Table of Contents

INTRODUCTION............................................... 2

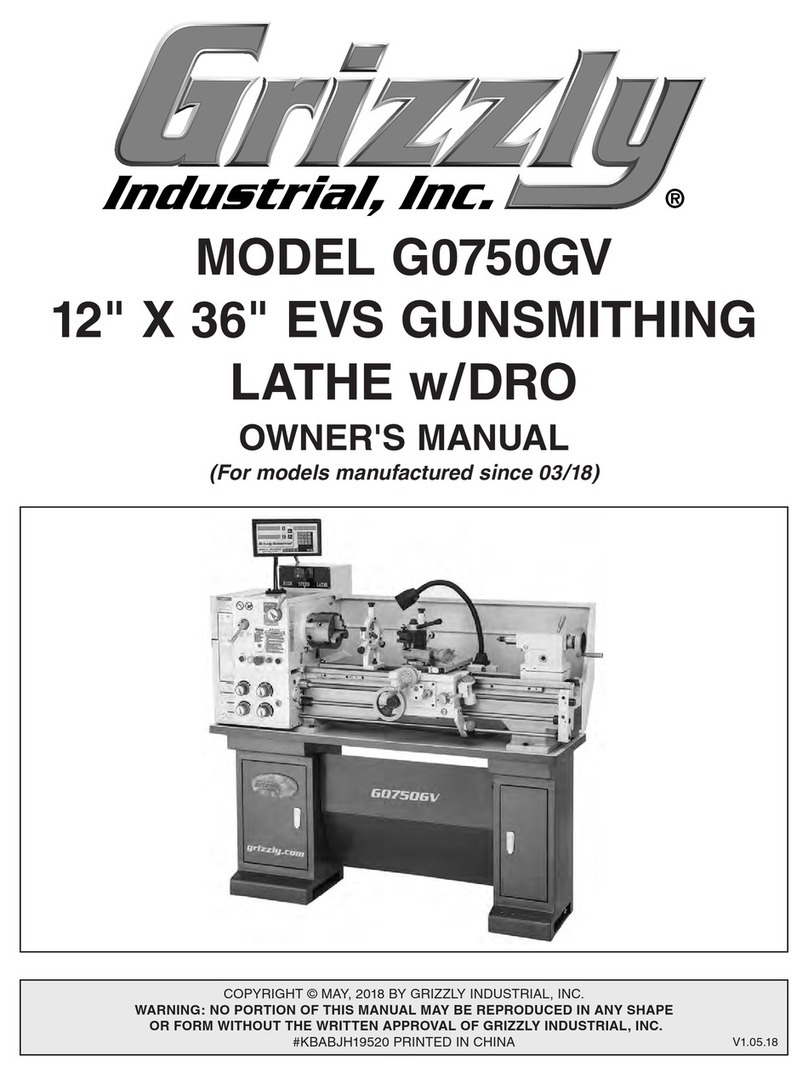

