Southern Cross 46 HAWK 3.0 User manual

’46 HAWK 3.0

Laser Diode Methane

Detector

December 2018

Southern Cross Inc.

3175 Corners North Court

Peachtree Corners, GA 30071

www.southerncrossinc.com

1 (800) 241-5057

’46 Hawk 3.0 Laser Diode Methane Detector

2

Updated 12102018

Contents

Figure 1: HAWK DIAGRAM....................................................................................................... 3

Figure 2: HAWK DIAGRAM (REAR VIEW) ................................................................................. 4

Figure 3: HAWK DIAGRAM (REAR PANEL) ............................................................................... 5

1.0: INTRODUCTION......................................................................................................... 6

2.0: WARRANTY STATEMENT ........................................................................................... 6

3.0: FEATURES AND SPECIFICATION ................................................................................. 7

4.0: PRINCIPLES OF OPERATION ....................................................................................... 7

Figure 4: INTERNAL BLOCK DIAGRAM ..................................................................................... 8

5.0: SAFETY GUIDELINES .................................................................................................. 8

6.0: DAILY IN-LINE FILTER INSTALLATION ......................................................................... 9

Figure 5: EXTERNAL PARTS & ASSEMBLY............................................................................... 10

7.0: PRE-START INSPECTION........................................................................................... 10

8.0: START-UP................................................................................................................ 11

9.0: DAILY RESPONSE (BUMP) TEST ................................................................................ 13

10.0: CALIBRATION PROCEDURE .................................................................................... 14

11.0: OPTION MENU WHILE IN SURVEY MODE ............................................................... 17

12.0: SHUT DOWN ......................................................................................................... 19

13.0: START-UP WHILE IN SLEEP MODE .......................................................................... 19

14.0: OPERATIONAL SUGGESTIONS ................................................................................ 20

15.0: IN-GROUND PIN POINTER...................................................................................... 20

16.0: SURVEY PROCEDURE ............................................................................................. 21

17.0: CHARGING BATTERY.............................................................................................. 22

18.0: BACK-UP BATTERY USE .......................................................................................... 22

19.0: DATA LOGGING..................................................................................................... 22

20.0: CLEANING AND CARE............................................................................................. 23

21.0: TROUBLESHOOTING .............................................................................................. 24

22.0: RETURNING EQUIPMENT FOR REPAIRS ................................................................. 25

23.0: REPLACEMENT PARTS............................................................................................ 26

24.0: SPECIFICATIONS .................................................................................................... 27

’46 Hawk 3.0 Laser Diode Methane Detector

3

Updated 12102018

Figure 1: HAWK DIAGRAM

Number

Name

Description

1 Probe Cone

Intake port for air samples. A pleated polyester

filter may be placed here under dusty

conditions.

2 Filter Housing

Contains filter element that should be changed

daily.

3 Probe Stiffener

Stiffens normally flexible probe tubing for

greater precision.

4 Probe Assembly

Directs filtered air samples to the laser diode for

analysis.

5Laser Diode Methane Detector

Provides rapid, specific, and accurate detection

of methane leaks.

6

Moisture Filter

Prevents moisture from entering unit.

Figure 1: HAWK DIAGRAM

1

2

3

5

4

6

’46 Hawk 3.0 Laser Diode Methane Detector

4

Updated 12102018

Figure 2: HAWK DIAGRAM (REAR VIEW)

Number

Name

Description

1

Light Emitting Diode (LED)

Lights during operation

2

Liquid Crystal Display (LCD)

Read out for functions

3 Operation Button

Turns on LCD backlight and scrolls through

options menu

4

Handle

Handgrip for use

5

Instrument Body

Houses electronic and sampling components

6 Recharge Port

Receptacle for the 110-volt battery recharger.

Use only Ault I.T.E. Power Supply

PW117RA0903B01.

7 Headset Port

Receptacle for optional alarm earphone

headset

8 Rear Panel Door

Slide open to the right for access to backup

battery tube, power switch, and computer

connection

Figure 2: HAWK DIAGRAM (REAR VIEW)

Name

Description

Light Emitting Diode (LED)

Lights during operation

Liquid Crystal Display (LCD)

Read out for functions

Turns on LCD backlight and scrolls through

1

2

3

4

5

6

7

8

’46 Hawk 3.0 Laser Diode Methane Detector

5

Updated 12102018

Figure 3: HAWK DIAGRAM (REAR PANEL)

Number

Name

Description

1

Recharge Port

Receptacle for the battery recharger

2 Headset Port

Receptacle for optional alarm earphone

headset.

