NOVOTEST UT-3M-EMA User manual

Operating manual

(Electromagnetic-acoustic) EMA Thickness

Gauge NOVOTEST UT-3M-EMA

Postal address and registered address:

51200, Novomoskovsk, Spasskaya Str., 5

Sales office:

landline: +38-056-767-23-25 (multichannel)

mobile: +38-067-565-82-33

http://novotest.ua/

Warranty repair and servicing:

tel. +38-056-767-20-25

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 2

CONTENTS

1 Description and operation of the device and its components.................................................................4

1.1 Intended use ....................................................................................................................................4

1.2 Device specifications ......................................................................................................................4

1.3 Package ...........................................................................................................................................5

1.4 Device components.........................................................................................................................5

1.5 Transducer.......................................................................................................................................6

1.6 Structure and functioning................................................................................................................7

1.7 Operating modes.............................................................................................................................7

1.8 Means of measurement, device, and accessories............................................................................8

1.9 Marking...........................................................................................................................................8

1.10 Packaging......................................................................................................................................8

2 Intended use ...........................................................................................................................................9

2.1 Operating restrictions......................................................................................................................9

2.2 Preparation for the use ....................................................................................................................9

2.2.1 Visual inspection......................................................................................................................9

2.2.2 Battery charging.......................................................................................................................9

2.2.3 Transducer connection.............................................................................................................9

2.3 Operation.......................................................................................................................................10

2.3.1 Turning on..............................................................................................................................10

2.3.2 “MEASUREMENT” mode....................................................................................................11

2.3.3 “SETTINGS”mode ...............................................................................................................16

2.3.4 “ARCHIVE”mode ................................................................................................................17

2.3.5 “INFORMATION”mode......................................................................................................17

2.3.6 Measurement..........................................................................................................................18

3 Maintenance of the device and its components ...................................................................................19

3.1 Safety precautions.........................................................................................................................19

3.2 Warranty........................................................................................................................................19

3.2.1 Basic warranty........................................................................................................................19

3.2.2 Extended warranty .................................................................................................................19

3.2.3 Warranty for repaired and replaced components ...................................................................19

3.2.4 Wearing parts.........................................................................................................................19

3.2.5 Owner obligations..................................................................................................................20

3.2.6 Warranty obligations..............................................................................................................20

3.2.7 Cases uncovered by warranty ................................................................................................21

3.2.8 Other warranties and consumer law.......................................................................................21

3.3 Maintenance..................................................................................................................................21

4 Running repairs....................................................................................................................................23

5 Storage .................................................................................................................................................23

6 Transportation......................................................................................................................................23

7 Disposal................................................................................................................................................23

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 3

Caution!

Please read this operating manual carefully before operating electromagnetic-acoustic (EMA)

thickness gauge NOVOTEST UT-3M-EMA.

Operating manual (hereinafter referred to as OM) includes the information required to inform

operator about the performance and operating procedure of the device –EMA Thickness Gauge

NOVOTEST UT-3M-EMA (hereinafter referred to as the device or thickness gauge). The document

contains the specification, description of the design and operating principle, as well as the information

necessary for the right product operation. Before using the device, operator must read this manual, as

the device must be operated by a person aware of the operating principle and design of the device.

The right and efficient operation of the device requires:

measurement technique;

conditions of measurement that meet the measurement technique;

a trained operator who read this operating manual.

NOVOTEST reserves the right to make minor changes that do not impair the technical

specification of the product. These changes may not be mentioned in this document.

The delivery set of the device includes the operation documents that are a part of this manual and

the device registration certificate.

This OM applies to all product modifications.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 4

1 DESCRIPTION AND OPERATION OF THE DEVICE AND ITS COMPONENTS

1.1 Intended use

Electromagnetic-acoustic (EMA) thickness gauge NOVOTEST UT-3М-EMA is intended for

measuring the wall thickness of metal and alloy parts, walls of steel pipes, flat-rolled stock, rods, etc.,

without the use of couplant and preliminary surface preparation. EMA Thickness Gauge allows testing

through a gap that might be air, rust, paint coating, fluid, plastic, salt deposits, etc.

The thickness gauge can be used in engineering, aerospace, metallurgy, in the mounting of metal

structures, thermal power plants and nuclear power plants, field laboratories, and in the testing of

vehicles.

