Pro-Cut B17 User manual

TECHNICAL MANUAL

PG / 6800.543.6618

CONTENTS

*NOTE: When service or replacement parts are required, please contact your local

Pro-Cut Representative through either the SuperTech app or through our website:

www.procutusa.com

Limited Warranty

Lathe Overview / Components

Brake Lathe Specifications

List of Standard Accessories

Acceptance from Carrier

Safety Information

Assembly of Lathe

Operations Procedures

Multi-Speed Settings

Set Up for Rotors or Drum Cutting

9

10/11

12

13

14

14

19

20

20

21

Machining Hub-less and Hubbed Drums

Detailed Instructions

Mounting Hubbed Drums or Rotors

Command Module - Machining Mode

Command Module - Set-Up Mode

Command Module - Statistics Mode

Advanced Tips

Diagrams

Maintenance Schedule

22

23

24

27

28

29

30

31

46

WWW.PROCUTUSA.COM PG / 7

OUR MISSION

Pro-Cut International is dedicated to providing our customers with the most advanced, precise,

and profitable tools for brake repair. We have worked with, learned from and solved problems

for people at all levels of the brake repair business - from the largest auto manufacturers and

national service chains to one-bay, one-man operations. It is a business our entire staff lives,

eats, and breathes. We welcome you to our table and look forward to working with you to im-

prove your brake service business.

PG / 8800.543.6618

You have just purchased what we feel is the finest bench brake lathe in the world. Your Pro-Cut B17 is a high

quality, precision engineered product designed to give you years of trouble free service. To familiarize yourself with

all its features, please take the time to read this owner’s manual carefully and store this manual in a safe place for

future reference.

Our job is not done until you feel your technician team was trained properly and received all the information needed

to operate the B17 efficiently, accurately, and above all, SAFELY.

Your warranty will begin once you sign off that you are happy with the training.

For Records and Information:

CONGRATULATIONS!

DATE TRAINED

SERIAL No.

PRO-CUT REP NAME

REP. CONTACT No.

FOUND ON BACK OF LATHE

WWW.PROCUTUSA.COM PG / 9

What Your Warranty Does Not Cover

This warranty does not apply to damage due directly to misuse, abuse, negligence or lack of maintenance.

Limited Warranty

This warranty extends to the original owner of the equipment. Pro-Cut International warranties this equip-

ment against defects in materials or workmanship as follows.

Labor

For the period of two (2) years from the original date of purchase, if we determine that the equipment

is defective subject to the limitations of this warranty, we will replace it at no charge for labor. Pro-Cut

International warrants any such work done against defects in materials or workmanship for the remaining

portion of the original warranty period.

Parts

For the period of two (2) years from the original date of purchase, we will supply, at no charge, new or

rebuilt replacement parts in exchange for parts we determine are defective subject to the limitations of

this warranty. Pro-Cut International warranties any such replacement parts against defects in materials or

workmanship for the remaining portion of the original warranty period.

PG / 10 800.543.6618

Lathe Overview

14

1

8

11

19

10

9

6

5

7

3

24

15

16

18

17

20

21

20

22

13

23

12

WWW.PROCUTUSA.COM PG / 11

1. Emergency Stop

2. Spindle Start/Stop

3. Spindle Speed Select Knob

4. Feed Start/Stop

5. Feed Quality Select Knob

6. Disc/Drum Cutting Plate Lock Lever

7. Disc Cutting Head

8. Drum Boring Bar

9. Drum Insert Holder

10. Disc Feed & Drum Depth Crank

11. Drum Feed & Disc Axial Position Crank

12. Disc Feed Motor

COMPONENTS

13. Drum Feed Motor

14. 1” Arbor

15. LED Task Lamp

16. Spindle Ring Lamp

17. Tool Cabinet Base

18. Motor

19. Draw Bar Cover

20. Way Covers

21. Disc Insert holder

22. Drum feed lock-out

23. Disc feed lock-out

PG / 12 800.543.6618

SPECIFICATIONS

· 90-264VAC 50/60Hz 1ph Input

· Rotor Capacity 4-24” [101.6-609.6mm]

· Maximum width of surface 3.5” [89mm]

· Maximum thickness 2.25” [57mm]

· Drum Capacity 6-28” [152-711mm]

· Friction surface capacity 6”

· Maximum Weight on 1” [25.4mm] Arbor: 150 lbs. [68kg]

· Maximum Weight on 1 7/8” Arbor: 300 lbs. [136kg]

· Spindle Speed RPM 100-140-180

· Feeds per Spindle Revolution: (Infinitely Variable)

· Disc 0.0016”-0.0039” [0.04-0.10mm] / rev.