3 3-Way Power Switch

(expanded view)

Place in the upper (Recharge/on) position to

power up using rechargeable batteries, middle

position (shown above) to turn the unit off, or

lower position (Lithium) to run on disposable

backup batteries

4

Rear Panel Sliding Door

Provides access when open

5 Data Port

Connects to computer for data logging

downloads

6 Backup Battery Holding Tube

Place 4 Lithium batteries in tube with the

positive (+) terminals facing inward

1

2

3

4

6

5

’46 Hawk 3.0 Laser Diode Methane Detector

6

Updated 12102018

1.0: INTRODUCTION

The ’46 Hawk revolutionizes gas leak surveying by providing you with the tools required for an

efficient survey in one lightweight instrument. The ’46 Hawk requires no fuel, thereby eliminating

hazmat worries. Your new survey tool operates over 12 hours on rechargeable batteries.

Emergency lithium AA batteries provide an additional eight hours of operation.

The ’46 Hawk simplifies leak surveys with easy to operate one button operation. After you have

selected your alarm point, you can begin your survey. When natural gas is detected, the

instrument will automatically range from PPM (parts per million) to %LEL (percent lower

explosive level) to %Gas. For in-ground pinpointing, simply attach the probe provided and take

the readings. There are no switches or calculations to be made – the ’46 Hawk makes the

adjustments for you!

2.0: WARRANTY STATEMENT

Southern Cross Corp. will repair any ’46 Hawk that develops any problem that is the

manufacturer’s fault under normal use and service at no charge to the customer for parts and

labor. The service policy is limited to repairing a ’46 Hawk which proves to be defective, with

return transportation prepaid, within one year of date of purchase. This does not include

consumable items such as batteries, filters, and intake cone components.

This service policy does not apply if the ’46 Hawk has been repaired, resold, or altered by

unauthorized persons or has been subject to misuse, negligence, or has had serial numbers

defaced or removed.

The manufacturer reserves the right to make changes in the design of the ’46 Hawk and to make

additions or improvements without incurring any obligation to modify any units previously sold.

After the one-year warranty period, the customer is responsible for any ’46 Hawk repairs at the

current material and labor prices. Other warranty packages may be available.

’46 Hawk 3.0 Laser Diode Methane Detector

7

Updated 12102018

3.0: FEATURES AND SPECIFICATION

•Designed for above and below ground leak searches and investigations

•Detects methane only

•Detects 1 PPM within 3 seconds

•Renders readings in actual PPMs

•Operates 12+ hours on rechargeable batteries

•Runs up to 8 hours on 4 lithium AA disposable batteries

•Records and stores monthly calibration data that can be downloaded onto any computer

with HyperTerminal and Microsoft Excel

•Laser reference and sample diodes are rated to last 5 years

•Pump rated to last 3 years

•Rechargeable batteries are rated to last 2 years

•Carrying case with battery charger, 4 backup batteries, andfilters included

4.0: PRINCIPLES OF OPERATION

Past models of handheld natural gas leak detectors used flame ionization detection technology.

This technology called for the burning of sample air and the electronic detection of flame-

produced hydrocarbon ions. These instruments required a constant flame powered by a

consumable non-hydrocarbon gas supply, which posed some risk in hazardous environments.

Southern Cross utilizes a new generation of laser diode-based handheld natural gas leak

detectors, thereby replacing the FI instruments. Advantages to the laser-based instrument

include: no need for hazardous fuel supplies, no risk of natural gas ignition by the instrument,

and full range (1 PPM to % LEL to % GAS) automatic detection.

The ’46 Hawk draws sample air through a chamber where a laser beam is reflected multiple times

across two mirrors (see diagram below). This is known as a multi-pass cell. The laser touches a

detector, which then communicates data to a digital signal processor (controller) and onto a

micro-controller for the alarm systems. This controller looks for absorption of a certain

wavelength of laser light that is caused only by methane.

’46 Hawk 3.0 Laser Diode Methane Detector

8

Updated 12102018

Figure 4: INTERNAL BLOCK DIAGRAM

This results in methane detection only and the elimination of false alarms. The laser diode

responds faster than other technologies to presence of methane and recovers faster from

exposure to high methane levels than other types of instruments. The ’46 Hawk’s sensitivity and

specificity for methane meets or exceeds that of older technologies.

