SOURCES LINE EM 50 User manual

ELECTROMAGNETIC TAPPING MACHINE

EM 50 (rev. IV)

Owner’s manual (small)

Thank you for purchasing our electromagnetic tapping machine SOURCES LINE EM 50.

To guarantee the correct working and the best performance of the machine, please read this

manual carefully before activating the appliance.

(High precision impact system)

2

PRECAUTIONS BEFORE USE

DEAR CUSTOMER

Before using the appliance, the user should read the following instructions carefully.

Keep this guide carefully for future consultation.

CONNECTIONS TO THE MAINS SUPPLY

The appliance should only be connected to an earthed socket installed in accordance with

the regulations:

Europe 230 v AC 50 Hz /60Hz

North America 115 v AC 50 Hz /60Hz

(Select the mains voltage AC 115v / 230v using the Switch below)

HANDLING

When you don’t use the “EM 50 Tapping Machine, switch off the button (n.1) on the

front panel and ”put it into the “flight case” or the padded transport bag .

CLEANING

In case of cleaning the various components of the system, absolutely don’t use any

solvent or alcohol, as they might damage the finishing and cancel the notices on the

panels, or on the labels . Only use a simple wet cloth.

IMPORTANT PRECAUTIONS

-Save the carton and packing material even if the equipment has arrived in good condition.

Should you ever need to ship the unit, use only the original factory packing.

-Read all documentation before operating your equipment. Retain all documentation for

future reference.

-Don’t put your hands under the machine while working; Danger of getting squashed.

-Do not spill water or other liquids into or on the unit, or operate the unit while standing

in liquid.

-Do not use the unit if the electrical power cord is frayed or broken. The power supply

cords should be routed so that they are not likely to be walked on or pinched by items

placed upon or against them, paying particular attention to cords and plugs ,

convenience receptacles , and the point where they exit from the appliance.

-Always operate the unit with the AC ground wire connected to the electrical

system ground.

-Do not remove the cover . Removing the cover will expose you to potentially

dangerous voltages . there are no user serviceable parts inside.

3

SPECIFICATIONS

GENERAL

-AC power supply: (select the AC 115/230 V “Switch”located at the bottom)

Europe 230 v ± 10% AC 50 Hz / 60Hz 170 w

North America 115 v ± 10% AC 60 Hz 170 w

- DC power supply: 25,2 v DC 6 A (recharge 0,8A , 12 hours)

- Operating Temperature: -10°C to +40°C (14°F to 104°F)

- Humidity : 90% [non condensing at 40°C ( 104°F)]

- Storage Temperature: -20°C to +60°C (-4°F to 140°F)

- Size: (550 x 260x 120) mm

- Weight: 12,5 Kg (441 ounce) battery except

- Power Low Indication DC:(Battery Pack) by means of inside “Buzzer”

- Battery Life: 45 minutes of continuous working .

PROTECTION FUSES

-1 pieces : 4,0 A -T- (5x20) “delayed”,AC 115V (North America)

-1 pieces : 2,0 A -T- (5x20) “delayed”, AC 230V (Europe)

(inserted within VDE electricity supply AC “rear side” near to battery doorway).

-1 pieces :6 A POLYSWITC(auto-restore fuse) inserted within the Ni-MH Battery Pack

STANDARD EQUIPEMENT

- EM 50: (Tapping Machine).