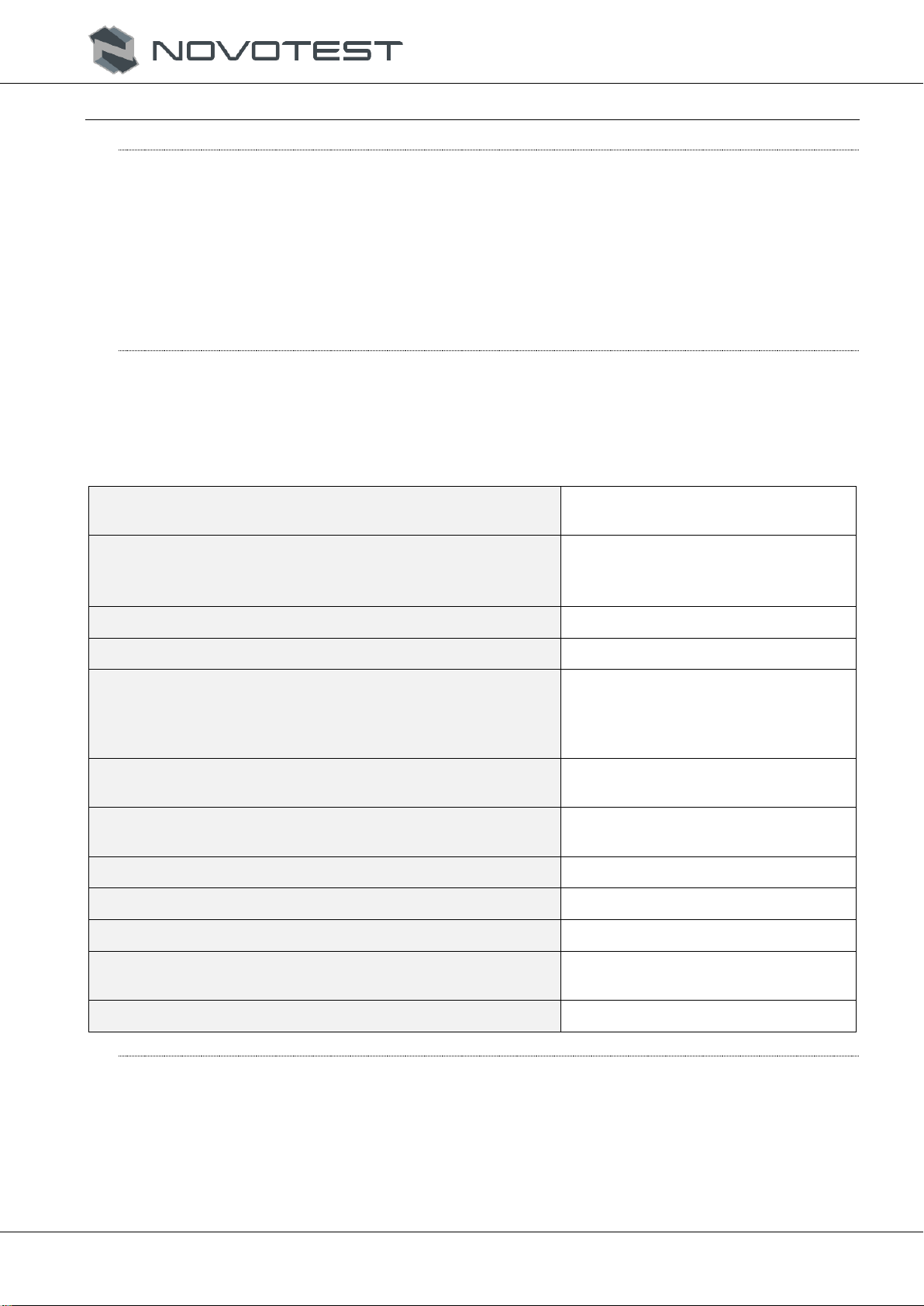

1.2 Device specifications

Electromagnetic-acoustic (EMA) thickness gauge NOVOTEST UT-3М-EMA is a portable device

enclosed in a shockproof casing with the chipboard, electronic components, and lithium-ion battery.

The product specifications are shown in the tab. 1.1.

Table 1.1 –Device specifications

Measurement range (depending on a transducer), mm

0.6 - 200

Permissible error, mm

(0.01h + 0.05)

where: h –nominal thickness, mm

Ultrasound velocity range, m/s

100 - 9999

Resolution, mm

0.01

Measurement modes

Autocorrelation (ACF)

Echo

Echo-Echo (dual echo)

Pique-Pique

Dimensions of the processing unit, max, mm

165х90х50

Power type

a built-in lithium-ion battery

Worktime without charging, min, h

8

Weight of the processing unit, max, kg

0.45

Display size

3.5 inches

Operating temperature range of the processing unit, °С

from -20 to +50

Air humidity, max

98 %, at 35 °С

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 5

1.3 Package

The processing unit of EMA Thickness Gauge UT-3М-EMA...............................................1 pc.