5.0: SAFETY GUIDELINES

The instrument is inherently safe, as it carries no flame or spark producing components. The

instrument operates on very low voltage and has eye safe low intensity laser.

Use Care When Installing Batteries

•The power switch MUST be in the Off (middle) position.

•Do not damage terminals.

•Double check battery connections.

Proper precautions for personal safety must be observed as described in the “Survey Procedure”

section.

’46 Hawk 3.0 Laser Diode Methane Detector

9

Updated 12102018

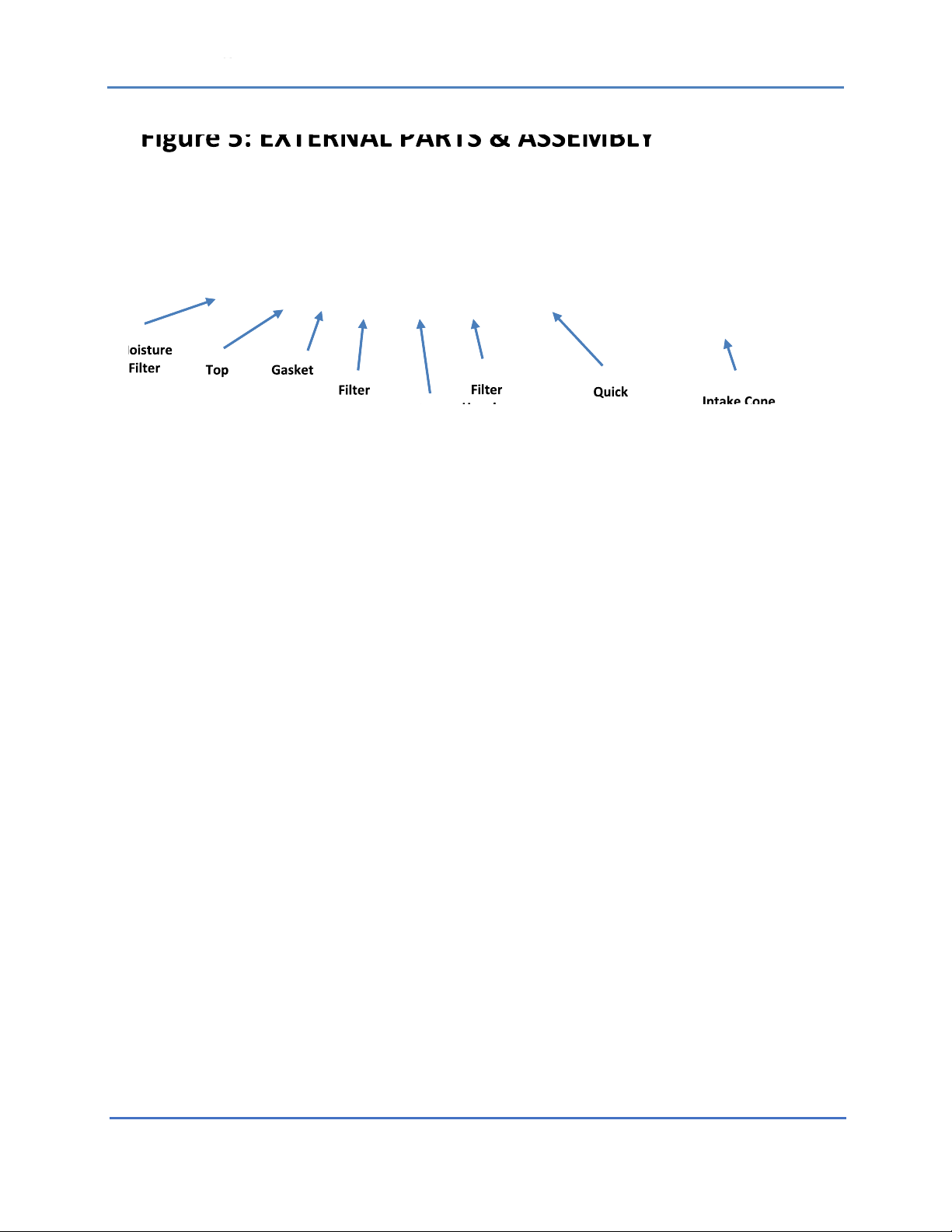

6.0: DAILY IN-LINE FILTER INSTALLATION

It is crucial that the in-line filter be installed correctly each day. Incorrect installation will allow

dirt into sample chamber, which could lead to an ERROR message and costly repair. The filter

housing for the ’46 Hawk is located in line in the probe.

