SoRoTo 120L User manual

MANUAL

FORCED ACTION MIXERS GB-04.12.18

MODEL 40L

Mixing capacity:

40 litres

MODEL 80L

Mixing capacity:

80 litres

MODEL 100L

Mixing capacity:

100 litres

MODEL 120L

Mixing capacity:

120 litres

THE RIGHT MODEL AND

SIZE DO MATTER.

FOR ANY JOB BIG OR SMALL

SOROTO OFFERS THE RIGHT

ONE.

English

3 / GBGB / 2

TABLE OF CONTENTS

SoRoTo 40L, 80L, 100L, 120L.....................................p. 3

Application .....................................................................p. 3

Before use.......................................................................p. 3

Before connecting the power supply ..............p 3

Operating the SoRoTo forced action mixer ...p. 3

Cleaning / maintenance...........................................p. 4

Transport .........................................................................p. 4

Safety ................................................................................p. 4

Technical data ...............................................................p. 6

Contact details .............................................................p. 6

Special features/spare parts..................................p. 7

Spare part list – 40 L .................................................p. 8

Spare part list – 80 L .................................................p. 10

Spare part list – 100 L ...............................................p. 12

Spare part list – 120 L................................................p. 14

SoRoTo 200L, 300L........................................................p. 16

Application .....................................................................p. 16

Before use.......................................................................p. 16

Before connecting the power supply ..............p 16

Operating the SoRoTo forced action mixer ...p. 16

Adjusting the phase turner.....................................p. 17

Cleaning / maintenance...........................................p. 17

Transport .........................................................................p. 18

Safety ................................................................................p. 19

Technical data ...............................................................p. 19

Contact details .............................................................p. 19

Spare part list – 200 L ..............................................p. 20

Spare part list – 300 L ..............................................p. 22

EU Declaration of Conformity....................................p. 24

MANUAL APPLIES TO

SoRoTo 40L, 80L, 100L, 120L

APPLICATION

The SoRoTo Forced Action Mixers are ideal for mixing all kinds of materi-

als used in the building industry, as well as for tasks where high demands

are imposed on the quality of the mix.

When mixing materials containing aggregates, we recommend using the

SoRoTo Mixer system with rubber blades. (NOTE: The SoRoTo Forced

Action Mixer 40L is not suited for mixing materials containing aggre-

gates).

When using steel blades to mix materials containing aggregates, the

mixer arms may work their way upwards and eventually stop turning.

BEFORE USE

Before starting the mixer, the telescopic legs must be positioned for

the right height for draining into a bucket or wheelbarrow. The easiest

way for adjusting the legs is to lay down the mixer, so it rests on all four

wheels. The legs are released and locked with the fitted lock splits/bolts.

BEFORE CONNECTING THE POWER SUPPLY

Before the power is connected, the mixer arms must be set in place, and

the lid must be closed. The safety grid in front of the mixer gate must be

attached at all times.

For your safety, please always follow the instructions listed above before

use.

OPERATING THE SOROTO FORCED ACTION MIXER

Close the lid and lock it into place using the rubber strap. Start the mixer

by pressing the green START button on the protective motor switch.

Pour the required material into the drum and add liquid.

The protective motor switch has a zero voltage releaser. In case of power

failure, the mixer must be restarted. For safety reasons, the mixer will not

start if the lid is open.

5 / GBGB / 4

NOTE

Never put your hand or any object into the machine when the power is

connected.

When the material has reached the desired consistency and the mix-

ing motion is finished, the mixing drum is emptied by opening the mixer

gate. The drum should be emptied right after mixing. Please observe that

the material may set in the mixing drum, if left too long.

NOTE

The safety grid should be in front of the output gate at all times. If the

machine is jammed, e.g. by larger stones, ensure that the plug is discon-

nected from the protective motor switch, before removing the obstruc-

tion. Do not put your fingers or any object through the mixer gate.

CLEANING / MAINTENANCE

Before cleaning the mixer, the plug must be removed from the socket.

Open the lid and lift the mixing blades o the axle. The mixer arms are

easily removed without using tools.

Firstly wash the mixer arms and the entire mixing drum using water.

When cleaning has ended, place the mixer arms onto the axle and close

the lid.

TRANSPORT

During transport of the SoRoTo Forced Action Mixer it is recommended

that the mixer is placed on the four wheels, and the lid is closed and

locked with the rubber strap.

SAFETY

When using an extension cable, please observe the following,

• Never use a longer cable than max 10 m.

• Always use a cable with a minimum dimension of 1 mm2.

• Never use the cable when it is rolled up. Always roll it out completely.

When mixing materials that emit unpleasant or dangerous vapours and/

or dust, a dust controller is recommended.