EMA transducer ..........................................................................................................As per order

2Lemo-2Lemo cable ...................................................................................................As per order

USB cable................................................................................................................................1 pc.

Charger....................................................................................................................................1 pc.

Packaging container ................................................................................................................1 pc.

Operating manual RDC.ED.UT-3М-EMA OM......................................................................1 pc.

Registration certificate RDC.ED.UT-3М-EMA RS ...............................................................1 pc.

* By a customer request, additional equipment or parts can be included in the package. The exact

information on the scope of delivery is specified in the registration certificate of the device.

1.4 Device components

The device consists of a processing unit enclosed in a durable and lightweight aluminum case, and

a transducer connected via sockets. The thickness gauge is controlled from the keyboard. Signals and

readings, the status of the device and other information are presented on a contrast color LCD / TFT

display.

The transducers are connected via coaxial cables, through the connectors that are located on the

top panel of the housing. The device is powered by a lithium-ion battery. The mini-USB connector,

located on the bottom of the case, is used to connect the device to a PC and to charge the battery. In

fig. 1.1 shows the components of the device.

1

2

3

4

5

1 –casing; 2 –contrast color LCD/TFT display; 3 –keyboard; 4 –transducer connection sockets;

5 –mini-USB slot.

Figure 1.1 –Electromagnetic-acoustic (EMA) thickness gauge NOVOTEST UT-3М-EMA

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 6

The keyboard buttons and their functions:

–

Turning on/off;

–

“Back” button (returning to a previous section of the menu);

–

Saving of a reading;

–

Parameters menu;

, , ,

–

Navigation through the menu;

–

Confirmation button.

1.5 Transducer

The thickness gauge is designed to function with EMA transducer (fix. 1.2). To prevent damaging,

EMA transducer comes with a protective cap. The cap fitted on a transducer during the testing does not

affect the measurement accuracy.

1

2

3

1 –2Lemo-2Lemo cable; 2 –protective cap; 3 –EMA transducer.

Figure 1.2 –EMA transducer

The transducer of EMA Thickness Gauge includes the permanent magnet that entails specific

requirements to the device operation:

1. If the device is moved near a sharp metal object, operator should exercise care as it might get

magnetized to the transducer and harm operator.

Note –If the device is placed in proximity of a plastic magnet card, this might lead to the card

failure.

2. If the transducer is placed on a loose and relatively lightweight sample, operator should hold it

with hand.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 7

3. If operator puts the device on a test object quickly and carelessly, it might bump against due to

additional acceleration caused by the magnetic field. To save the service life of the transducer,

it is recommended to place it on a test object smoothly and hold the device meanwhile.

4. It is recommended to put the device on the test object at a 60angle. Once the transducer

touches the test object, the transducer should be put upright.

1.6 Structure and functioning

The operating principle of the device is based on measuring the propagation time of an acoustic

wave through the test object. The measured time is converted into thickness using the preset velocity

of the ultrasonic wave propagation.

The acoustic wave is formed through electromagnetic-acoustic conversion directly on the surface

of the test object, bypassing the contact medium between the transducer and the test object. Due to this

conversion, the wave is not distorted in this medium.

The special data processing algorithm allows measuring the thickness of the test object correctly

in the presence of interfering factors such as metal anisotropy, multiple reflectors, and external noise.

The device eliminates the human factor, making thickness measurements fully automatic.

1.7 Operating modes

The device works in the following modes:

1. “MEASUREMENT”:

“AUTO”;

“MANUAL”;

“В SCAN”;

“CONTROL”;

“CALIBRATION”.

2. “ARCHIVE”:

“PREVIEW” – preliminary viewing mode;

“VIEW” – viewing of the saved readings;

“LOAD MEAS.” –the mode of measuring of the readings;

“DELETE” – removal of the selected measurements from the archive;

“DELETE ALL” – removal of all the saved measurements from the archive;

“EXIT”.

3. “SETTINGS”:

“LANGUAGE”;

“BRIGHTNESS”;

“COLOR SCHEME”;

“SOUND”;

“TYPE F”;

“CLEAR. SD”;

“TRANSDUCER”;

“MATERIAL”;

“SCALE”;

“TIME”;

“DATE”.