Steps to Install In-Line Filter:

1. Unscrew the filter housing. Remove gasket, spring, and micron filter. Gasket may stay in

the top section of the filter housing. Be careful not to lose the gasket.

2. Attain clean filter. (Remove dirty filter and replace with clean filter)

3. Install spring with wide end first into filter housing.

4. Install closed end of filter on top of spring (small end of spring) in filter housing.

5. Place gasket at opposite end of filter (see picture below).

6. Assemble both parts of filter housing.

7. Tighten by hand; it is not necessary to use a wrench. The O-ring on the top section of the

filter housing will provide a leak-free seal.

’46 Hawk 3.0 Laser Diode Methane Detector

10

Updated 12102018

Figure 5: EXTERNAL PARTS & ASSEMBLY

A DIRTY FILTER message indicates blockage from the following:

•Dirty filter,

•Moisture,

•Obstruction of the sample flow into the instrument, and/or

•Filter installed incorrectly.

To correct DIRTY FILTER, follow the instructions below:

•Replace moisture filter with a clean, dry filter.

•Inspect probe for obstructions.

•Ensure spring, O-ring, and filter are positioned in filter housing correctly.

•Push Operation Button – The LCD will display CLEARING CELL and then 0PPM.

If message does not clear, replace moisture filter. Never operate without both filters.

7.0: PRE-START INSPECTION

Prior to turning on the ’46 Hawk, Southern Cross recommends conducting a visible inspection of

the unit for damages such as cracks, broken probe, and missing or loose components.

Top

Gasket

Filter

Spring

Intake Cone

Quick

Connect

Filter

Housing

Moisture

Filter

Figure 5: EXTERNAL PARTS & ASSEMBLY

Top

Gasket

Filter

Spring

Intake Cone

Quick

Filter

Housing

Moisture

Filter

’46 Hawk 3.0 Laser Diode Methane Detector

11

Updated 12102018

8.0: START-UP

The ’46 Hawk will arrive fully assembled and ready to go. Please follow the steps below for startup

out of the box or after a complete shutdown.

Warm Up/Initial Set Up

Step 1: To power on, slide rear panel door to the right.

Push power switch to upper (recharge) position. Unit will

then start. Slide panel back to closed position.

Step 2: The LCD will display ’46 Hawk + current software

on the screen.

Step 3: LCD will display BATTERY %.

Step 4: Several seconds later, the LCD will display WARM-

UP.

Step 5: Choose an Alarm Option. Set your alarm point by

pressing the operation button. When you find the desired

alarm point, hold operation button and wait for beep.

NOTE: You must choose an alarm point. Unit will repeat

alarm choices until alarm is chosen.

’46 Hawk 3.0 Laser Diode Methane Detector

12

Updated 12102018

Warm Up/Initial Set Up

Step 6: Mute Alarm/Headset. If you do not choose to

mute alarm, unit will bypass this option and continue.

Step 7: The LCD will display CLEARING CELL. This will last

for approximately 1.5 minutes.

Step 8: The LCD will display START SURVEY and then

display 0 PPM. You are now ready to survey.

NOTE: Bump Testing can be done at this point. See Daily

Response Testing in next section.

’46 Hawk 3.0 Laser Diode Methane Detector

13

Updated 12102018

9.0: DAILY RESPONSE (BUMP) TEST

Step 1: The Survey Technician can perform a Daily

Response Test (Bump Test). Once initial warm up/start up

is completed and LCD displays 0 PPM, the response test

can be conducted.

Step 2: Twist demand flow regulator onto the 1000-PPM

test gas cylinder. Detach Quick Connect between filter

housing and cone on probe. Connect demand flow

regulator tubing to Quick Connect at cone end of probe.

Step 3: The LCD will display a reading 2%-3% LEL.

Step 4:

Disconnect demand flow regulator and gas

cylinder. Assemble probe Quick Connect to cone Quick

Connect.

NOTE: If LCD does not display 2%-3% LEL or does not

return to 0 PPM, proceed to calibration procedure.

’46 Hawk 3.0 Laser Diode Methane Detector

14

Updated 12102018

10.0: CALIBRATION PROCEDURE

The Hawk does a self-check calibration on startup. If

recalibration is needed, it can be done at the necessary

frequency. This should only be needed once a month.