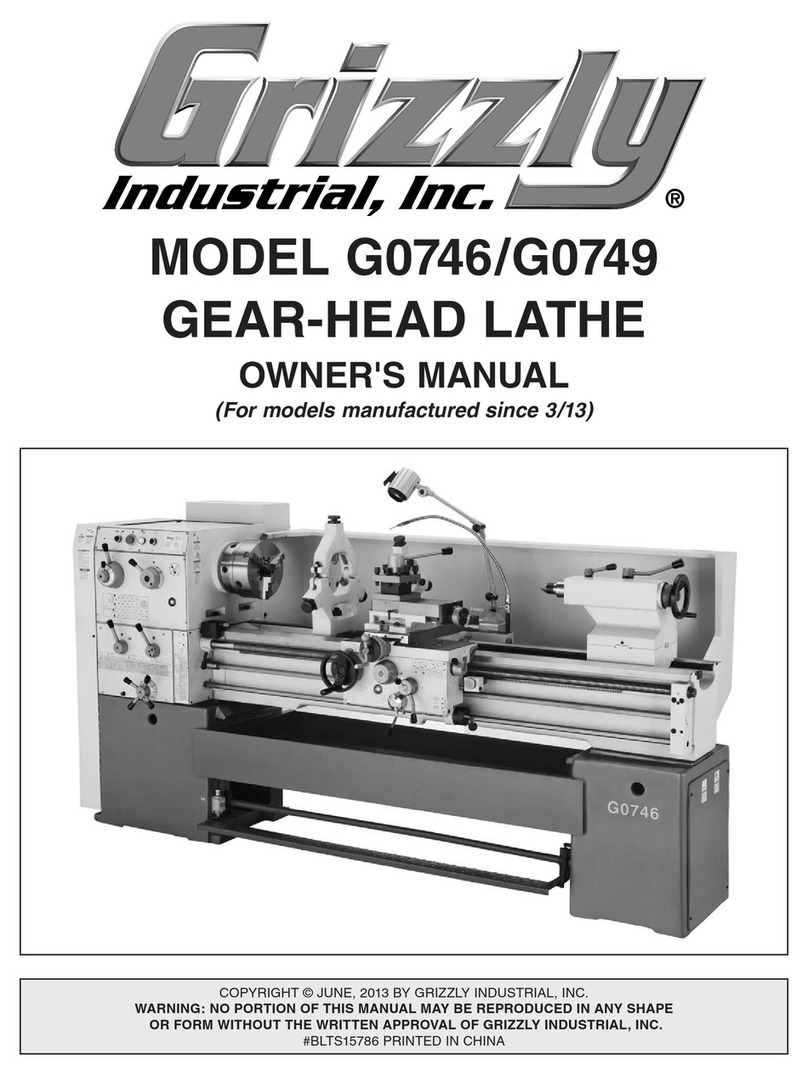

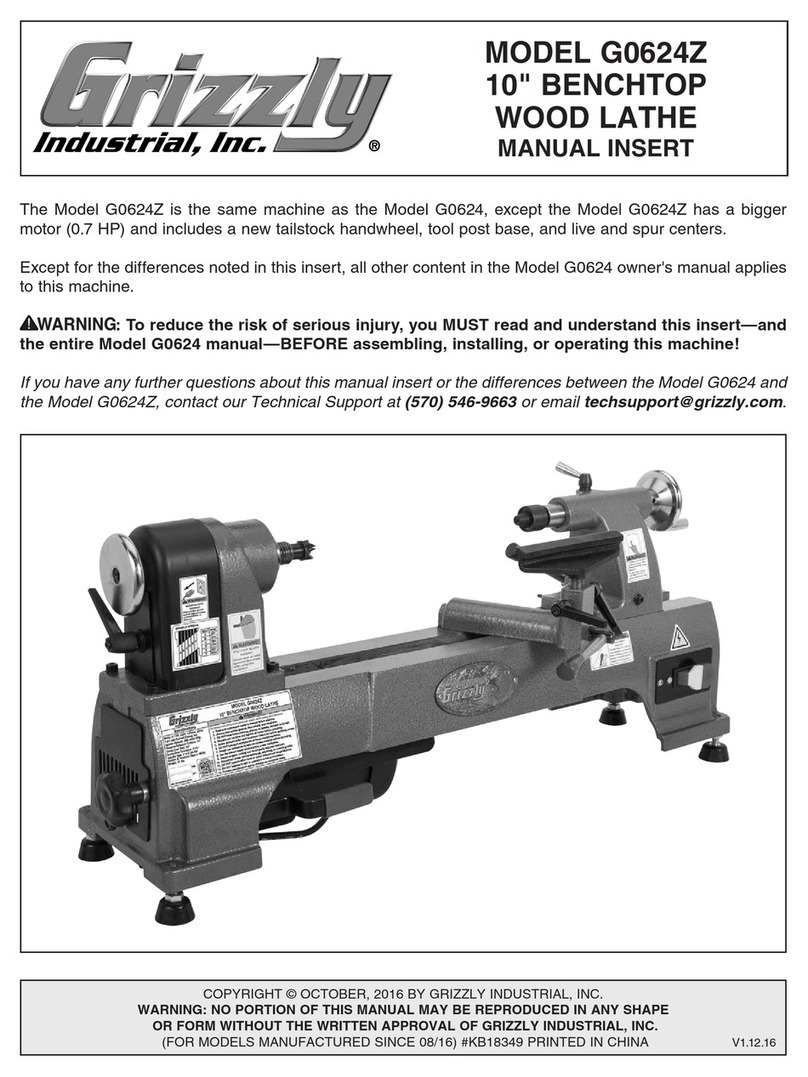

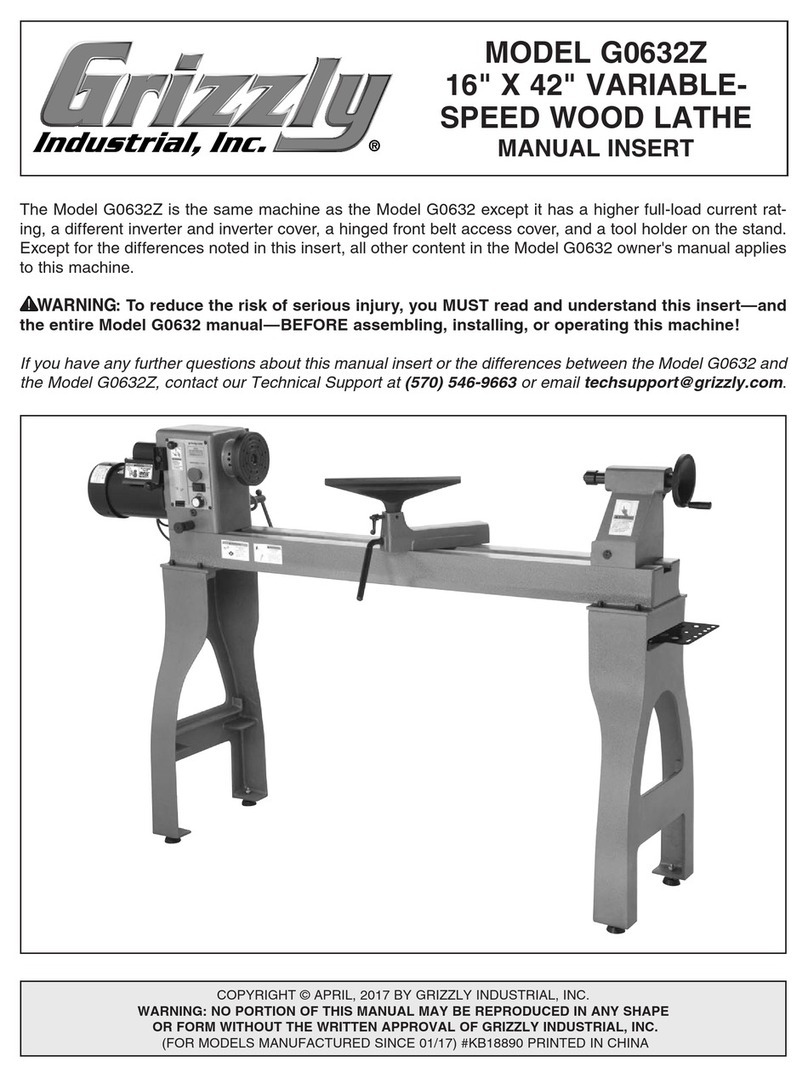

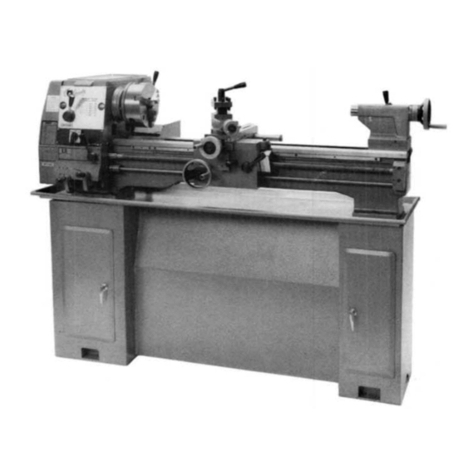

Machine Description ...................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