4. “INFORMATION”:

about the device.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 8

1.8 Means of measurement, device, and accessories

The operability of the device is estimated using the reference samples. The measurement error of

the device must be within the permissible error. If the permissible error is exceeded, the device must

be calibrated according to c. 2.3.2.5.

Adjustment and setting of the device must be done by NOVOTEST.

1.9 Marking

The front panel of the device must show the designation of the device and the trademark of

NOVOTEST.

The serial number is located on the back of the device.

1.10 Packaging

The processing unit and transducer are supplied in the packaging container excluding the damage

when transporting.

To avoid mechanical damage of the cable and sockets of the device, disconnect the transducer

from the device before placing it into the container.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 9

2 INTENDED USE

2.1 Operating restrictions

The device must be operated away from dust and aggressive environments, and with consideration

of features of the test objects in line with the agreed technical specifications, and the device must be

used within its technical characteristics.

The magnetic of radio noise at the place of operation of the thickness gauge must not exceed the

value that could impair the operation, i.e. it must not create the voltage at the amplifier input of the

thickness gauge that is more than half of its maximum sensitivity.

If the magnetic field of radio noise is strong, the place of operation of the thickness gauge must be

shielded from the external magnetic field.

The device must be used by a person who has read this operating manual.

If the device id carried to the place of operation at sub-zero temperature and placed in a room with

a temperature above zero, it should be kept in a package for at least 6 hours to avoid the moisture

buildup.

2.2 Preparation for the use

2.2.1 Visual inspection

Before an operation, the device must be checked visually, and its parts, processing unit,

transducer, slots, and connection cable must be checked for damages.

2.2.2 Battery charging

To charge the battery, connect the power unit to the slot on the bottom edge of the device. The

device can be operated during the charging.

The full battery charging takes up to 14 hours. When the device is being charged, it is prohibited

to leave it unwatched. The device can be also charged by connecting it to a PC.

To avoid battery failure during long storage, the battery should be charged each 2 months, even

when the device was not in operation.

2.2.3 Transducer connection

The transducer should be connected to the sockets in the top part of the device by a connection

cable.

Caution!

To avoid failure of sockets and cables, follow the operating instructions for the use of connectors

below!

The connector assembly of the device (fig. 2.1) consists of two parts: the device socket and the

cable plug.

Figure 2.1 –Connectors used in the thickness gauge

Figure 2.2. shows the connection and disconnection of the connectors.

The device socket

The cable plug

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 10

Caution!

Disconnecting the plug from the socket, hold it by the ribbed part and never pull the cable!

Figure 2.2 –Handling of the connectors

Note –The transducer should be connected when the device is off.

2.3 Operation

2.3.1 Turning on

Turn the device on by pressing “ ” on the control panel. When the device is on, the display

will show the logo с and the name of the device, version of firmware, and the serial number of the

device (fig. 2.3).

Figure 2.3 –Display after turning the device on

After displaying this logo, the device will go to the main menu (fig. 2.4).

Figure 2.4 –Main menu

Connection

Disconnection is wrong

Disconnection is right

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 11

The main menu of the thickness gauge consists of four sections:

1. “MEASUREMENT” –entering the measurement mode;

2. “ARCHIVE” –displaying of all the saved measurement results;

3. “SETTINGS”–in this section, the following parameters can be set: language, brightness,

color scheme, sound, type f., clear SD card, transducer, material, scale, time and date;

4. “INFORMATION”–displaying the information about manufacturer and the device.

2.3.2 “MEASUREMENT”mode

To enter the “MEASUREMENT”mode, choose the needed point using “ ” and “ ”, and

confirm the selection by pressing “ ”.

In the MEASUREMENT mode, the display is split into two sections: main and informational (top

part of the display) (fig. 2.5). The main section contains the working section of the mode, and the

informational section features the battery charge, connection to PC, SD card connection, and the

current time.

Figure 2.5 –Display of the thickness gauge

In “MEASUREMENT” mode, the thickness gauge can be operated in the following modes:

“AUTO”;

“MANUAL” mode;

“В SCAN” mode;

“CONTROL” mode;

“CALIBRATION” mode.

To switch the operating mode of the thickness gauge, press “ ”, and select the needed mode

by using “ ” and “ ”, press “ ” to confirm the selection. To navigate through the

parameters, use “ ” and “ ”, and use “ ” and “ ” to change the value.