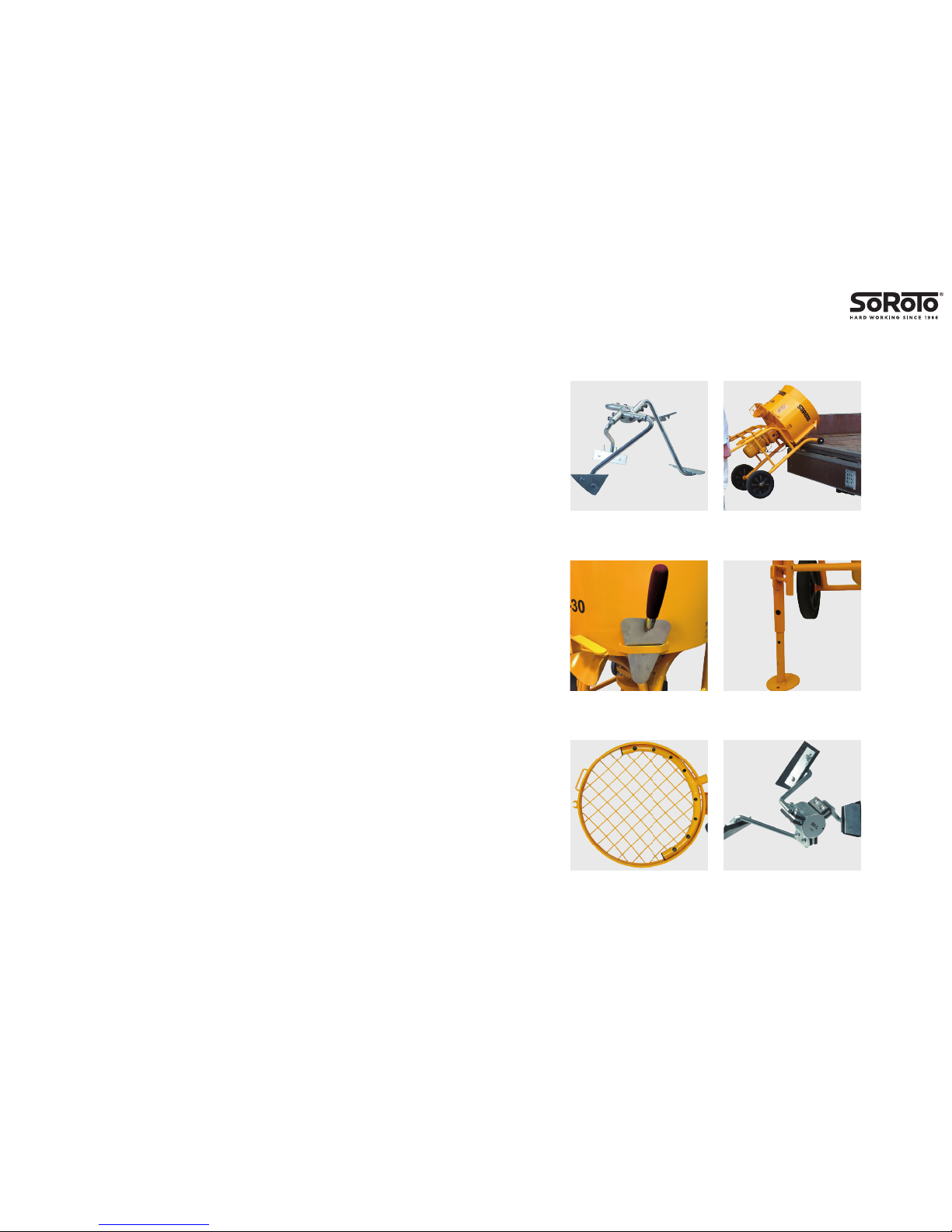

SMALL LOADING

WHEELS

and the use of customized

lowered nuts mean you

can easily load the ma-

chine onto the truck. Even

the biggest machines are

easy to handle

OPTIONAL

DUST CONTROLLER

helps avoiding dangerous dust

discomfort - without losing the

opportunity to keep an eye on the

mixture, as you do with a closed

forced action mixer

GEAR MOTOR

selected under the

motto:

maximum power

— minimum load.

