1110

Specifications

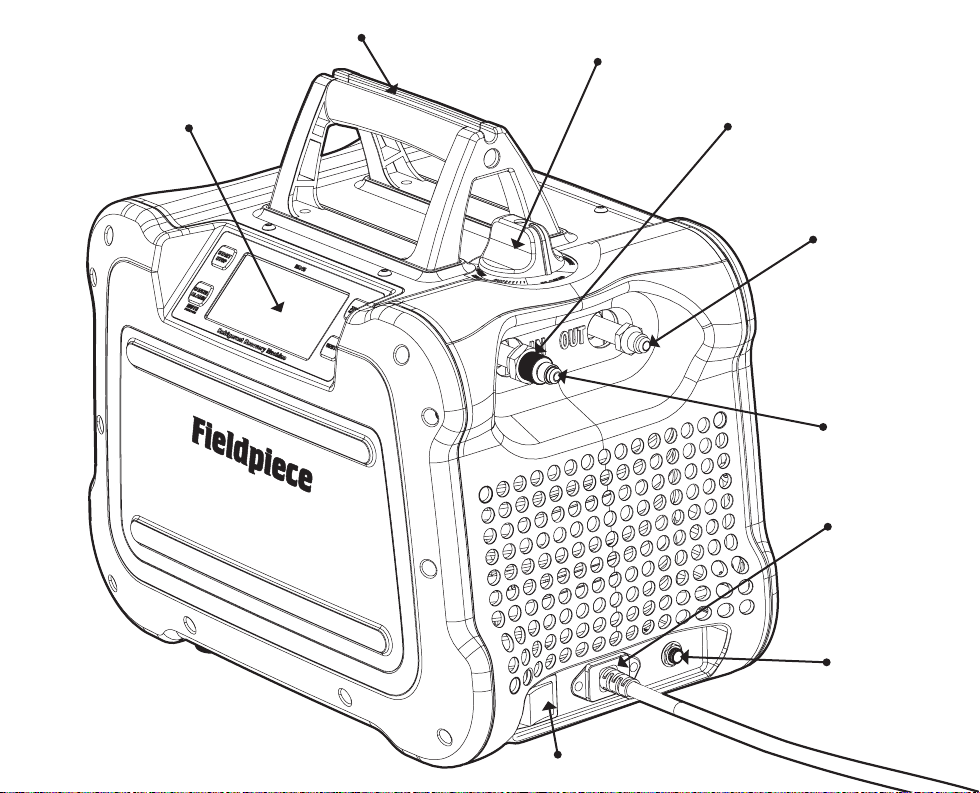

Display: 2 x 10000 count LCD with status messages

Backlight: Blue color

Measurement rate: 3.3 times per second, nominal

Input Port Pressure Sensor Range:

-76 cmHg to 4100 kPa (-30”Hg to 600 psig)

Output Port Pressure Sensor Range:

-76 cmHg to 4100 kPa (-30”Hg to 600 psig)

High Pressure Cuto: 3850 kPa (558 psig), nominal

Pressure Relief Valve: 4.2 MPa (609 psig), nominal

Resolution and Units: 5 Kpa (2 cmHg), 1 psig (1”Hg),

0.05 bar (2 cmHg), 0.01 Mpa (2 cmHg)

Pressure Sensor Accuracy:

± 1.3 cmHg, ± 0.5“ Hg (Vacuum)

± (0.6% of reading +14 kPa), ± (0.6% of reading +2 psig)

Final Recovery Vacuum: 38 cmHg, 14.9”Hg

Compressor: Twin cylinder reciprocating (oil-less)

DC Motor: 746 Watt (variable smart speed)

Power Source: 95 to 130 VAC @ 50 Hz 1 phase

Nominal Current Draw: 12.0 A

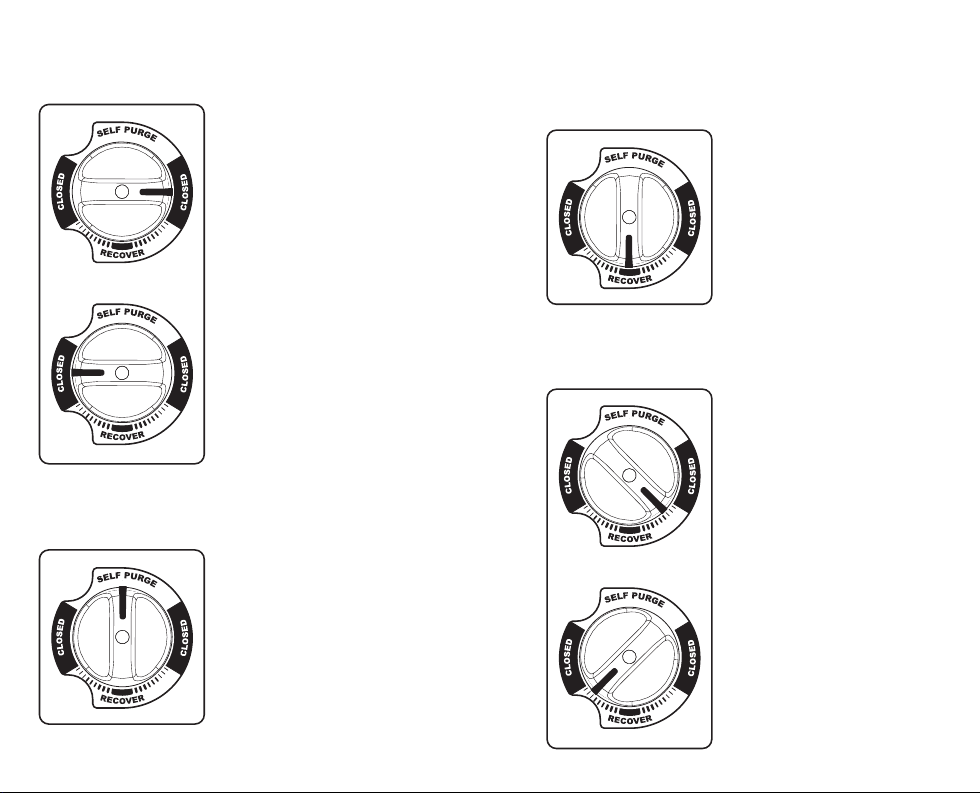

Valve: Single dual-route ball valve

Input Port Filtration: 9 mm mesh screen, stainless

Noise: Sound pressure level <70 db(A)