Identification ................................................... 3

Machine Data Sheet ...................................... 4

SECTION 1: SAFETY....................................... 7

Safety Instructions for Machinery .................. 7

Additional Safety for Metal Lathes ................. 9

Additional Chuck Safety ............................... 10

SECTION 2: POWER SUPPLY ...................... 11

SECTION 3: SETUP ....................................... 13

Preparation .................................................. 13

Unpacking .................................................... 13

Needed for Setup ......................................... 13

Inventory ...................................................... 14

Cleanup ........................................................ 15

Site Considerations ...................................... 16

Lifting & Moving ........................................... 17

Anchoring to Floor ....................................... 17

Leveling ........................................................ 18

Lubricating Lathe ......................................... 18

Adding Cutting Fluid .................................... 18

Power Connection........................................ 19

Test Run ...................................................... 19

Spindle Break-In .......................................... 22

Recommended Adjustments ........................ 22

SECTION 4: OPERATION.............................. 23

Operation Overview ..................................... 23

Controls ........................................................ 24

Chuck & Faceplate Removal/Installation ..... 27

Three-Jaw Chuck ......................................... 30

Four-Jaw Chuck ........................................... 31

Faceplate ..................................................... 32

Centers ........................................................ 33

Tailstock ....................................................... 35

Offsetting Tailstock ...................................... 35

Aligning Tailstock ......................................... 36

Drilling with Tailstock ................................... 37

Cutting Fluid System .................................... 39

Steady Rest & Follow Rest .......................... 39

Tool Post ...................................................... 40

Spider ........................................................... 41

Spindle Speed.............................................. 41

Manual Feed ................................................ 43

Power Feed.................................................. 43

Feed Settings ............................................... 44

Thread Settings............................................ 45

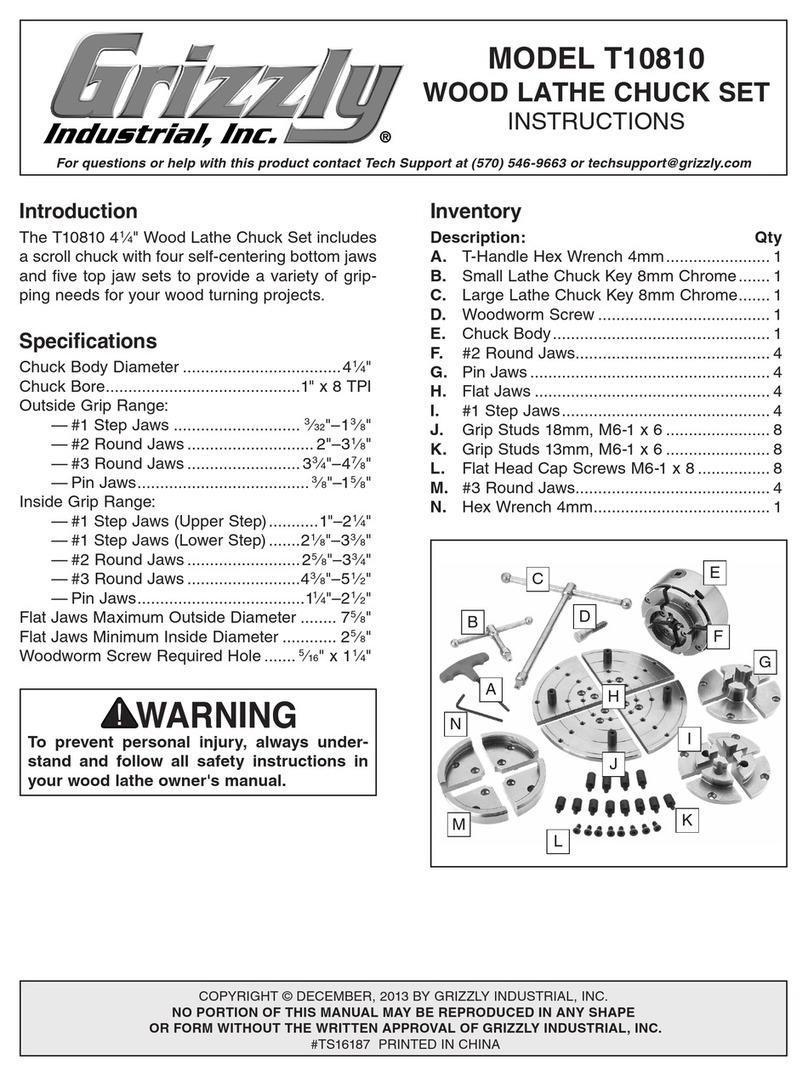

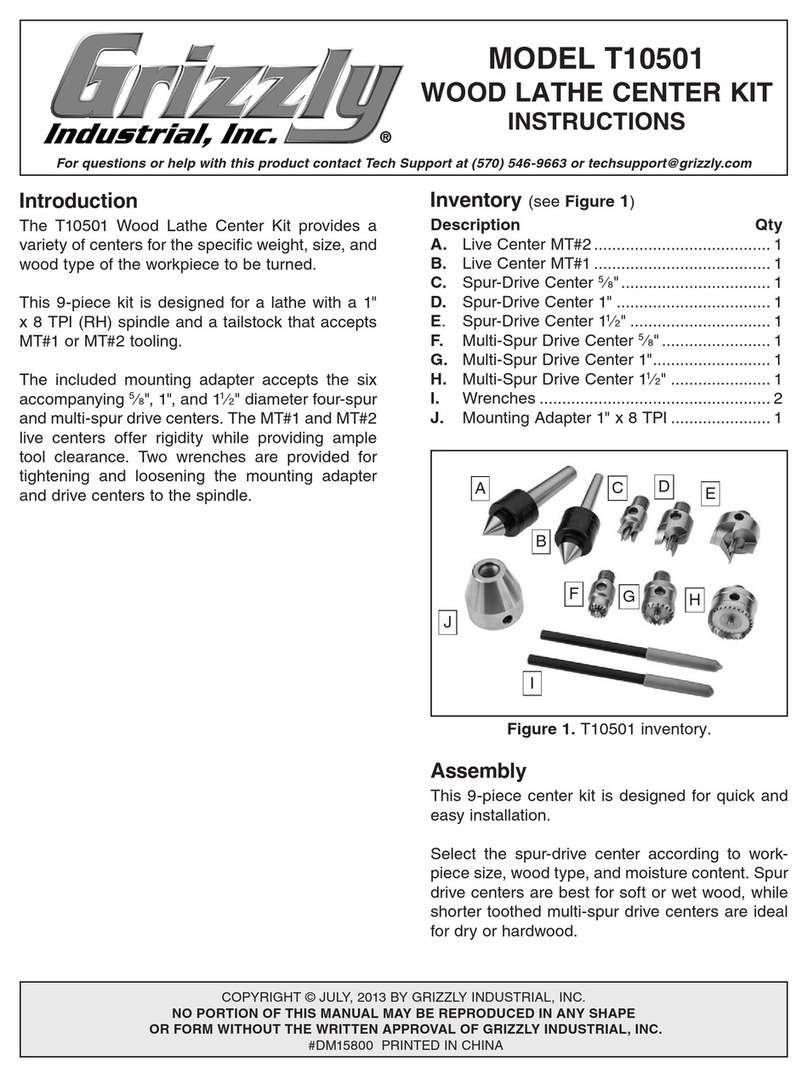

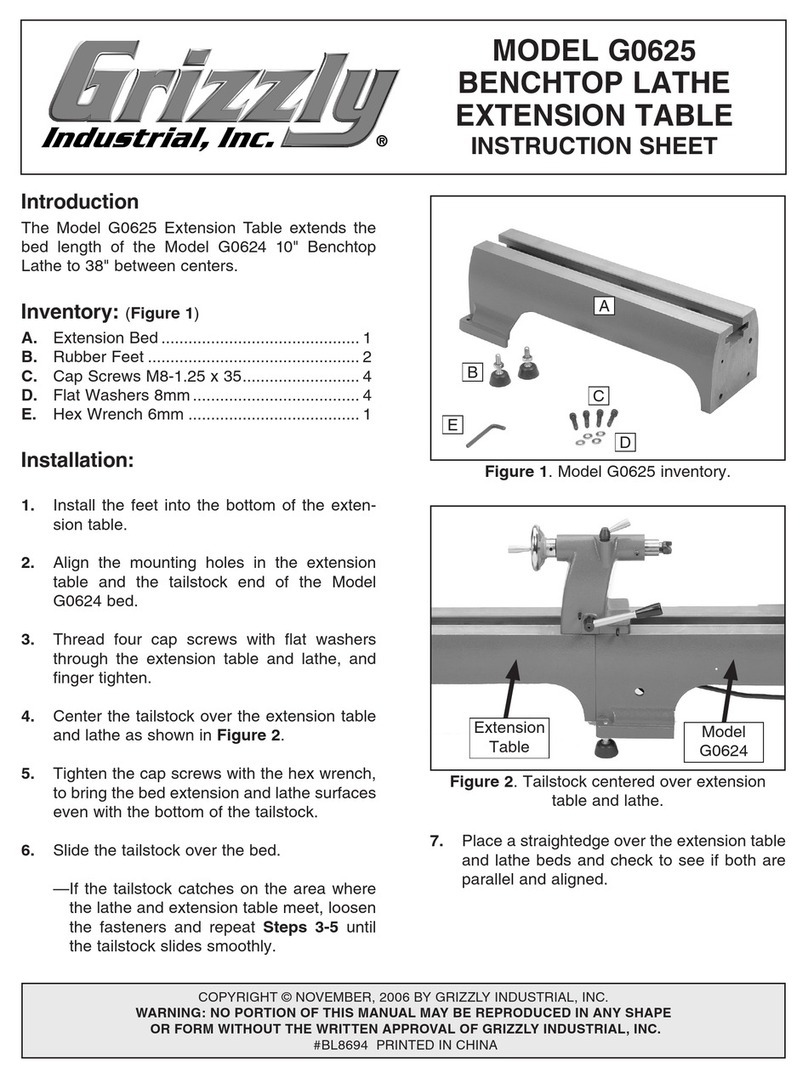

SECTION 5: ACCESSORIES ......................... 49