- CABAC-EM1/EM2: (AC 115v/ 230 v electrical cable) : Plug to VDE (4-5 meter)

- O.MAN-EM50: Owner’s manual: (small)

OPTIONAL ACCESSORIES / SPARE PARTS

- RC 50: (Kit Remote Control) Tx + Rx (R.F. 434 Mhz) + external Antenna -

. able to cross walls - (50 mt range in clear field)

-TX EM-50: Transmitter replacement (Tx) “Wally” 434 Mhz

- BAG 50: (Transport Bag) soft and padded

- FC 50: (Aluminum Strong Flight case) Size WxHxD (720x370x215)mm ;

(28,3x14,5x8,5) inch ; 7,5 Kg (265 ounces)

- BP 50 : (Battery pack Ni-MH)(25,2 V- 4,5 Ah) ;1,6 Kg (56 ounces)

- HM5-EM : Iron’s Hammers (set 5 pcs.) 30 mm diameter, 500 grams ISO 140

- ALCRT-EM : (Aluminum Bottom carter) included of rubber feet and look clips

Technical features and appearance may be changed without notice

4

TURN THE TAPPING MACHINE ON

-Unhook the two clips, open the Aluminium Bottom Carter, and remove it.

-Select the AC Mains voltage of your country 115v / 230v

(see red selector located at the bottom)

-Open completely the three support bearings as in the photo

-

5

-Put the device on the floor, make sure it is a flat surface, if possible (see the

level above the device).

-Press the switch on the bottom (n.1) on the right for “115/ 230v”AC ,or on

the left for the DC “BATTERY”(optional )

-Do not adjust the height of the support feet ( if possible ).

-Press START (manual functioning), or REMOTE CONTROL (switch n 3)

to put the tapping machine in function.

-(ATTENTION : please follow the correct instructions when you close the

back carter (see photo)

POSITION OF THE MACHINE DURING USE

Avoid putting EM 50 near sources of heat or in dusty places, with low temperatures or

humidity. Place EM 50 on the floor to test with attention.

To remove the machine, don’t drag it on the floor, but raise it avoiding possible damages

to the hammers that normally lean on the floor.

Clean the floor removing the dust or other foreign bodies from the places where you have

to do the test.

In these conditions, thanks to the precision of the machine, the hammers will have

constant impacts with the floor and the results will be more precise.

SUPPORT BEARINGS

Big non-slip rubber bearings against vibrations, with good smoothing features .

According to ISO 140 the fall height of the five hammers on the floor has to be of

40 mm +/- 5% .

Do not adjust the feet in height because, according to the ISO regulation, the fall height

of the hammers must be exactly of 40 mm +/- 5 % .

Any change in the height might modify the calibration of the machine .

(ATTENTION)

ISO:140 - ISO 717 - …..... (OK) Not ISO ..(If possible do not adjust the feet)

