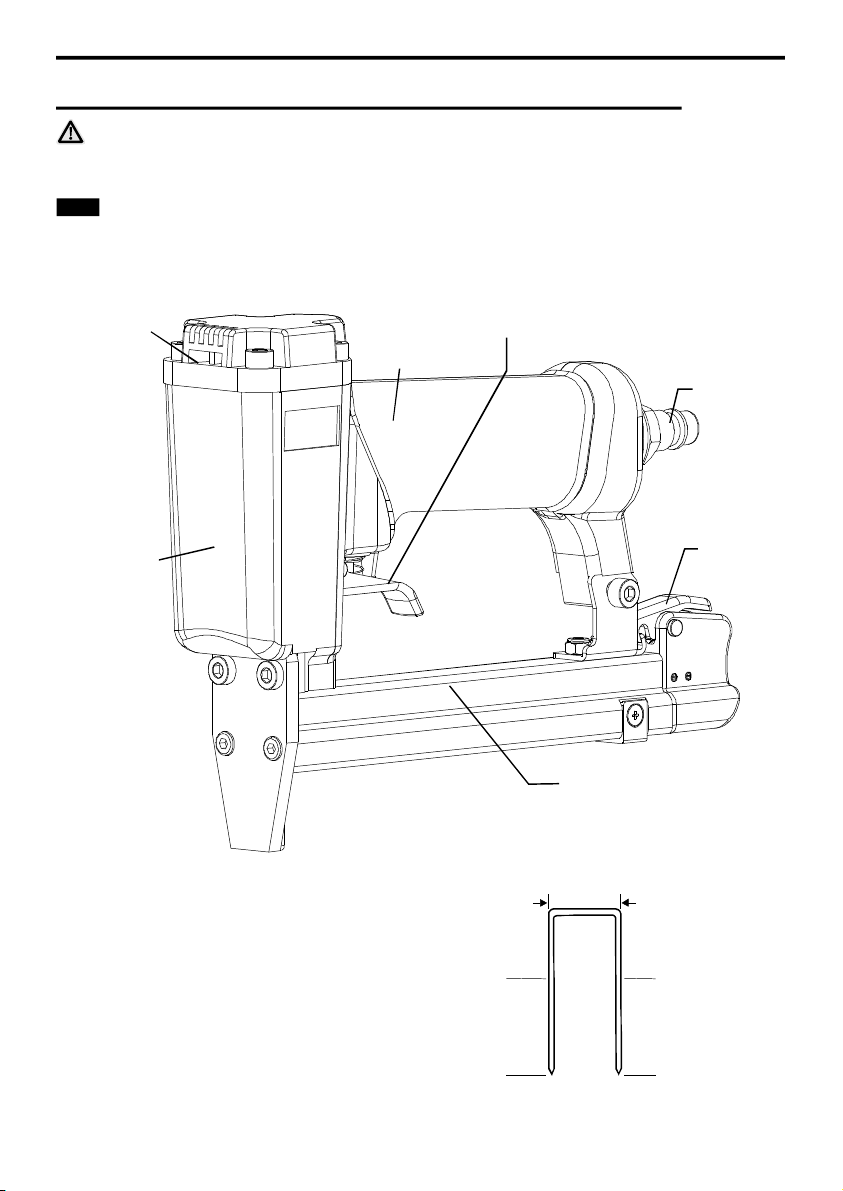

WARNING

keepthismanualforthe safetywarningsand precautions,

operating, inspection, maintenance.Keepthismanualand

thereceiptinasafeanddryplaceforfuturereference.

OPERATORSANDOTHERSINWORK AREAMUST WEAR

SAFETY GLASSES WITH SIDESHIELDS. Whenoperating

thetool,always wearsafetyglasses withsideshields,

and makesureothersinworkareawearsafetyglasses.

TOOLUSEANDCARE

NEVERPOINTTOOLATYOURSELFOROTHERSIN

WORKAREA.

KEEPFINGERSAWAYFROMTRIGGERWHENNOT

DRIVING FASTENERSTOAVOIDACCIDENTALFIRING.

NEVERMODIFY ORALTERATOOL.

KNOWTHISTOOL.

Alwaysassumethetoolcontains

fasteners.Neverpointthetoolatyourselforothers,

whetheritcontainsfastenersornot.If fastenersare

mistakenlydriven,itcanlead tosevereinjuries.Never

engageinhorseplay withthetool. Respectthetool as a

working implement.

Nevercarrythetoolwithfingeron triggersinceyou

coulddriveafastenerunintentionallyand injureyourself

orsomeoneelse.Alwayscarrythetoolbythe handle

only.

Doingso maycause

ittomalfunctionandpersonalinjuriesmayresult.

Readmanualcarefully,learnits

applications andlimitations,as wellas the specific

potentialhazardsrelatedtothistool.