· Drum 0.0016”-0.0039” [0.04-0.10mm] / rev.

· Motor: 0.54 HP 400W

· Lathe Weight: 492 lbs. [223 kg]

· Lathe Shipping Weight: 557 lbs. [252 kg]

· Stand Net Weight: 308 lbs. [140 kg]

· Stand Shipping Weight: 391 lbs. [178 kg]

WWW.PROCUTUSA.COM PG / 13

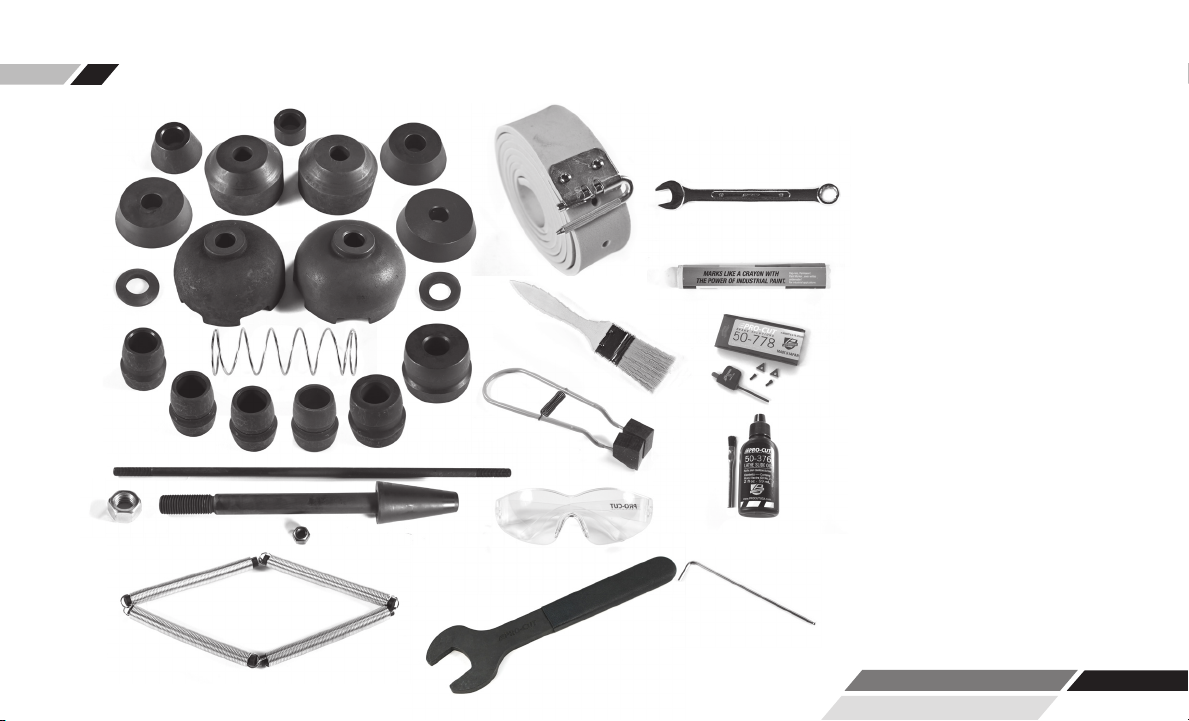

1 Draw Bar with Hex Nut

2 Large Bell Clamp

2 Small Bell Clamp

4 Centering Cones

3 Silencers

6 Double Taper Radius Adapters

1 Standard 1” Arbor

1 Arbor Nut

1 1” Spacer

1 Set of Alignment Washers

1 Spring

1 Match Mark Crayon

1 Chip brush

1 T-8 Tip Screw Wrench

1 3mm Gib Screw Wrench

1 8/10mm Gib Nut Wrench

1 Safety Glasses

1 Way Oil w/Brush

1 Performance Plus Inserts

1 35mm Arbor Nut Wrench

*IMAGES NOT TO SCALE

STANDARD ACCESSORIES INCLUDED WITH THE B17 BENCH LATHE

PG / 14 800.543.6618

Carefully inspect all items received in this shipment. If there is damage or evidence of mishandling in transit, determine

the extent of damage and notify the transit company as well as Pro-Cut or your local Pro-Cut rep immediately. Although we

are not responsible for damage incurred in transit, we will assist in the preparation and filing of claims.