A powerful motor

which, on the other

hand, has the lowest

possible ampere

consumption, so the

strain on the power

grid and the environ-

ment is minimized

SAFETY GRID

in front of the

discharge chute,

together with the

safety switch, en-

sure that you do

not risk harming

yourself in the

working machine

SPARE POWER OUTLET

Models 200L and 300L

are equipped with a spare

power outlet for work

lighting, industrial

vacuumcleaner,

belt conveyor or the like

BRACKET

is mounted on

every machine

for holding a

brick trowel

BUCKET

STAND

All 240V

machines are

equipped

with a robust

bucket stand

for a masonry

bucket TELESCOPIC

LEGS

ensure the right

working height

WHEELS

the mixer is

easily moved

from one place

to another on

the construction

site without any

use of a vehicle

OPTIONAL

TURBO ARM

Can be mounted on the 300L mixer

(e.g. for masonry mortar)

DISTINCTIVE SOROTO

MIXER ARMS

are removed without tools

facilitates cleaning and

replacement. Also avail-

able with rubber blades for

mixes containing

aggregates

RUBBER STRAP

The machines are

equipped with a rubber

strap that ensure that the

grid lid does not open

during use or transport

the original and some extra

7 / GBGB / 6

TECHNICAL DATA

Model 40L/30

Motor: 230V/110V - 0.75 kW – 50 Hz

W/L/H: 60*60*85 cm

Mixing capacity: 40 L.

Weight: 64 kg (empty).

LAeq< 75dB(A) with mortar.

Dust controller is not an option

Model 80L/30

Motor: 240V/110V - 1.1 kW – 50 Hz

W/L/H: 60*75*106 cm

Mixing capacity: 80 L.

Weight: 88 kg (empty).

LAeq< 75dB(A) with mortar.

Prepared for mounting of dust controller

Model 100L/30

Motor: 240V/110V - 1.1 kW – 50 Hz

W/L/H: 68*80*106 cm

Mixing capacity: 100 L.

Weight: 98 kg (empty).

LAeq< 75dB(A) with mortar.

Prepared for mounting of dust controller

Model 120L/30

Motor: 240V/110V – 1.1 kW – 50 Hz

W/L/H: 72*95*118 cm

Mixing capacity: 120 L.

Weight: 105 kg (empty).

LAeq< 75dB(A) with mortar.