Operator can change the resolution of the selected parameter by pressing “ ”. The selected

resolution is displayed by a special number ( , , , ) next to the value being changed.

2.3.2.1 “AUTO” mode

In this mode, the device automatically analyses the measured signals, selects the measurement

method, sets the parameters of the receive path, and displays the measured thickness value.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 12

In the “AUTO” mode (fig. 2.6), the speed of ultrasound velocity in the test object must be set (the

measurement of the velocity). The ultrasound velocity should be set through the calibration, or

manually in the “SPEED” parameter (from 1000 to 9999 m/s).

Caution!

The device employs a transversal wave. The speed of propagation of transversal waves in steel is 3250

m/d.

Figure 2.6 –“AUTO” mode

When testing materials with high attenuation, big objects, and using a big sounding range, the

noise amplitude can be compared to the amplitude of the valid signal and the valid signal can be

difficult to see with strong noise. For these cases, the device implements averaging that can be done by

2, 4, 8, 16, 32, 64 and 128 signals.

2.3.2.2 “MANUAL” mode

In the “MANUAL” mode, the measurement and testing are performed, and also setting of the

device according to a specific task (fig. 2.7). All parameters for the settings of measurement are

divided into categories (tab. 2.1) and depending on the selected category, operator can set different

parameters.

Figure 2.7 –“MANUAL”mode

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 13

Table 2.1 –Parameters of “MANUAL”mode

Categories

Parameters

PIQUE-

PIQUE

AMP.

START

WIDTH

THRESHOLD

DUR.

DELAY.

LEVEL

FRONT

AMP.

START

THRESHOLD

DUR.

DELAY.

AVG.

ECHO

AMP.

START

WIDTH

THRESHOLD

DUR.

DELAY.

ECHO-

ECHO

AMP.

GATE А/

GATE В

START

WIDTH

THRES

HOLD

DUR.

DELAY

Description of the parameters of the “MANUAL” mode:

–“AMP.”: amplification is adjusted automatically (AGC), or manually;

–“START”: the point of start of the selected gate (from 0 to the maximum measurement range);

–“WIDTH”: the width of the selected gate of the beam control. This value can vary from 0 to the

maximum measurement range. The total of start and width of the gate cannot exceed the maximum

measurement range;

–“THRESHOLD”: the threshold of the amplitude of processing of “THRESHOLD”echo signals.

The range is from 0 to 100%;

–“DUR.”: duration of scanning;

–“DELAY”: this parameter sets the delay of the start of scanning against the monitoring pulse;

–“LEVEL”: turn on/turn off;

–“AVG.”: turn on / turn off, and set the quantity;

–“GATE А/GATE В”: a selection of the gate. It can be А or В.

2.3.2.3 “В SCAN” mode

“В SCAN” mode (fig. 2.8) is used for displaying of В-Scan that is the shape of the test object.

This mode is used for detection of the corrosion damages, reduction, and lamination when scanning

the test object and graphical B-scan.

Figure 2.8 –“В SCAN” mode

All the settings of parameters of measurement in the “В SCAN” mode are divided into groups

(tab. 2.2).

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 14

Table 2.2 –“В SCAN” parameters

Groups

Parameters

AUTO

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

ACF

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

PIQUE-

PIQUE

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

FRONT

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

ECHO

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

ECHO-ECHO

MIN.

MAX.

THRESHOLD

1

THRESHOLD

2

SIGNAL

Description of the “В SCAN” settings:

–“MIN.”: the lowest value of the measurement range;

–“MAX.”: the highest value of the measurement range;

–“THRESHOLD 1” and “THRESHOLD 2”: minimum and maximum measurement threshold;

–“SIGNAL”: turning on/off of the sound signal.

2.3.2.4 “CONTROL” mode

This mode is used when it is necessary to examine the products by the exact thickness (minimum

and maximum). When the measured thickness exceeds the set thresholds, signalization is triggered so

the product can be rejected.

“CONTROL” mode (fig. 2.9) allows operator to estimate the corrosion damage in the percentage

of the reference thickness value.

Figure 2.9 –“CONTROL” mode

All parameters of settings of the measurement in the “CONTROL”mode are divided into groups

(tab. 2.3).

Table 2.3 –“CONTROL” mode parameters

Groups

Parameters

AUTO

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

ACF

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

PIQUE-PIQUE

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 15

FRONT

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

ECHO

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

ECHO-ECHO

REF.