SAFETY INFORMATION

This manual has been prepared for the operator and those responsible for the maintenance of the brake lathe. Its purpose,

aside from proper maintenance and operations, is to promote safety through the use of accepted practice. READ AND

UNDERSTAND THE SAFETY AND OPERATING INSTRUCTIONS COMPLETELY BEFORE OPERATING THE MACHINE.

In order to obtain maximum life expectancy and efficiency from your brake lathe; follow the operating instructions and

maintenance manual carefully. The specifications put forth in this manual were in effect at the time of publication. How-

ever, owing to Pro-Cut’s policy of continuous improvement, changes to the specifications may be made at any time without

obligation on the part of Pro-Cut International, LLC.

ACCEPTANCE FROM TRANSPORTATION CARRIER

WWW.PROCUTUSA.COM PG / 15

Read, understand and follow the safety and operating instructions found in this manual. Know the limitation and hazards

associated with operating the machine.

SAFETY INSTRUCTIONS

1.

SPECIAL PRECAUTIONS: The Pro-Cut B17 brake lathe was designed to machine the portions of the brake drum & disc

brake rotor that come in contact with the friction material. When used according to the instructions herein, this lathe will

perform satisfactorily within the work piece size range designed for this model. During the machining operation, the work

piece rotates. Be especially cautious of rotating spokes and mounted accessories. During machining, material removal may

cause a sharp edge to be generated, where a chamfer or radius previously existed. Use care in handling machined parts.

SECURING THE MACHINE: The model B17 weighs approximately 470 pounds and must be bolted to either the Pro-Cut Heavy

duty bench 50-4100, or a bench capable of supporting the machine, its accessories and work piece.

GROUNDING THE MACHINE: In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. The lathe is equipped with an electric cord having an equipment-

grounding conductor and a grounding plug. The plug must be plugged into a match outlet that is properly installed and

grounded in accordance with all local codes and ordinances. Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified electrician. If repair or replacement of the electric cord or plug is nec-

essary, do not connect the to a live outlet until repairs are performed. Check with a qualified electrician or service personal

if the grounding instructions are not completely understood, or if in doubt as to whether the lathe is properly grounded.

EXPLOSION RISK: This machine generates internal sparks. Do not use at less than 18” [0.46m] above grade level, and never

use below grade level. Work area should be well ventilated and free of explosive funes.

2.

3.

4.

5.

PG / 16 800.543.6618

USE PROPER EXTENSION CORD: Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole recep-

tacles that accept the lathe’s plug. Repair or replace damaged or worn cord immediately. Make sure your extension

cord is in good condition. When using an extension cord, be sure to use one that is 15’ or less and 14ga or heavier (i.e.

12ga). An undersized cord will cause a drop in line voltage resulting in a loss of power and overheating.

EYE SAFETY: Wear an approved safety face shield, goggles, or safety glasses. (Ordinary eyeglasses are not safety glasses

and do not provide the degree of protection necessary.)

RESPIRATORY SAFETY: If the operation or area is dusty a face or dust mask should be used.

PERSONAL PROTECTION: Before operating the machine, remove tie, rings,watches and other jewelry, and roll up sleeves

above the elbow. Remove all outer loose clothing and confine long hair. Protective type footwear must be worn. Hearing

protectors must be used where noise exceeds the level of exposure allowed in Section 1910.95 of the OSHA Regula-

tions. DO NOT WEAR GLOVES.

DO NOT USE LATHE IN DANGEROUS ENVIRONMENT: Don’t use the lathe in damp or wet locations, or expose the lathe to

rain. Keep the work area well lighted.

WORK AREA: Keep the floor around the machine clean and free of foreign materials. Pro-Cut recommends the use of

anti-skid floor strips where the operator normally stands, and that each machine has its own work area marked off. Make

certain that the work area is well lighted and ventilated. Provide for adequate workspace around the machine. The work

area should not be readily accessible to anyone except the operator.

SAFETY INSTRUCTIONS (continued)

5.

6.

7.

8.

9.

10.

WWW.PROCUTUSA.COM PG / 17

DO NOT OVERREACH: Maintain a balanced stance and keep your body under control at all times.

HAND SAFETY: Keep hands away from moving parts when the machine is under power. Never clear chips or debris when

the machine is under power and never use your hands to clear the chips. Never use compressed air to clean machine;

use only a soft bristle brush or vacuum cleaner.