6

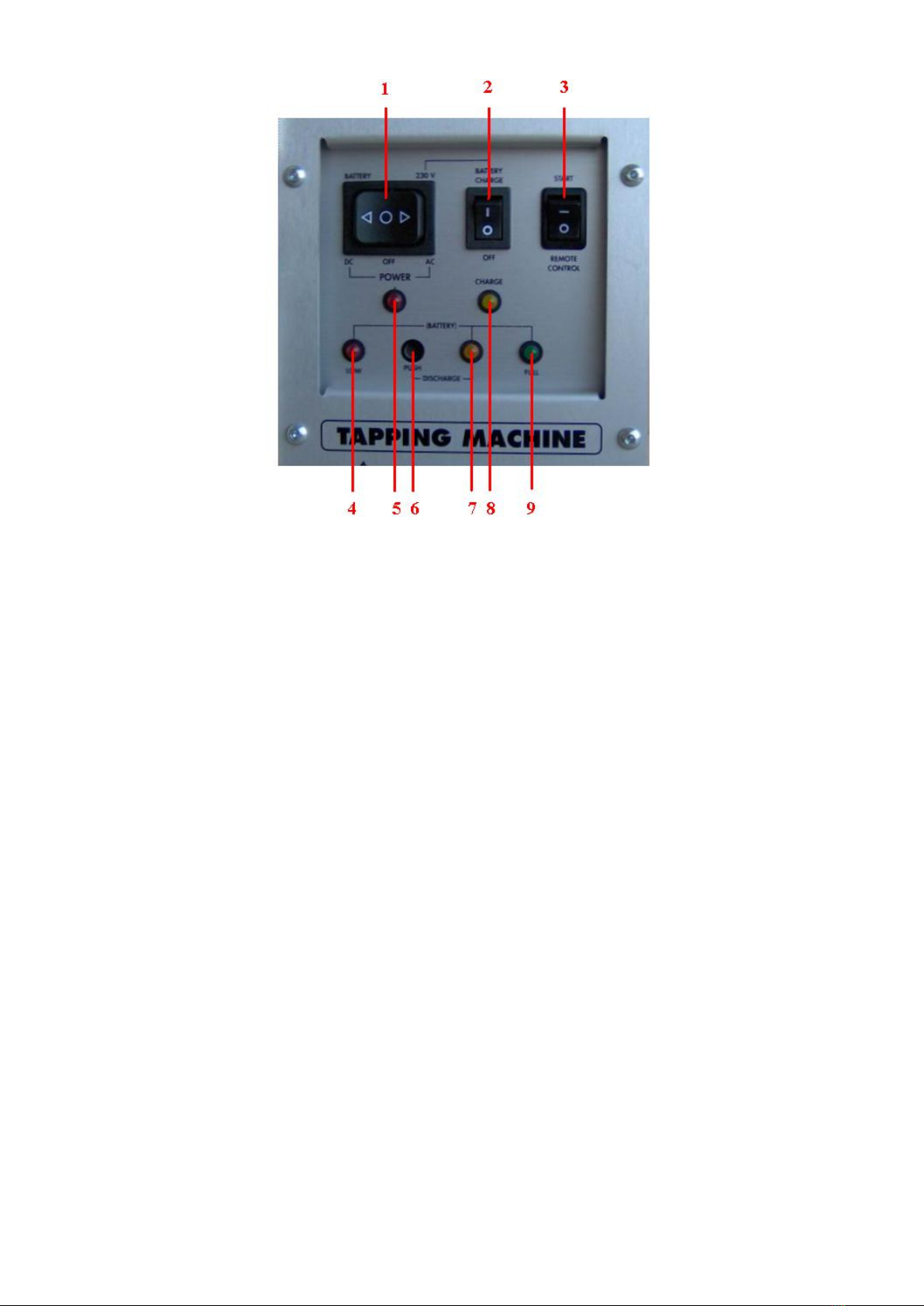

FRONT PANEL

1) SWITCH ON BUTTON

Press it to switch on the machine.

To the left it is to “BATTERY DC”, to the right it is to “(115v) 230 v AC “

2) SWITCH TO CHARGE THE BATTERY PACK

To charge the (optional) battery pack , you need to press this switch and the switch n. 1 ( AC 230 v )

3) START SWITCH / REMOTE CONTROL

Selector to select the type of functioning, manual or remote-controlled.

This selector is usually located on “REMOTE CONTROL”, so you can activate/deactivate

the machine at a distance by a radio control (optional).

In case of functioning without radio control ( manual mode), the machine can be switched

on with the selector (n 3) on “START”; to switch it off you must move again

the selector on “REMOTE CONTROL”

4) RED LED

The led is switched on only if the battery pack is run out of batteries (only if the batteries are

working).

5) RED LED

The led is switched on only if the SWITCH (n1) battery or 230 v are working

6) INSIDE BUTTON

To refresh the battery pack , you have to press this button every 20/30 cycles of working .

(Press only when the battery pack is low , led n. 4 is ON ).

7) ORANGE LED

The led is switched ON only if you press the button n. 6 .

8) INTERMITTENT YELLOW LED

The led is switched ON only during the batteries charging

9) GREEN LED

The led is switched ON only when the battery is full

7

Notes on the quality of the measures

Attention, not to commit errors, before starting the procedure it is necessary to verify that

the inferior part of the hammers and the floor (where you will make the test )are well

cleaned from dust or other things. To clean the hammers use a cotton cloth and alcohol.