THRESHOLD 2

THRESHOLD 1

SIGNAL

Description of settings of the “CONTROL” mode:

–“REF.”: reference thickness;

–“THRESHOLD 1”and “THRESHOLD 2”: minimum and maximum thresholds of the thickness

measurement;

–“SIGNAL”: Turning on/off of the sound signal.

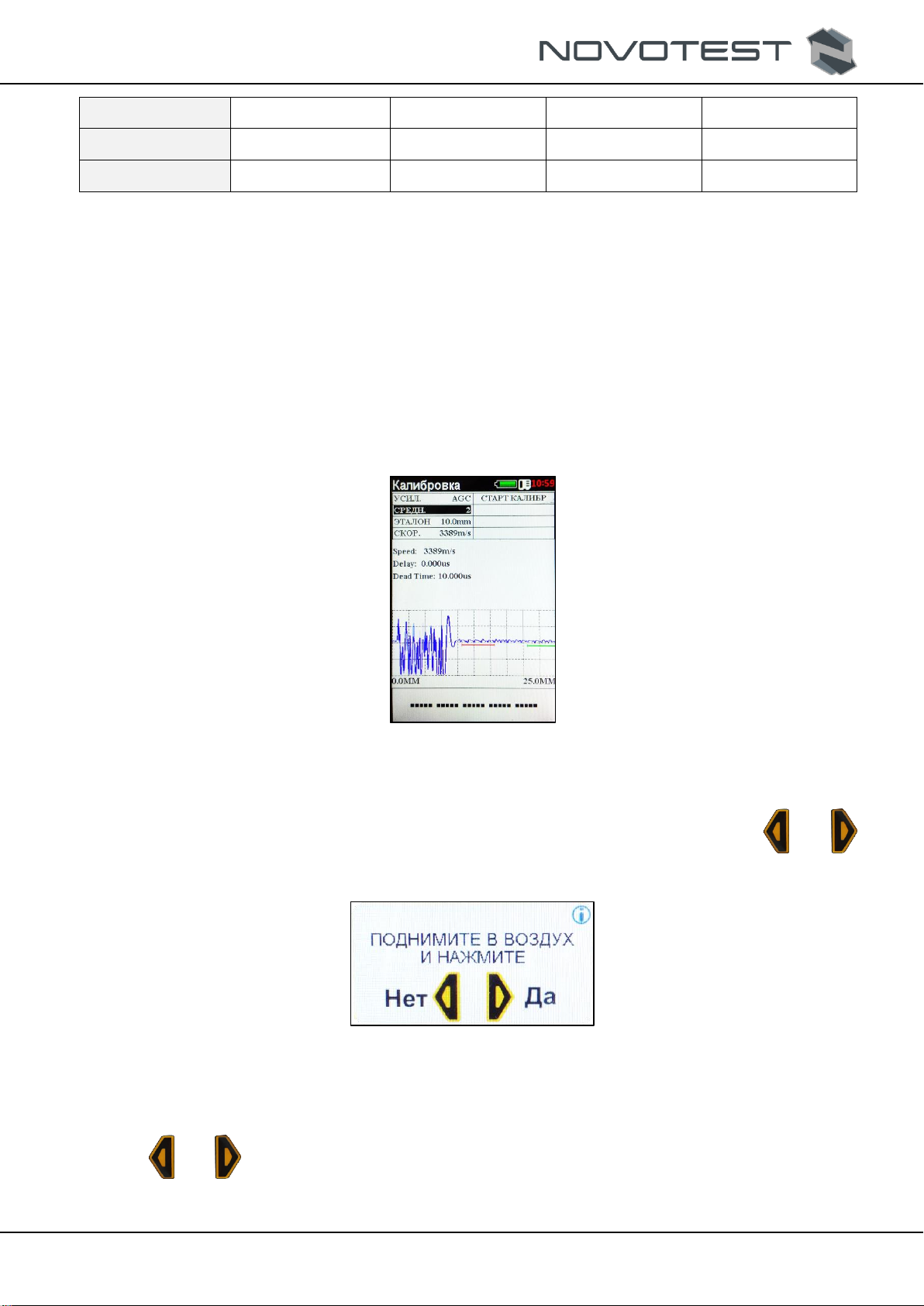

2.3.2.5 Calibration

To calibrate the device, place the EMA transducer on the test object. In “Calibration”mode, set

“AVG.”that can be done by 2, 4, 8, 16, 32, 64 and 128 signals (the averaging can be deactivated if

necessary), set the thickness of the reference sample “REFERENCE” and press “START

CALIBRATION”.