MACHINING PREPARATION: Tighten all appropriate locks before operating the lathe. Be sure work piece is secured.

Remove adjusting keys and wrenches. Be sure to check to see that all adjusting wrenches are removed from the lathe

before turning the machine on.

CHECK DAMAGED PARTS: Before further use of the lathe, a guard or other part that is damaged should be carefully

checked to determine if it will operate properly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, & any other conditions that may affect the lathe’s operation. A

guard or other part that is damaged should be properly repaired or replaced.

MAINTAIN TOOLS WITH CARE: Keep tools sharp and clean for best and safest performance. Follow instructions for lubri-

cating and changing accessories.

NEVER STAND ON LATHE: Serious injury could occur if the lathe is tipped or if the cutting tool is unintentionally con-

tacted.

SAFETY INSTRUCTIONS (continued)

10.

11.

12.

13.

14.

15.

PG / 18 800.543.6618

MACHINE CAPACITY: Do not attempt to use the machine for other than passenger car and light truck drums, discs, or for

operations for which the machine was not intended.

CARELESS ACTS: Give the work you are doing your undivided attention!

Disconnect Electrical Power before performing any service, maintenance, or changing of accessories, adapters, or work

pieces on machine.

JOB COMPLETION: If the operator leaves the machine area for any reason,the machine should be turned off, and the

spindle brought to a complete stop before the operator departs. In addition if the operation is complete, the operator

should clean the machine and work area. NEVER CLEAN THE MACHINE WITH THE POWER ON.

REPLACEMENT PARTS: Use only Pro-Cut replacement parts and accessories, risk of injury may result in accessories other

than those recommended are used.

MISUSE: Do not use the machine for other than its intended use. If used for other purposes, Pro-Cut International, LLC,

disclaims any expressed or implied warranty, and holds itself harmless for any injury or loss that may result.

SAFETY INSTRUCTIONS

16.

17.

18.

19.

20.

21.

WWW.PROCUTUSA.COM PG / 19

SETTING UP BRAKE LATHE FOR FIRST USE

All machined surfaces are covered with a protective coating before packaging and they must be thoroughly cleaned.

The spindle, arbor taper and mounting surface on top of ways must be cleaned and wiped dry. Install the draw bar in

the arbor. Insert the draw bar through the spindle. Install the nut on the rear of the draw bar, and tighten. Make sure

all inserts, bolts, and set screws are tight.

· Machine must be securely fastened to work bench surface before operating.

· Five mounting holes on the base are provided for this purpose.

LUBRICATION

Lubricate ways by oiling felt wipers on the end of cross slide every week with Pro-Cut 50-376 way oil or equivalent.

For other iron surfaces we recommend high quality rust prevention coating such as CRC brand 3-36 multi-purpose

lubricant and corrosion inhibitor.

ASSEMBLY OF BRAKE LATHE

PG / 20 800.543.6618

The B17 Multi-Speed Lathe has three spindle speeds and variable cross feeds (0.0016-0.0039” [0.04-0.1mm] per

revolution) to accommodate a wide range of machining tasks.

Choose spindle speed based on the size of the work piece, slower for larger diameter parts.

The feed adjustment has 11 quality settings, from the finest finish (1) to the coarsest finish (11). Finer finishes use

a lower feed rate, and so take longer. The coarsest finish setting, when used with Pro-Cut inserts is designed to give a

finish at or about 100 micro-inch / 2.54 micron Ra, the upper roughness limit allowed for many vehicles. The fine set-

ting can achieve surface finishes as low as 45 micro-inch / 1.14 micron Ra. Insert edge quality and rotor condition and

material will affect these numbers.

No guarantee can be made for inserts not purchased from Pro-Cut, as insert corner radius, relief angle, material com-

position and edge preparation can have a strong effect on cutting quality, insert lift, and tendency of the work piece to

vibrate. Always use Genuine Pro-Cut 50-778 inserts for best results.

Unlike earlier, more primitive lathes, you do not have to guess what speed and feed combination to use, just choose your

RPM based on size and finish number based on desired surface roughness.

The maximum recommended depth of cut is 0.012” / 0.3mm per insert.

B17 MULTI-SPEED BRAKE LATHE OPERATION PROCEDURES OPERATION

Other manuals for B17

1

Table of contents

Other Pro-Cut Lathe manuals