The best results from the tapping machine SOURCES LINE EM 50 are obtained when you

test floors that are very uniform and horizontal. ( pict. 1)

Using the bidirectional level on the generator, choose ,if possible, points to test with good

building characteristics.

In case of tests on floors that are not perfectly horizontal, do not adjust the height of the

support feet, the machine will work slightly “inclined” but always parallel to the floor

(pict.2).

The hammers will fall perpendicularly to the floor from a constant height of 40 mm ( as

required by ISO 140/6 –140/7…).

In these working conditions the level of the impacts of the hammers on the floor will be

slightly inferior (a small slowdown of their fall speed, due to the friction between hammer

and track), bringing to a maximum error of ( - 0,2 ÷ - 0,5) dB noise generated (not

relevant value).

An adjustment in height of the support feet, to bring the machine to a perfect

horizontal position

(pict. 3), might change the fall height ( 40 mm) and the points of impact of the

hammers on the floor, causing mistakes ( -2 ÷ - 4) dB and invalidating the

measures obtained.

(fig.1) IDEAL CONDITION

Floor and tapping machine perfectly horizontal.

(fig.2) ACCEPTABLE ERROR

Inclined floor and tapping machine parallel to it

( No adjustment of the support feet).

(fig.3) MAXIMUM ERROR

Inclined floor and tapping machine, brought to an horizontal

position because of the adjustment of the height of the support feet

8

Inside Battery Pack

-BP 50- Battery Pack (new) : Ni-Mh 25,2 v- 4,5Ah

Protection by POLYSWITCH 6A (AUTO RESTORE FUSE)

In case the batteries are completely run-down, the time needed for the recharge is of about

12 hours.

When the charge finishes, the internal circuit of the Tapping Machine SOURCES LINE

EM 50, disconnects automatically, and the green led ( N.9) turns on .

ATTENTION :

For a good operation close well the connectors to three poles before turning the instrument

on.

Remove the “Battery Pack”from the instrument during the transport (by the courier)

“Battery” connections :

Dimensions of the packet of batteries:

(W x H x D) (390 x 84 x 20) mm

Weight: 1,6 kg

NOTE) Ni-Mh batteries. When you substitute the batteries, dispose of the old ones according

to the present regulation

RoHS

9

INFORMATION ABOUT THE FUNCTIONING AND THE MAINTENANCE OF

THE BATTERIES

Ni-MH batteries, used in the Tapping Machine, can work for some years, but just if used

correctly.

Their life is longer if they are used regularly and in the correct way, instead if they are

used a few times the life of the batteries will be shorter.

The main cause of the damage is due to the spontaneous self-discharge. When the batteries

are new it is up to 1% each day, but if used incorrectly the spontaneous self-discharge

could reach the 5% a-day ( 20 days are sufficient to discharge completely the battery

risking to damage it permanently).

Not all the elements of the Battery Pack get old at the same time and in the same way.

Because of this, after some time( especially if the battery is not used a lot), some elements

that are part of the battery pack could be “ slightly damaged”, modifying their ability of

supplying electrical current and the work potential difference.

In this case, the total potential difference of the Battery Pack (composed of n.21 cells in

series “21x 1.2 v=25.2V” assumed value )will not be as it was in origin, it will be as lower

as many elements are damaged, and the electrical current will certainly be lower than the

minimum one necessary for the correct functioning of the Tapping Machine.

If this is the situation, you can try to reactivate the Battery Pack making some

charge/discharge cycles proceeding in this way.

1) Charge the Battery Pack until full charge (Green led on).

2)Wait for at least 30 minutes to let the battery cool itself.

3)Repeat the sequence of charge, turning the Switch Off and then On (Switch 2)( leveling

of the electrical current of the cells) and wait until the charge is completed( Green led on).

4)Wait until the battery is cold. Turn the Switch n.2 Off and On again.