SECTION 6: MAINTENANCE......................... 53

Schedule ...................................................... 53

Cleaning ....................................................... 53

Unpainted Cast Iron ..................................... 53

Ball Oiler Lubrication .................................... 54

Oil Reservoirs .............................................. 56

V-Belt Tension ............................................. 57

Cutting Fluid System .................................... 58

SECTION 7: SERVICE ................................... 59

Gib Adjustments........................................... 61

Backlash Adjustment ................................... 63

Half Nut Adjustment ..................................... 64

Leadscrew Endplay Adjustment .................. 64

Shear Pin Replacement ............................... 65

Feed Clutch Adjustment .............................. 66

Tailstock Lock .............................................. 67

Bearing Preload ........................................... 67

V-Belt Replacement ..................................... 70

Gap Insert Removal & Installation ............... 70

Brake Shoes ................................................ 72

Machine Storage .......................................... 73

SECTION 8: WIRING...................................... 74

Wiring Safety Instructions ............................ 74

Wiring Overview ........................................... 75

Electrical Box Wiring .................................... 76

Switches and Pump Motor ........................... 77

Spindle Motor 110V & 220V Connection ..... 78

Electrical Box Photo ..................................... 79

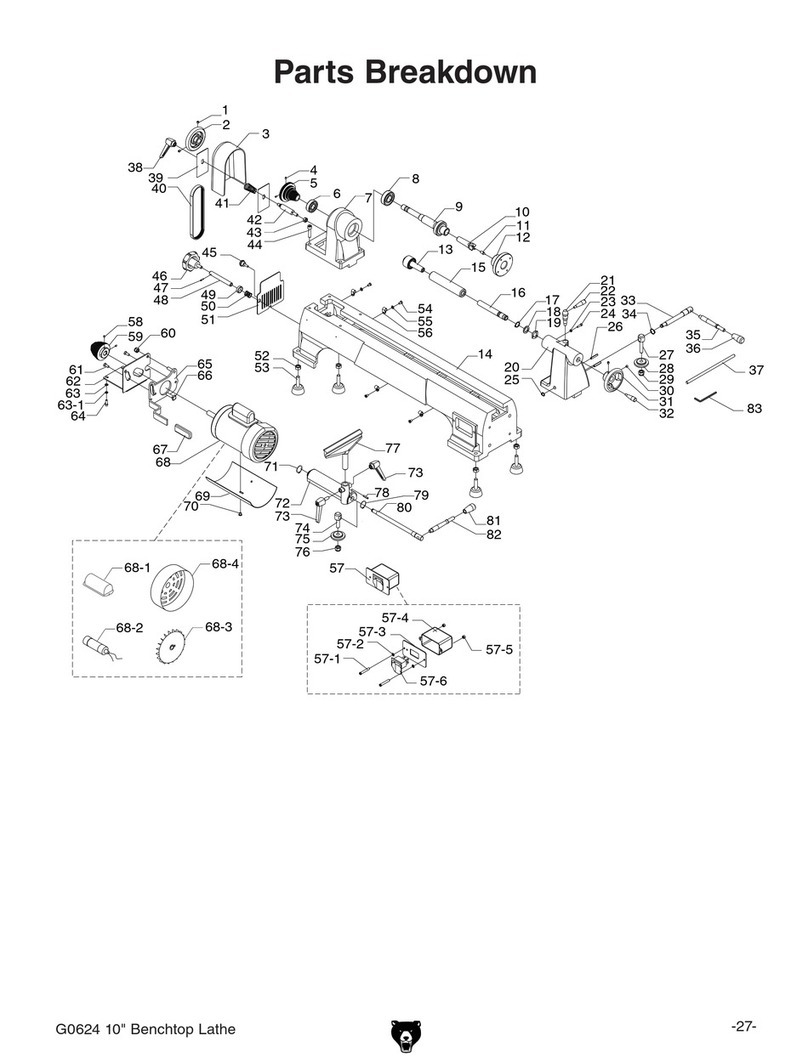

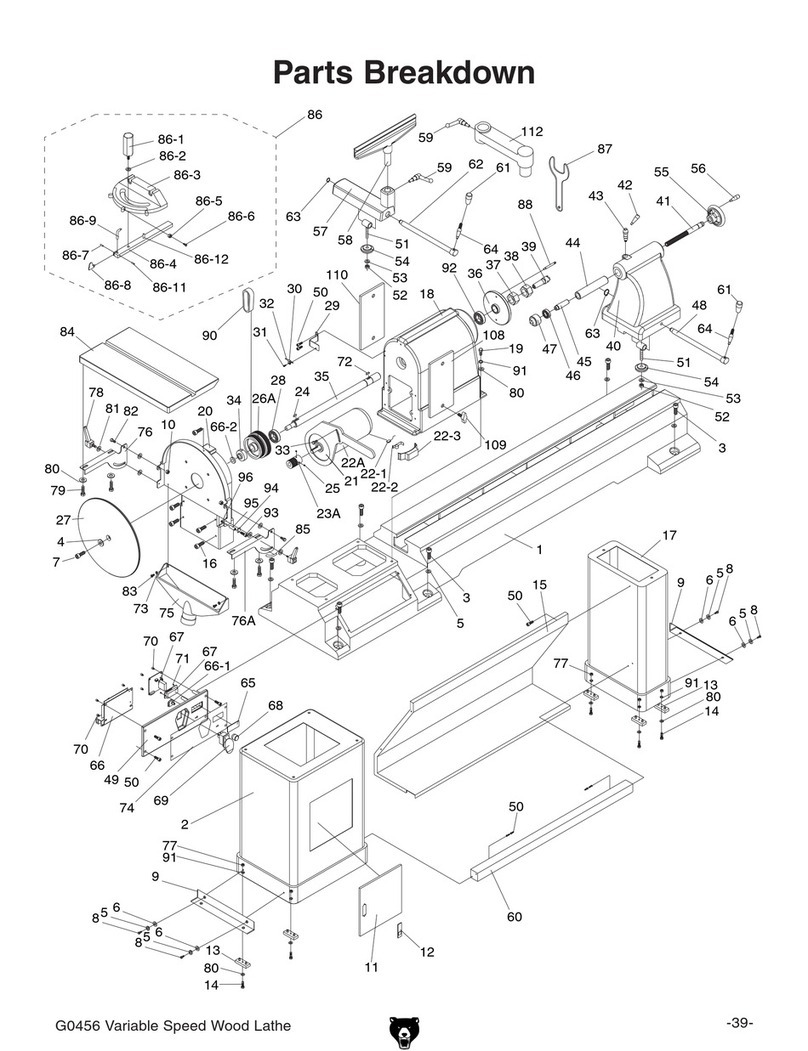

SECTION 9: PARTS....................................... 80

Headstock Case and Shift ........................... 80

Headstock Drive........................................... 82

Headstock Spindle ....................................... 84

Change Gears.............................................. 86

Quick Change Gearbox Drive ..................... 87

Quick Change Gearbox Shift ....................... 89

Apron .......................................................... 91

Cross Slide ................................................. 93

Compound Slide ......................................... 95

Rests ........................................................... 96

Tailstock ...................................................... 97

Pump ........................................................... 99

Motor and Feed Rod ................................. 100

Cabinet and Brake .................................... 102

Main Electrical Breakdown ........................ 104

Accessories ............................................... 105

Labels Breakdown ..................................... 106

WARRANTY AND RETURNS ...................... 109