Figure 2.10 –“CALIBRATION” menu

Put the transducer into the air (away from the test object) according to the instruction on the

display “PUT INTO THE AIR” (fig. 2.11), then confirm or reject the action by pressing “ ” or “

”.

Figure 2.11 –“PUT INTO THE AIR”

The device will make a measurement and shows the new instruction on the display “PUT ON

THE SAMPLE” (fig. 2.12), and then operator should confirm or reject the action by pressing the

button “ ” or “ ”.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 16

Figure 2.12 –“PUT ON THE SAMPLE”

The device will make a measurement and display the thickness of the reference sample. If the

measured value is different from the reference sample and error is more than (0.01h + 0.05) mm, the

device must be re-calibrated.

2.3.3 “SETTINGS”mode

When “SETTINGS” mode is selected (fig. 2.13), the device will go to the settings of the next

parameters:

“LANGUAGE”: setting the language of the device menu (English and Russian are

available);

“BRIGHTNESS”: change of the display brightness (10%, 20% … 100%);

“COLOR SCHEME”: selectin of the color scheme (01, 02);

“SOUND”: Turning on/off (“ON”, “OFF”);

“TYPE F.”: “Median” filter, “OFF”;

“CLEAR. SD”: Clearing of SD card (switching “OFF”to “ON”), the SD card level is

shown on the bottom part of the display;

“TRANSDUCER”: the selection of the stored transducers;

“MATERIAL”: aluminum, duralumin Д16Т, bronze, tungsten, iron, gold, brass, ЛС-59-1

brass, magnesium, manganese, copper, molybdenum, nickel, tin, lead, silver, steel

20ГСНДМ, ХН77ЕЮР steel, 40ХНМА steel, ХН70ВМТЮ steel, ХН35ВТ steel,

Х15Н15ГС steel, СТ3 steel, chromium, zinc, cast iron, 40х13 steel, user;

“SCALE”: measurement units (mm, μm);

“TIME”: time setting (24h);

“DATE”: setting the date, month, and year DATE/MONTH/YEAR.

Figure 2.13 –“SETTINGS” mode

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 17

To navigate through «SETTINGS»menu, use “ ” and “ ” buttons, to select the

parameter to be changed, press “ ”, and select the needed value by pressing “ ”, “ ”, “ ”,

“ ” select the needed value that is confirmed by pressing “ ”.

2.3.4 “ARCHIVE”mode

This mode allows seeing all the saved measurement values and, if needed, download the selected

file to continue working with the required settings (fig. 2.14).

Figure 2.14 –“АРХИВ” mode

The saved measurement values are listed and sorted by the date of creation. To handle the saved

files, select the saved file by using “ ” and “ ”, and press “ ”.

2.3.5 “INFORMATION”mode

In this mode, operator can view the product information: battery charge, voltage, consumed

voltage, total operation time, measurement time, serial number, firmware version, and chipboard

version (fig. 2.15).

Figure 2.15 –“INFORMATION” mode

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 18

2.3.6 Measurement

Before using the device, make sure that the battery is charged sufficiently. The green battery icon

confirms that the battery is charged by 100%. If there is no charge or the charge is low (the red icon),

the battery must be charged by a charger or by connecting the device to a PC.

1. Connect the EMA transducer to the device.

2. Turn the device on by pressing “ ”.

3. Select the operating mode of the thickness gauge by pressing “ ”, and set the needed

parameters.

4. In needed, calibrate the device according to. 2.3.2.5.

5. Put EMA transducer on the teste object and achieve a stable value on the display (fig.

2.16).

Figure 2.16 –Measurement

6. To save the measurement value, press “ ”. Then, the name of measurement can be set

with a virtual keyboard (fig. 2.17).

Figure 2.17 –The input of the measurement

Use “ ”, “ ”, “ ” and “ ” to navigate through the keyboard, select the needed

symbol by pressing “ ”.

7. To turn the device off, enter the main menu and press “ ”.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 19

3 MAINTENANCE OF THE DEVICE AND ITS COMPONENTS

3.1 Safety precautions

After commissioning of the device, it is recommended to inspect it periodically to check the

following:

operability;

compliance with the operating requirements;

battery charge level;

absence of damage to the device components.

When using the charger connected to 220V at 50 Hz, operator should observe the regulations in

“Safety procedure when operating consumer electronic units”.