5)Push the internal button “CONDITIONING”(n.6). The orange led (n.7) will turn On and

it will start the procedure of battery discharge.

It could take 10/15 hours to complete the discharge.

When the battery is completely empty, the orange led (n.7) will turn Off and the procedure

of recharge will immediately start( yellow led On n.8). At the end of the charge the green

led(n.9) will turn on.

6)Wait for at least 30 minutes to let the battery cool itself, turn Off and then On the Switch

n.2 (second leveling of the electrical current of the cells) and let the battery charge again.

End of the process of Battery Pack Conditioning(recond)

Now use the Battery Pack and verify its functioning.

Pay attention: When the battery is new, the Tapping Machine can work ceaselessly for

40/50 minutes ( push the START side of the switch n.3).In St-By mode the Battery Pack

will be able to work for about 50 hours.

MAINTENANCE OF THE EFFICIENCY OF THE BATTERY PACK

To extend the life of the Ni-MH batteries it is important to keep them charged and, in case

of irregular or missed usage, repeat the charge cycle each 1-2 month(s).

The batteries will work better if the Battery Pack is charged the day before the use of the

Machine( if the B.P. is old, repeat the charge cycle twice before using it to “ level the

charge of the cells”).

The potential difference values can be read on the Voltmeter placed on the rear panel.

10

CHECK OF THE CHARGE OF THE Ni-MH BATTERY

Through the Voltmeter placed on the rear panel ( near the AC 115/230V socket input) and

pushing the right button it will be possible to measure the Battery Pack potential

difference.

Just in case of continuous functioning(switch n.3 on START side; or after having turned

the device On using the starting button with the “optional” remote control) and not with

the St-By mode, you can have the most reliable value to determine the state of the residual

charge.

The following values of potential difference can be slightly different according to the age

of the Battery Pack cells.

I) 25.0 V approximately( charge at 100%) maximum potential difference as the device is

just turn On.

II) 23.0 V- 23.5 V( residual charge at about 50%) after 20-25 minutes of functioning.

III) 21.0 V( residual charge 0%, close to the switching off) after 40-50 minutes of

ceaselessly functioning.

During the charge phase the Battery could reach a potential difference of over 30.0 V

( in particular at almost completed charge).

INTERNAL SIGHT

ELECTROMAGNETIC WORKING PRINCIPLE

To work, the machine uses an electromagnetic principle.

It has five powerful copper coils, around brass units, inside which there are iron tempered

hammers.

11

These are raised by the magnetic field created by the coils, thanks to the piloting of a

sophisticated controlled quartz electronic circuit. The hammers fall off liberally “ without

friction” from a fixed height in the way and at the frequency required by ISO 140 rule.

The high quartz precision allows to have 10 impacts a second ( as required by the

regulation ISO 140) with a precision of ± 0,001 %.

Mechanical tapping machines operated by an engine reach an average precision of ± 10%.

Another advantage of this electromagnetic system is that it does not have any other

mechanical organ in movement ( apart from the hammers).

It does not require any kind of maintenance.

Another important feature of EM 50 is that it has small vibrations because the lifting of the

hammers is very soft.

The mechanical models are operated by an electrical engine that moves some cams that, to

lift the hammers, strike against them creating dangerous vibrations.

These ones transmitted to the floor through the support feet, cause an undesirable noise

that worsens the quality of the measure.

Thanks to these simple advantages, the tapping machine SOURCES LINE EM 50 has a

very great precision and repeatability in the time of the beats always equal and constant in

any condition of use.

STRONG CHASSIS

The chassis of EM50 is very

Strong to guarantee unaltered

the

characteristic in the time .

It is made in Anticorodal and

Peralluman aluminium lead

free (RoHS accordant

ANTENNA

The Antenna of the receiver

is arranged below the

Tapping Machine to increase

the distance of operation

between the remote control

and the receiver, and to be

protected.