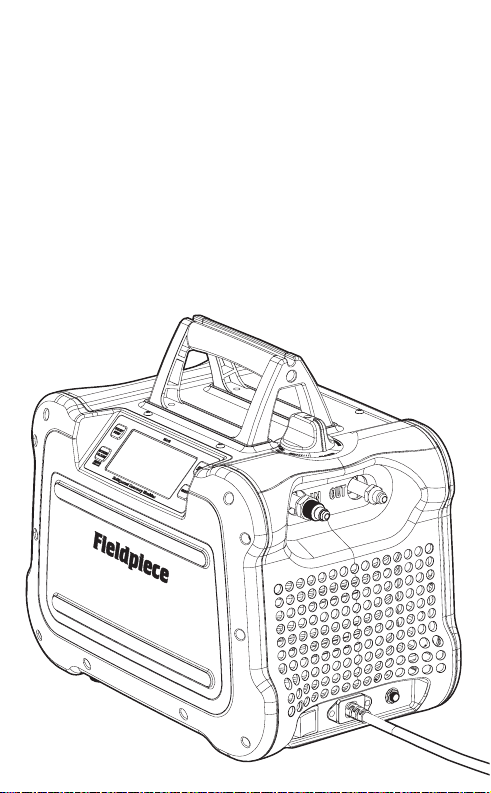

Dimensions: 376 mm x 250 mm x 344 mm (14.8”x 9.8”x 13.5”)

Weight: 10 kg (22 lbs)

Operating Environment: 0°C to 43°C (32°F to 109°F)

Storage Environment: -20°C to 60°C (-4°F to 140°F)

Approved Refrigerants: 12, 22, 32*, 134A, 143A*, 401A, 401B, 401C,

402A, 402B, 404A, 407A, 407B, 407C, 407D, 408A, 409A, 410A,

448A, 452A, 500, 502, 507, 509, 1234YF*, 1234ZE*

* Class A2L (mildly ammable) refrigerant

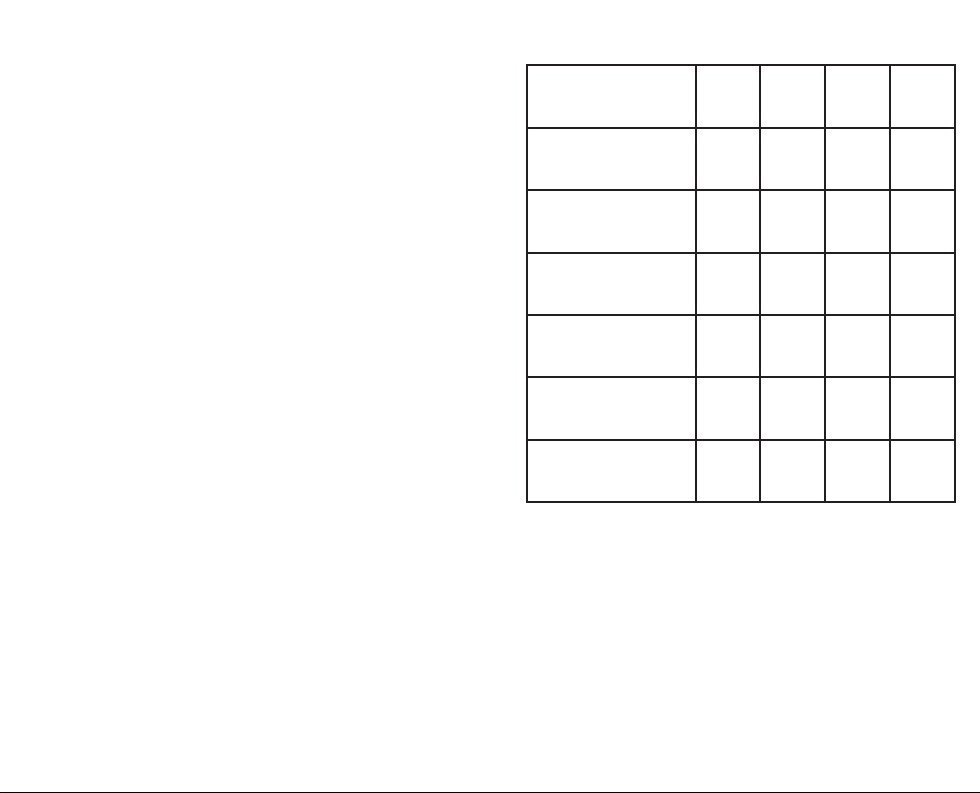

Performance Data

Refrigerant R22 R134A R407C R410A

Push/Pull Recovery

(kg/min) 4.6 5.4 5.2 7.2

Liquid Recovery

(kg/min) 4.7 2.9 5.1 5.6

Vapor Recovery

(kg/min) 0.28 0.28 0.33 0.33

Final Recovery Vacuum

(kPa) 50.8 50.8 50.8 50.8

Residual Trapped

Refrigerant (kg) 0.005 0.008 0.004 0.005

High Temp (104°F) Vapor

Recovery (kg/min) 0.40 - - -