-2-

Operation and Safety

•Chuck Key Safety: A chuck key left in the

chuck can become a dangerous projectile

when the spindle is started. Always remove

the chuck key after using it. Develop a habit

of not taking your hand off of a chuck key

unless it is away from the machine.

•Disconnect Power: Disconnect the lathe

from power before installing and removing

the chuck or doing any maintenance or

adjustments. Accidental lathe startup can

cause severe injury or death.

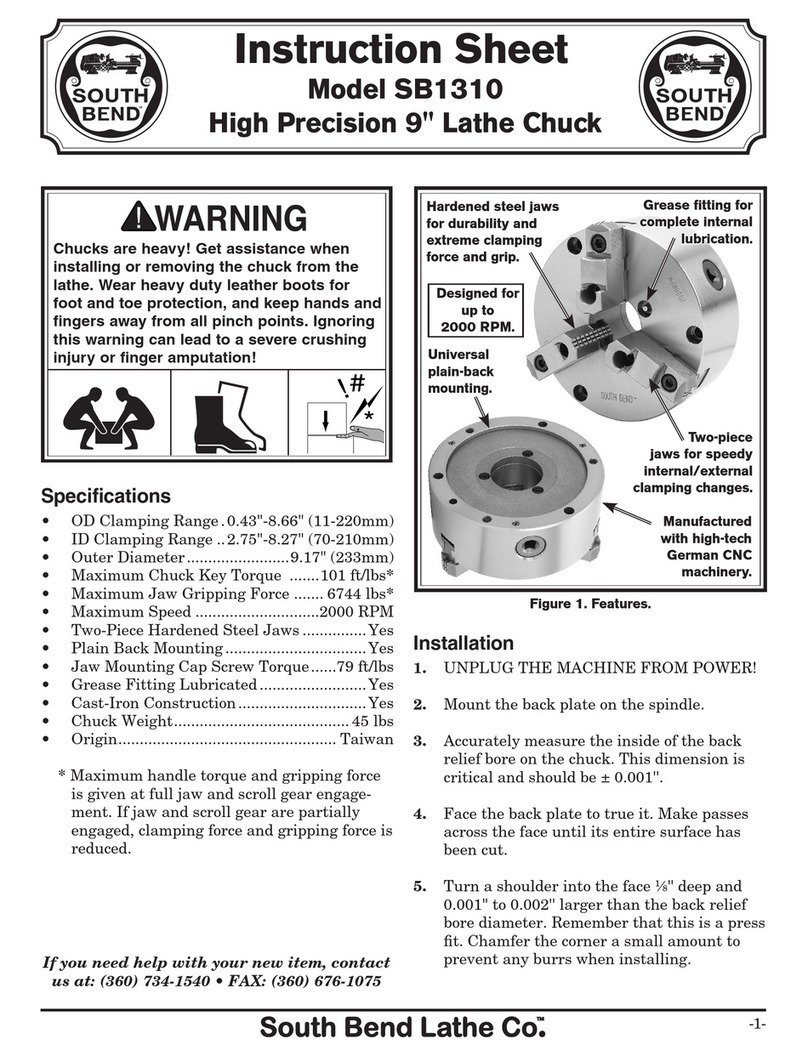

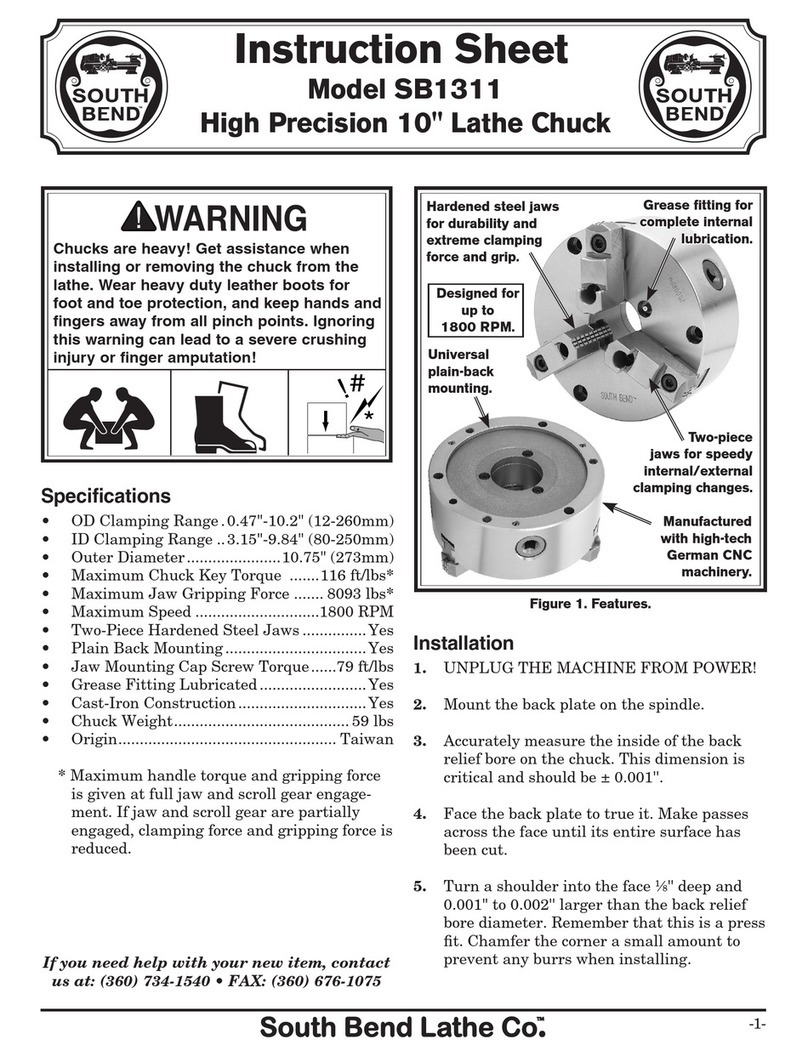

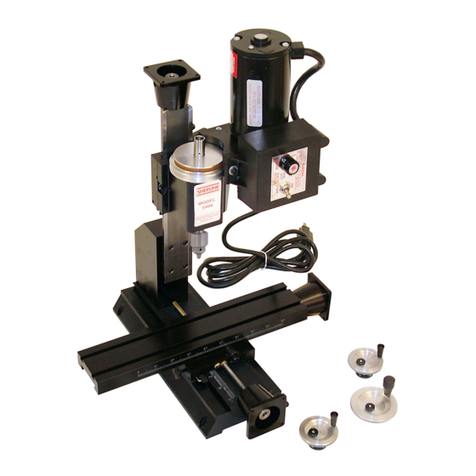

6. Set the chuck on the back plate, aligning the

shoulder with the relief bore. Use a transfer

punch to mark the back plate. If a transfer

punch is not available, a drill bit of the same

size as the mounting holes in the chuck can

be used. Lightly tap on the bit, rotate it 90°

and tap it again.

7. Remove the chuck from the back plate and

center punch the marks. Drill and tap the

holes for M10-1.5 threads.

8. Remove the back plate from the lathe, and

place it in to a freezer for 30 minutes, and

place the chuck in an oven at 100° F. for the

same amount of time.

9. Put on insulated leather gloves and place

the chuck on the back plate. Line up the

mounting holes and thread in the cap screws

supplied.

10. Snug the first M10-1.5 cap screw, then

alternate the cap screws across the chuck

until you reach a final torque of 53.5 ft/lbs.

Alternating the tightening process insures

the chuck will be pressed on straight. This

step should be repeated until the back plate

fits snugly against the chuck. If the chuck

fits loosely on the back plate, or is crooked on

the shoulder, it will be necessary to recut the

back plate face and shoulder again. If you

are also installing the chuck by threading

the M10-1.5 hex bolts into the chuck from

the back side of the mounting plate, repeat

Step 9 on these bolts, but torque them to

53.5 ft/lbs.