HAMMERS

According to the law, the hammers of 30 mm in diameter are made of temperate steel, they

weigh 500 +/-12 grams each and in the lower part where they hit the floor have a 500mm

radius spherical profile.

12

WARRANTY

This machine has been made with high quality materials and great care in manufacturing.

SOURCES LINE gives you a guarantee for the component parts of this machine for what

regards the defects of manufacturing or materials, for the duration of ( 24) twenty-four

months from the date of purchase.

Conditions

1) The obligations of SOURCES LINE are limited to the repairing of the failures. The

substitution or repairing of the faulty parts is subordinated to its final decision.

2) All the repairs under guarantee must be made by SOURCES LINE or by an authorized

Technical services centre. The repairs made at unlicensed laboratories will not be

refunded by SOURCES LINE

3) Periodic controls, calibrations, maintenance and repairs are not under guarantee.

4) Guarantee is not valid in case of defects different from materials or assemblage and in

particular are excluded:

- damages caused by accidents, negligence, alterations, use of unoriginal spare parts or not

appropriate packing.

- damages due to wrong voltage current, insufficient ventilation, lightnings, fire, floodings

or any other cause not imputable due to SOURCES LINE.

5) No recompense is due to the buyer during the period of the repair of the machine.

6) The guarantee is valid only if this document is filled out in any part and handed in with

the copy of the bill of purchase.

SOURCES LINE model /n. series :…………………/……………………..

Date of purchase : ....……/…..….../…….….

Name, address and telephone n. of the Buyer::…………………………………….

………………………………………………………………………..

Retailer:………………………………………………………………

13

Declaration of CE conformity

(Electromagnetic Compatibility)

Manufacturer: SOURCES LINE

Address: 1 Monte Cimone Street 41035 Massa Finalese (MODENA) ITALY

Model name : EM50 (TM50-XM50-BAS004)

Type of equipment : Tapping machine

To which declaration applies , complies with the provisions of the directives of the

Council of the European Union on the approximation of the laws of the members States:

Relating to low Voltage Directive 2006/95/EC, conformity is proven by compliance with

the following standards:

-EN 60065 (06/2004) + A1 (01/2007): Audio video and similar electronic apparatus.

Safety requirements.

Relating to Electromagnetic Compatibility 2004/108/EC, conformity is proven by

compliance with the following standards:

EN 55024 (09-1998) + A1 (10-2001)+A2(01-2003)+S1(03-2008) : Immunity

EN 55022 (01-2009): Emission

Date 01/04/2011

The legal representative of SOURCES LINE

Maurizio Bergamini

14

Declaration of conformity to ISO regulation

Manufacturer: SOURCES LINE

Address: 1, Monte Cimone Street 41035 Massa Finalese (MODENA) ITALY

Model name : EM50 (TM50-XM50-BAS004)

Type of equipment : Tapping machine

For tests of sound insulation of floor tapping, declares that “ EM 50”

answers the following prescriptions of these regulations:

ISO: 140 / 10140 / 16283 / 717; DIN 52210; BS 5821; ASTM E 492

The legal representative of the SOURCES LINE

Maurizio Bergamini

----------------------------------------------

Manufacturer:

SOURCES LINE 1, Monte Cimone Street

41035 Massa Finalese (MODENA) Italy

Tel (+39) 0535 96301

http://www.sourcesline.com e-mail: [email protected]om

Table of contents

Popular Test Equipment manuals by other brands

Inficon

Inficon VORTEX operating manual

Fieldpiece

Fieldpiece MR45UK 110VAC Operator's manual

Sensidyne

Sensidyne Gilian Gilibrator 3 STABLFLOW quick start guide

Sealey

Sealey Auto Service VS0271 instructions

Fiber Instruments Sales

Fiber Instruments Sales ATLAS MINI OTDR manual

Viavi

Viavi OneAdvisor 800 400G Module Quick Card User Guide