If the device is not in operation for a long time, the batteries must be disconnected from a power

supply and taken out from the device. Using this, the storage regulations of the battery must be

observed.

The device can be used only be the persons instructed and certified by the ІІ qualification category

by safety engineering using the measuring devices.

3.2 Warranty

The above information about the warranty servicing applies to all the NOVOTEST products.

The manufacturer warrants the compliance of the device with the technical specifications with

compliance with the terms of transportation, storage, and operation, and timely maintenance at least

once a year.

3.2.1 Basic warranty

The device purchased from NOVOTEST or an authorized dealer is covered by the basic warranty

–3 years, subject to the timely maintenance at least once a year.

If any part of the device fails due to the defect of the material or a manufacturer, it shall be

repaired or replaced by the manufacturer, or any authorized dealer of NOVOTEST, regardless of the

transferring of the ownership right to a third party during the warranty period.

The warranty applies from the date of purchase of the device, normally, from the shipment date. If

the device is purchased by an intermediate, the warranty period starts from the date of receipt of the

device by an intermediate.

3.2.2 Extended warranty

There is a special program of extension of the basic warranty from 3 to 5 years. To take advantage

of this program, user needs to pay the certificate with the purchasing. The terms and conditions of the

extended warranty are specified in the certificate.

3.2.3 Warranty for repaired and replaced components

All branded parts of NOVOTEST installed during the warranty repair apply to the NOVOTEST

warranty (up to the end of the warranty period).

The spare parts replaced during the warranty service, shall not be returned to the device owner.

3.2.4 Wearing parts

The parts wearing during the device operation are divided into two main categories. The first part

includes the parts that need to be replaced or adjusted with frequency stipulated by the maintenance

schedule of the device, and the second part includes the wearing parts, which frequency of replacement

or adjustment depends on the conditions of the product operation.

RDC.ED.UT-3M-EMA.000 OM

Operating manual

EMA Thickness Gauge NOVOTEST UT-3M-EMA

Page. 20

3.2.4.1 The parts replaced during the maintenance

The parts listed above have limited service life and need replacement or adjustment with the

periods stipulated by the schedule of the device maintenance. For these parts, the basic warranty

applies before the first part replacement or adjustment. The warranty period for each part cannot

exceed the limitations (by the time of operation of the device or working hours), specified in the

conditions of the basic warranty.

built-in batteries;

gaskets, if they are removed due to accompanying adjustment;

grease and operating liquids.

3.2.4.2 Wearing parts

The parts listed below that have limited service life or need to be replaced (adjusted) due to the

damage. However, these parts are subject basic warranty of NOVOTEST during 12 months:

transducers and their components;

connection cables.

Note: The parts wearing due to friction (such as movable parts of measuring transducers,

ultrasonic piezoelectric transducers, support arm etc.) are not covered by the basic NOVOTEST

warranty, if these parts fail due to wear and tear during the device operation. However, if in the

warranty period these parts fail due to defect of material or workmanship, they shall be repaired or

replaced under the basic warranty.

3.2.5 Owner obligations

The operating manual and registration certificate of the device specifies the information about the

proper operation and maintenance of the device.

Proper operation and maintenance of the device will help avoid costly repairs caused by incorrect

operation, negligence or improper maintenance. Besides, following our recommendations will extend

the service life of the device. Therefore, the device owner should:

If any defect or fault is found, submit the device to NOVOTEST or the authorized dealer

of NOVOTEST for a warranty repair as soon as possible. This can minimize the repair

required for the device.

Use only branded spare parts and couplants of NOVOTEST (with appropriate labels)

during the device maintenance.

Note: The failure to perform the device maintenance in time under the maintenance schedule

deprives of the right to warranty repair or replacement of the faulty parts.

Use only branded spare parts and couplants of NOVOTEST (with appropriate labels).

Make records of the device maintenance in the registration certificate and keep receipts

and bills. If necessary, they will prove that the maintenance was made in time (according

to periodicity specified in the registration certificate), using the recommended spare parts

and couplants. This will help in making warranty claims to defects that might occur due to

a deviation from the device maintenance schedule or the use of unauthorized parts or

materials.

Clean the casing of the device and probe according to recommendations of NOVOTEST.

Fulfill the operation and storage requirements in line with NOVOTEST recommendations.

3.2.6 Warranty obligations

NOVOTEST warranty shall not apply if replacement or adjustment is caused by one of the

following factors:

Table of contents

Other NOVOTEST Test Equipment manuals