Step 1: Start in Survey Mode. 0 PPM is displayed on LCD.

Press and hold Operation Button. Notice back light is

illuminated. Press Operation Button until you see OPTION

MENU.

Step 2: OPTION MENU will prompt the following:

•GO TO SURVEY

•ALARM LEVEL

•MUTE ALARM/HEADSET

•CALIBRATE?

Press and hold Operation Button at CALIBRATE? prompt.

Step 3: The LCD will display CALIBRATION. Do not press

button. This step takes approximately 5 seconds.

Step 4: The LCD will then display ZERO CHECK for

approximately 1.5 minutes. Do not press Operation

Button – wait for next prompt.

’46 Hawk 3.0 Laser Diode Methane Detector

15

Updated 12102018

Step 5: The LCD will now display ENTER 1000 PPM.

Connect demand flow regulator to 1000 PPM test gas

cylinder. Twist on barbed connected of the demand flow

regulator, while attached to gas cylinder, into the probe

Quick Connect and leave connected. (See daily response

test for connection details.)

Step 6: Once gas and regulator are connected, press and

hold Operation Button. The LCD will display CALIBRATING

for approximately 1.5 minutes.

Step 7: The LCD will display CAL ACCEPTED. LCD will

display REMOVE 1000 PPM. Disconnect demand flow

regulator from unit probe cone, then press and hold

Operation Button.

Step 8: The LCD will display CLEARING CELL for

approximately 1.5 minutes.

’46 Hawk 3.0 Laser Diode Methane Detector

16

Updated 12102018

Step 9: Connect cone Quick Connect to the probe Quick

Connect.

Step 10: The LCD will display START SURVEY and go

immediately to 0 PPM.

Step 11: If LCD displays CALIBRATION FAIL

, check

connections are secure. Check 1000 PPM calibration test

gas to be correct type and above 350 psi. Next, press

Operation Button for OPTION MENU

, then choose

CALIBRATE? and retry calibration. If CALIBRATION FAIL

occurs again, turn unit completely off and restart in warm

up mode, then try to calibrate. Call Southern Cross

support if calibration fails more than 3 times at 800-241-

5057.

NOTE:

Provided response testing (bump test) is

performed daily. Once per month calibration is

recommended in a clean air environment. The ’46 Hawk is

not sensitive to false positive readings or calibration

interference from non-methane hydrocarbons.

’46 Hawk 3.0 Laser Diode Methane Detector

17

Updated 12102018

11.0: OPTION MENU WHILE IN SURVEY MODE

Step 1: To access the OPTION MENU while in survey

mode, press and hold the Operation Button for at least 3

seconds. You will see OPTION MENU displayed on the

LCD.

Step 2: The LCD will display GO TO SURVEY? If you want

to go to survey, press and hold the Operation Button. 0

PPM will appear on the LCD. You are now ready to survey.

Not pressing Operation Button will lead to next option

screen.

Step 3: Next, the LCD will display ALARM LEVEL? If you

want to change the alarm level, press and hold the

Operation Button. LCD will prompt you to choose alarm

level. Press and hold the Operation Button at desired

alarm level. Not pressing the Operation Button will lead to

next option screen.

Step 4: Next, the LCD will display REZERO? If you want to

manually perform a zero reset, see

section 21,

“Troubleshooting”, for detailed instructions. Not pressing

Operation Button will lead to next option screen.

’46 Hawk 3.0 Laser Diode Methane Detector

18

Updated 12102018

Step 5: Next, the LCD will display CALIBRATE? If you want

to calibrate the system, press and hold the Operation

Button. Not pressing Operation Button will lead to next

option screen.

Step 6: Next, the LCD will display MUTE ALARM? Press

Operation Button to mute alarm. If you do not want to

mute alarm, do not press Operation Button. The next

prompt will then be displayed.

Step 7: The LCD will repeat STEP 1. Not pressing Operation

Button will lead to next option screen.

’46 Hawk 3.0 Laser Diode Methane Detector

19

Updated 12102018

12.0: SHUT DOWN

13.0: START-UP WHILE IN SLEEP MODE

Step 1: To shut unit down, move power switch to middle

position. Unit will turn completely OFF. The power switch

is located behind the back-rear slide panel.

Step 2: Wipe down the instrument with a clean, dry cloth

and store it in the case.

Step 3: For daily use, it is best to keep unit running all day.

The rechargeable battery will last for more than 12 hours.