•Secure Clamping: A thrown workpiece may

cause severe injury or even death. When

swapping the chuck jaw positions, use a

torque wrench to re-torque the M10-1.5 jaw

mounting cap screws to 53.5 ft/lbs. When

clamping a workpiece, maximum gripping

force is attained at full jaw and scroll gear

engagement. If jaw and scroll gear are par-

tially engaged, clamping force is reduced.

•Speed Rates: Operating the lathe where

maximum chuck speed is exceeded, or at too

high of a speed for an unbalanced workpiece,

can cause the workpiece to be thrown from

the chuck. Always use the appropriate feed

and speed rates. A thrown workpiece may

cause severe injury or even death.

•Large Chucks: Large chucks are very

heavy and difficult to grasp, which can lead

to crushed fingers or hands if mishandled.

Get assistance when installing or removing

large chucks to reduce this risk. Protect your

hands and the precision ground ways by

using a chuck cradle or piece of plywood over

the ways of the lathe when servicing chucks.

•Safe Clearances: Often chuck jaws will

protrude past the diameter of the chuck and

can contact a coolant nozzle, tooling, tool

post, or saddle. Before starting the spindle,

make sure the workpiece and the chuck

jaws have adequate clearance by rotating it

through its entire range of motion by hand.

•Stopping Lathe By Hand: Stopping

the spindle by putting your hand on the

workpiece or chuck creates an extreme risk

of entanglement, impact, crushing, friction,

or cutting hazards. Never attempt to slow

or stop the lathe chuck by using your hand.

Allow the spindle to come to a stop on its

own or use the brake (if equipped).

•Long Stock Safety: Long stock can whip

violently if not properly supported, causing

serious impact injury and damage to the

lathe. Reduce this risk by supporting any

stock that extends from the chuck/headstock

more than three times its own diameter.

Always turn long stock at slow speeds.