Prepared for mounting of dust controller

TECHNICAL SUPPORT / WAREHOUSE

Fabriksparken 11

DK-2600 Glostrup

Tel. +45 3672 7800

teknik@soroto.dk

SALES / ADMIN

Fabriksparken 13

DK-2600 Glostrup

Tel. +45 3672 7500

soroto@soroto.dk

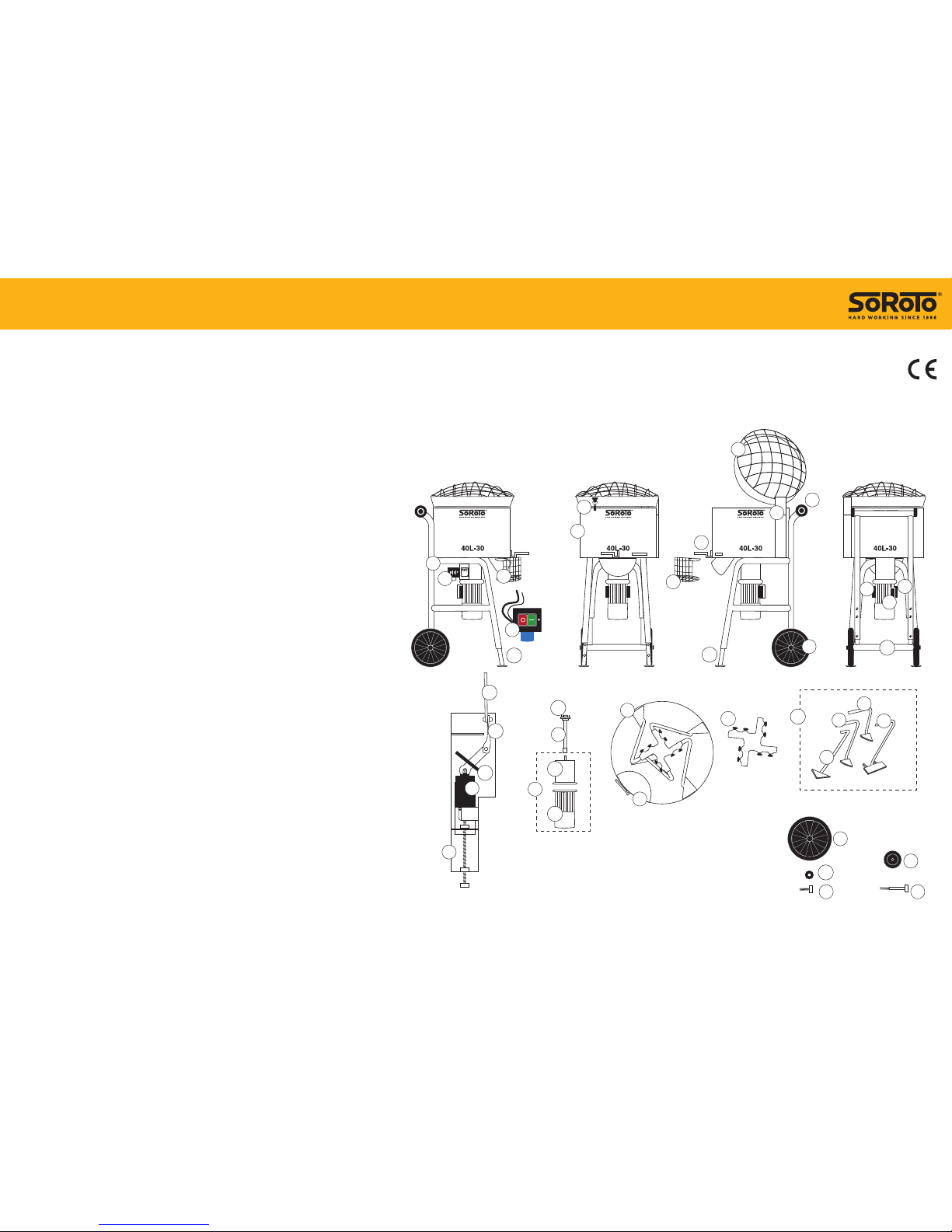

INCLUDING

Mixer arms with steel blades

and cross joint

INCLUDING

Bracket for holding a brick

trowel

OPTIONAL

Dust controller for better OSH*.

Available for 80-300 L mixers

INCLUDING

Small loading wheels

for easy on-/unloading

INCLUDING

Telescopic legs for setting the

right working hight

OPTIONAL

Rubber blades for mixes

containing aggregates

* Occupational Safety and Health

9 / GBGB / 8

POS.NO. DESCRIPTION SPARE PART NO.

2 Grid lid (hinge 100 mm) ............................................................... 40.002

3 Mixer drum incl. mixer gate, complete set ............................ 40.003

3 R Rubber strap for grid lid .............................................................. 40.003R

4 Frame, complete w/wheels etc. ................................................ 40.004

4 A Frame, “Body” — excl. wheels and telescopic legs ........... 40.004B

5 Loading wheels (1 pc.), 80 mm, excl. bolt ............................. 40.005

5 B Bolt (1 pc.) for 80 mm loading wheel ..................................... 40.005B

6 Wheel (1 pc.), 200 mm, excl. bolt ............................................. 40.006

6 B Bolt (1 pc.) for 200 mm wheel ................................................... 40.006B

6 W Washer (1 pc.) for 200 mm wheel ............................................ 40.006W

7 Mixer gate incl. bolt ....................................................................... 40.007

8 Switch 9.5 Amp. w/thermal circuit breaker ......................... 40.008

8 E Safety switch — by the grid lid .................................................. 40.008E

8 K Cassette for safety switch, complete ...................................... 40.008K

8 K1 Piece for safety switch, bended metal part.......................... 40.008K1

8 K2 Piece for safety switch, twisted metal part. ......................... 40.008K2

8 K3 Piece for safety switch, rubber part ........................................ 40.008K3

9 Mixer arm (1 pc.), Side (long) ..................................................... 40.009

9 A Mixer arm (1 pc.), Side (short) ................................................... 40.009A

10 Mixer arm (1 pc.), Side-base ....................................................... 40.010

11 Mixer arm (1 pc.), Rake ................................................................. 40.011

12 Drive shaft, complete .................................................................... 40.012

12 A Spring pins, complete set of 4 pcs. incl. a jig ...................... 40.012A

13 Gear motor 0.75 kW, 30 RPM, 230V ....................................... 40.013

13 G - Gear only ......................................................................................... 40.013G

13 M - Motor only ...................................................................................... 40.013M

14 Starting capacitor 125 µF ............................................................. 40.014

15 Operating capacitor 25 µF .......................................................... 40.015

16 Phase capacitor 20 µF .................................................................. 40.016

17 B Telescopic leg (1 pc.), rear ........................................................... 40.017B

17 L Telescopic leg (1 pc.), front — left side ................................... 40.017L

17 R Telescopic leg (1 pc.), front — right side ................................ 40.017R

17 SB Bolt and nut (1 set) for telescopic leg (1 pc.) ....................... 40.017SB

19 Safety grid — by the mixer gate ............................................... 40.019

22 Mixer arms, 4 pcs., complete set .............................................. 40.022

22 A Mixer arms, 4 pcs., wo/cross joint ............................................ 40.022A

30 Discharge chute (incl. nuts) ........................................................ 40.030

44 Cross joint for mixer arms, steel ............................................... 40.044

3R

2

5

3

7

7

8

8

4

9

9A

6

6

5

6B 5B

10

11

12

44

8E

8E

8K

22

19

15

16

30

14

13

13M

17R 17L

13G

22A

17B

6W

8K3

8K2

8K1

12A

SPARE PART LIST - 40L, 230V

GB-28.11..18

Spare Part List for the 40 L mixers, 110V, is available online at

www.soroto.com

This manual suits for next models

3

Table of contents