Charge unit nightly using the charger provided by

Southern Cross. It should have yellow tape around the

jack. Do not use a different charger, as it could cause the

batter to overheat or undercharge.

Step 1: Press and hold Operation Button. The LCD will

display ’46 HAWK 3.0 (Note: Operation Button will not put

unit to sleep mode on version 3.0, but it can wake unit up

from sleep mode).

Step 2: The LCD will go through same start up sequence as

described in “Warm Up/Initial Start Up” section.

’46 Hawk 3.0 Laser Diode Methane Detector

20

Updated 12102018

14.0: OPERATIONAL SUGGESTIONS

•The ’46 Hawk is manufactured with precision parts. Unnecessary shaking or shock to the

instrument should be avoided.

•Keep liquid from entering the ’46 Hawk. If the ’46 Hawk gets wet for any reason (dropped

in water, extensively rained on, etc.), shut unit off, remove backup batteries, and dry

instrument completely.

15.0: IN-GROUND PIN POINTER

•To attach the in-ground pinpointer, detach the quick connect

below filter housing. The probe is now detached from cone.

•Connect in-ground pinpointer end to the quick connect on

probe cone end.

•The ’46 Hawk will automatically read in- ground leaks the same

as the Hawk reads above ground leaks without switching or

changing settings.

Know the Importance of Pinpointing!

•Pinpointing the gas leak using the below ground probe will save

time, money, and frustration, while also mitigating potential hazards.

•It is important to have accurate locations of all below-ground gas pipes in the leak. Make

use of available maps, drawings, locate marks, and your own expertise.

•Center the leak by determining the highest sustained gas reading at theouter boundaries

of the leakage spread.

•Start bar holes at the estimated leak location and work outward along the pipe. The

spacing of the bar holes depends on the leak spread. Small spreads could be started with

bar holes every 5 feet, while larger spreads may require bar holes every 10 to 15 feet.

•Maintain consistency in the spacing and depth of all bar holes. Bar holes must be taken

to probe depth for the most accurate pinpointing. Be careful not to damage the pipe!

•All below-ground readings must be taken at an equal depth. The highest sustained

reading usually indicates the leak location. Additional bar holes can be made to narrow

the source of the leak.

•In some cases, several bar holes will give equal readings. A useful techniqueis to measure

the concentration at the top of the bar hole. The hole with the highest reading is

probably nearest the leak.

Table of contents

Other Southern Cross Gas Detector manuals

Popular Gas Detector manuals by other brands

Helio

Helio SL Series operating manual

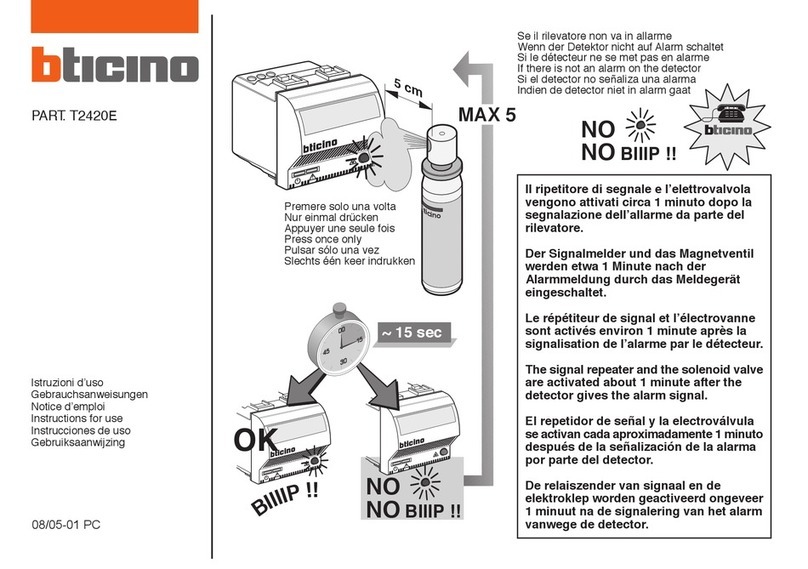

Bticino

Bticino AXOLUTE Instructions for use

Emerson

Emerson Rosemount 936 quick start guide

olympia electronics

olympia electronics BS-377/WP/A manual

Crowcon

Crowcon Flamgard-4/20 Installation, operating and maintenance guide

EsiWelma

EsiWelma Sensigas URS20SL quick start guide